A kind of porous metal-doped titanium dioxide self-cleaning composite nano-coating and its preparation method and application

A porous metal, titanium dioxide technology, applied in titanium dioxide, titanium oxide/hydroxide, fire-retardant coatings, etc., can solve the problems of lack of control of coating forming microstructure, complicated curing methods, and difficulty in preparing titanium dioxide coating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

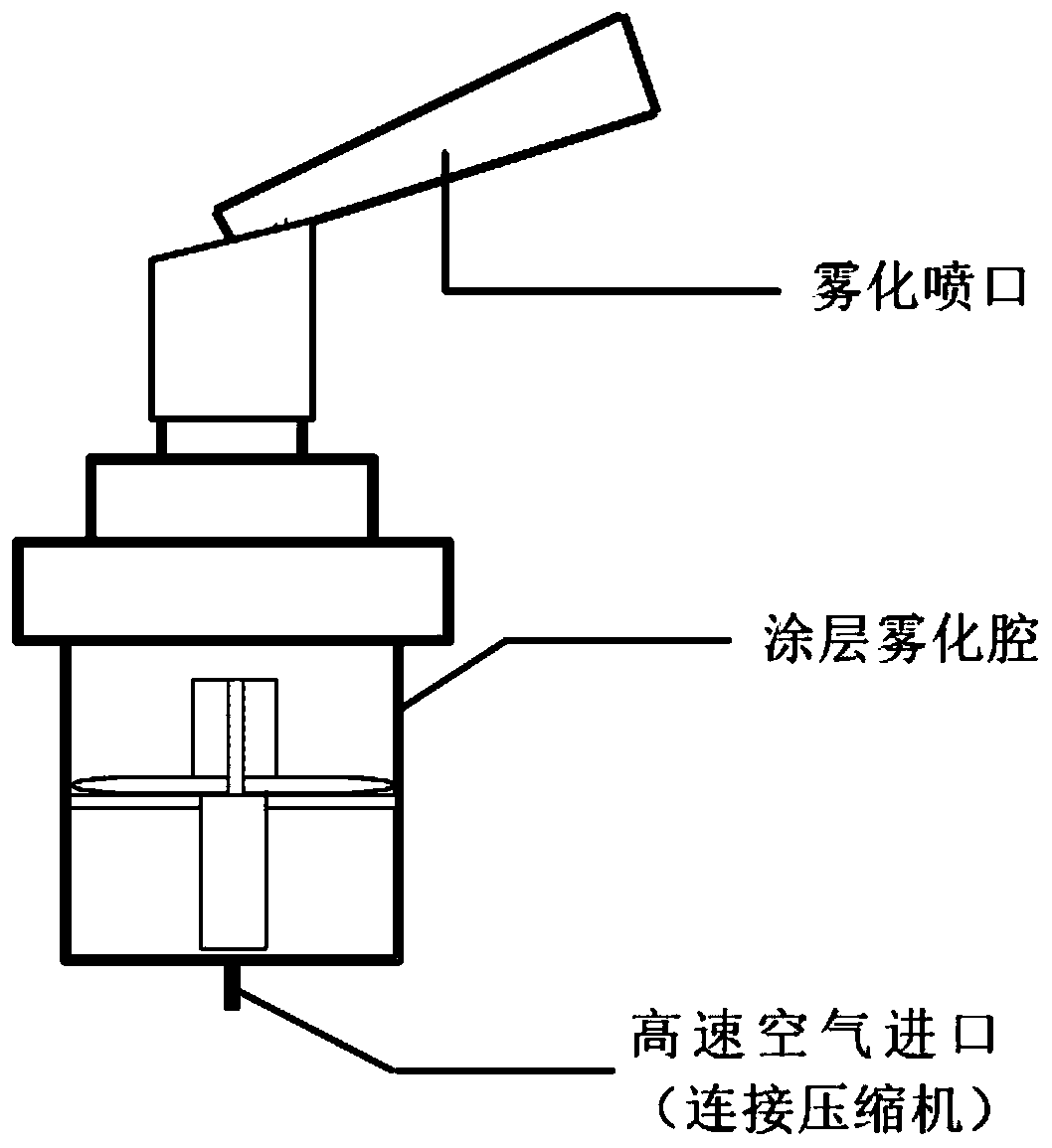

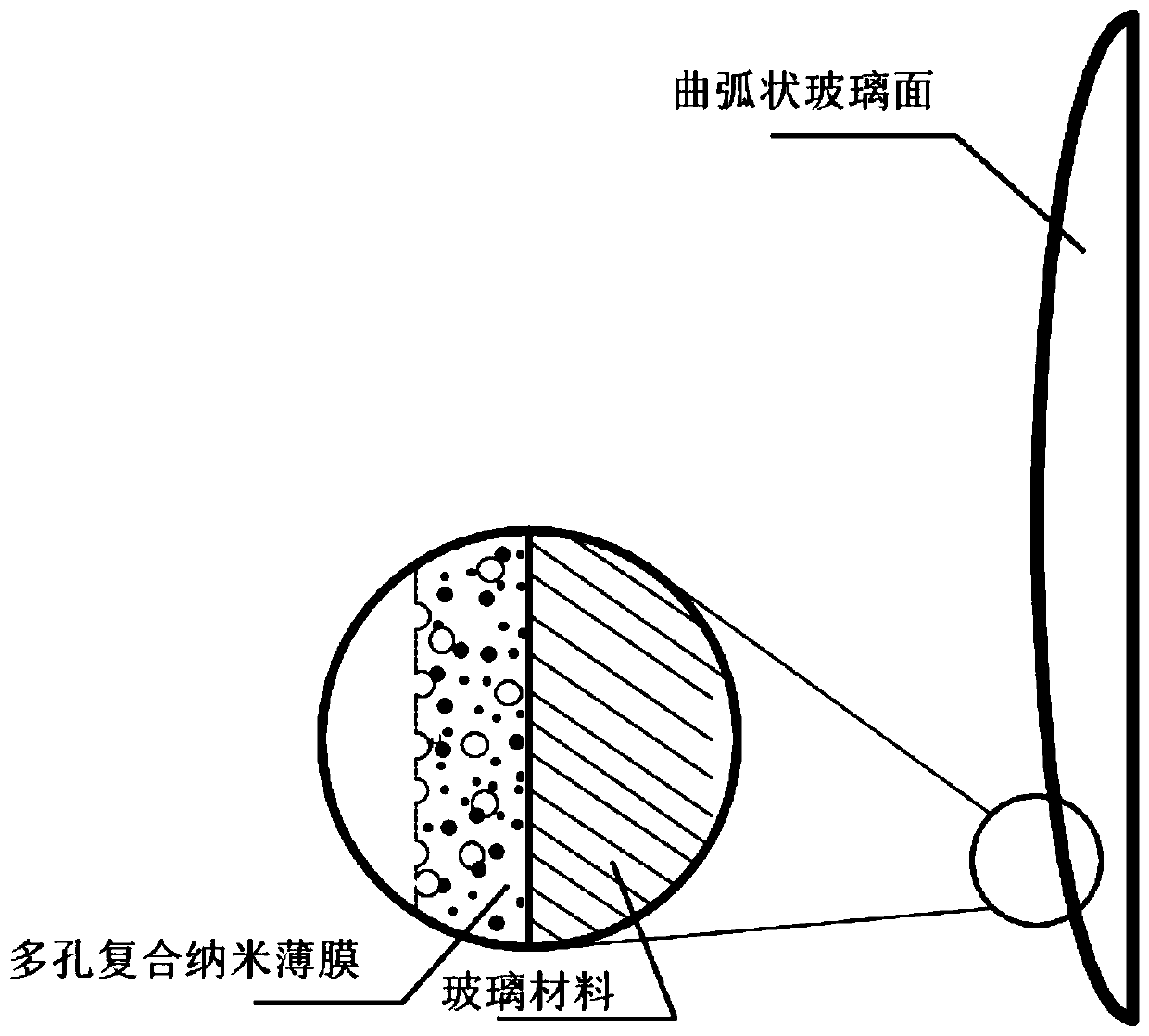

Method used

Image

Examples

Embodiment 1

[0067] 1. Preparation of ruthenium-bismuth doped titania self-cleaning composite nanocoating

[0068] (1) Preparation of initial titania sol

[0069] Add 16.00mL butyl titanate (A.R.), 65.00mL absolute ethanol and 2.4mL acetylacetone (A.R.) into a clean 500mL beaker, stir well to obtain solution A; add 65.00mL absolute ethanol to another clean beaker , add 0.8g PEG-200 and 0.4g P123, dissolve it completely under ultrasonic vibration, add 1.00mL of distilled water, adjust the pH of the solution to 2.7 with concentrated nitric acid to prepare solution B;

[0070] Slowly add solution B to solution A under magnetic stirring, adjust the pH of the solution to 3.1 with concentrated nitric acid, stir at a constant temperature of 35°C for 150min, and let it stand for 24h to obtain stable TiO 2 Sol.

[0071] (2) Step-by-step doping of ruthenium-bismuth rare metals

[0072] Initial TiO 2 After the aging of the sol, ultrasonic oscillation was carried out for 15 min, and transferred to...

Embodiment 2

[0079] The difference between this example and Example 1 is that the average molecular weight of PEG is selected as 400 in this example.

Embodiment 3

[0081] The difference between this example and Example 1 is that the average molecular weight of PEG is 800 in this example.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com