Patents

Literature

44results about How to "Eliminate dead spots" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

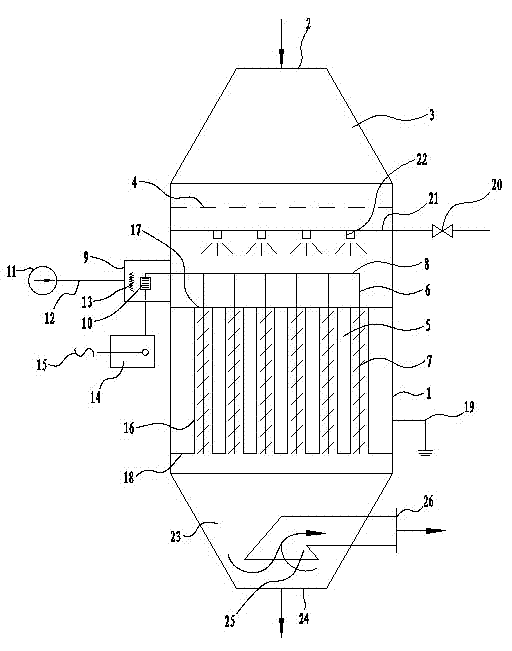

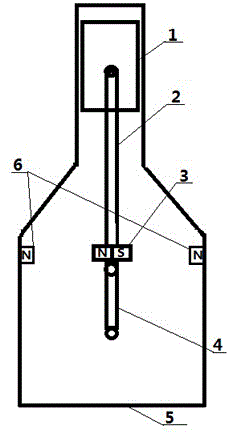

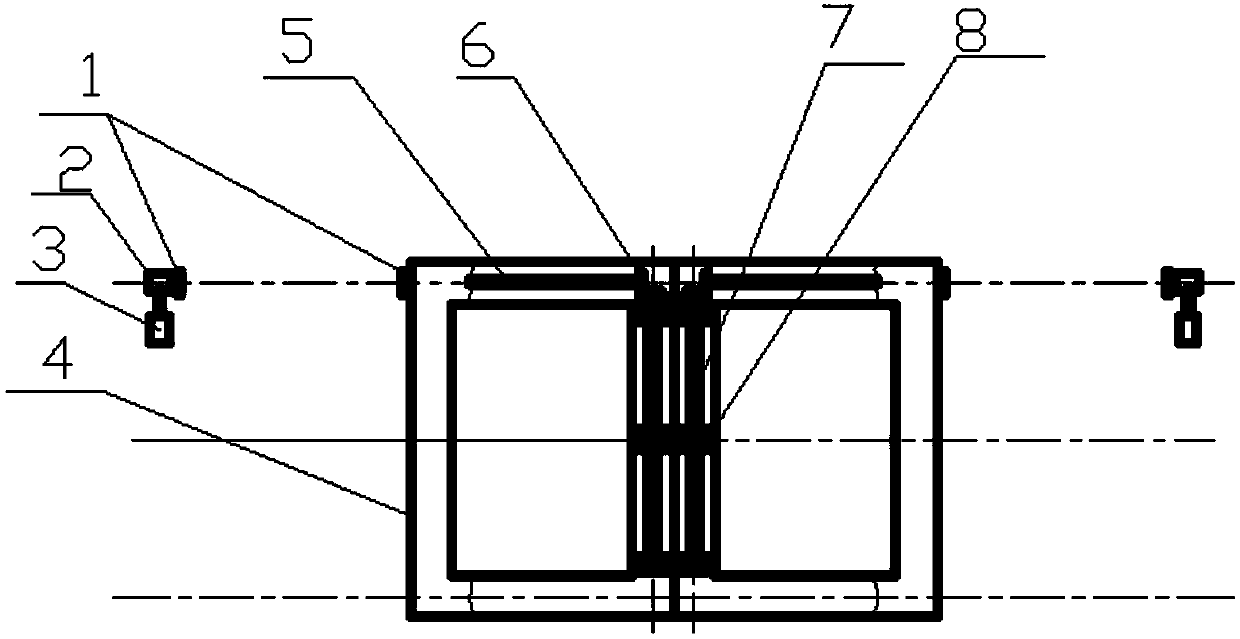

Wet type electrostatic precipitator

ActiveCN103203284AEliminate "dead spots"Improve efficiencyExternal electric electrostatic seperatorElectrode constructionsChemical industryLow voltage

The invention discloses a wet type electrostatic precipitator. A shell is internally divided into an air inlet chamber, an electrode chamber and an air outlet chamber, wherein the air inlet chamber is internally provided with a water spray pipe head which is provided with a nozzle; the electrode chamber is internally provided with a dust collection pipe, and an electrode pipe passes through the interior of the dust collection pipe; a support frame is hung at the upper end of the electrode pipe; the outer end of the support frame and an electrical insulating tube chamber are supported with by an electrical insulator; the outer end of the support frame is connected with a high voltage end negative pole of a transformer / rectifier; a low voltage end external power supply shell of the transformer / rectifier is connected with a power supply shell to be in ground connection; and the cleaning water spray is controlled by the electric field change in the electrode chamber. The wet type electrostatic precipitator has the PM 2.5 removal rate being more than 99%, and has the capability of effectively removing multiple pollutants such as acid mist, various heavy metals and aerosol, thus being widely applied to waste gas treatment in the petro-chemical, chemical industry, pharmacy, war industry and incineration industry.

Owner:SUNIC ENERGY & ENVIRONMENT TECH CHONGQING

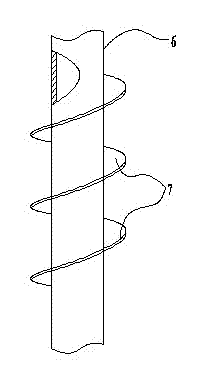

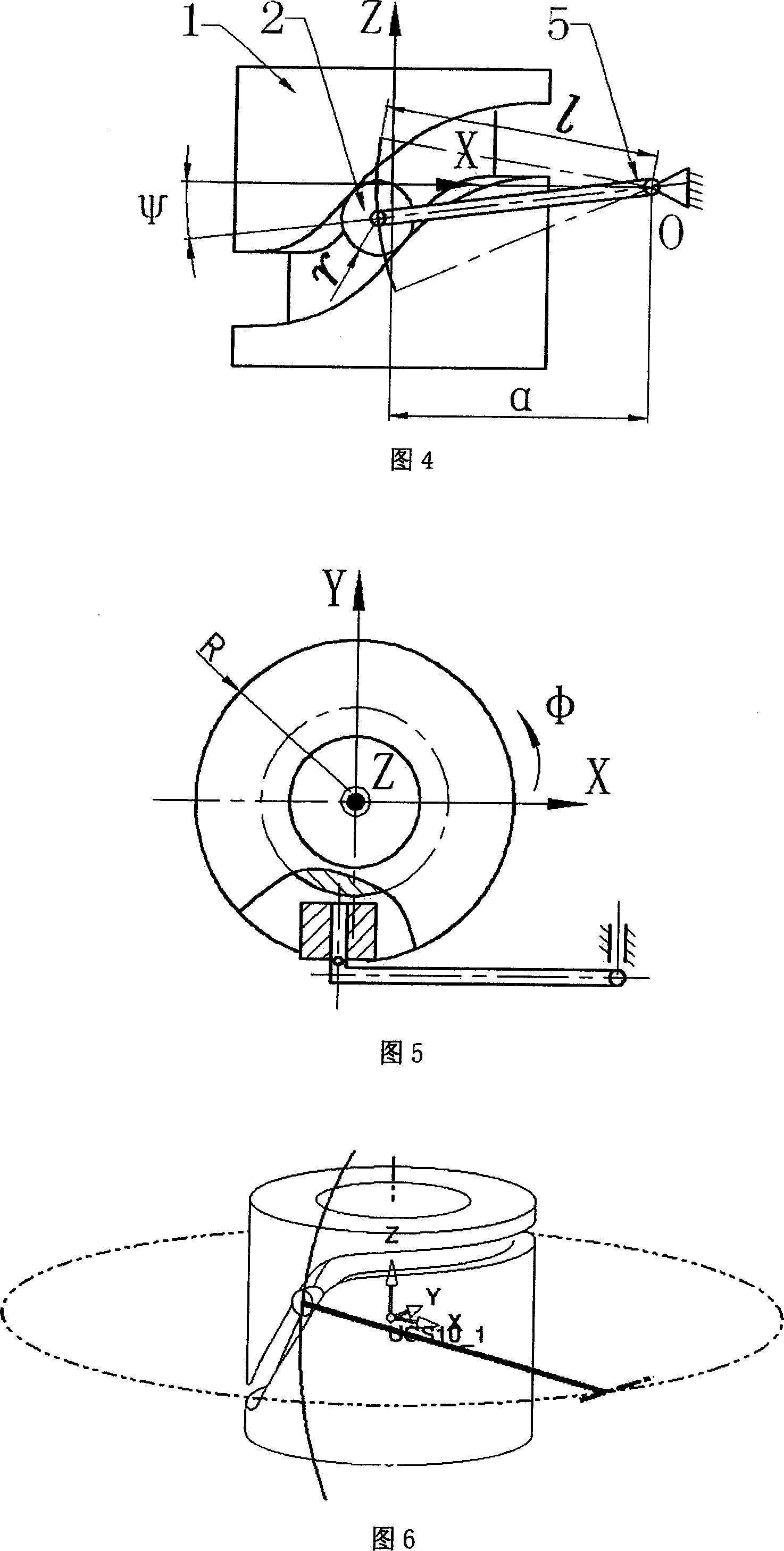

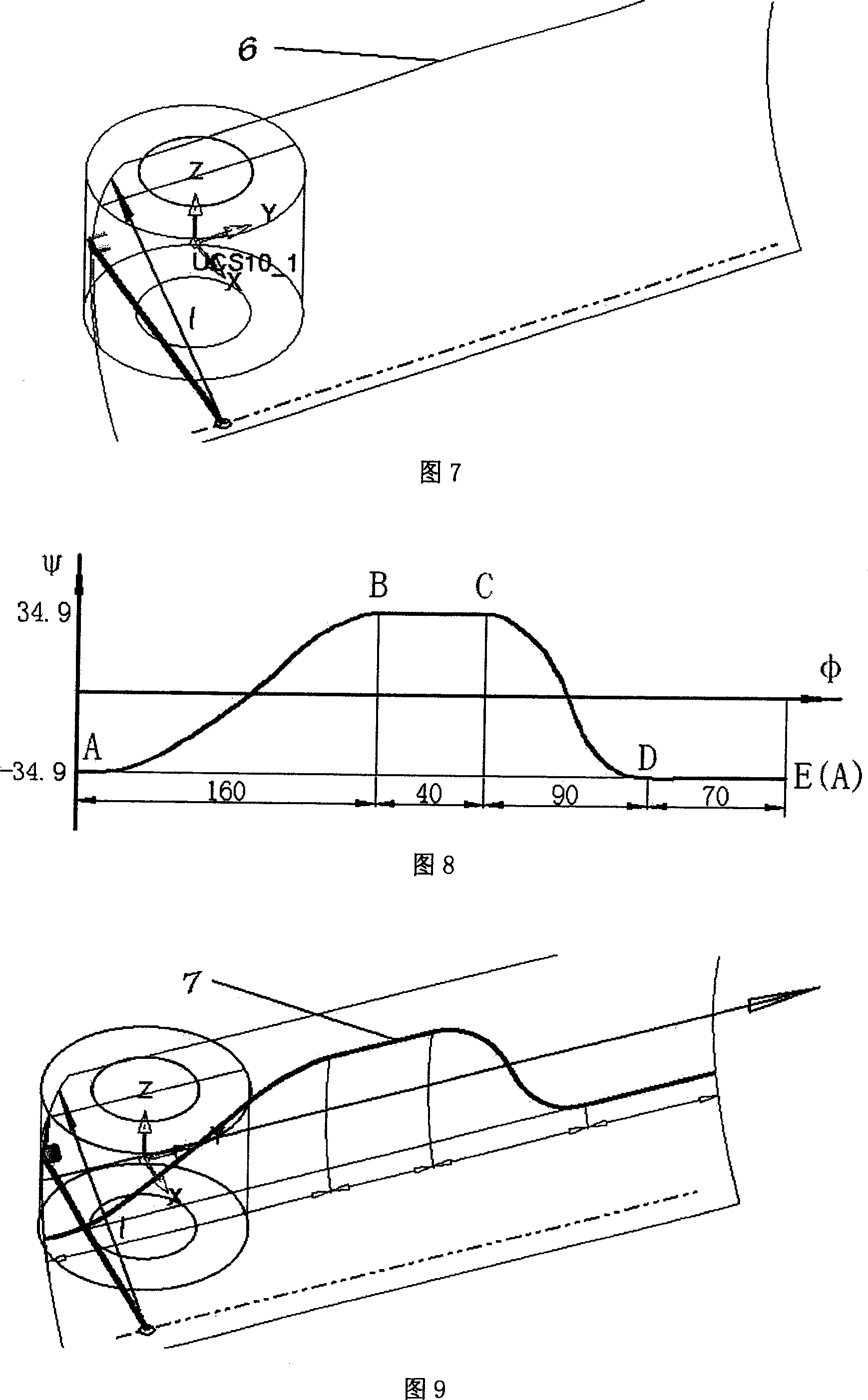

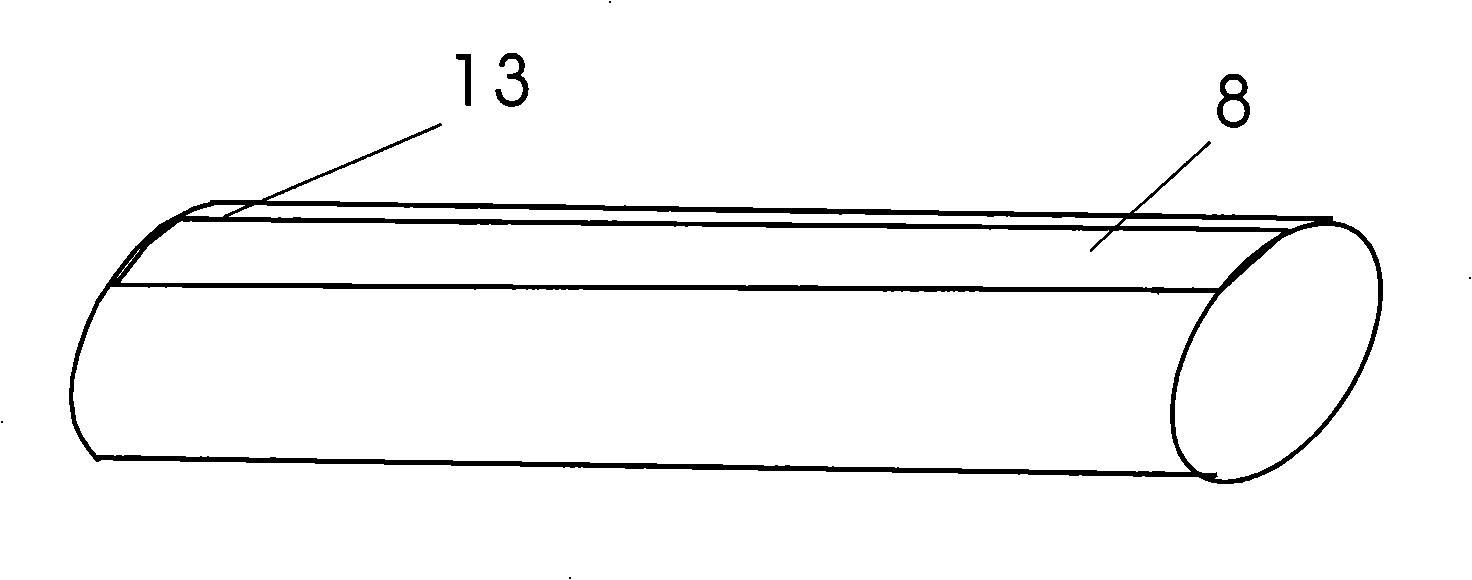

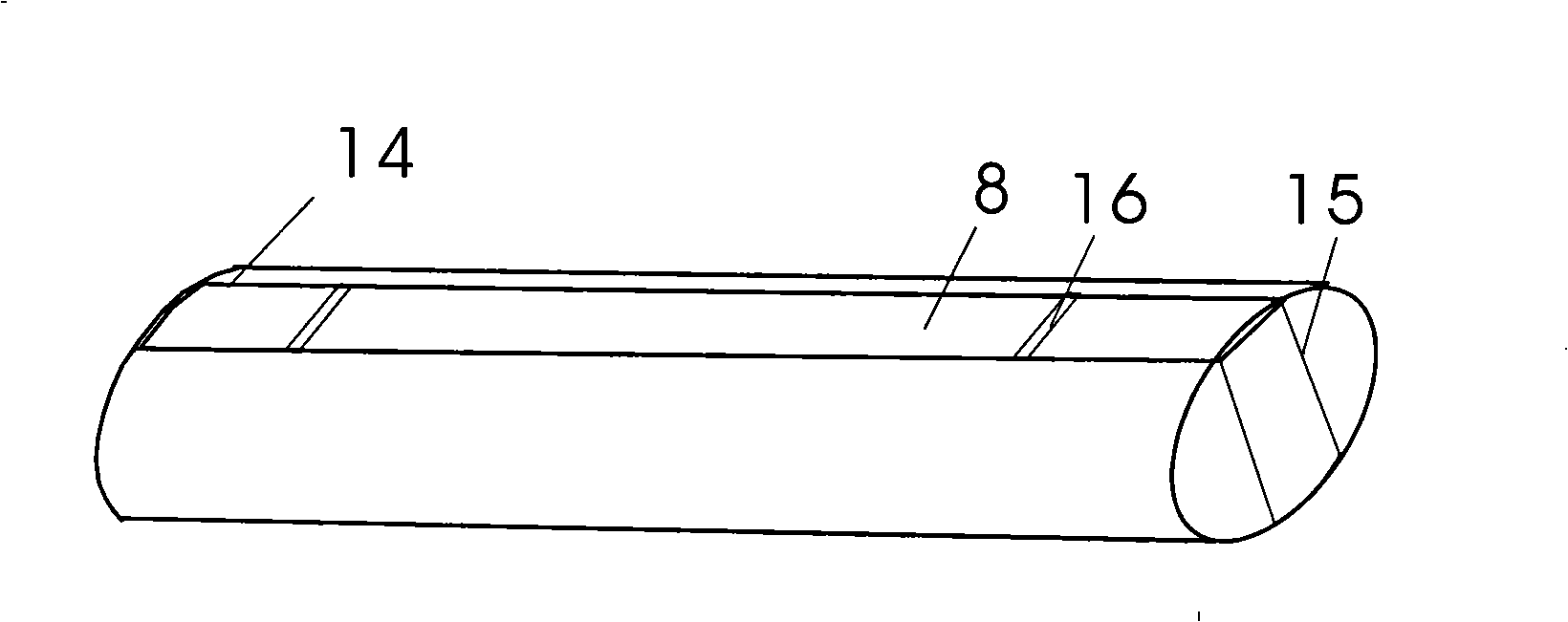

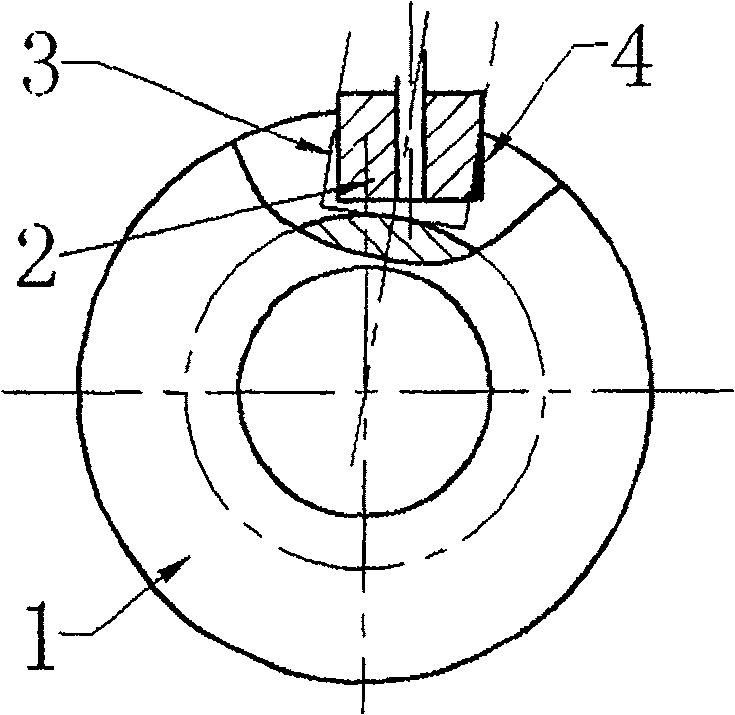

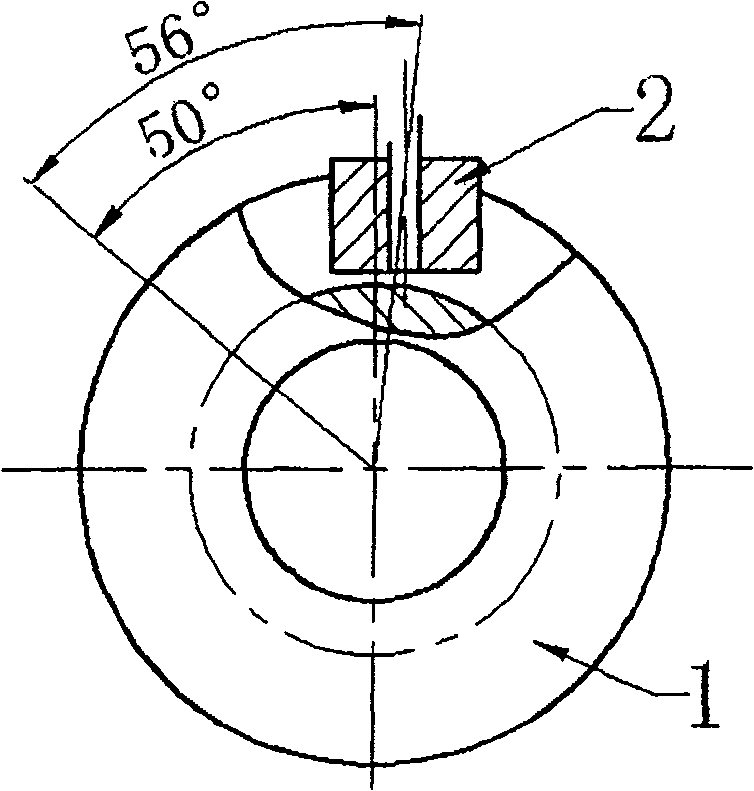

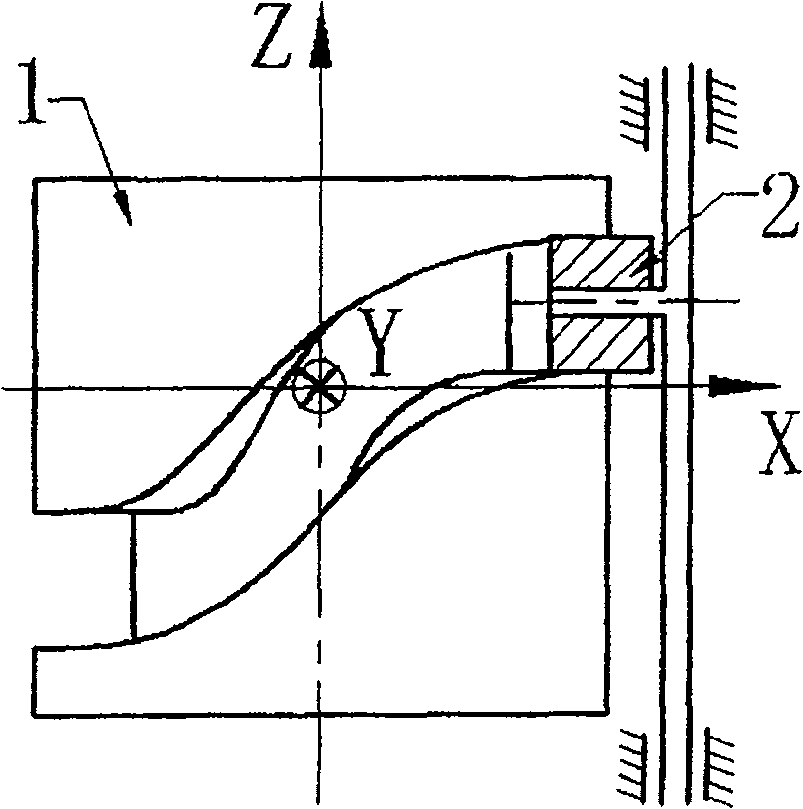

Processing method for groove of oscillating follower cylinder cam

InactiveCN101008439AAvoid interferenceEliminate "dead spots"Programme controlComputer controlEngineeringCam

The invention relates to a method for processing the swing inactive cylinder cam groove, characterized in that the motion of swing inactive cylinder cam is divided into the arc swing along with the swing rod and the rotation relative to the cam, wherein, the arc swing can be decomposed into two mutually perpendicular straight motions in the swing plane as 3D motion, and the rotation relative to the cylinder cam is unfolded into the cylinder face that contacting the relation between the swing angle of swing rod and the rotation angle of cylinder cam as swing angle curvature onto the unfolded cylinder face, or projecting the relation between the displacement of swing inactive element and the rotation angle of cylinder cam as displacement curvature onto the unfolded cylinder face to obtain the 3D unfolded line; then based on the 3D unfolded line, processing the 3D blade track to be used in digit-control machine. The invention can avoid the error of general 2D unfolded method.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

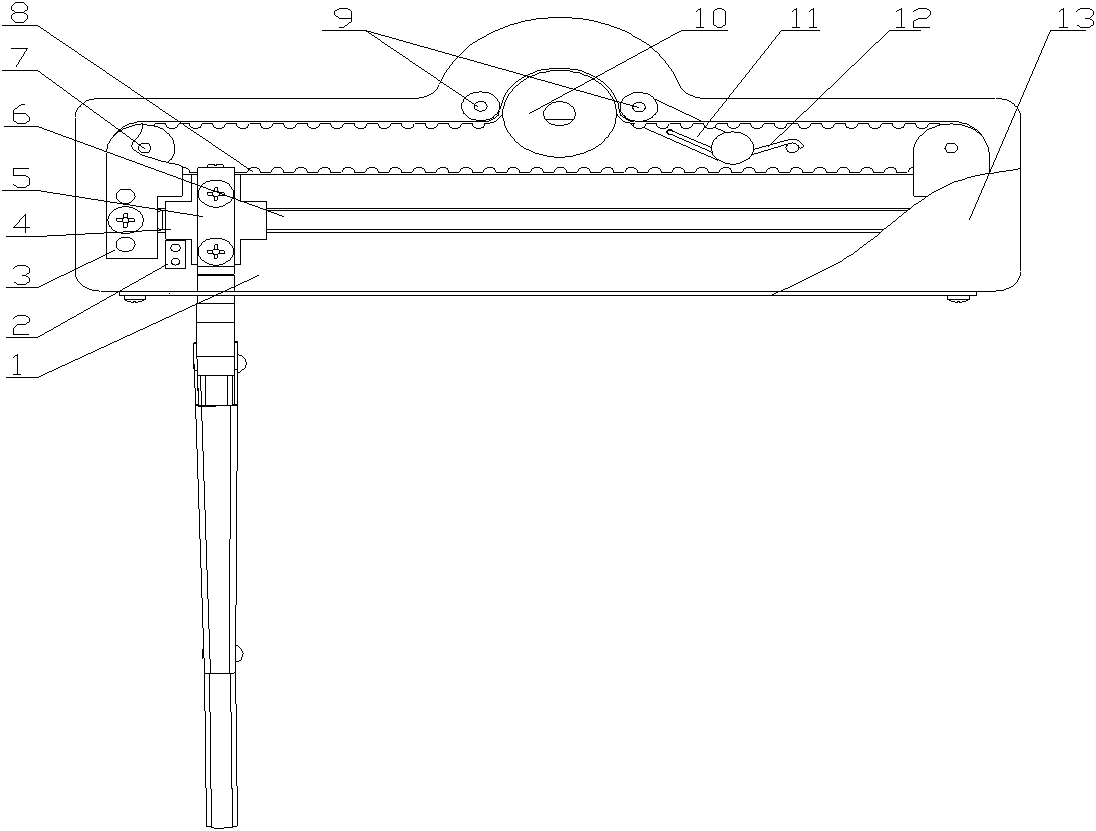

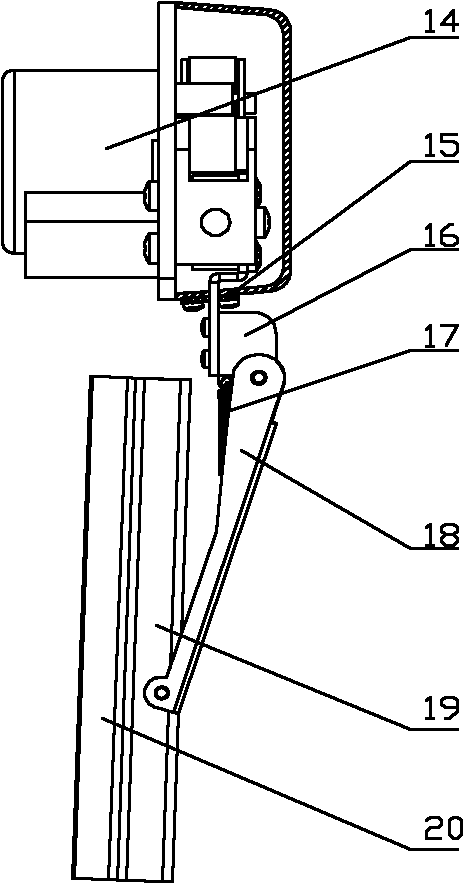

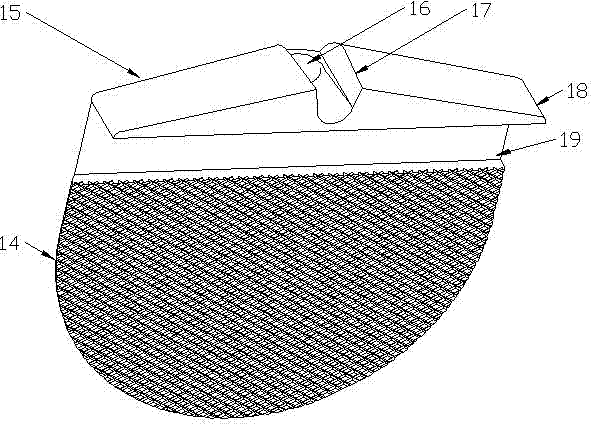

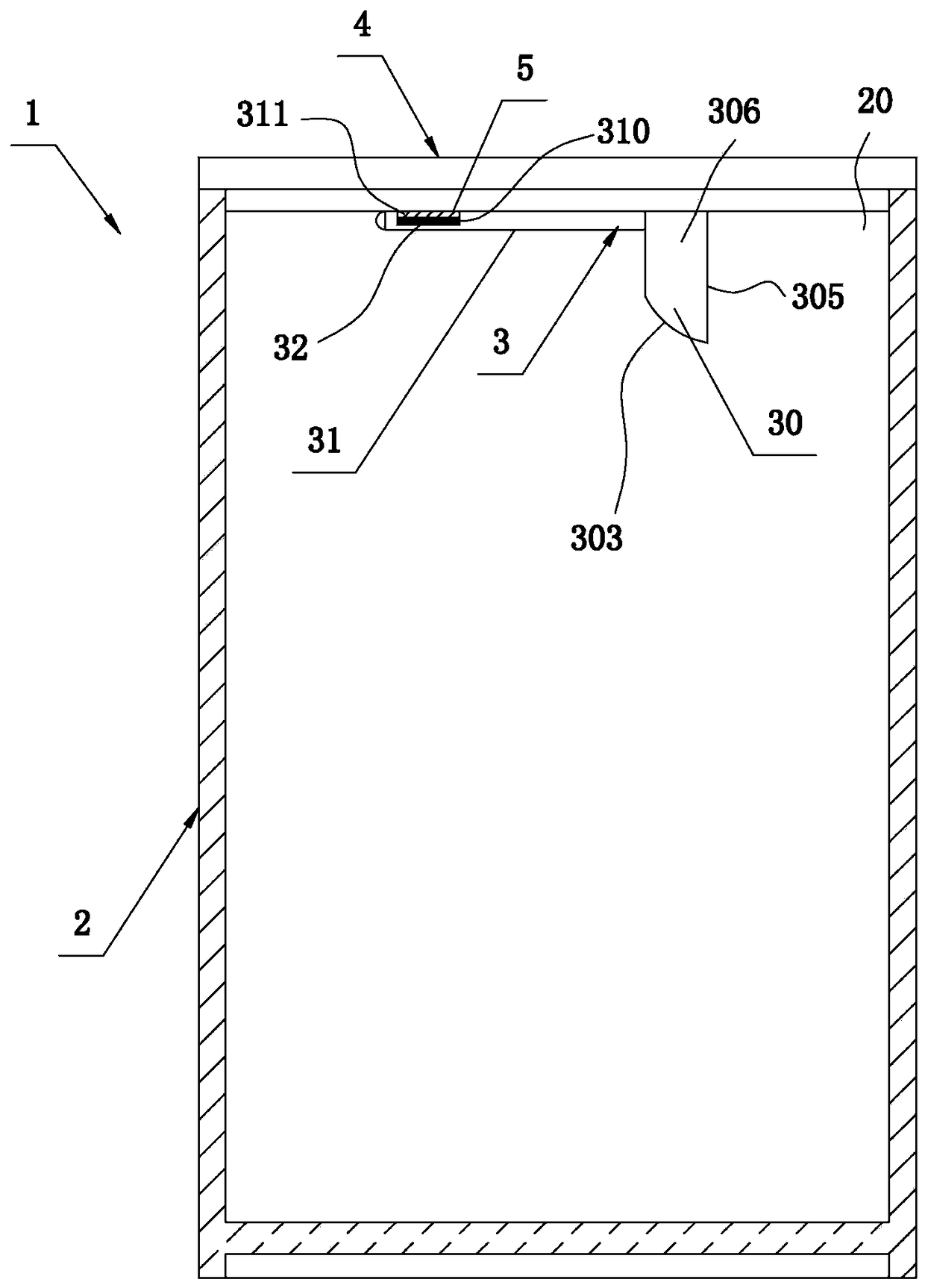

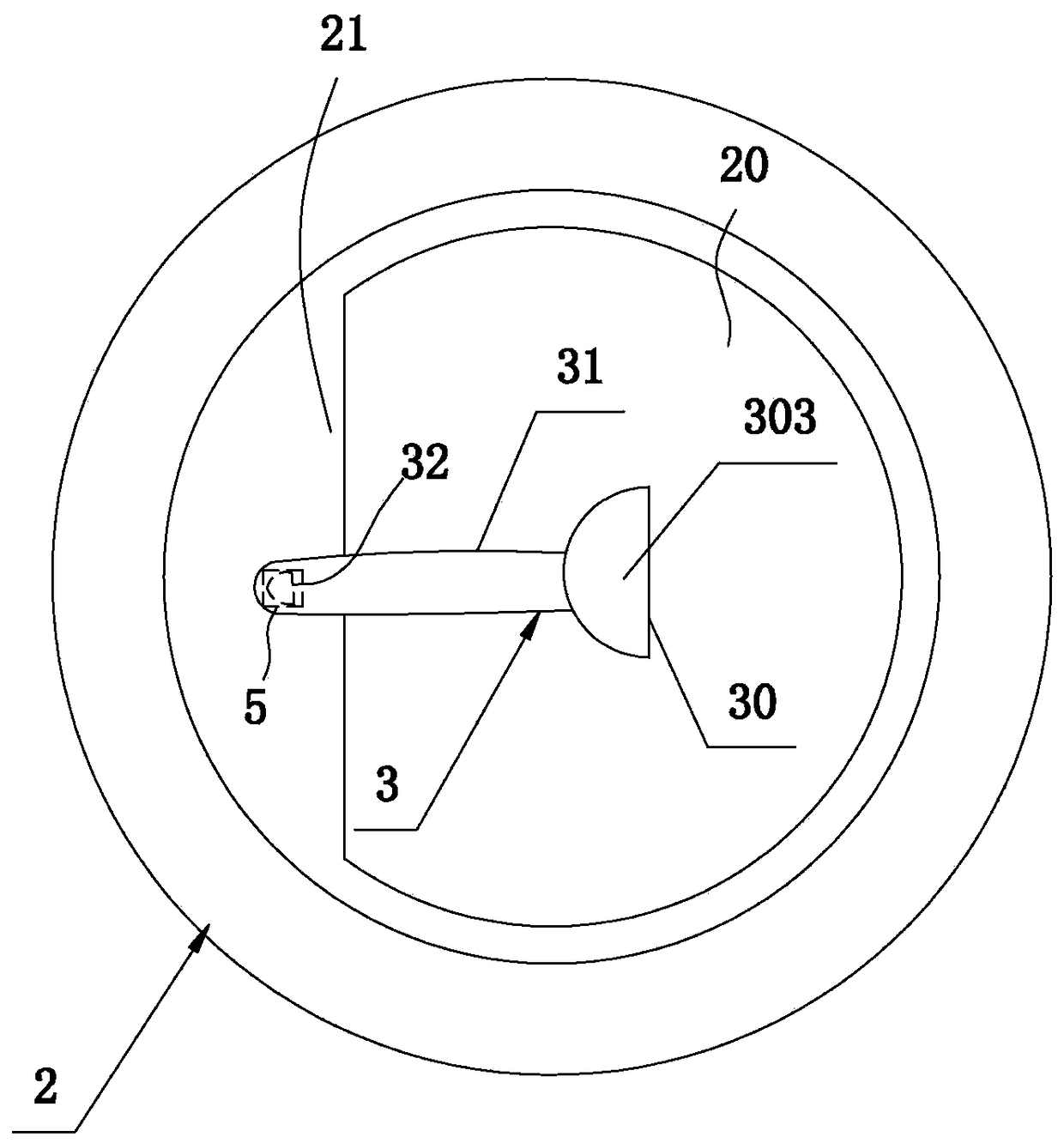

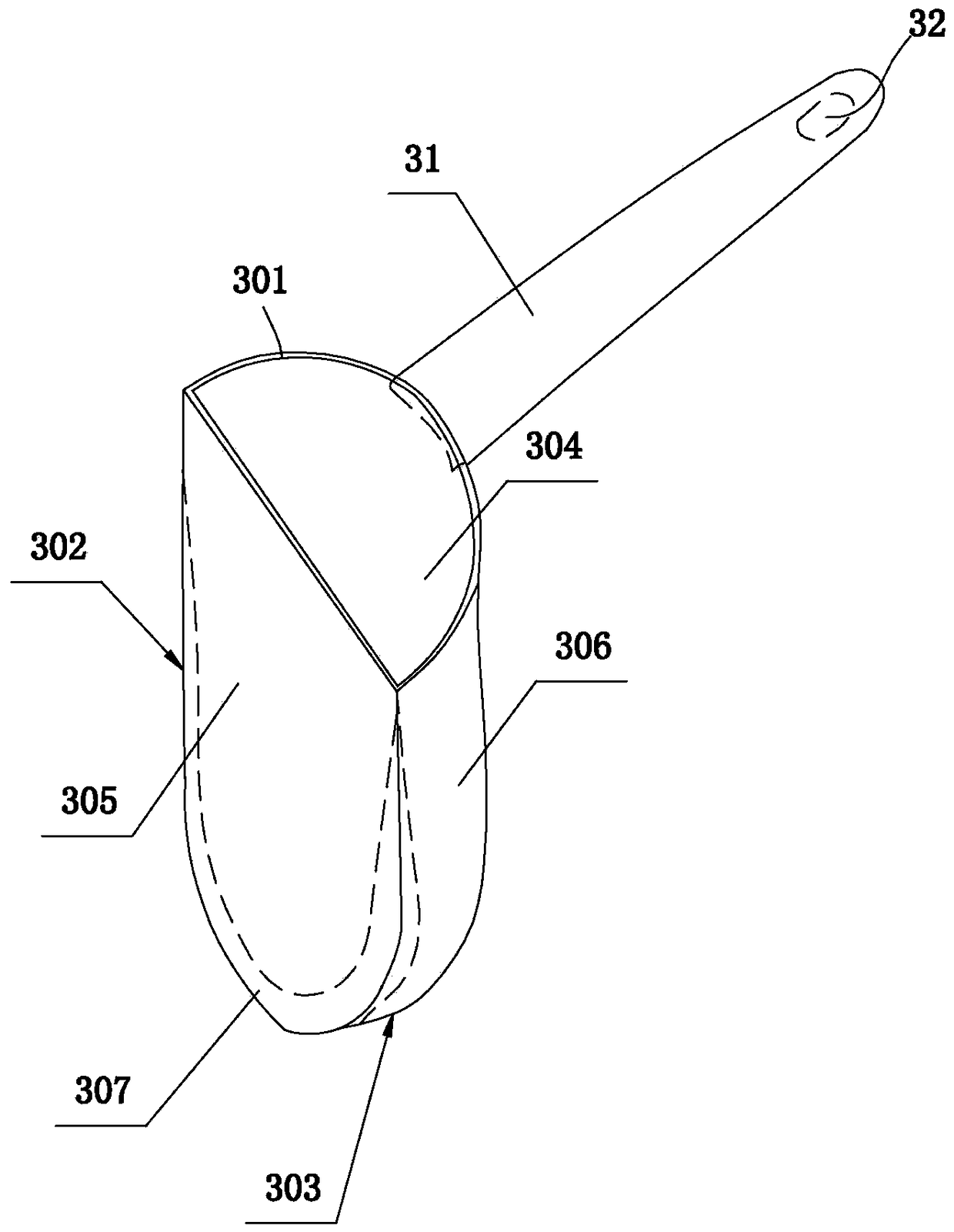

Rain wiper of camera protective cover and video monitoring system

ActiveCN102123240AIncrease working areaEliminate dead spotsTelevision system detailsColor television detailsVideo monitoringFixed frame

The invention belongs to the field of video monitoring, and provides a rain wiper of a camera protective cover and a video monitoring system; the rain wiper comprises a substrate, a reflective optical coupler, a fixing frame, a sliding block, a connecting sheet, a guide rail, a driven wheel, a belt, a pinch roller, a belt wheel, a pressing sheet, a spring, a shell, a motor, a sealing rubber bar, a large rain wiper arm, a small rain wiper arm, a rubber bar clamping plate and a rubber bar; the connecting sheet and the sliding block are fixed together; the connecting sheet is used for clamping the belt; the sliding block is sheathed on the guide rail; the connecting sheet is connected with the large rain wiper arm; the large rain wiper arm is connected with the small rain wiper arm; the small rain wiper arm is connected with the rubber bar clamping plate; the rubber bar clamping plate is connected with the rubber bar; and the spring is further connected between the large rain wiper arm and the small rain wiper arm. In the invention, the structure such as a reflective optical coupler is adopted so that the work area is rectangular and the view window blind side splodge is effectively eliminated; and the belt torque is born on the motor shaft so that the damage rate of the rain wiper is reduced.

Owner:TIANJIN YAAN TECH CO LTD

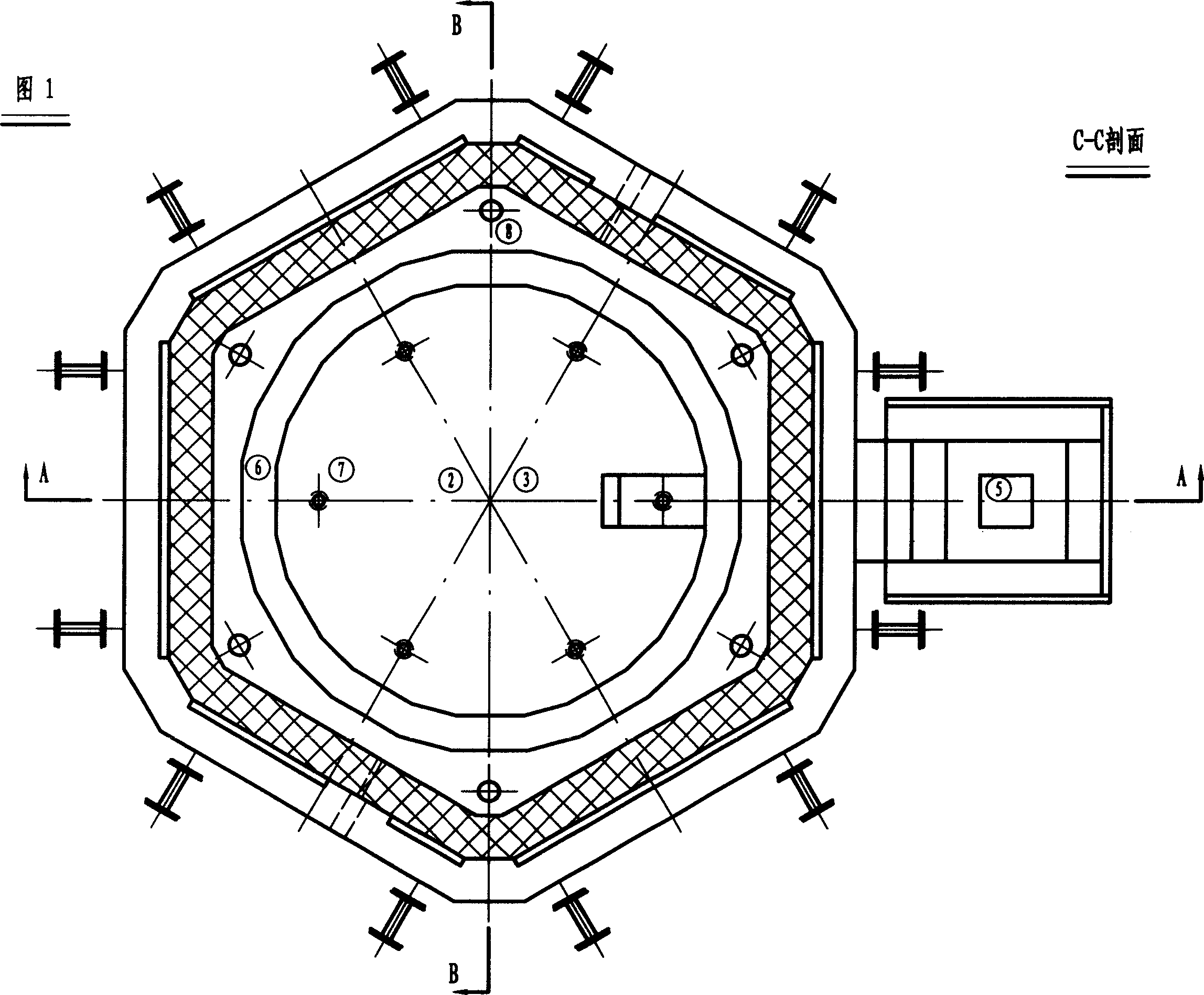

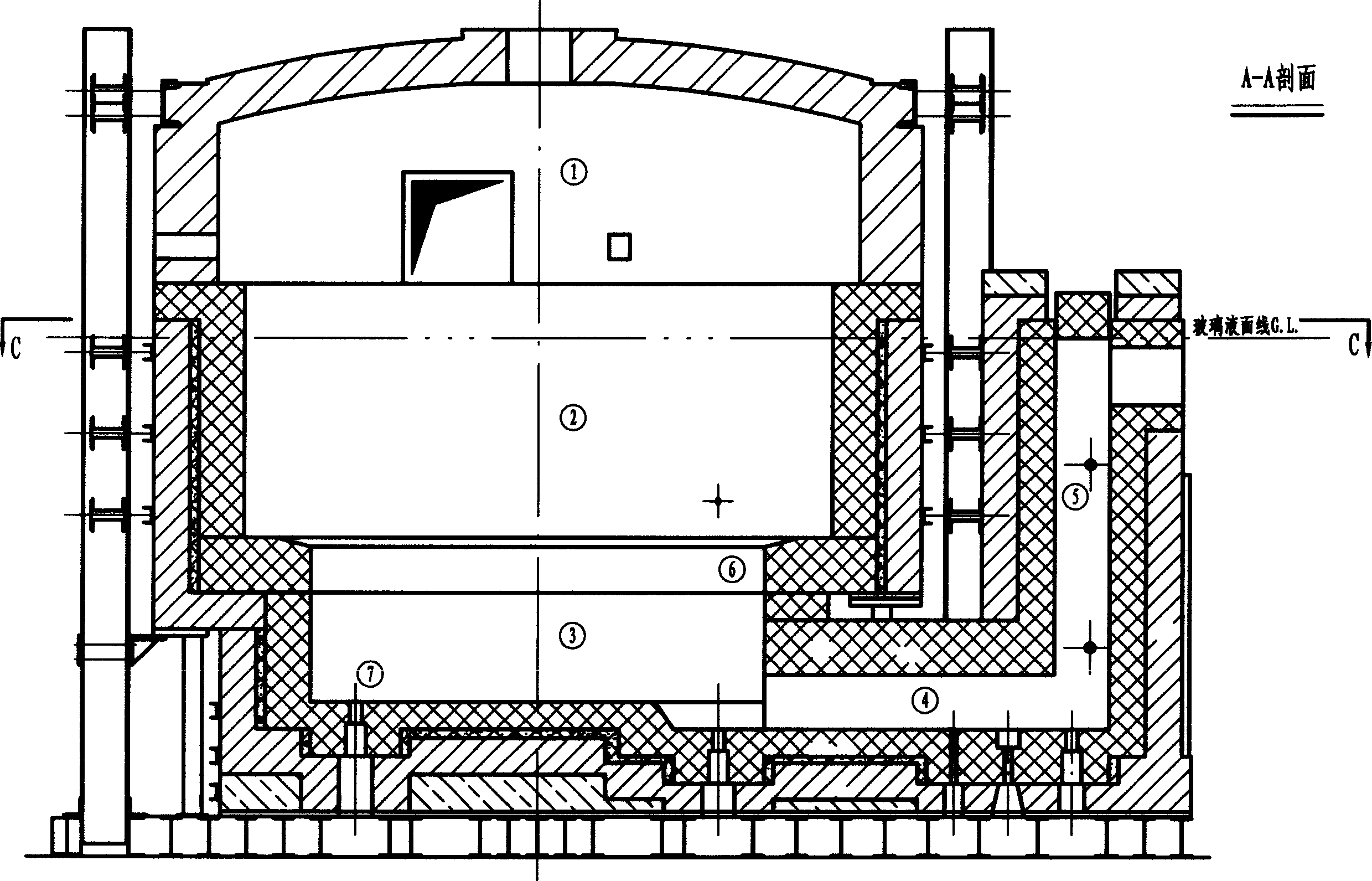

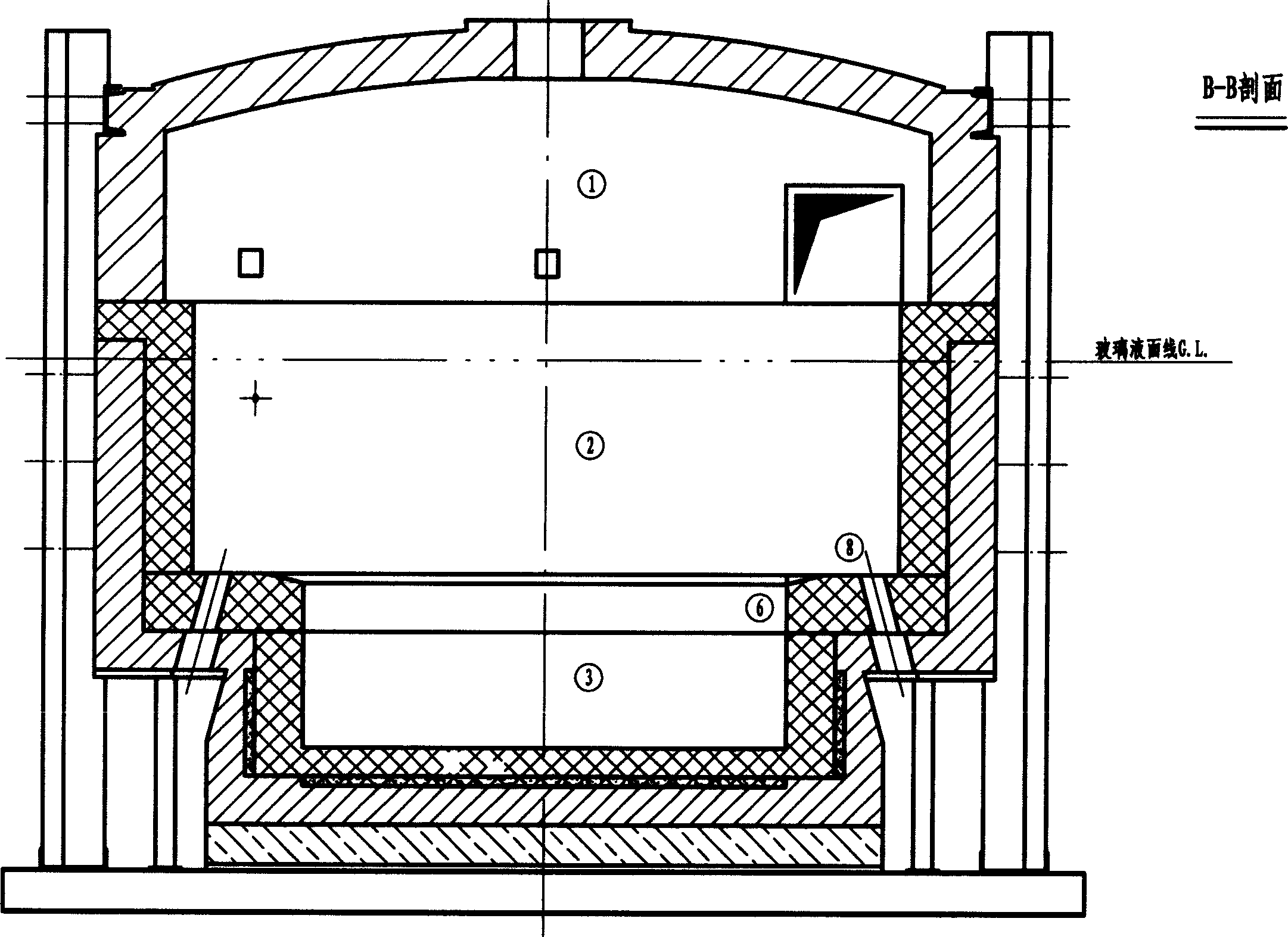

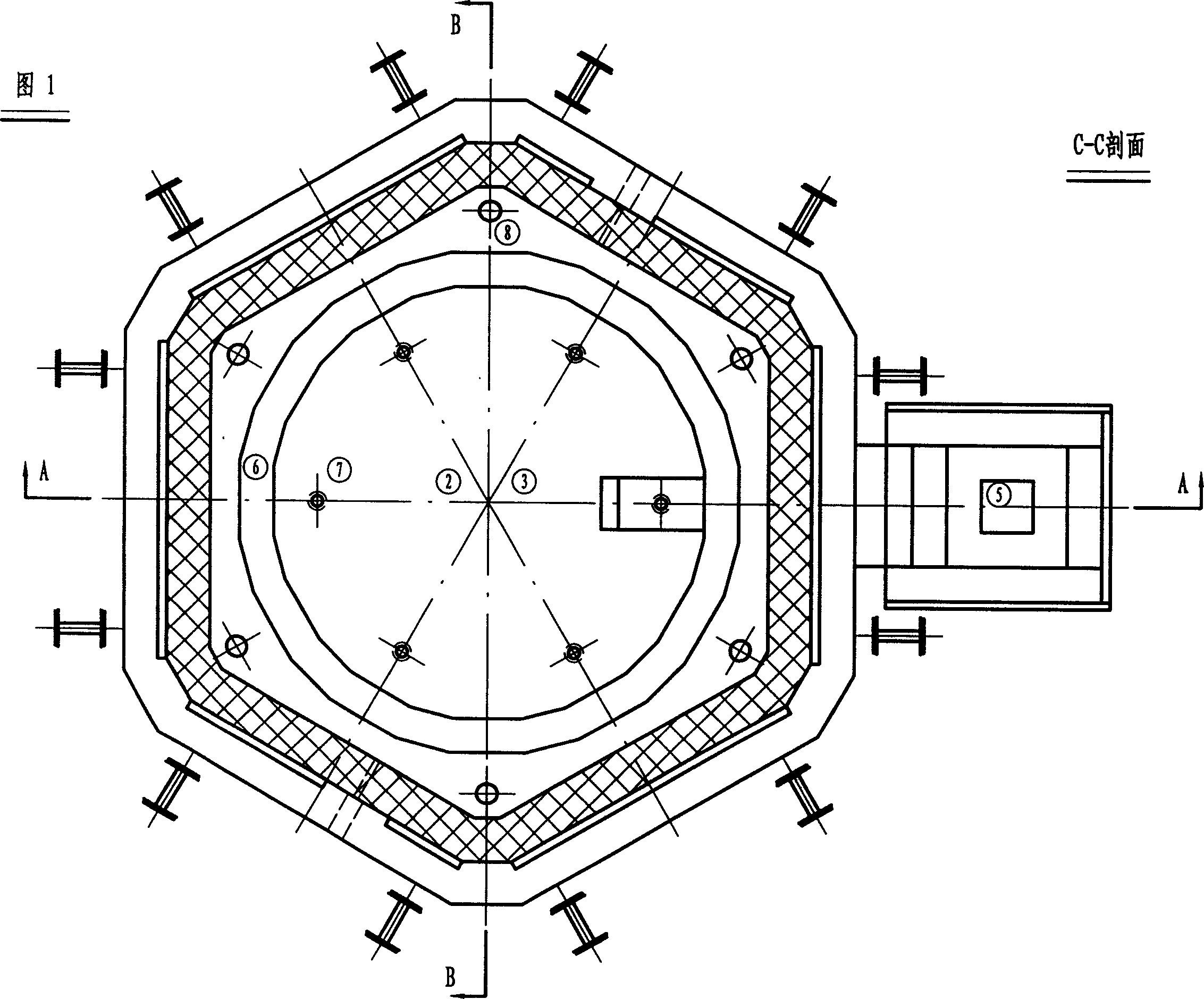

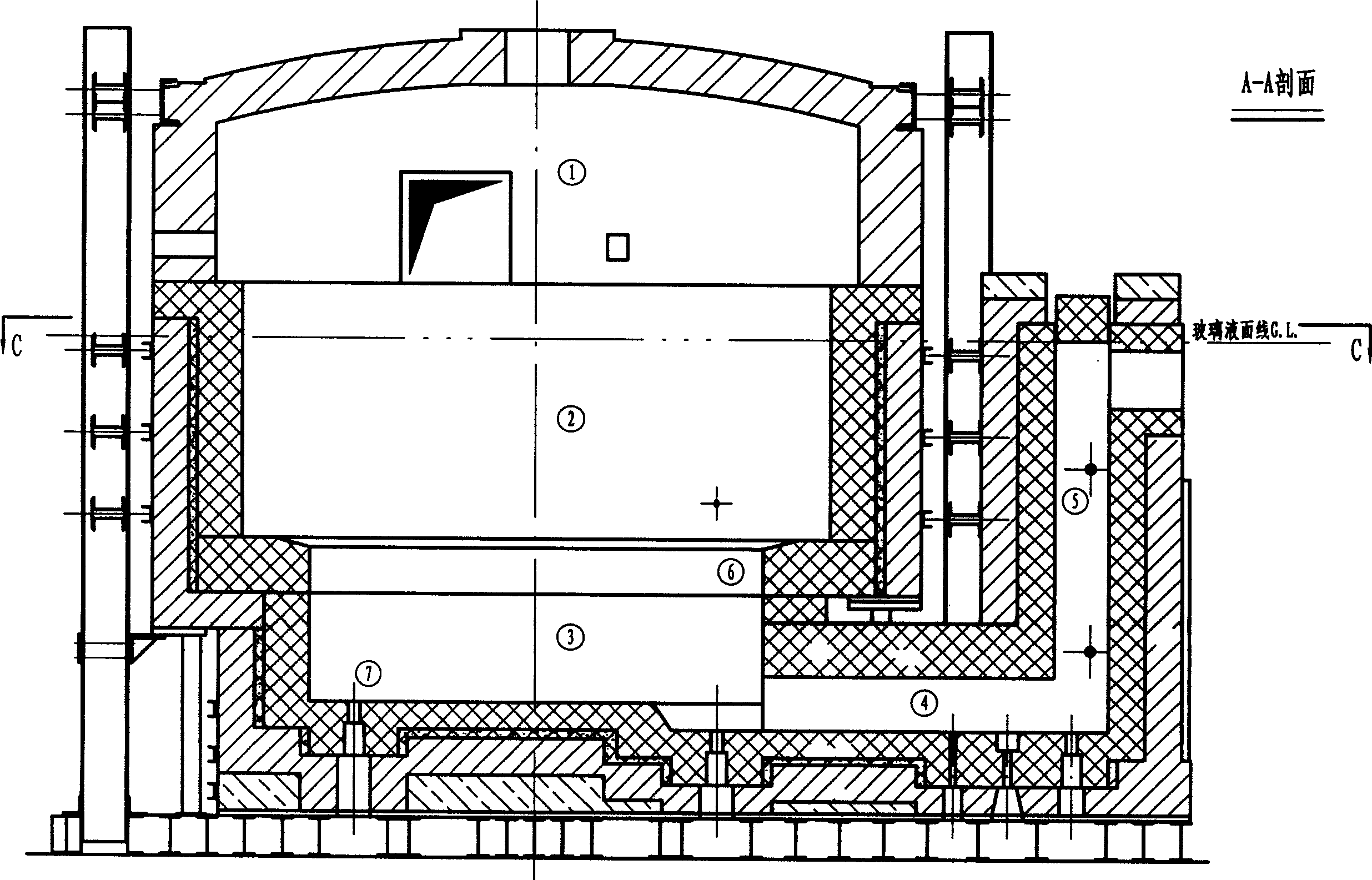

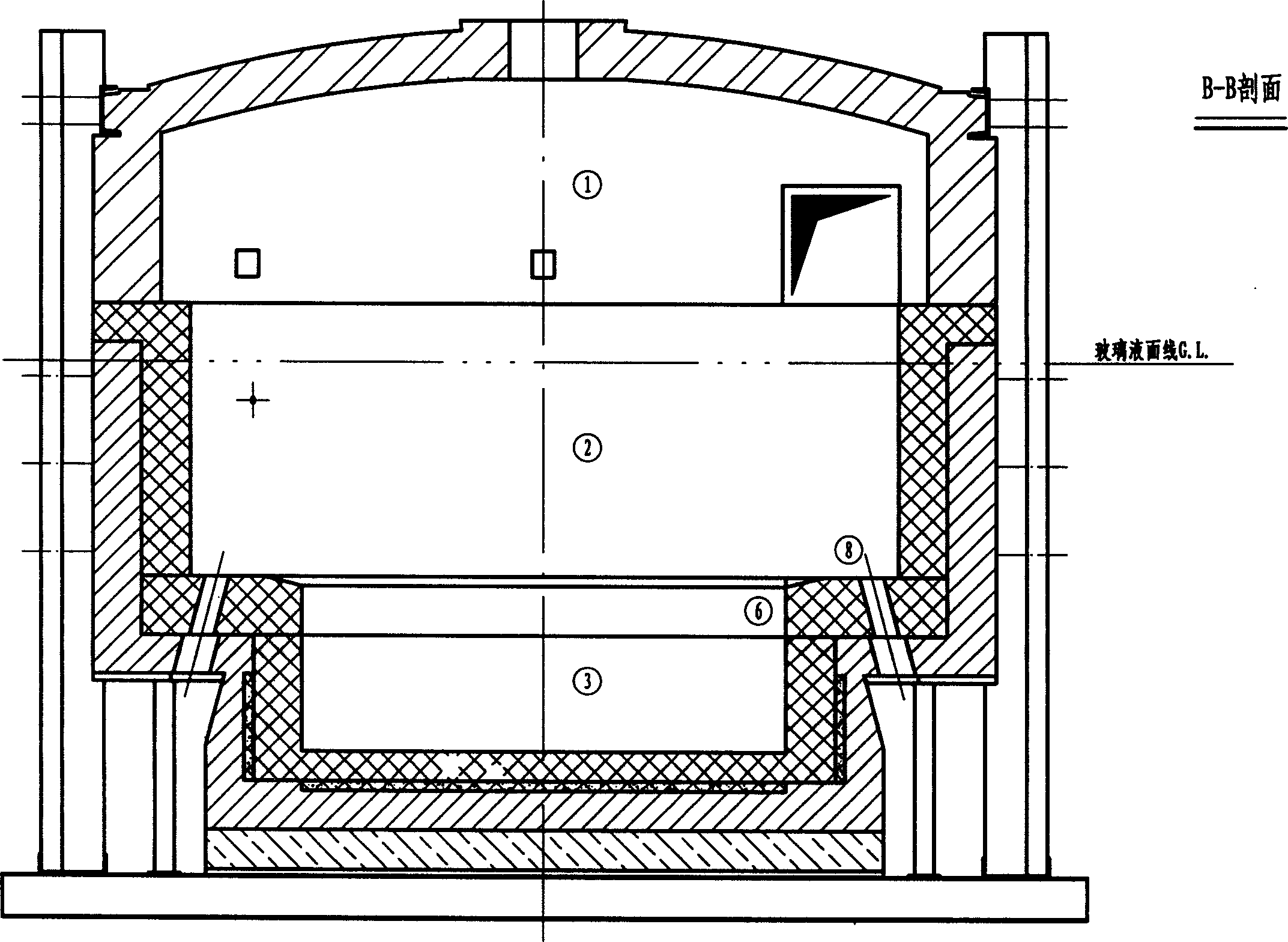

Hexagonal step type electrofusion furnace technology for high boron silicon instrument galss

InactiveCN1513780AEven heat distributionEliminate "dead spots"Glass furnace apparatusElectric furnaceElectricityBrick

A stepped hexagonal cold-top full-electric smelting furnace for smelting the high-boron silicon glass used for instrument is composed of flame space, smelting pool, liquid flowing hole, and lifting channel. Said smelting pool is composed of the hexagonal upper pool with large area, the tetrahexagonal lower pool with small area, and the transition bricks for connecting both pools. Six molybdenum electrodes are vertically installed to said transition bricks. Its advantage is uniform heat distribution.

Owner:力诺集团股份有限公司

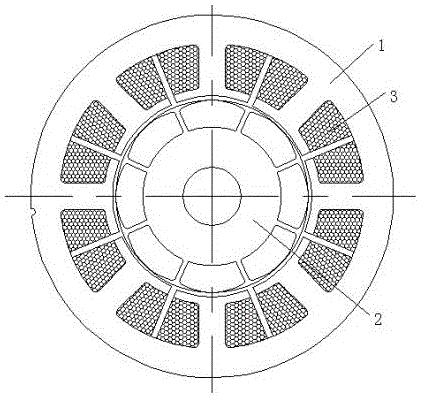

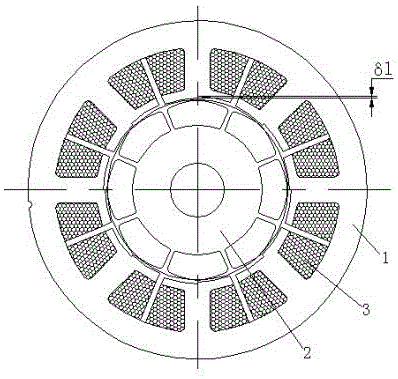

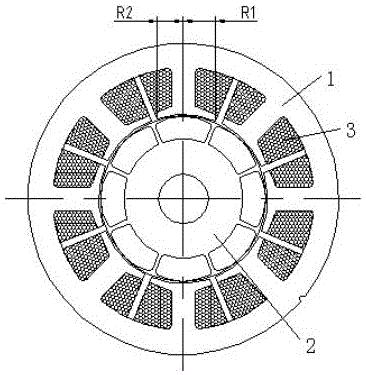

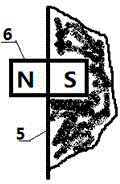

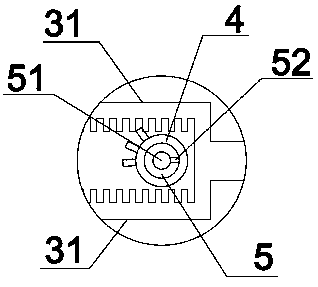

Single-phase permanent magnet brushless direct-current motor with auxiliary teeth and auxiliary windings

InactiveCN105099112ASmooth startEliminate "dead spots"Synchronous machines with stationary armatures and rotating magnetsPermanent magnet rotorMagnetomotive force

The invention discloses a single-phase permanent magnet brushless direct-current motor with auxiliary teeth and auxiliary windings. The single-phase permanent magnet brushless direct-current motor includes a stator and a permanent magnet rotor; the stator is provided with a plurality of stator main pole teeth and stator auxiliary pole teeth which are uniformly distributed along the circumference of the stator, wherein the stator main pole teeth and the stator auxiliary pole teeth are arranged at intervals; the total number of the tooth slots of the stator main pole teeth and stator auxiliary pole teeth is twice of the number of the poles of the permanent magnet rotor of the motor; the width of the stator main pole teeth is 1.55 to 2 times of the width of the stator auxiliary pole teeth; main tooth arc surfaces are formed at the roots of the stator main pole teeth; auxiliary tooth arc surfaces are formed at the roots of the stator auxiliary pole teeth; slot openings are formed between the main tooth arc surfaces of the stator main pole teeth and the auxiliary tooth arc surfaces of the stator auxiliary pole teeth; and the central line of each slot opening deviates from the central line of a corresponding stator auxiliary pole tooth by a certain angle. After the single-phase permanent magnet brushless direct-current motor of the invention is energized, a magnetomotive force F generated by stator current has voltage difference, and therefore, a dead point can be eliminated; and the starting instant magnetomotive force voltage difference can change with the magnitude of the controllable stator current, and therefore, the starting instant magnetomotive force voltage difference can be controlled, and the motor can be started smoothly without vibration.

Owner:ZHE JIANG YILIDA VENTILATOR CO LTD

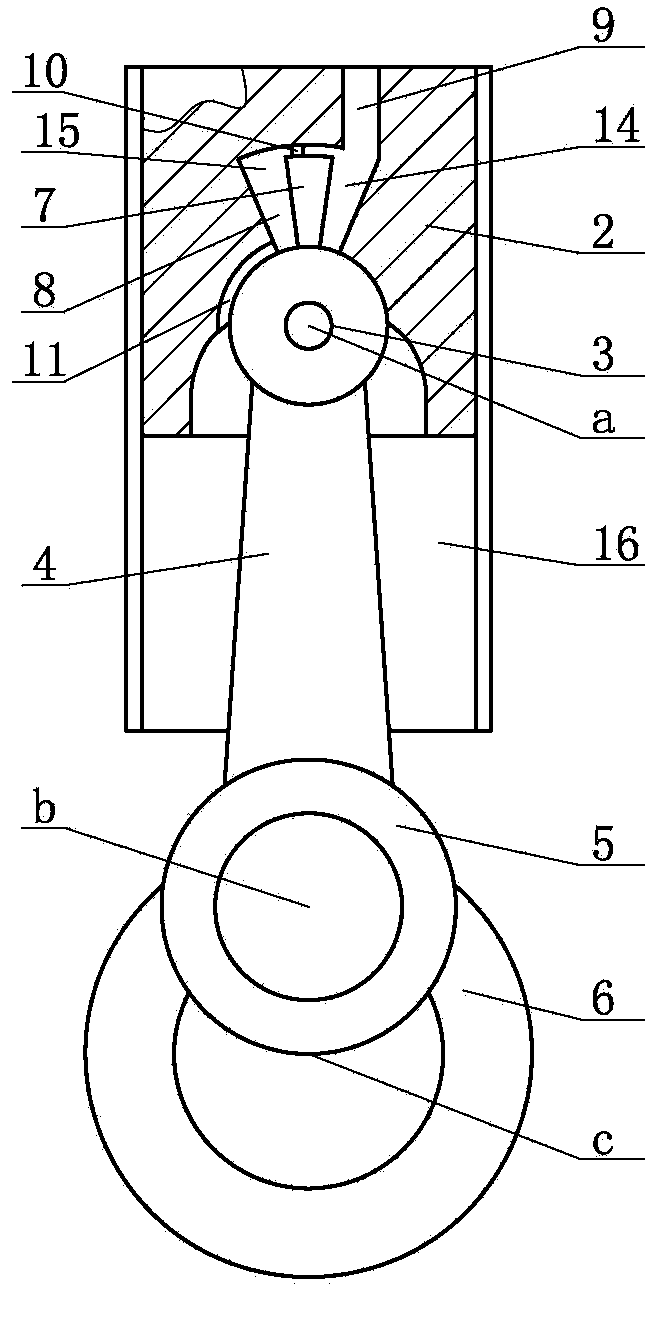

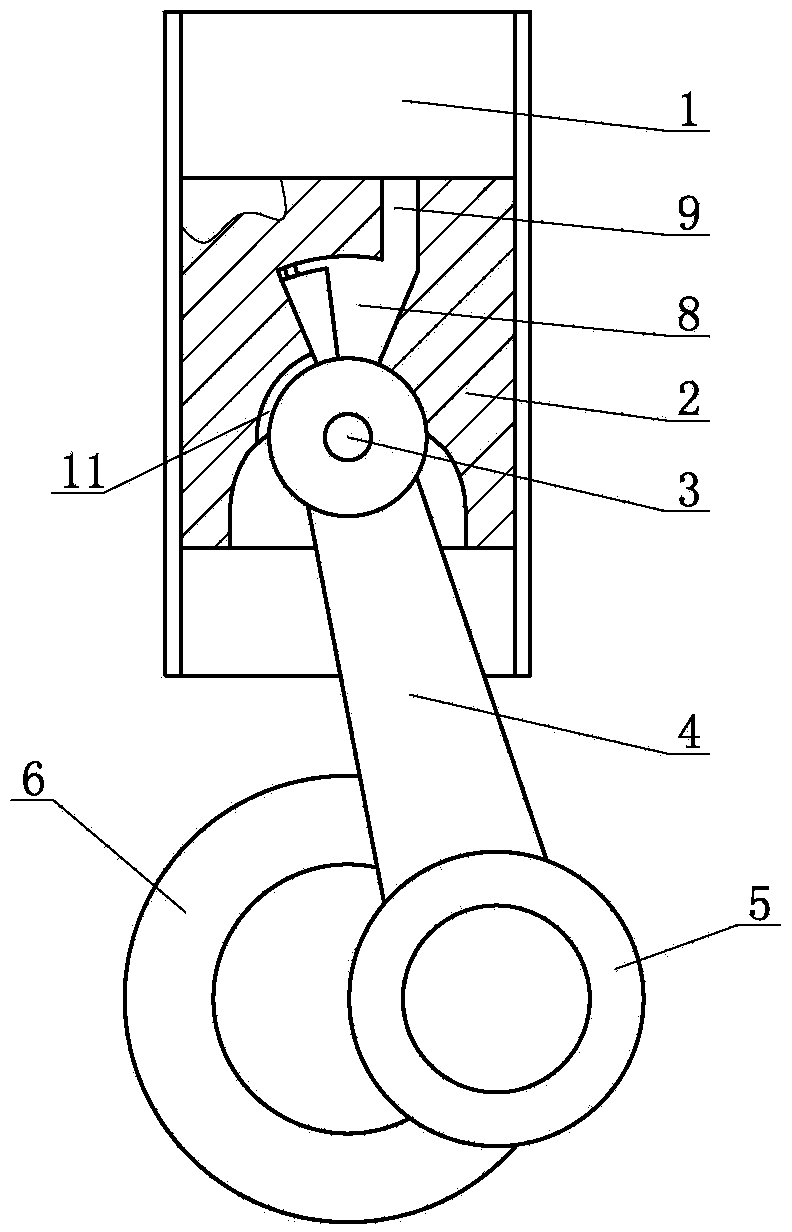

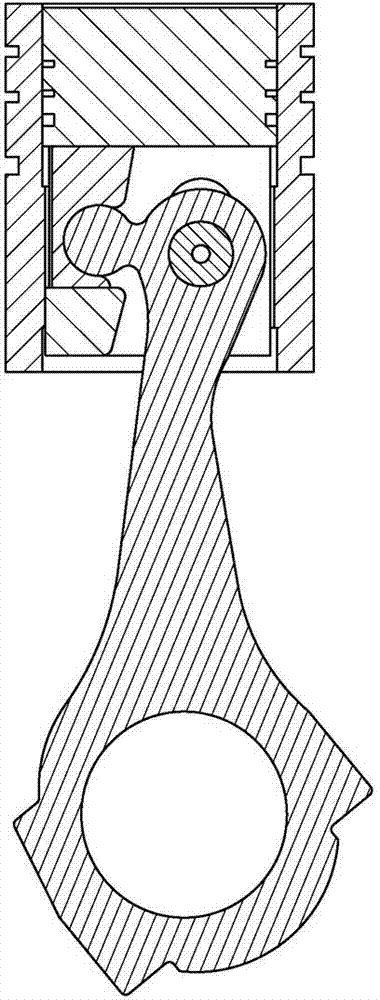

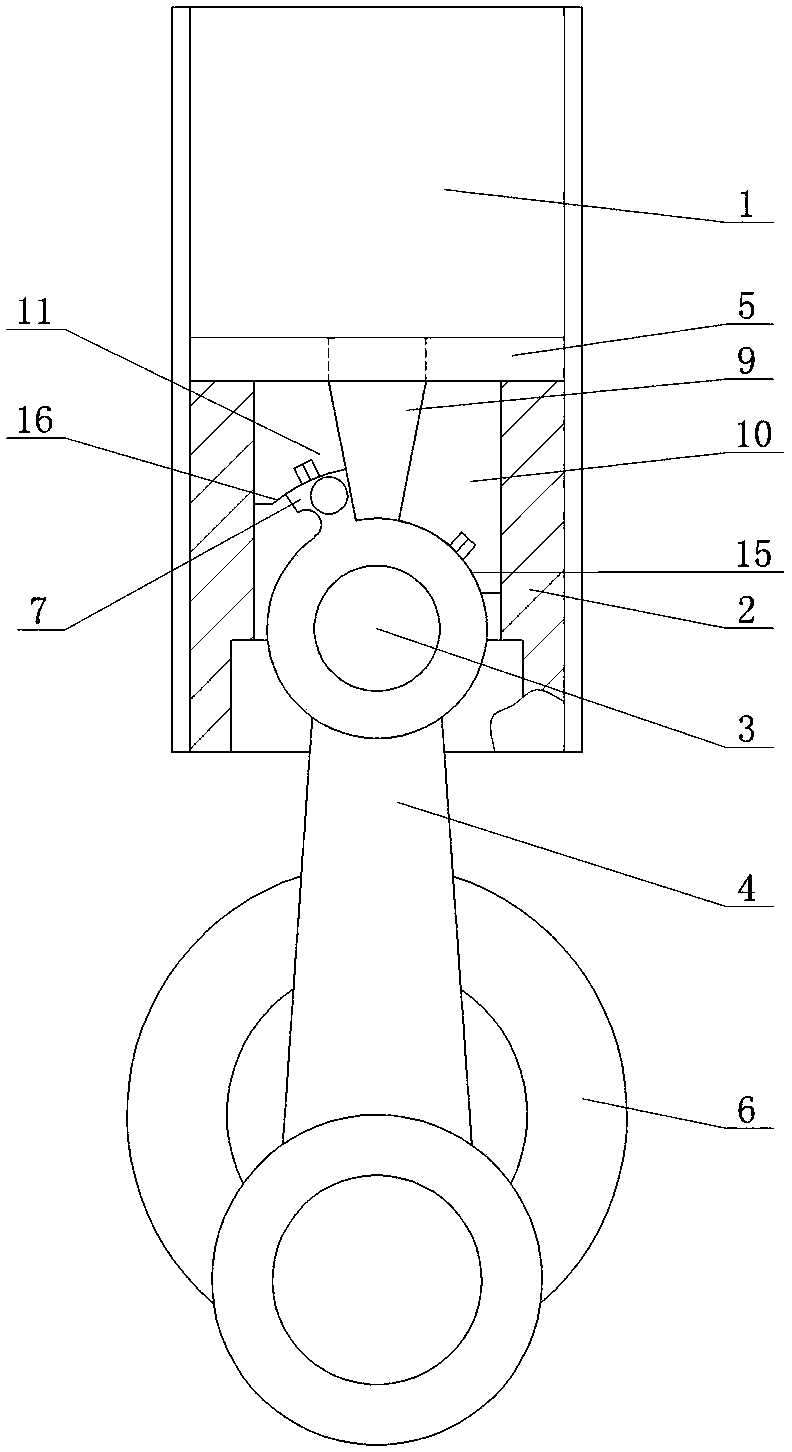

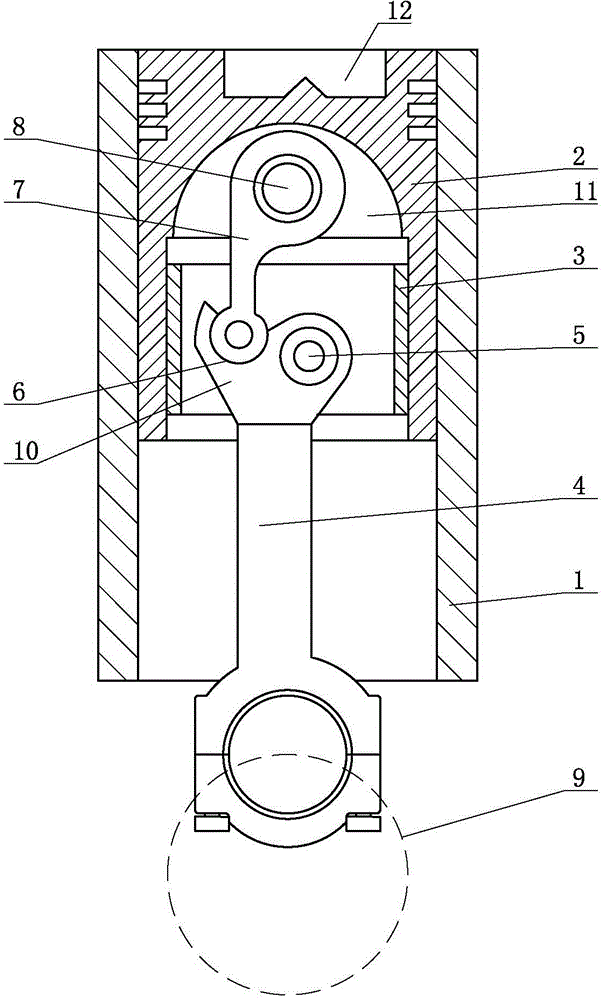

Connecting rod piston type combustion chamber combined dead-center-free reciprocating internal combustion engine

InactiveCN103742263AExtended service lifeIncreased thrust areaCombustion enginesPistonsTop dead centerExternal combustion engine

The invention discloses a connecting rod piston type combustion chamber combined dead-center-free reciprocating internal combustion engine which comprises a shell, a connecting rod, a crank and a crankshaft. A cylinder is arranged in the shell, a piston head is mounted in the cylinder, an inner cavity and a piston pin hole are formed in the piston head, the piston head is hinged to the connecting rod through a piston pin which is matched with the piston pin hole, and the connecting rod is located in the inner cavity. Smoothness of the internal combustion engine can be effectively improved, and service life of the internal combustion engine is prolonged. The dead center distance with the top dead center position about 15-25 degrees of an original internal combustion engine is utilized, working stroke of an original conventional piston is elongated, and thrust area of the piston is increased, so that the internal combustion engine is ensured to output power under maximum pressure. The piston head, the piston pin and the connecting rod can act for power output at an angle more than 180 degrees, particularly power output with piston running top and bottom dead centers of crankshaft 180 degrees + piston block output thrust angle of crank angle 90 degrees more than and equal to crank angle 180 degrees. Dead centers are eliminated, and the connecting rod piston type combustion chamber combined dead-center-free reciprocating internal combustion engine further has the advantages of simple structure and simplicity in manufacturing.

Owner:尹建

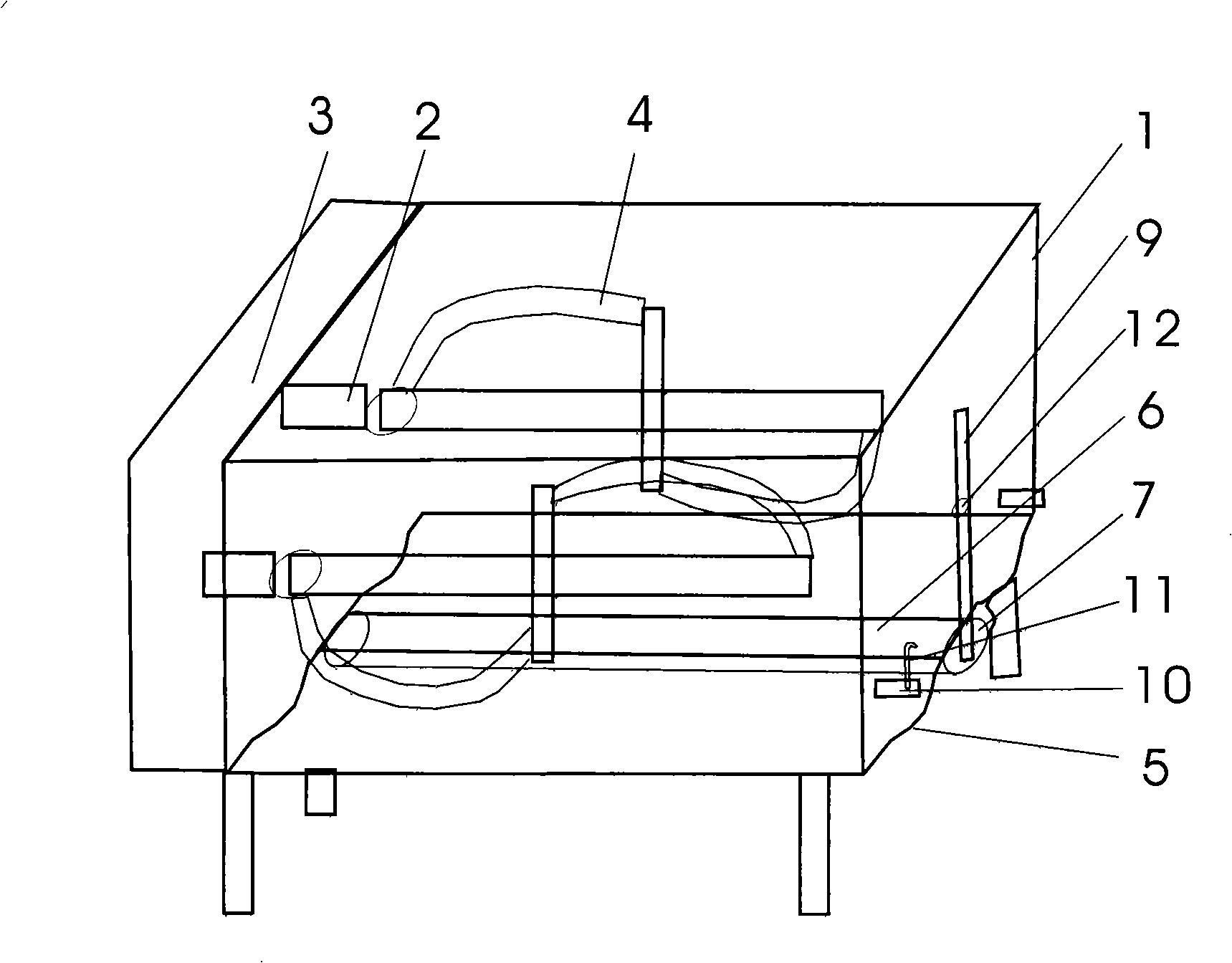

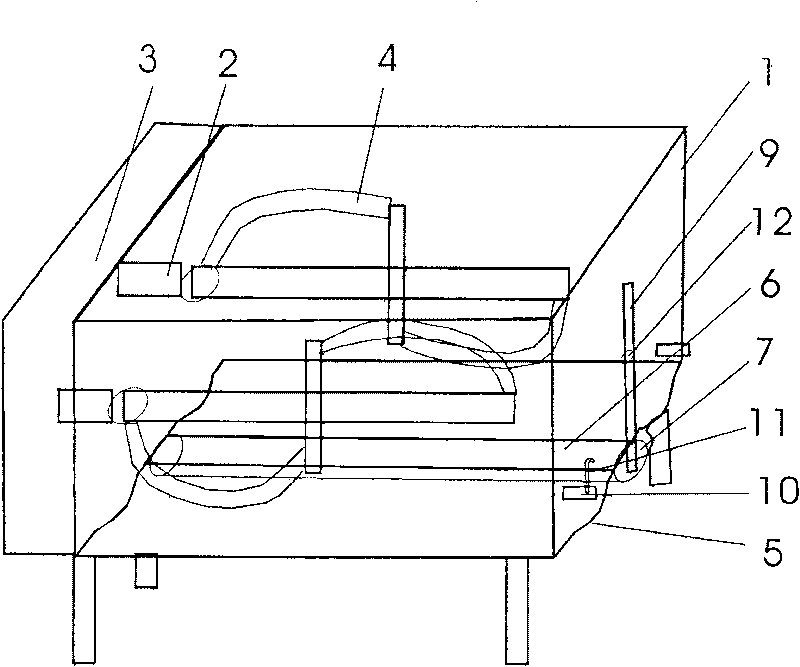

Concrete stirrer for double-horizontal shaft experiment

InactiveCN101347960AEliminate "dead spots"Eliminate dead endsCement mixing apparatusEngineeringMechanical engineering

The invention discloses a twin-horizontal-shaft concrete mixer for testing which comprises a cylinder, and two parallel stirring shafts which are horizontally arranged in the cylinder; the two parallel stirring shafts are connected with the slewing gear of a motor gearbox and provided with stirring vanes. The bottom of the cylinder is provided with two sink marks arranged at the lower part which the two stirring shafts are corresponding to; a discharge hole is arranged between the two stirring shafts; the lower part of the discharge hole is provided with a compass rotor; the discharge hole forms a tight fit with the rotor provided with a discharge passage. One end of the rotor is fixed with a push rod. Two push rod limit posts are arranged at the outside of the side wall of the cylinder. With the structure adopted, the two-horizontal shaft concrete mixer for testing of the invention has the advantages of simple structure, convenient operation, etc.

Owner:SHANGYU HONGXING MACHINERY INSTR MFG

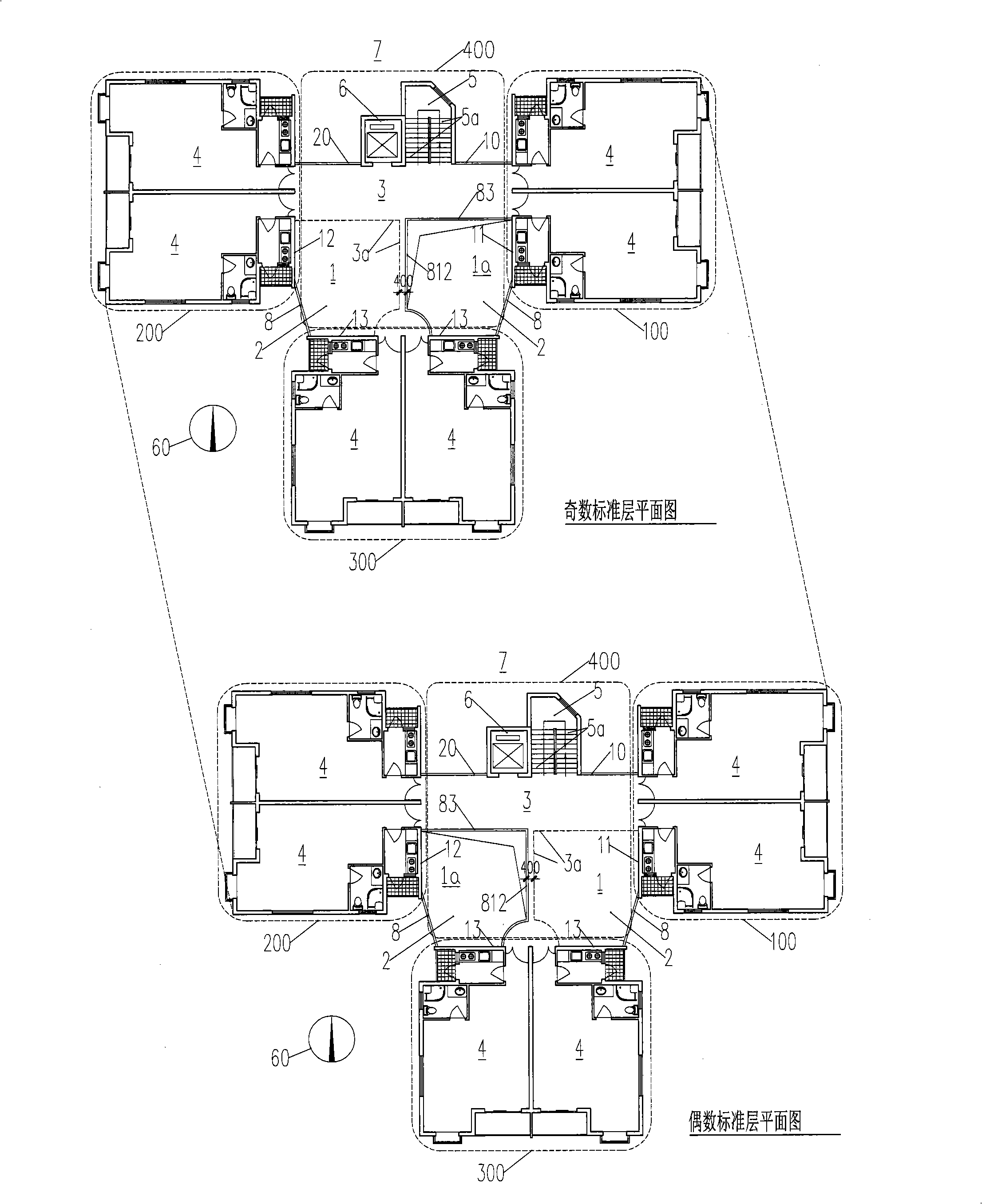

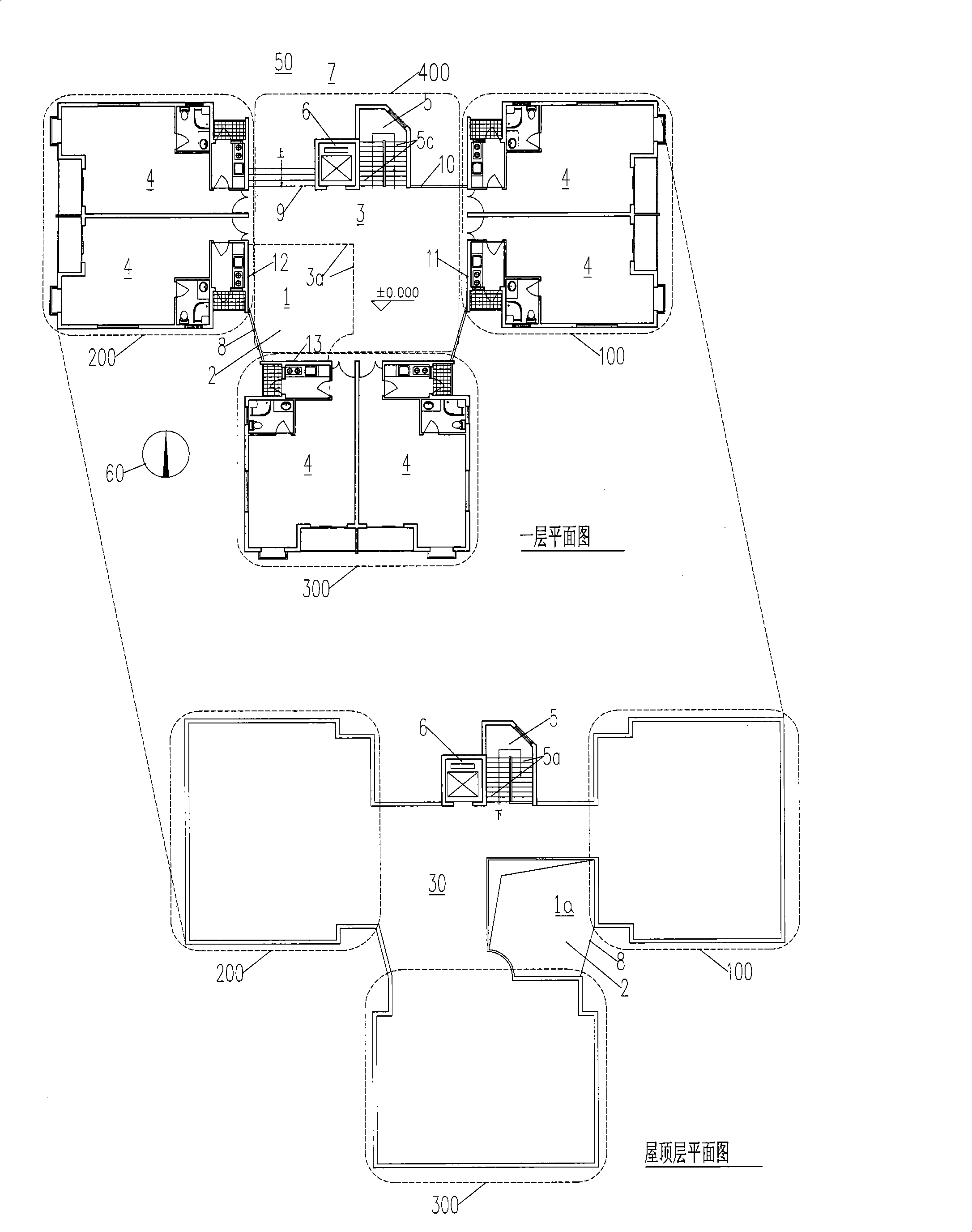

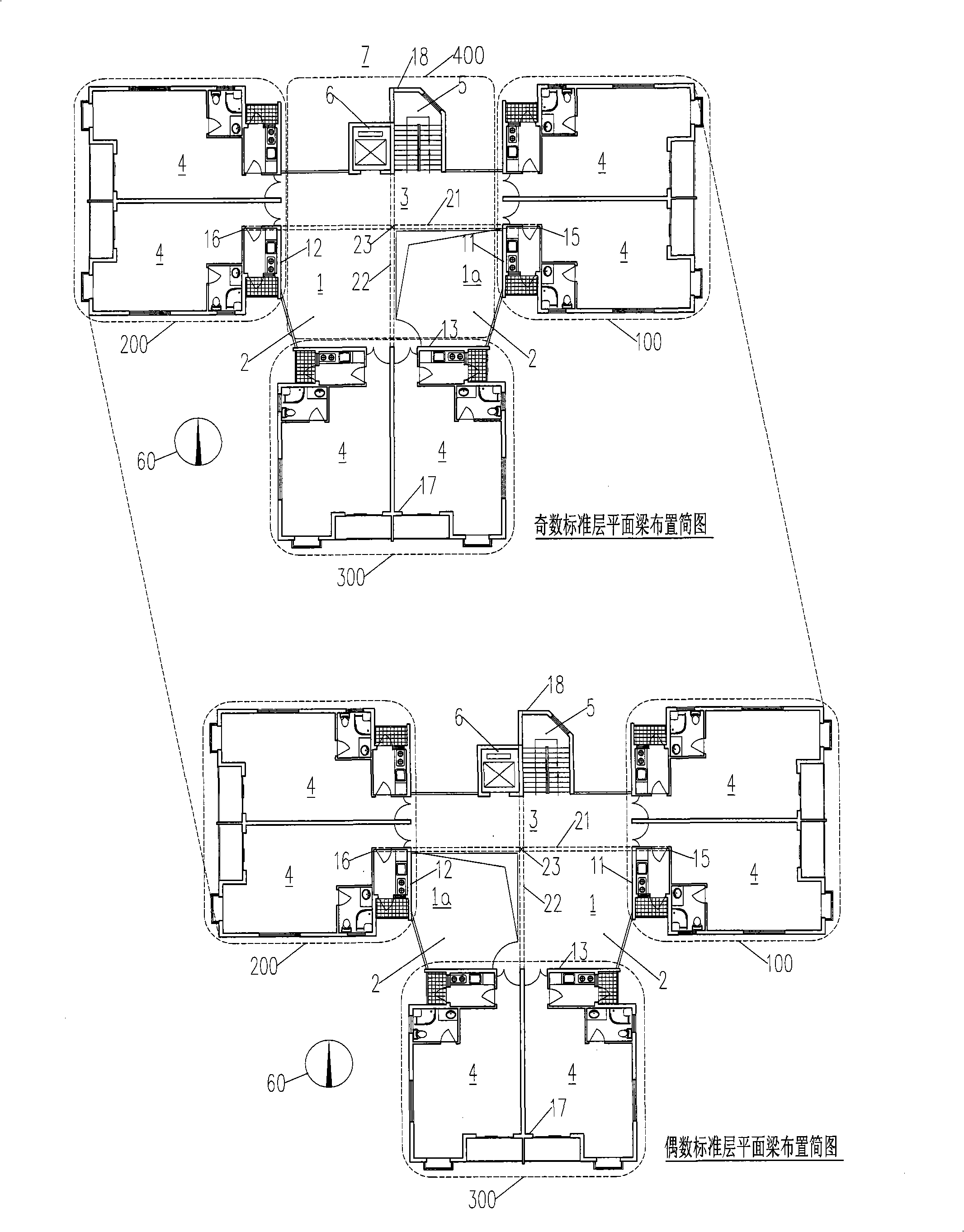

Aerial garden building

An aerial park construction is composed of a tower building with the indoor space. The three tower buildings are arrayed as Y or T shape; there is a distance between two tower buildings which forms threes opening surfaces; each building board of at least continuous four floors connects the three tower buildings; each building board is opened at the three directions; the height of the upper space of at least a block of area of each floor is two floors or more than two floors; and the area is opened outwards to form an aerial park. The aerial park construction provides the indoor using space and aerial park with great lighting, ventilative sun shining. The aerial park is tightly related to the using units, which has a strong enclosing feeling and naturally extents a plurality of floors. The invention boosts the outdoor sports and neighborhood communication of the floor people.

Owner:郭建军

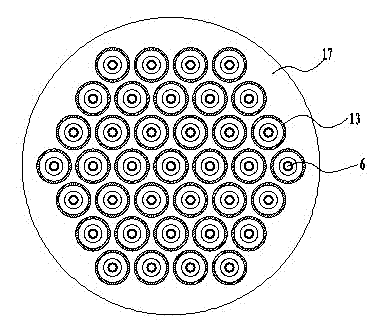

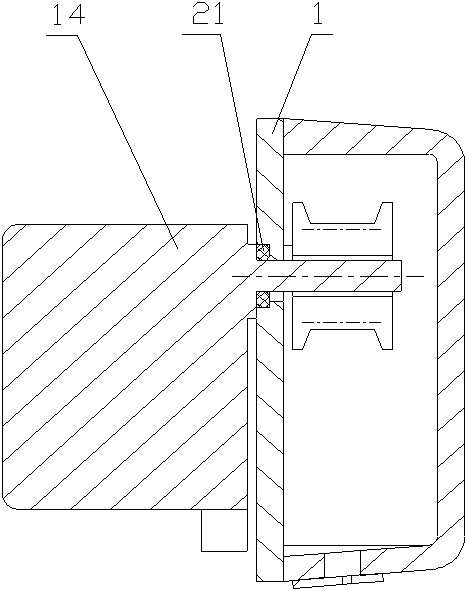

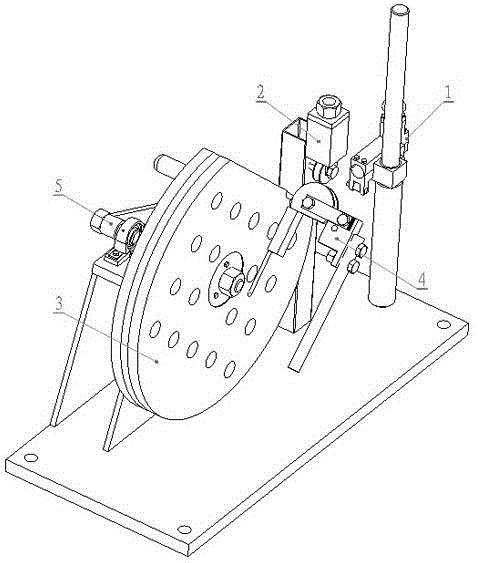

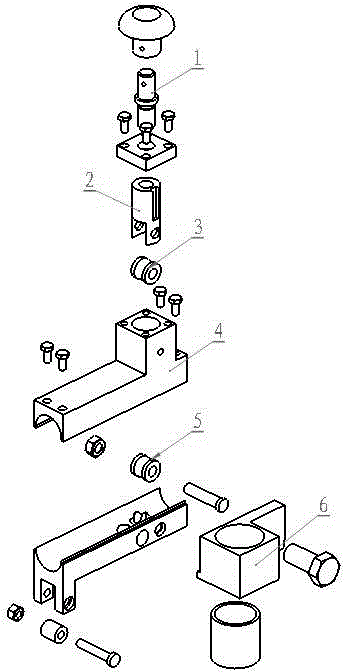

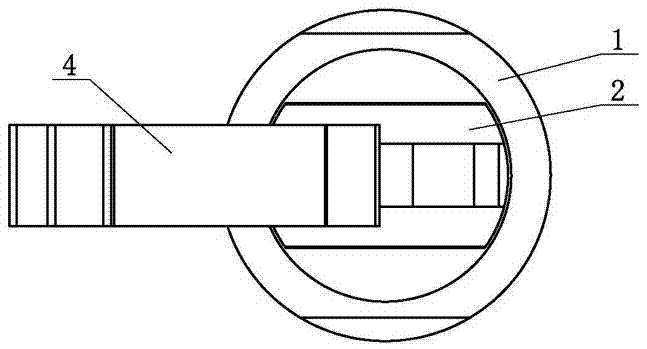

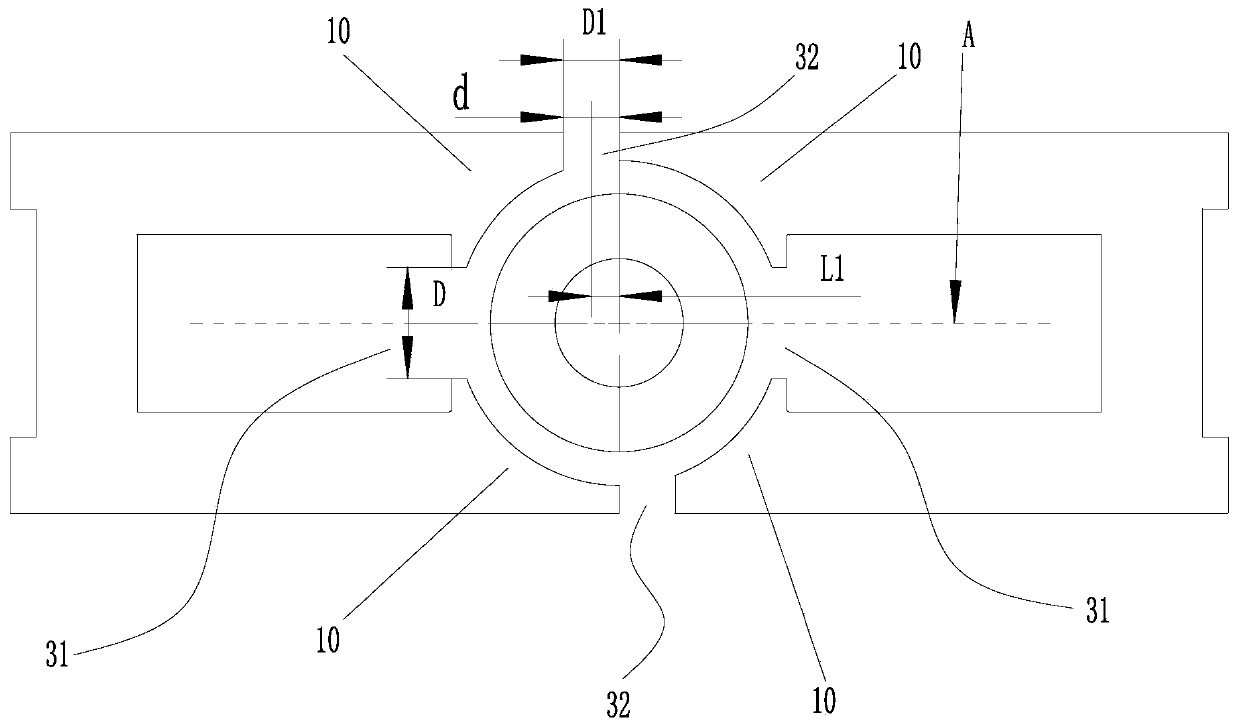

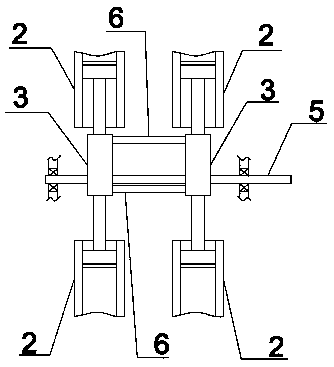

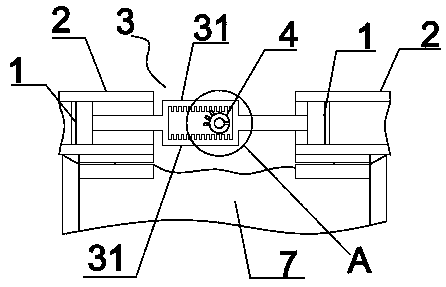

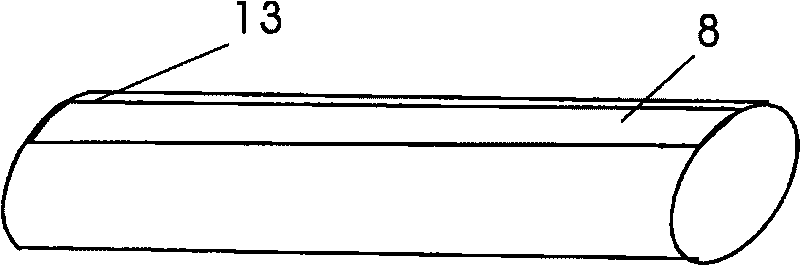

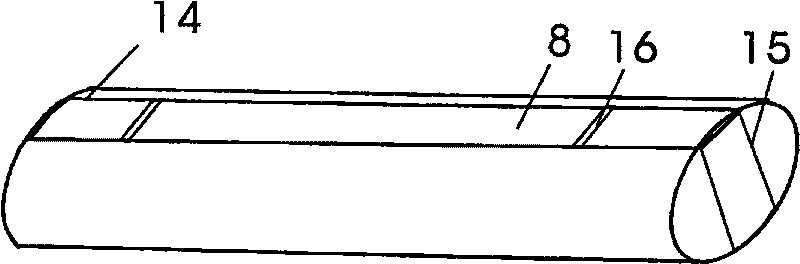

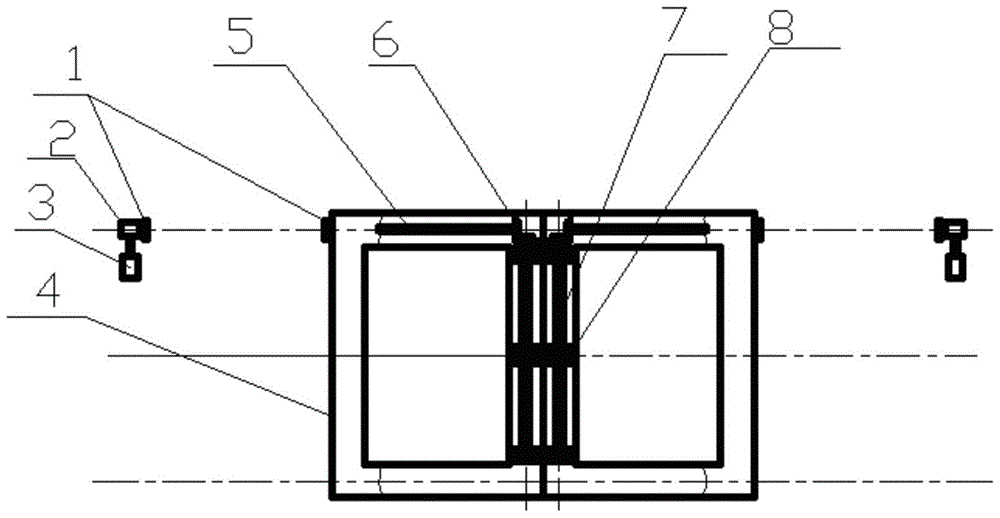

Coil pipe clamp

ActiveCN102873151ATo achieve the purpose of the coilEliminate dead spotsFixed bearingRotational axis

The invention discloses a coil pipe clamp, which comprises a coil pipe device, a fixed pulley guide device and an inner stress elimination device, wherein the whole clamp is fixed on a substrate; the coil pipe device comprises a rotating shaft, a fixed bearing, a driving handle, a disk wheel, a guide wheel and a manual pipe bender; the fixed pulley guide device comprises a fixed pulley, a supporting frame and a bolt; and the inner stress elimination device comprises a supporting rod, a limiting bracket, a guide bracket and a bolt component. In the process of eliminating inner stress by the inner stress elimination device, the rotating shaft rotates, and a coil pipe conveying angle can be automatically adjusted according to angle change of a bent pipe, so that the inner stress can be eliminated, and dead points of a coil pipe can be gradually eliminated; and a phenomenon that the coil pipe tends to be recovered after being separated from the coil pipe clamp because of releasing of the inner stress can be avoided. By the coil pipe clamp, the performance of the coil pipe is perfected, the service life of the coil pipe is prolonged, and the safety of a water-cooling heat exchanger using a helical coil pipe is correspondingly improved.

Owner:天津凯德实业有限公司

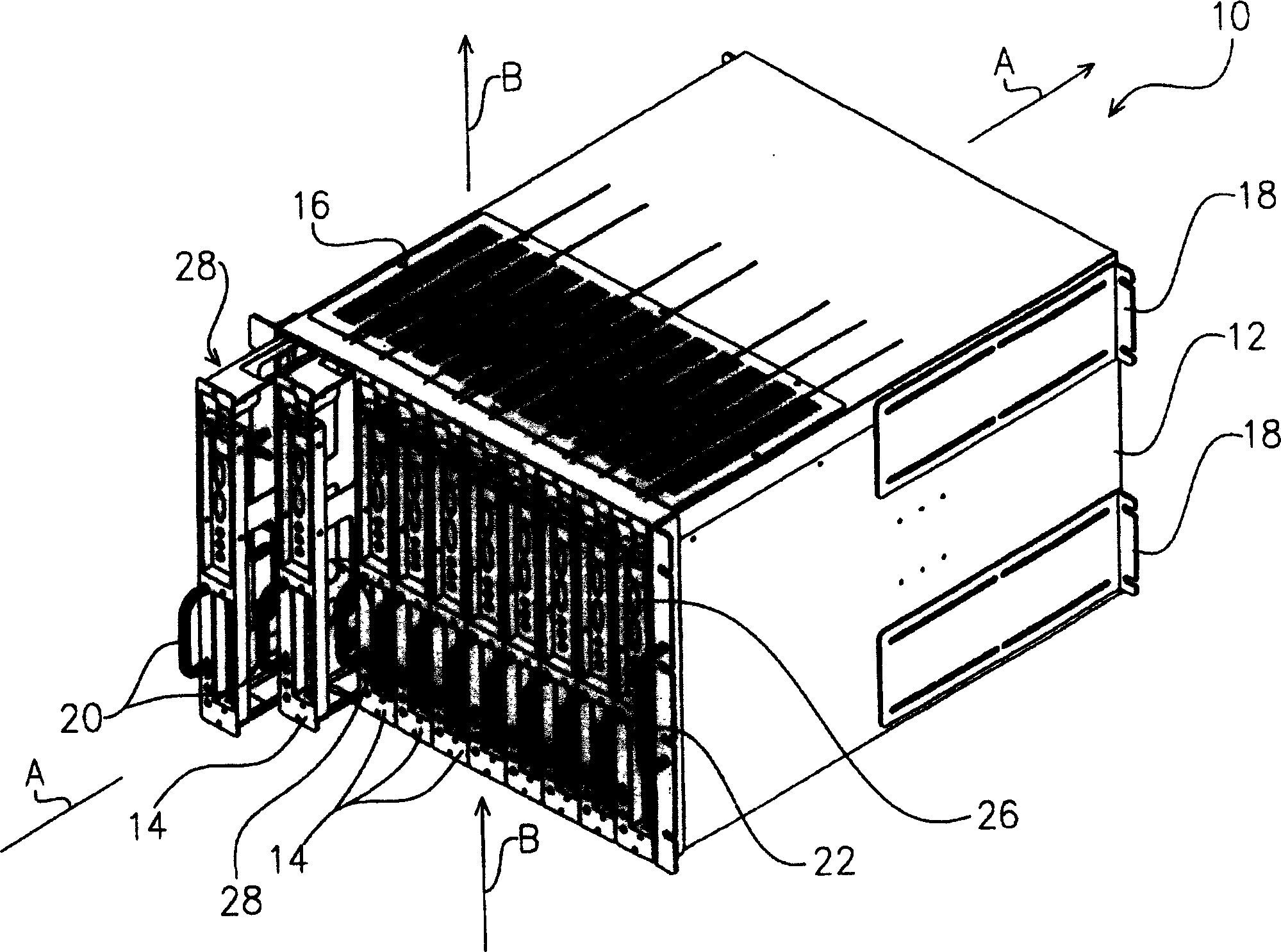

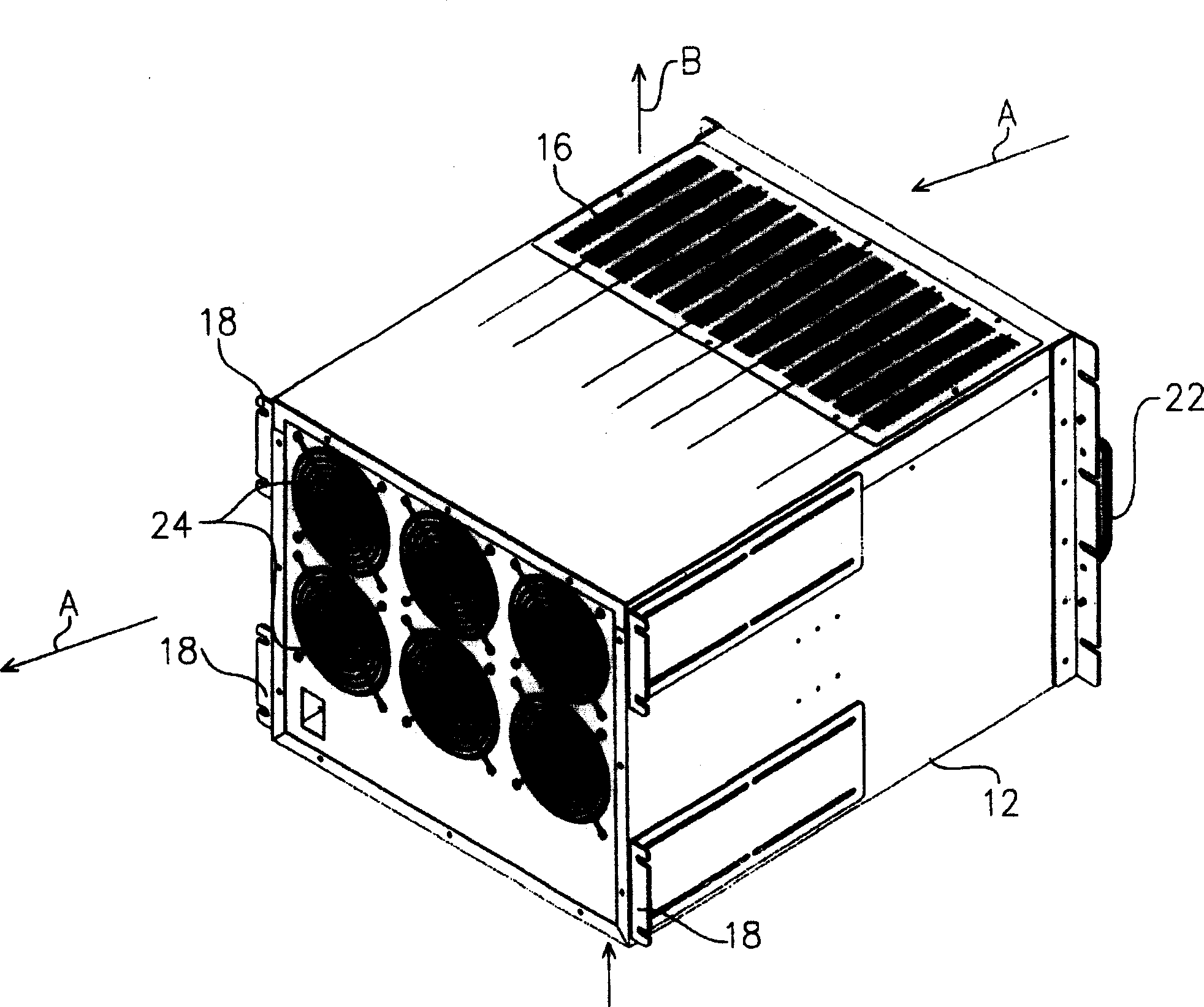

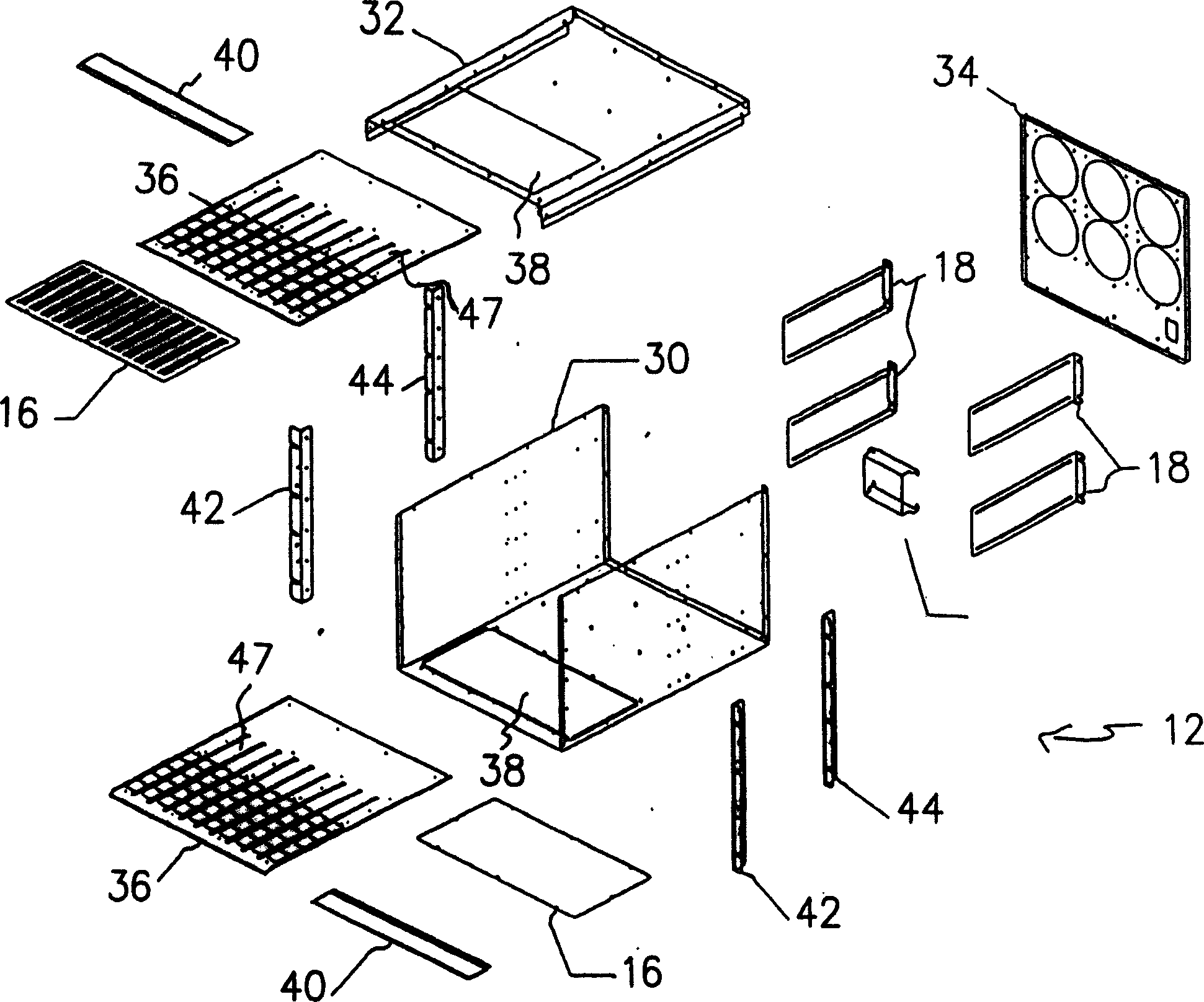

Computer system and method for cooling computer system

InactiveCN1536465AImprove cooling efficiencyImprove cooling effectDigital data processing detailsCooling/ventilation/heating modificationsElectronic componentPhysics

A computer system and a method for cooling the system incorporate removable modules within a housing. The housing includes a parallelepiped structure with at least four walls. The four walls include at least two sets of opposing walls. Both walls of one set of opposing walls include opposing first and second openings substantially aligned with each other to allow passage of a cooling medium therethough. The module is receivable through a third opening in the parallelepiped structure and includes an electrical component region. The housing includes a first airflow path in-line with the third opening and a second airflow path between the first opening and the second opening. The first airflow path and the second airflow path are directed across the component region of the module when the module is received within the housing.

Owner:吴善萍 +1

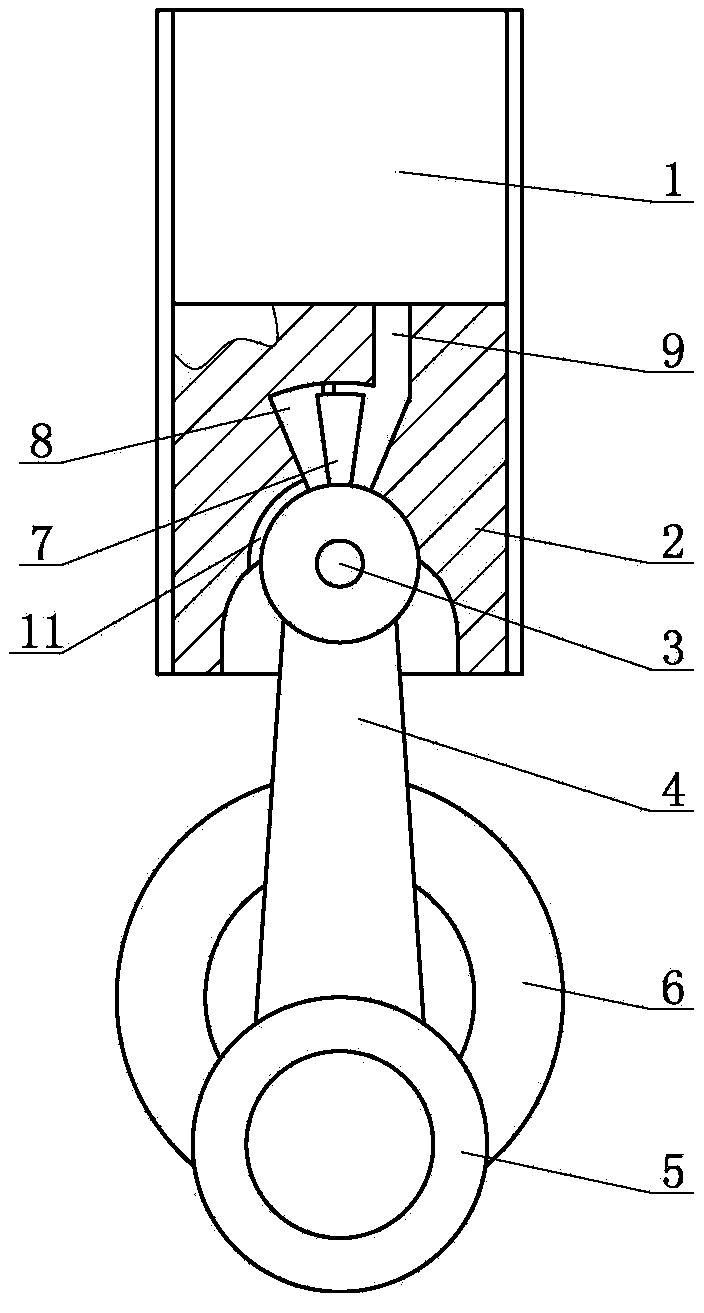

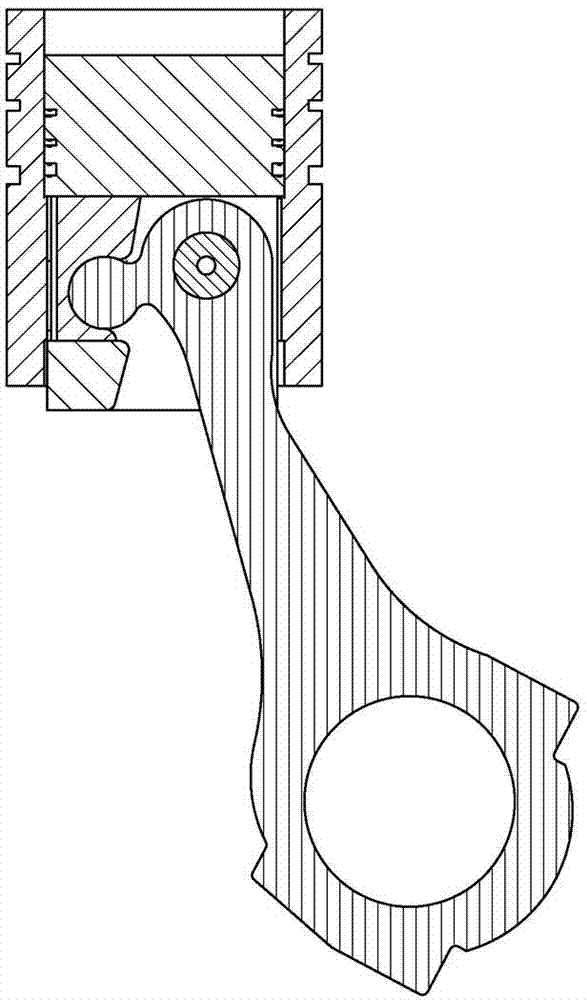

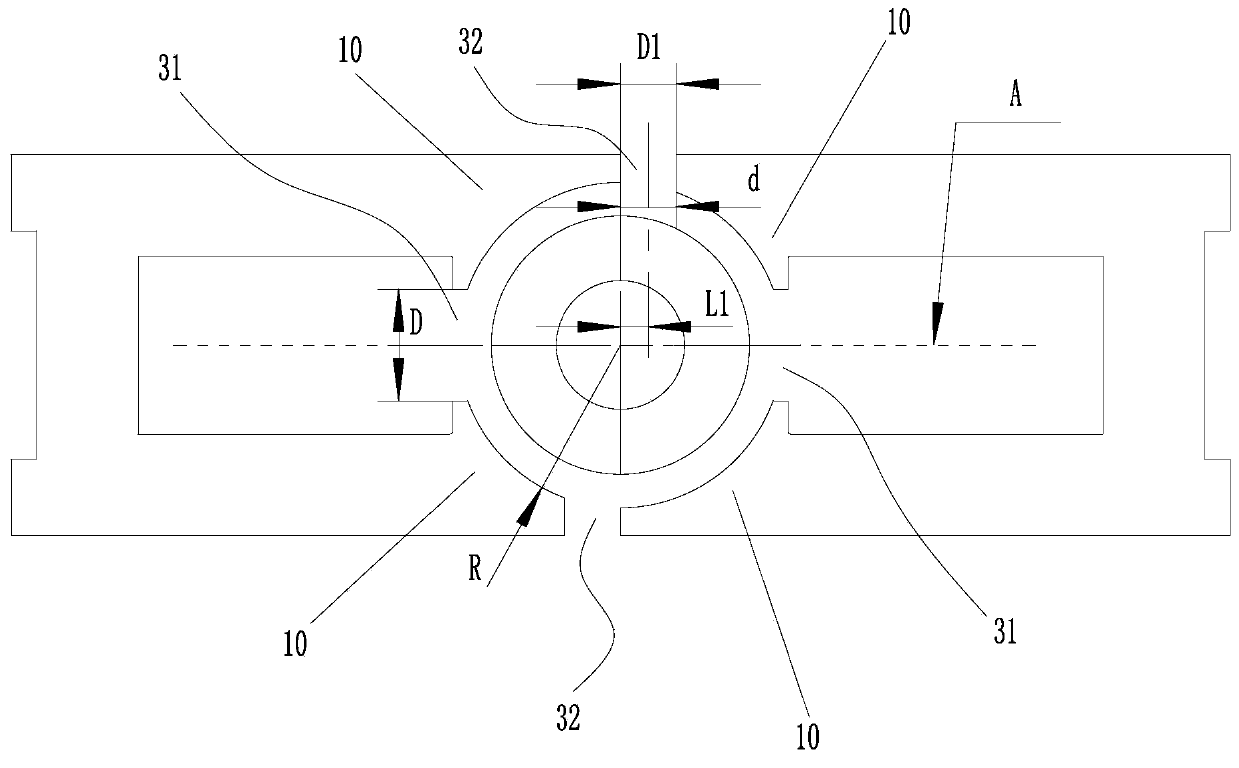

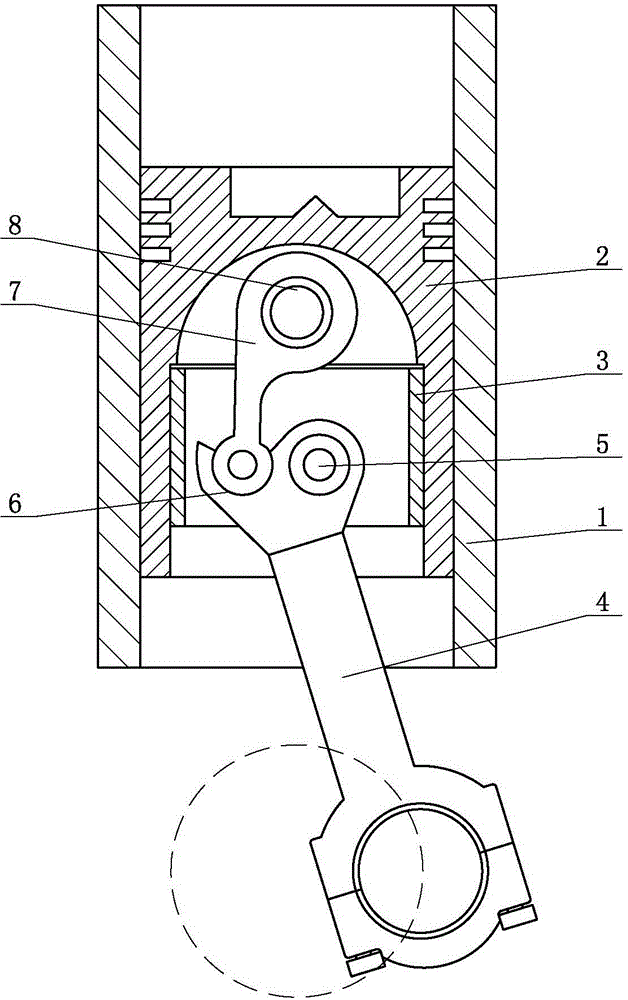

Double-piston servo connecting-rod mechanism of dead-point-free internal combustion engine

InactiveCN104265453AAvoid dead spotsEliminate dead spotsMachines/enginesEngineeringInternal combustion engine

A double-piston servo connecting-rod mechanism of a dead-point-free internal combustion engine comprises a main piston. An inner cavity is formed in the main piston along the axis direction of the same, a pin hole is formed in the main piston and perpendicular to the axis direction of the same and is communicated with the inner cavity, a pin shaft is mounted in the pin hole, an auxiliary piston is mounted in the inner cavity, two fixing plates are arranged at the lower end of the auxiliary piston side by side, a first sliding chute is formed between the two fixing plates, a guide block is arranged between the fixing plates and is located on the lower portions of the fixing plates, a space in the upper portion of the guide block is a second sliding chute, a slider is mounted in the second sliding chute, an arc groove is arranged in the slider, the guide block guides the slider, the pin shaft is connected with the upper end of a connecting rod which is hinged with the main piston through the pin shaft, the connecting rod is capable of swinging relative to the main piston by taking the pin shaft as an axis, and a single-cylinder internal combustion engine can be promoted and applied more sufficiently. The double-piston servo connecting-rod mechanism has the advantages of simple structure and convenience in manufacture.

Owner:尹建

Processing method for groove of oscillating follower cylinder cam

InactiveCN100417840CAvoid interferenceEliminate "dead spots"Programme controlComputer controlClassical mechanicsCam

The invention relates to a method for processing the swing inactive cylinder cam groove, characterized in that the motion of swing inactive cylinder cam is divided into the arc swing along with the swing rod and the rotation relative to the cam, wherein, the arc swing can be decomposed into two mutually perpendicular straight motions in the swing plane as 3D motion, and the rotation relative to the cylinder cam is unfolded into the cylinder face that contacting the relation between the swing angle of swing rod and the rotation angle of cylinder cam as swing angle curvature onto the unfolded cylinder face, or projecting the relation between the displacement of swing inactive element and the rotation angle of cylinder cam as displacement curvature onto the unfolded cylinder face to obtain the 3D unfolded line; then based on the 3D unfolded line, processing the 3D blade track to be used in digit-control machine. The invention can avoid the error of general 2D unfolded method.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

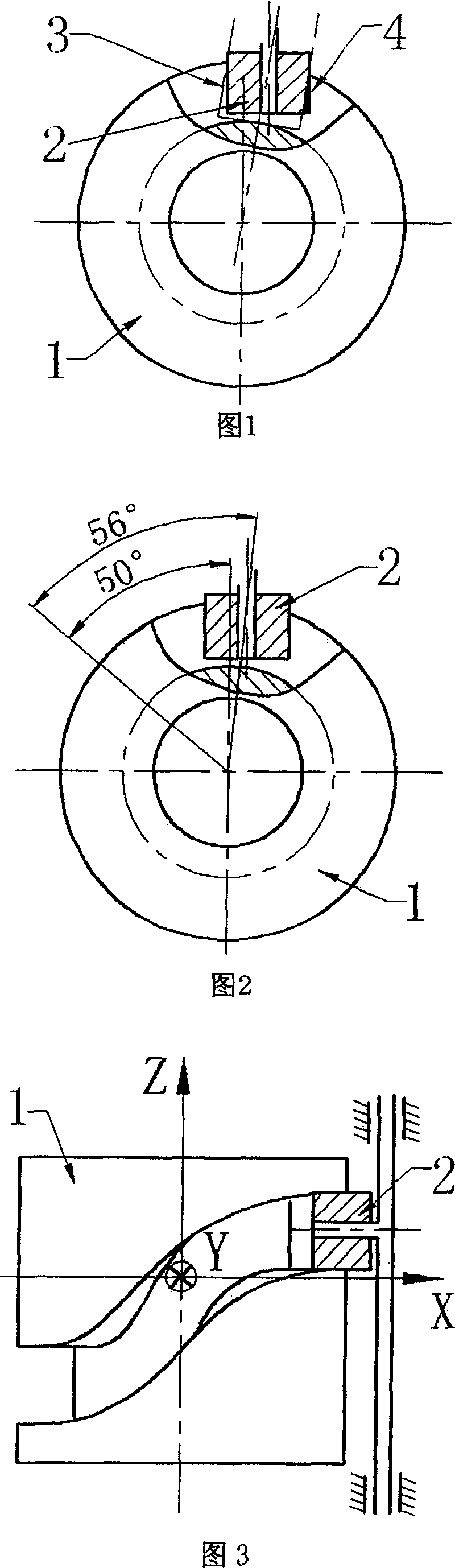

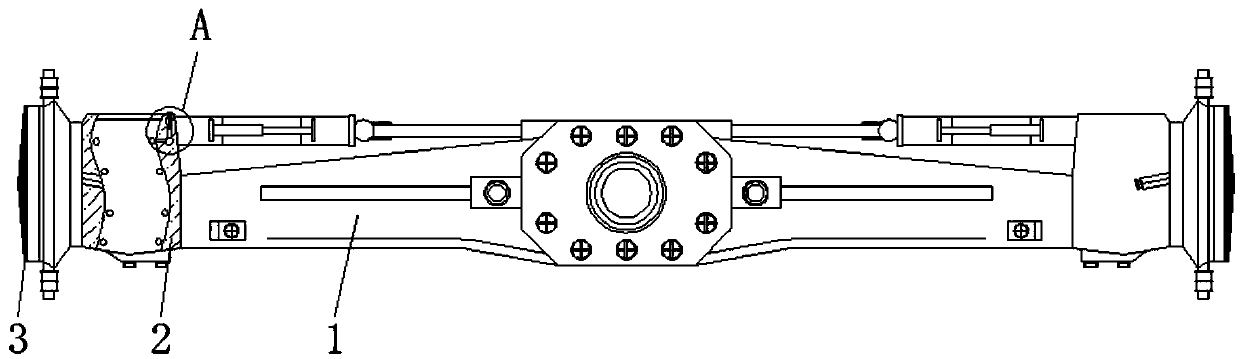

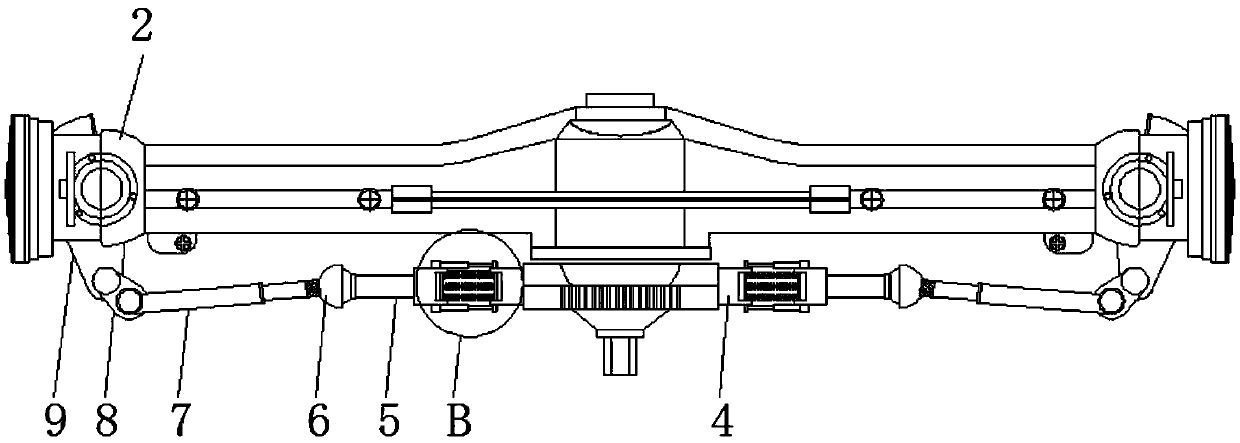

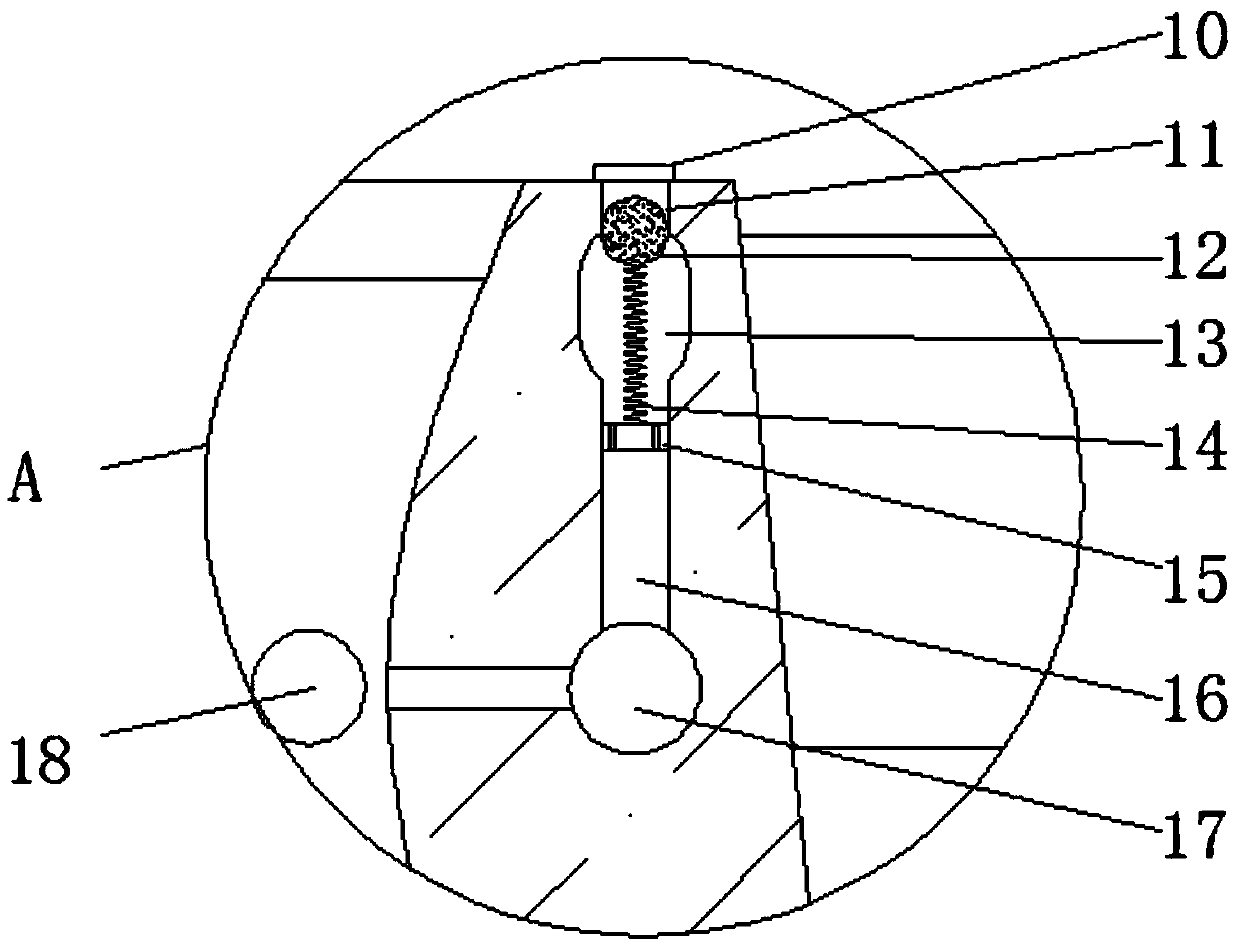

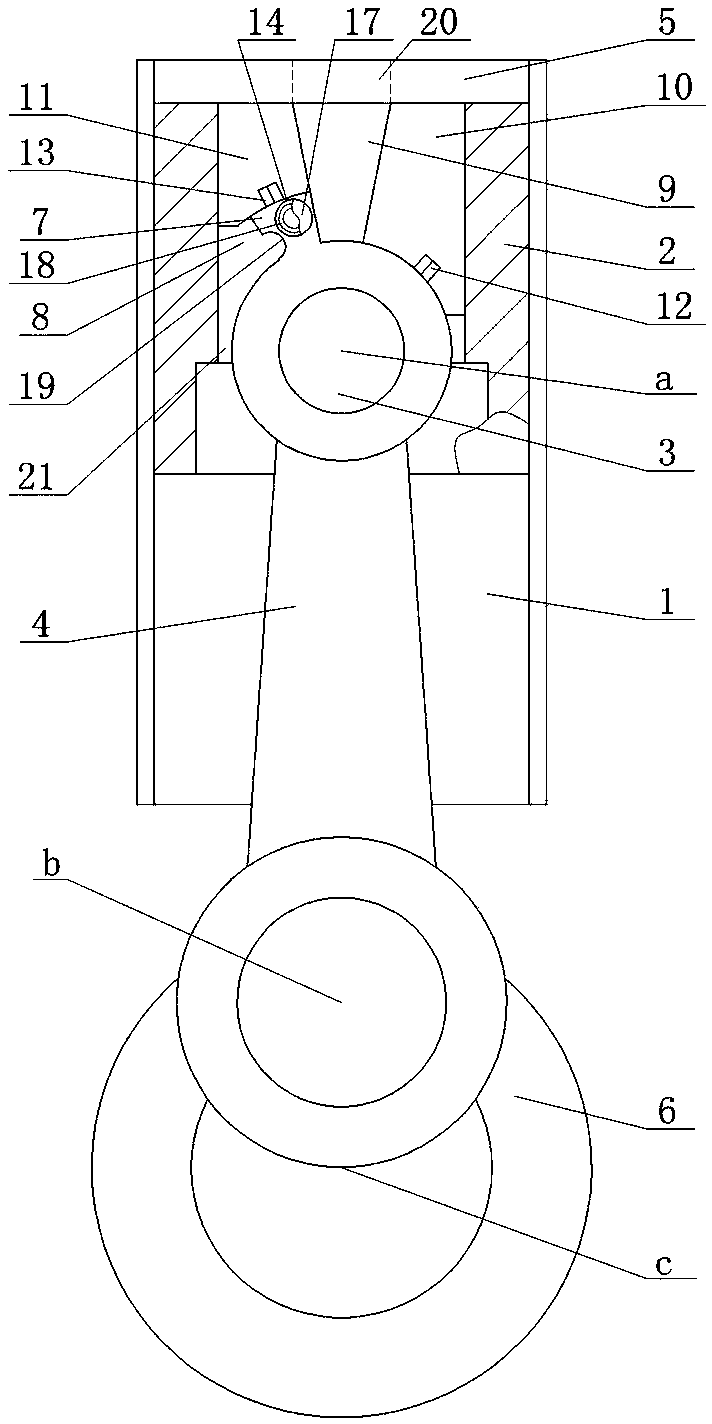

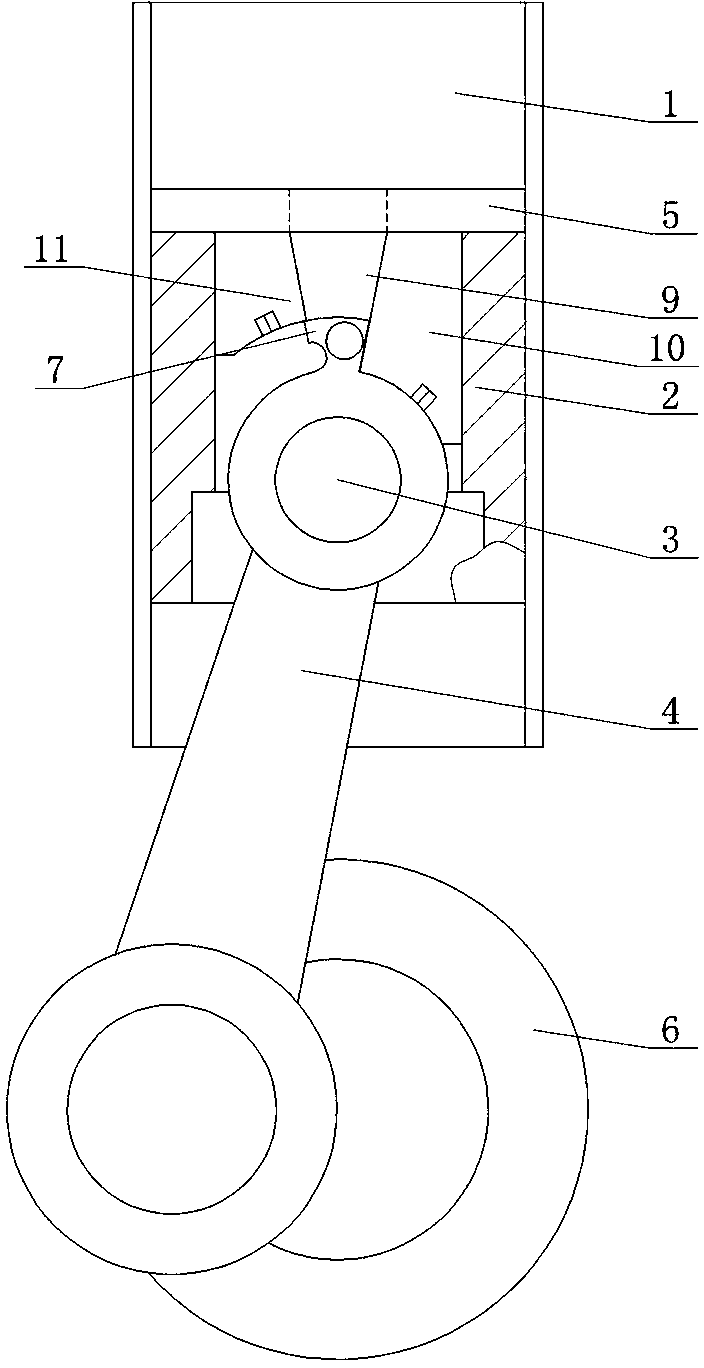

Front drive axle with large steering angle

ActiveCN109624611APlay a buffer roleImprove stabilitySteering linkagesFluid steeringTurn angleSteering angle

The invention discloses a front drive axle with a large steering angle, which comprises a front axle shell, wherein the front axle shell is integrally formed, two steering knuckle shells which are symmetrically distributed are fixedly arranged at two ends of the front axle shell, the inner rotation angle of a front wheel of the front axle shell is more than 50 degrees, the inner corner of the front wheel is the angle at which the trapezoidal arm in the steering trapezoid rotates when the front end of the front wheel deflects to the outer side of the drive axle to the maximum angle, the outer corner of the front wheel of the front axle shell is more than 40 degrees, the outer corner of the front wheel is the angle at which the front end of the front wheel deflects to the inner side of the drive axle to the maximum angle. The angle of rotation of the trapezoidal arm in the steering trapezoid is increased, so that the dead point in the steering process is eliminated by increasing the steering angle, the number of left and right steering turns of the steering wheel is consistent, the operability is improved, when the front drive axle is in a working state, when the driving oil rod is used for steering, when the vehicle turns, the tension spring is compressed under the action of impact force, thereby playing a role in buffering the driving oil rod and improving the stability of thedriving oil rod.

Owner:河北铠特农业机械有限公司

Reciprocating internal combustion engine without dead point

InactiveCN103850790AExtended service lifeIncreased thrust areaMachines/enginesPistonsExternal combustion engineInternal combustion engine

The invention discloses a reciprocating internal combustion engine without a dead point. The reciprocating internal combustion engine without dead point comprises a shell, a connecting rod and a crankshaft, wherein a piston cavity is arranged in the shell; a piston head is mounted in the piston cavity; a piston head is formed by connecting a piston head main body with a sealing end cover; an inner cavity and a piston pin hole are formed in the piston head main body; the inner cavity is communicated with the piston pin hole; an air inlet is formed in the center of the sealing end cover; a second sealing block and a first sealing block are arranged on the inner side of the sealing end cover; the first sealing block and the second sealing block are respectively located at two sides of the air inlet. According to the reciprocating internal combustion engine without the dead point, the about 15-25-degree dead point distance of the upper dead point position of the original internal combustion engine is utilized, the working stroke of the traditional piston is lengthened, the thrust area of the piston is increased, the power is enabled to be output when the pressure of the internal combustion engine is maximum, the working efficiency is improved, the energy consumption is reduced, and the power performance and the economy of the internal combustion engine are effectively improved.

Owner:尹建 +1

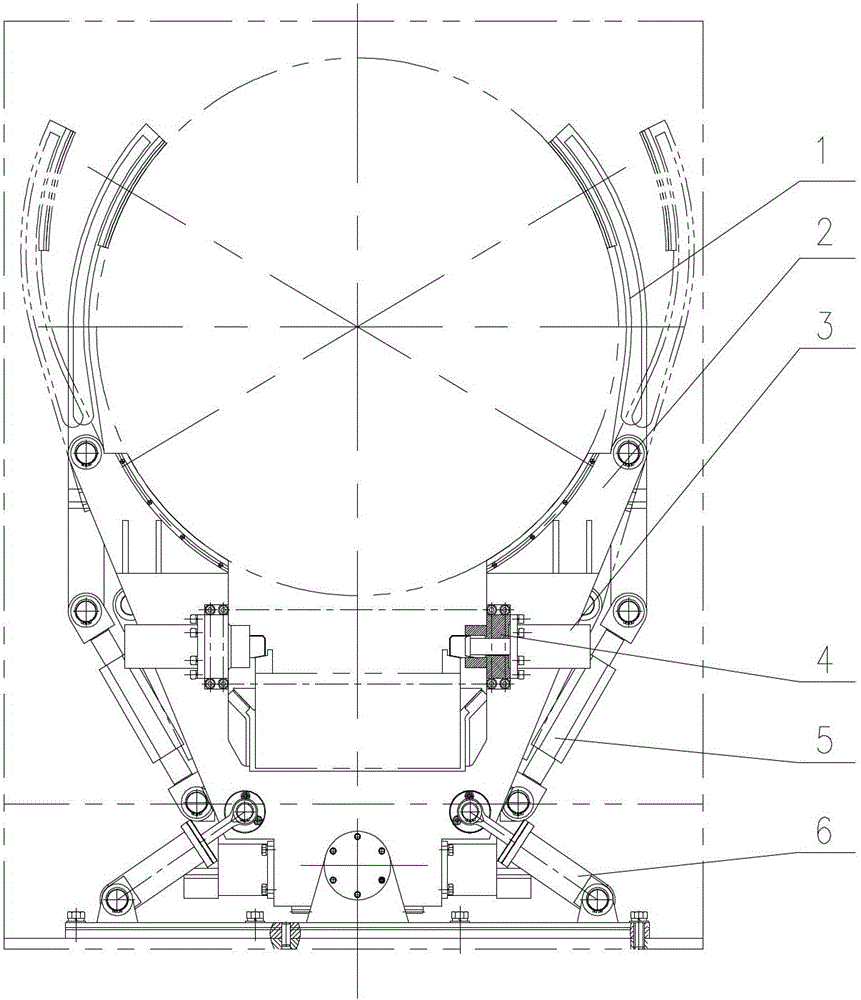

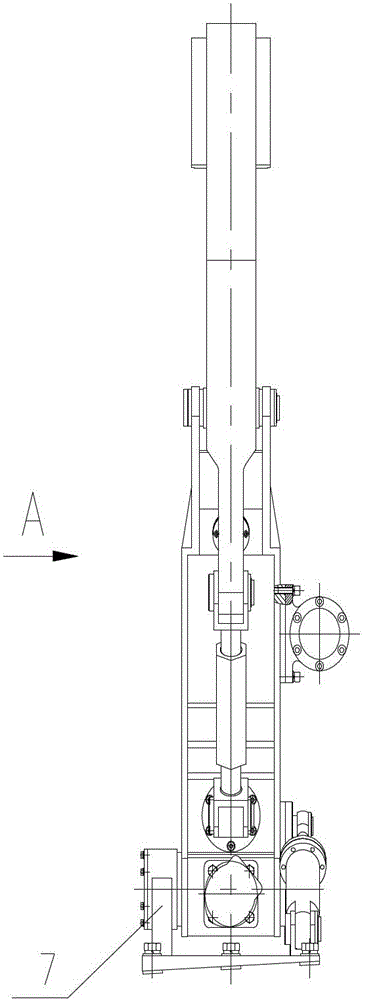

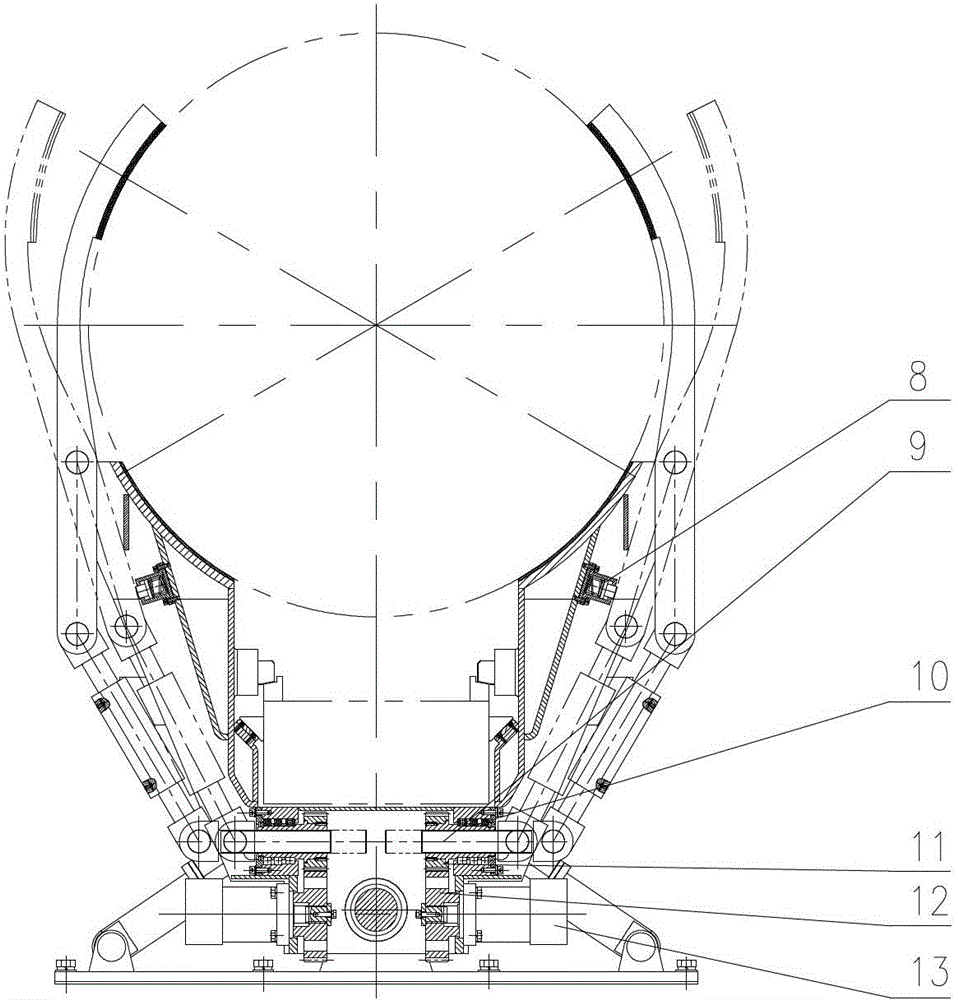

Device for clamping vehicle-mounted large-diameter cylinder

Owner:GUIZHOU AEROSPACE TIANMA ELECTRICAL TECH

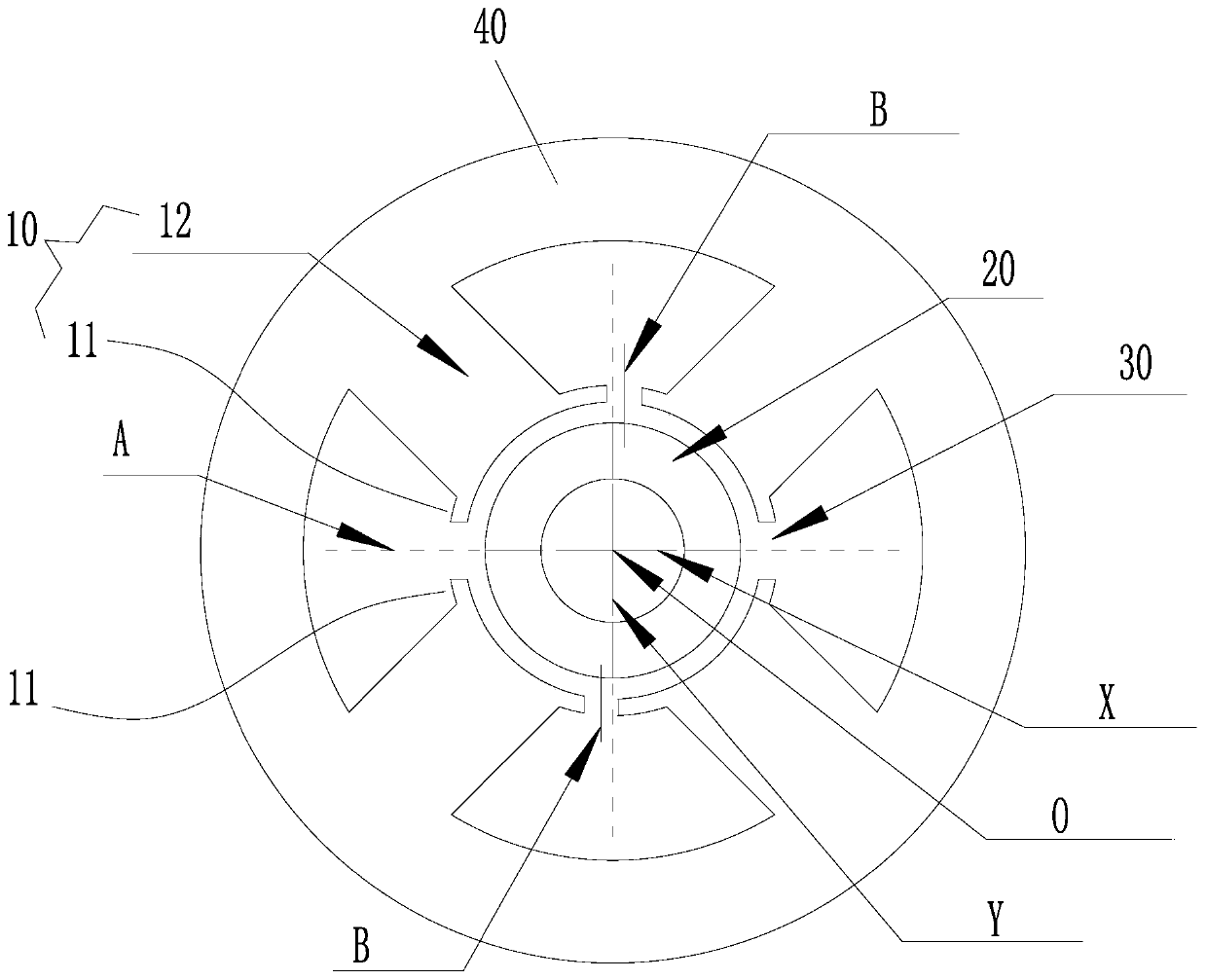

Piston type internal combustion engine for quickly passing through dead point through magnetic boosting

InactiveCN104481686AReduce lossesTo achieve the purpose of energy savingMachines/enginesMagnetic tension forceMagnetic poles

The invention discloses a piston type internal combustion engine for quickly passing through dead point through magnetic boosting. The piston type internal combustion engine comprises a cylinder, a piston, a connecting rod and a crank, wherein the end, hinged to the crank, of the connecting rod is provided with a magnet I; the connecting line of the N pole and the S pole of the magnet I is perpendicular to the connecting rod and is positioned in the plane of rotation of the crank; the inner wall of the cylinder is also provided with a pair of magnets II; when the connecting rod and the crank are collinear and the connecting rod is positioned at the position of an upper dead center, the pair of magnets II is positioned on the two sides of the magnet I and the connecting line of the pair of magnets II is collinear with the connecting line of the pole N and the pole S of the magnets I; when the polarities of the magnetic poles, on the side opposite to the magnet I, of the magnets II are the same and the crank starts to rotate from the upper dead center, the magnetic pole, on the same side as the linear speed direction of the crank, of the magnet I is reverse to the polarity of the magnetic pole of the oppositely arranged magnet II. The piston type internal combustion engine has a simple structure, and the relaxation time at the dead center is shortened, so that the purpose of improving the efficiency by shortening the energy consumption time as much as possible is achieved.

Owner:ZHEJIANG UNIV

Single-phase permanent magnet motor and dust collector with same

PendingCN110912289AEliminate the problem of starting dead spotsEliminate dead spotsMagnetic circuit stationary partsElectric equipment installationElectric machineClassical mechanics

The invention provides a single-phase permanent magnet motor and a dust collector with the same. The single-phase permanent magnet motor comprises a plurality of stator teeth, the plurality of statorteeth form an accommodating cavity for accommodating the rotor part, and a notch of a stator groove is formed between the tooth boot parts of the adjacent stator teeth. The number of the notches is multiple. The plurality of notches are arranged at intervals along the circumferential direction of the rotor part, and the structural characteristic of at least one notch in the plurality of notches isdifferent from the structural characteristics of the other notches. By setting the notches of the stator slots to have different structural characteristics, the problem that dead points exist in motor starting in the prior art is solved, and the starting torque and the output torque of the motor can be improved. Compared with a common single-phase permanent magnet motor, the cogging torque of themotor is greatly reduced, the torque ripple is greatly reduced, and the starting torque and the output torque of the motor are obviously improved.

Owner:GREE ELECTRIC APPLIANCES INC

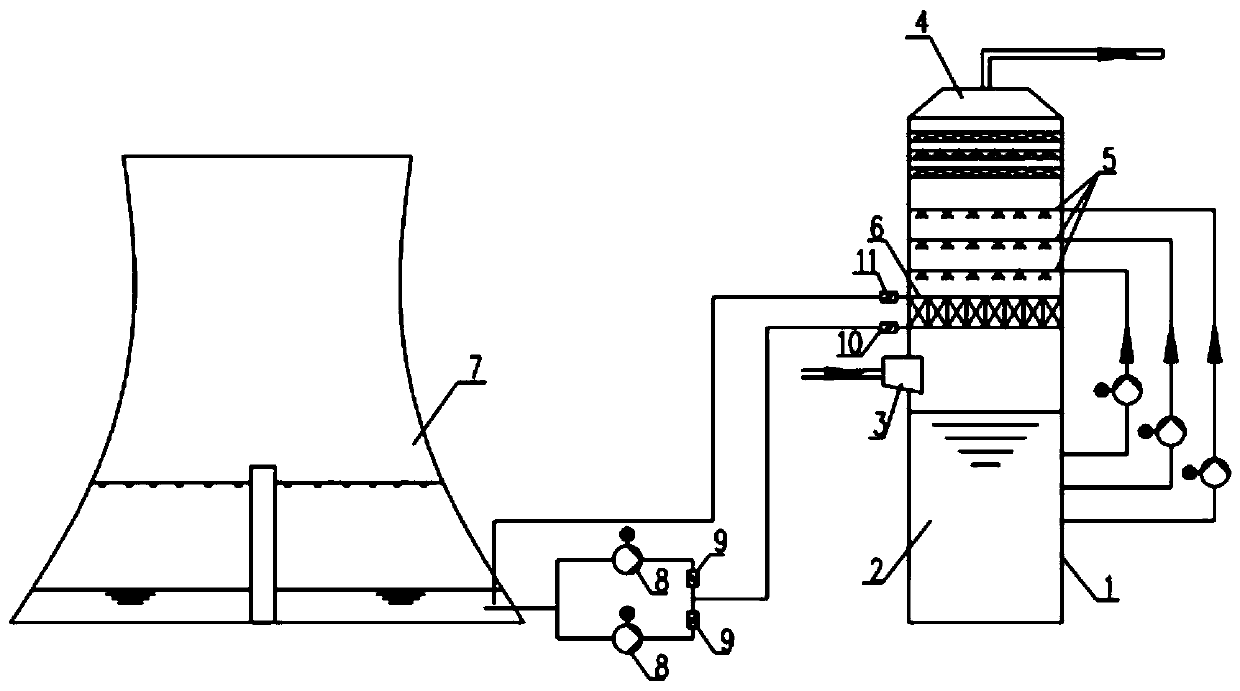

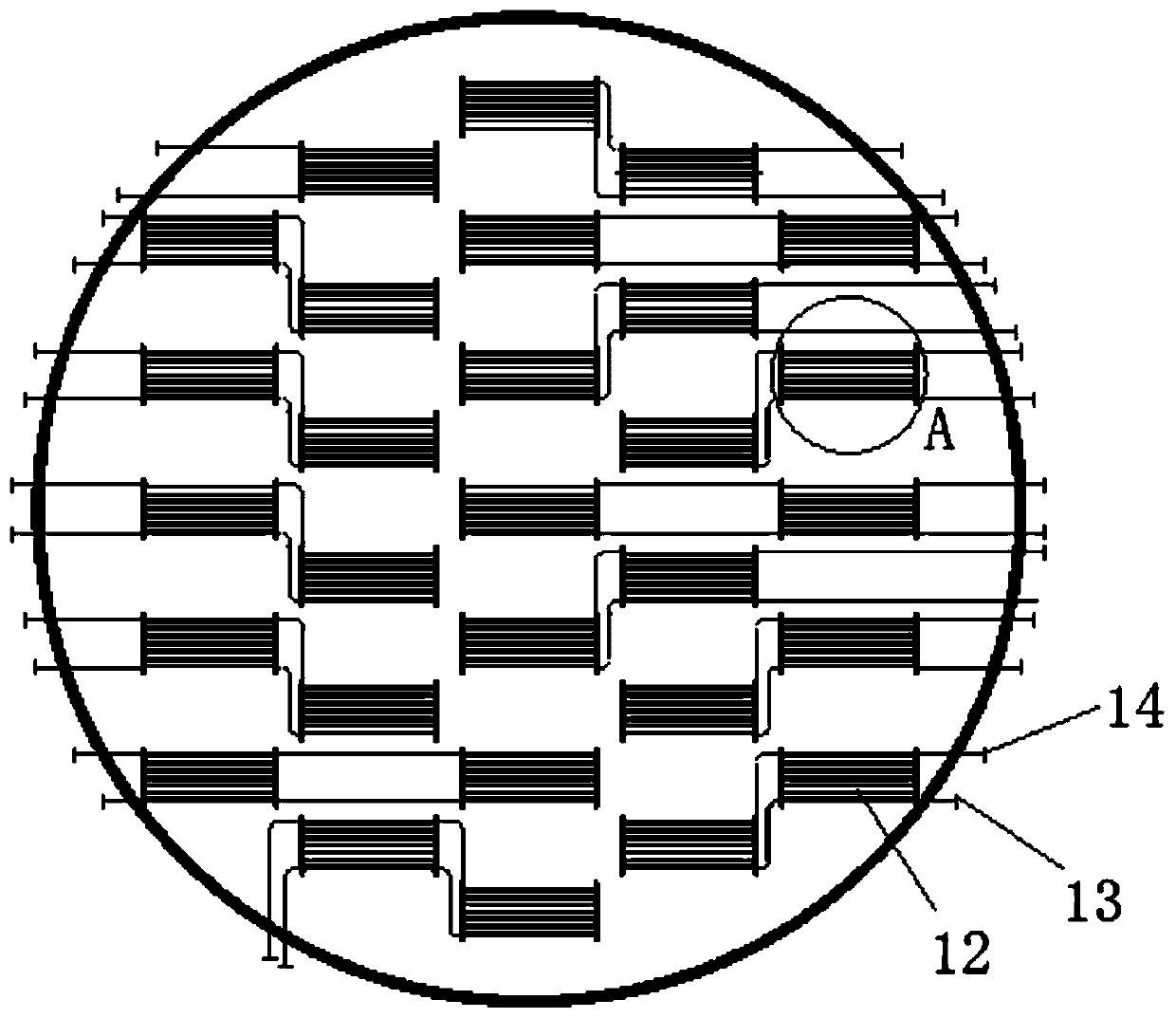

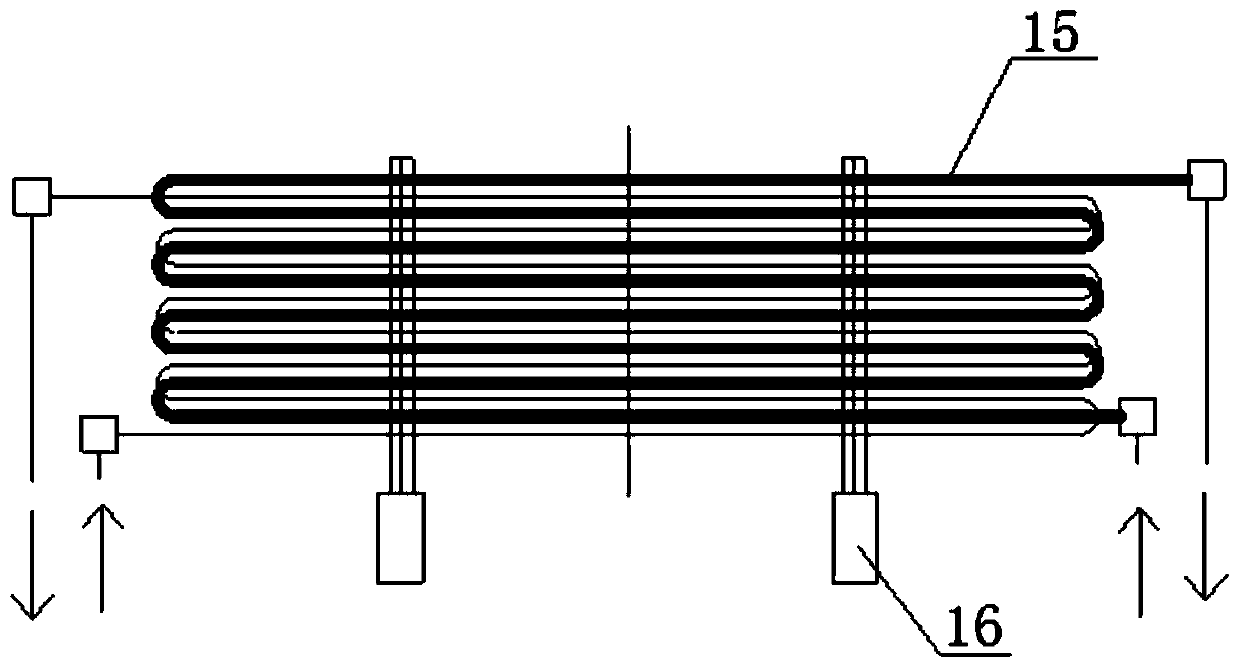

Condensing type white smoke removing system and method for flue gas slurry

InactiveCN109806697APlay the role of distributing airRapid primary coolingUsing liquid separation agentCombustion technology mitigationFlue gasEngineering

The invention discloses a condensing type white smoke removing system and method for flue gas slurry. The white smoke removing system comprises a desulfurization tower and a water cooling tower, wherein the desulfurization tower is sequentially provided with a slurry tank, a flue gas inlet, a heat exchange layer, a spraying layer, a demister and a flue gas outlet from bottom to top; the slurry tank is connected with the spraying layer through a pipeline; the pipeline is provided with a first water pump; the heat exchange layer comprises a plurality of heat exchangers; the plurality of heat exchangers are uniformly distributed on the cross section of the desulfurization tower; heat exchange pipes on each heat exchanger are arrayed in a matrix; the heat exchange pipes on adjacent layers in the vertical direction are distributed in a staggered manner; the heat exchange pipes are parallel to the cross section of the desulfurization tower; a water cooling tank is arranged at the bottom of the water cooling tower; a water inlet and a water outlet of each heat exchanger are connected with the water cooling tank through a pipeline and each pipeline is provided with a second pump. Accordingto the condensing type white smoke removing system, the modularized heat exchangers are arranged between an inlet flue of the desulfurization tower and the spraying layer on the bottommost layer anda space in the tower is sufficiently utilized; white smoke of flue gas is alleviated and even removed and the water consumption in a desulfurization process is reduced.

Owner:SHANDONG SHANDA WIT ENVIRONMENTAL ENGINEERING CO LTD

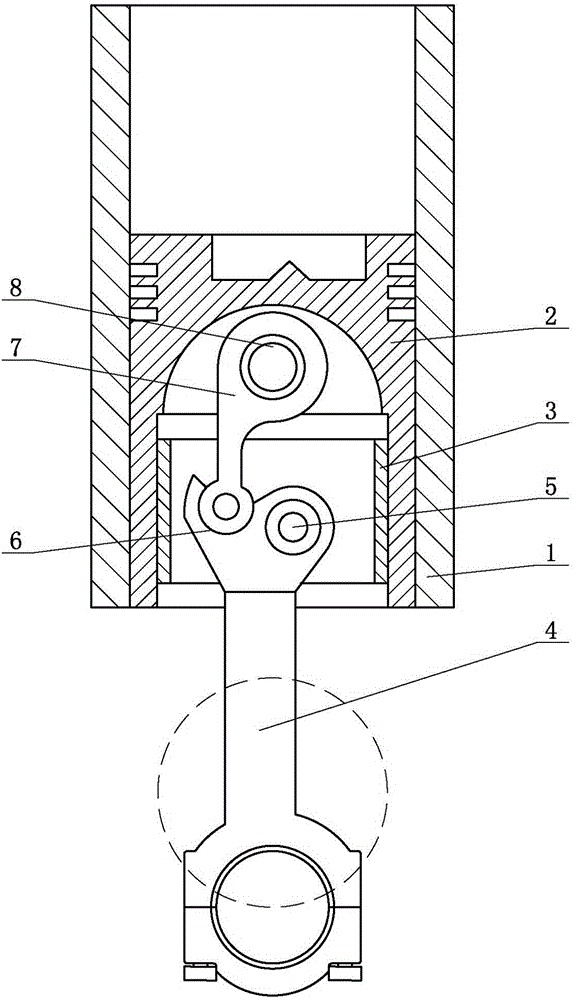

Reciprocating piston built-in chained connecting rod dead-point-free engine piston connecting rod set

InactiveCN104791484AEliminate engine dead spotsReduce energy consumptionPlungersMachines/enginesCrankshaftEnergy consumption

The invention discloses a reciprocating piston built-in chained connecting rod dead-point-free engine piston connecting rod set. The reciprocating piston built-in chained connecting rod dead-point-free engine piston connecting rod set comprises a piston and a connecting rod. The bottom of the piston is hollow, a movable sleeve is arranged in an inner cavity in the bottom of the piston and can axially move along the inner wall of the inner cavity, the movable sleeve is internally provided with a first fixing shaft, the small end of the connecting rod is hinged to the first fixing shaft, a stirring block is arranged at the side of the small end of the connecting rod, a groove or a pin hole is formed in the stirring block and located in one side of the first fixing shaft, one end of a push rod is arranged in the groove or the pin hole in a matched mode, the other end of the push rod is hinged to a second fixing shaft, and the second fixing shaft is installed in the inner cavity of the piston. The movable sleeve can do reciprocating movement in the inner cavity along the axis, and the piston guides for the movable sleeve. According to the reciprocating piston built-in chained connecting rod dead-point-free engine piston connecting rod set, the dead point of an engine can be fundamentally eliminated, energy consumption is reduced, and the loss of the piston connecting rod set and a crankshaft is reduced. Replacing is facilitated after abrasion, waste is avoided, heat dissipating is more convenient, strength is higher, and the running efficiency of the engine can be effectively ensured.

Owner:尹建

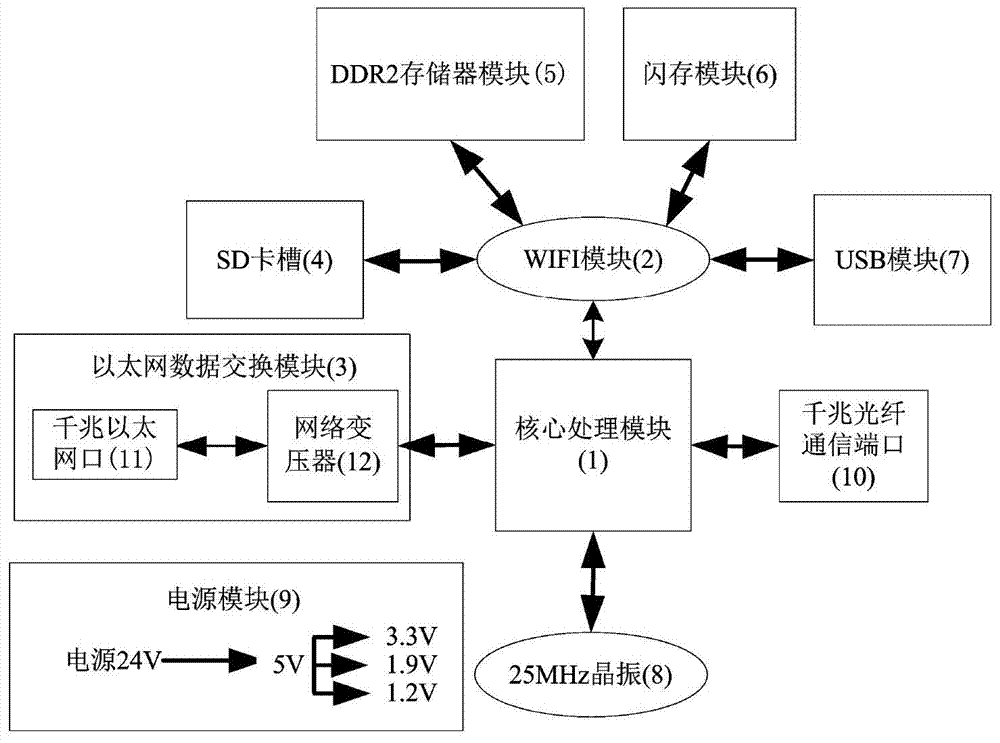

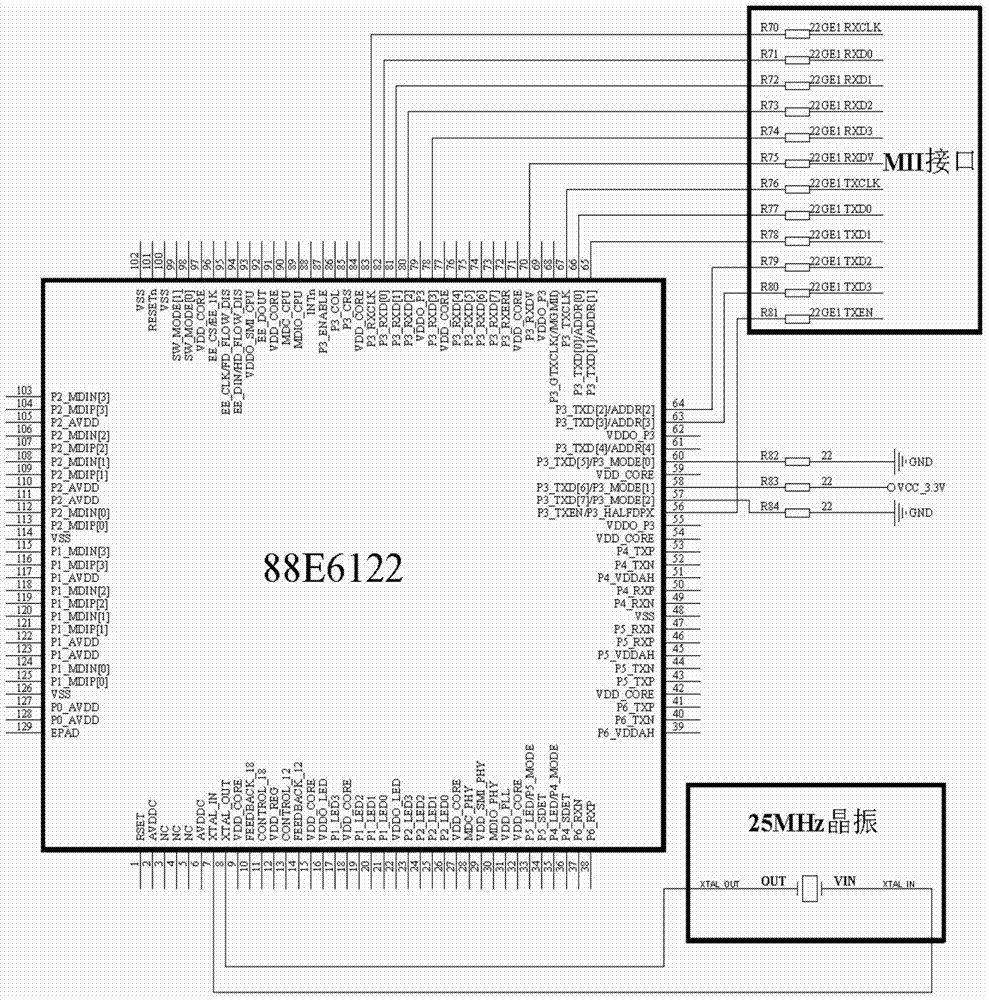

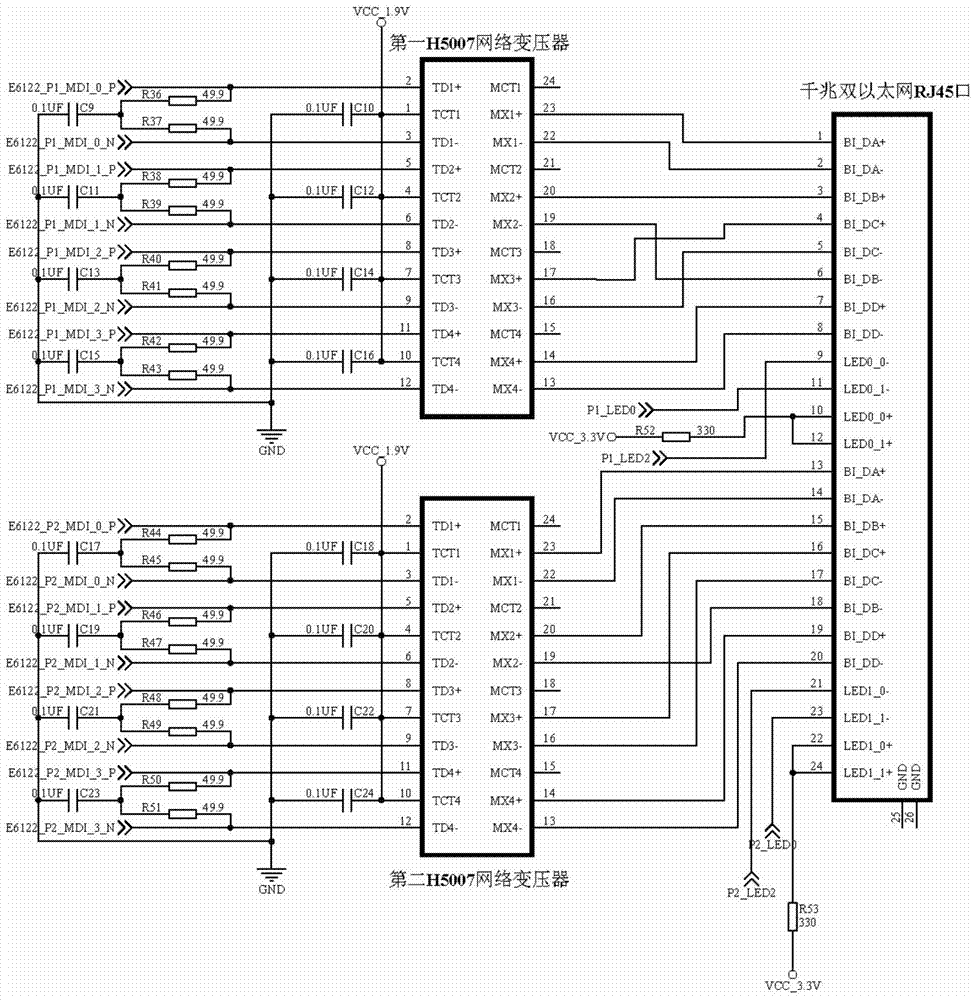

Looped network router used in wireless MESH network

InactiveCN104852854AFlexible accessGuaranteed direct communicationData switching networksWireless mesh networkUSB

The invention discloses a looped network router used in a wireless MESH network. The looped network router comprises a core processing module, a WIFI module, an Ethernet data exchange module, an SD card slot, a DDR2 memorizer module, a flash memory module, a USB module, a 25MHz crystal oscillator and a power supply module; wherein the core processing module is respectively in double-way connection with the Ethernet data exchange module and the 25MHz crystal oscillator; the WIFI module is respectively in double-way connection with the SD card slot, the DDR2 memorizer module, the flash memory module and the USB module; each kilomega serial port of the core processing module is connected with a kilomega optical fiber communication port so as to add access ways of the router; the WIFI module detects and accesses in a wireless network of other neighbouring router so as to provide wireless connection for the user; the core processing module and the WIFI module are interconnected via an MII port. The looped network router used in the wireless MESH network of the invention can be used for forming an optical fiber loop network, an electric loop network and a photoelectric loop network, and the looped network manner is flexible. The looped network router used in the wireless MESH network of the invention could remove the dead space of the network and solve the problem that the wiring is difficult.

Owner:尚一民

Novel horizontal gear and gear rack engine

InactiveCN108798883AOvercome the \"dead spot\"Overcoming the Knocking ProblemGear lubrication/coolingMachines/enginesGear wheelEngineering

Owner:ZHEJIANG UNIV

Concrete stirrer for double-horizontal shaft experiment

InactiveCN101347960BEliminate "dead spots"Eliminate dead endsRotary stirring mixersCement mixing apparatusEngineeringMechanical engineering

The invention discloses a twin-horizontal-shaft concrete mixer for testing which comprises a cylinder, and two parallel stirring shafts which are horizontally arranged in the cylinder; the two parallel stirring shafts are connected with the slewing gear of a motor gearbox and provided with stirring vanes. The bottom of the cylinder is provided with two sink marks arranged at the lower part which the two stirring shafts are corresponding to; a discharge hole is arranged between the two stirring shafts; the lower part of the discharge hole is provided with a compass rotor; the discharge hole forms a tight fit with the rotor provided with a discharge passage. One end of the rotor is fixed with a push rod. Two push rod limit posts are arranged at the outside of the side wall of the cylinder. With the structure adopted, the two-horizontal shaft concrete mixer for testing of the invention has the advantages of simple structure, convenient operation, etc.

Owner:SHANGYU HONGXING MACHINERY INSTR MFG

Hexagonal step type electrofusion furnace technology for high boron silicon instrument glass

InactiveCN1217867CEven heat distributionEliminate "dead spots"Glass furnace apparatusElectric furnaceElectricityBrick

A stepped hexagonal cold-top full-electric smelting furnace for smelting the high-boron silicon glass used for instrument is composed of flame space, smelting pool, liquid flowing hole, and lifting channel. Said smelting pool is composed of the hexagonal upper pool with large area, the tetrahexagonal lower pool with small area, and the transition bricks for connecting both pools. Six molybdenum electrodes are vertically installed to said transition bricks. Its advantage is uniform heat distribution.

Owner:力诺集团股份有限公司

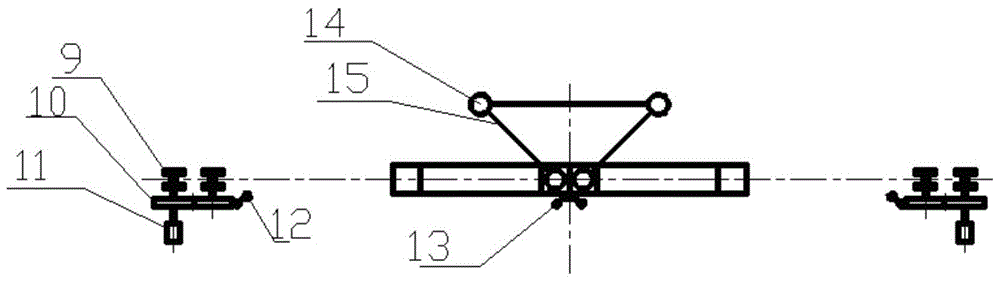

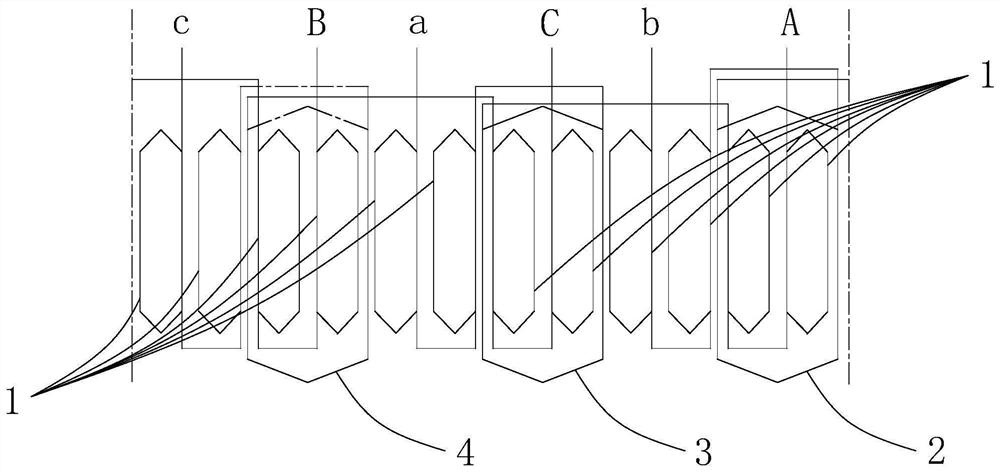

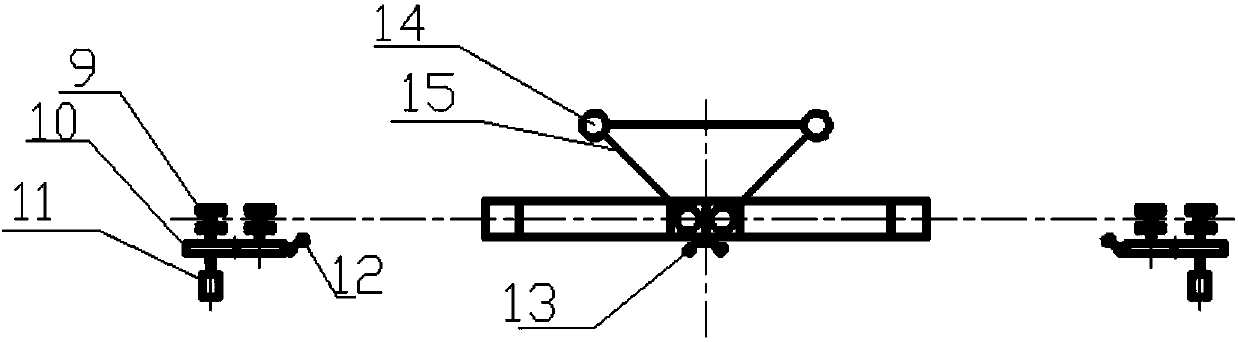

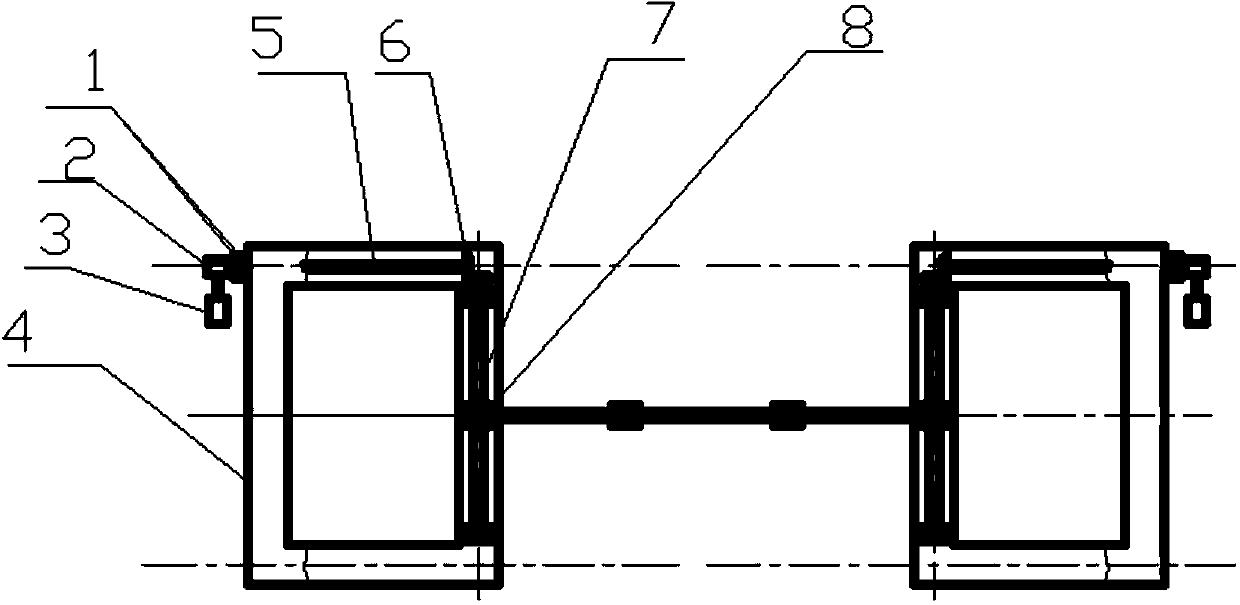

An automatic steering device for removing the dead point of the connecting rod

The invention relates to automatic steering equipment capable of removing connecting rod dead points. The equipment comprises a sliding block sliding device and a torque transmission device which adopt a bilaterally symmetrical structure, wherein the sliding block sliding device comprises an outer frame and winding group structures; the torque transmission device comprises clutches, a speed reducer, a horizontal shaft, a right-angled helical gear and a perpendicular shaft; sliding blocks are taken as driving parts of a mechanism, when three connecting rods are driven by the sliding blocks at two ends, the dead points can appear inevitably when the connecting rods are in a straight line and then folded, as a result, the sliding blocks cannot return and move, and the equipment is blocked now. The equipment is improved for the dead points of the three connecting rods, so that the sliding blocks slide in a barrier-free manner and turnover directions can be decided.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

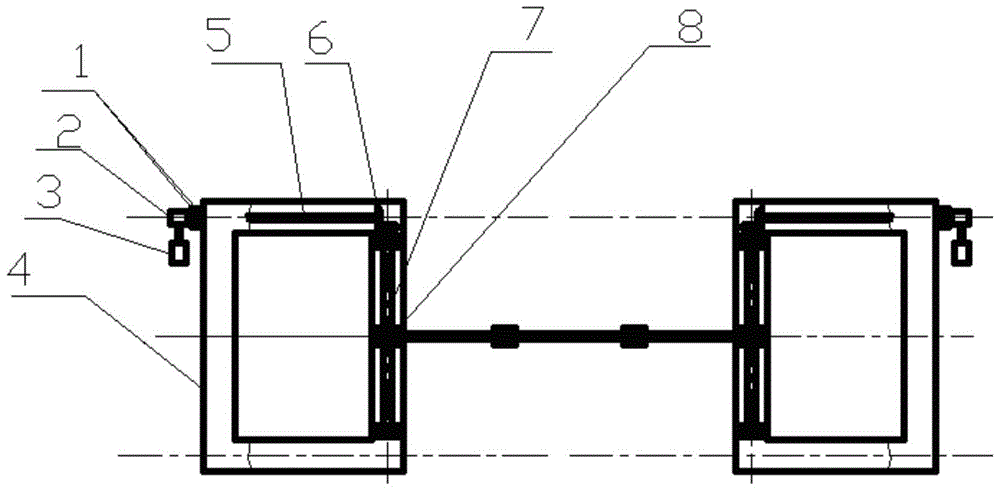

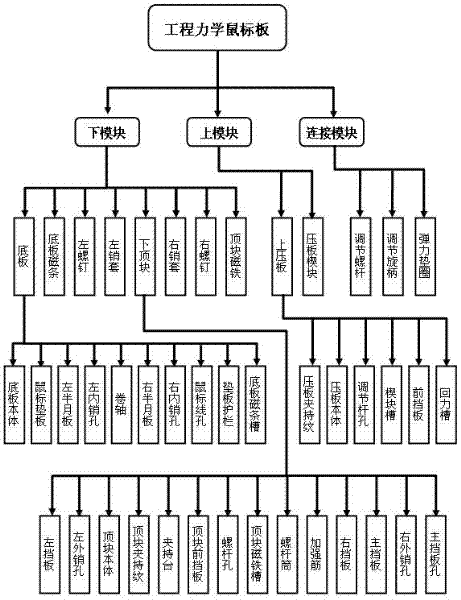

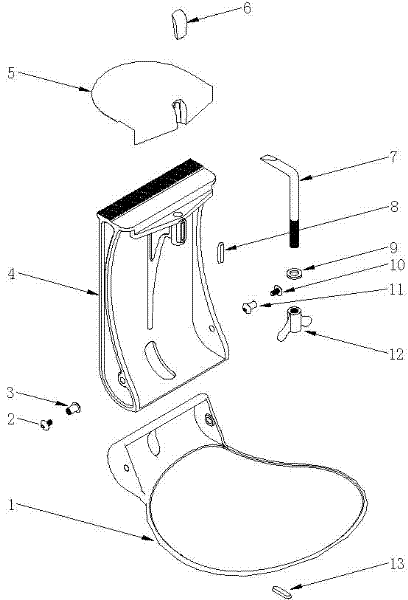

Human engineering mechanics mouse board

InactiveCN102129309BReduce labor intensityGet rid of the pain of "mouse hand"Input/output processes for data processingHuman bodyCTS - Carpal tunnel syndrome

The invention relates to a mouse board, especially to a mouse board adopting a pendent structure and conforming to the requirements of human engineering mechanics. The product is composed of three parts including a lower mould, an upper mould and a connection module, and comprises thirteen parts including a bottom board, a bottom board magnetic strip, a left screw, a left pin bush, a lower jacking block, a right pin bush, a right screw, a jacking block magnet, an upper pressing board, a pressing board wedge block, an adjusting screw rod, and an adjusting rotary handle and an elastic gasket, the mouse board has the characteristics of being in line with physiological rule of human body and movement rule of mouse, more stable usage, wider adaptability and the like, and when the mouse board is in use, a user can use the mouse at the most appropriate height only by placing the mouse board horizontally and has no longer need of raising the arm up forcibly in the process of using the mouse on the mouse board so as to avoid the symptoms of 'carpal tunnel syndrome' such as numbness of upper wrist, soreness of arm and the like. In addition, the product of the invention has the characteristics of being simple in implementation, easy in manufacturing, eye-pleasing, firm and durable, convenient in use and the like, and has extensive market and certain social and economical values.

Owner:郑小玲

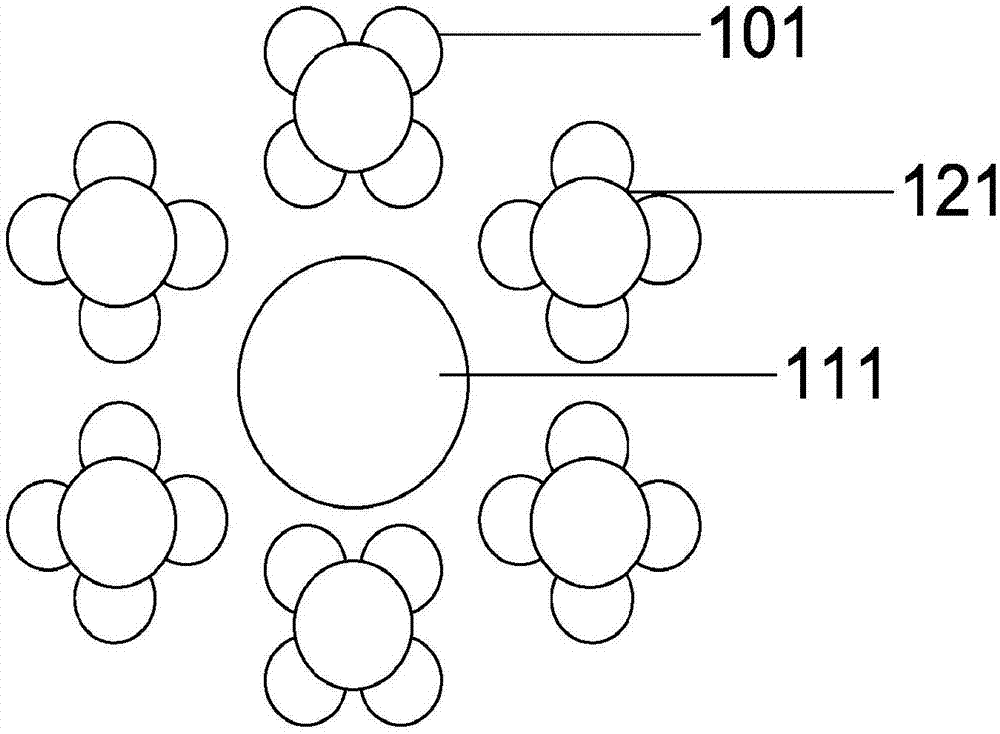

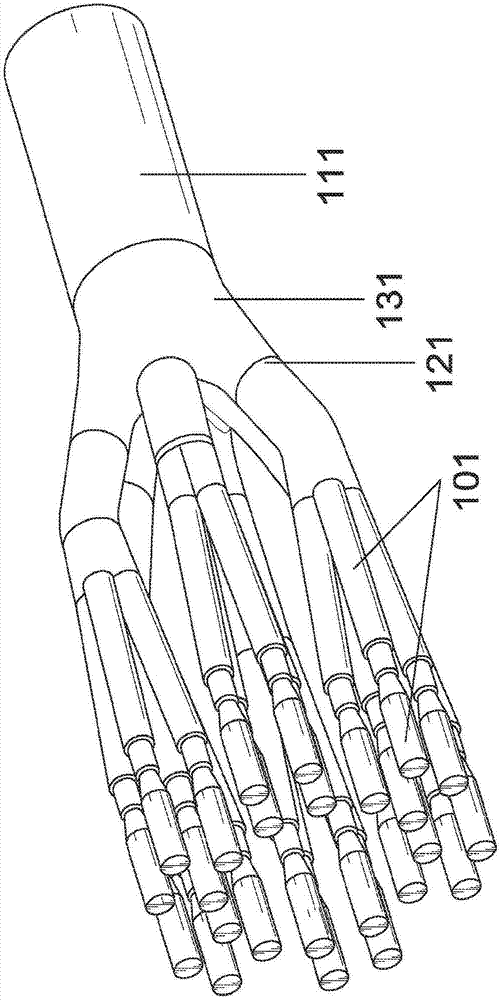

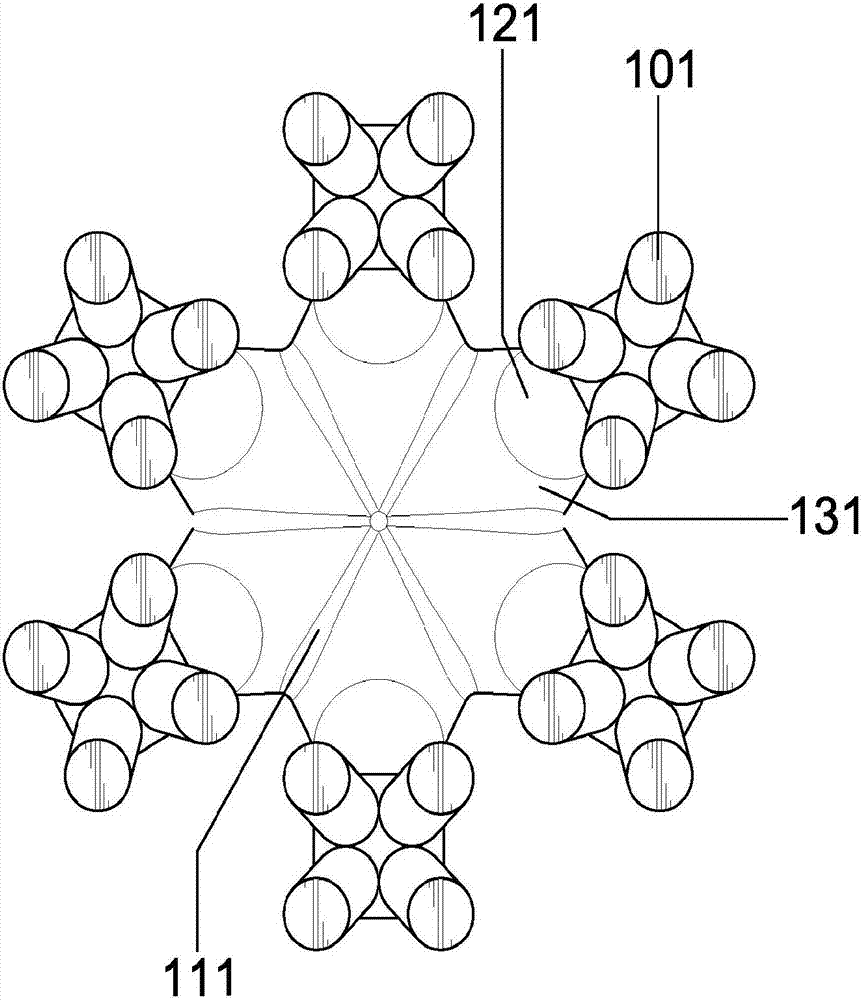

Improved drying methods

InactiveCN107428032ASimple structureEliminate dead spotsGranulation by liquid drop formationLiquid spraying apparatusEngineeringSolvent

A process for drying resinous materials, comprising: delivering, by way of a plurality of resin channels, resin fluid comprising polymer and solvent into at least first and second steam channels (101) having within a flow of steam, the first and second steam channels (101) each receiving resin fluid from a plurality of resin channels, the first and second steam channels each (101) being received by a stage 1 manifold (121), the steam and resin being delivered under conditions so as to separate at least some of the solvent from the resin fluid; and collecting at least some of the polymer from the resin fluid.

Owner:SABIC GLOBAL TECH BV

A structure-improved milk powder spoon

A milk powder scoop with an improved structure comprises a major scoop body and a scoop handle which is connected with one end of the major scoop body. The major scoop body comprises a scoop mouth, a minor scoop body which is formed by the downward extension of the periphery of the scoop mouth, and a scoop bottom which is connected with the tail end of the minor scoop body. An accommodating cavity used for containing milk powder is jointly formed by the minor scoop body and the scoop bottom in a surrounded manner. The minor scoop body comprises at least a straight wall and an arc wall with two ends connected with the two ends of the straight wall correspondingly. The upper portion of the accommodating cavity is a semi-cylindrical cavity jointly formed by the straight wall and the arc wall in a surrounded manner. By means of refitting the minor scoop body of the milk powder scoop to a semi-cylindrical structure mainly formed by the straight wall and the arc wall, the straight wall of the minor scoop body is made to attach to the bottom of a milk powder tin closely. During the process of milk powder scooping, dead angle positions where the milk powder cannot be scooped can be eliminated by the straight wall to guarantee that residual milk powder at the bottom of the milk powder tin can be utilized and thus the waste of milk powder during the process of using the milk powder tin can be reduced effectively.

Owner:王炯铭

Stator and permanent magnet brushless direct current motor

PendingCN111884388AIncrease the excitation areaReduce cogging torqueWindings conductor shape/form/constructionDC - Direct currentEngineering

The invention discloses a stator, and the stator comprises a stator core; the stator core is provided with at least one group of A-phase, b-phase, C-phase, a-phase, B-phase and c-phase which are arranged in sequence; each phase comprises at least two groups of pitches; and the stator further comprises element windings arranged in the pitches in a one-to-one correspondence mode, B-phase auxiliary windings wound on the A-phase, the C-phase and the B-phase auxiliary windings; the winding direction of the B-phase auxiliary winding is opposite to that of the adjacent b-phase element winding, and the B-phase auxiliary winding is wound on all the group pitches in the A phase at the same time; the winding direction of the A-phase auxiliary winding is opposite to that of the adjacent a-phase element winding, and the A-phase auxiliary winding is wound on all the group pitches in the C phase at the same time; and the winding direction of the C-phase auxiliary winding is opposite to that of the adjacent c-phase element winding, and the C-phase auxiliary winding is wound on all the group pitches in the B phase at the same time. By arranging the auxiliary winding on the stator, the cogging torque and the torque ripple of the permanent magnet brushless direct current motor with the stator can be reduced.

Owner:JIANGSU FULIHUA GENERAL EQUIP

Automatic steering equipment capable of removing connecting rod dead points

The invention relates to automatic steering equipment capable of removing connecting rod dead points. The equipment comprises a sliding block sliding device and a torque transmission device which adopt a bilaterally symmetrical structure, wherein the sliding block sliding device comprises an outer frame and winding group structures; the torque transmission device comprises clutches, a speed reducer, a horizontal shaft, a right-angled helical gear and a perpendicular shaft; sliding blocks are taken as driving parts of a mechanism, when three connecting rods are driven by the sliding blocks at two ends, the dead points can appear inevitably when the connecting rods are in a straight line and then folded, as a result, the sliding blocks cannot return and move, and the equipment is blocked now. The equipment is improved for the dead points of the three connecting rods, so that the sliding blocks slide in a barrier-free manner and turnover directions can be decided.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

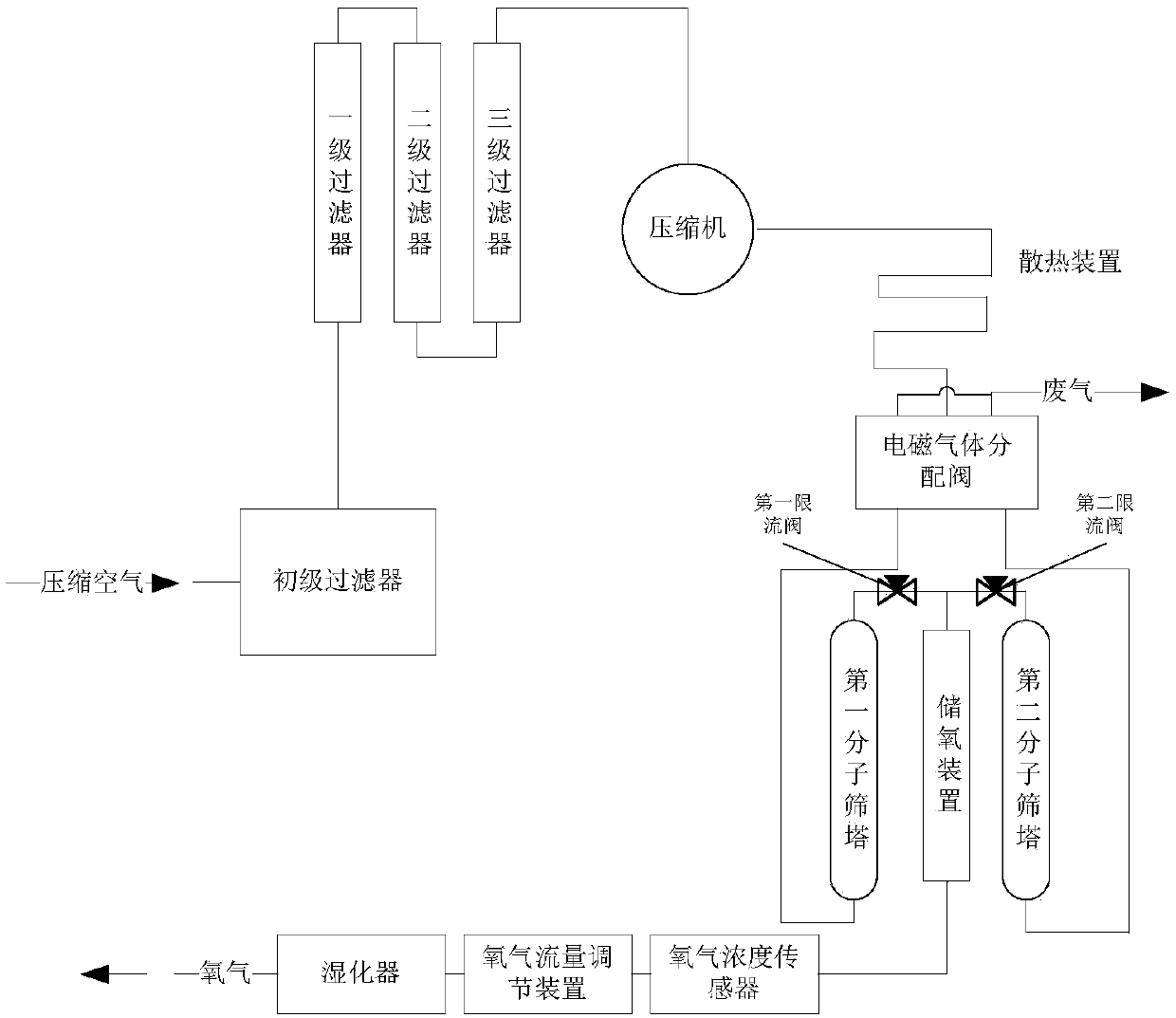

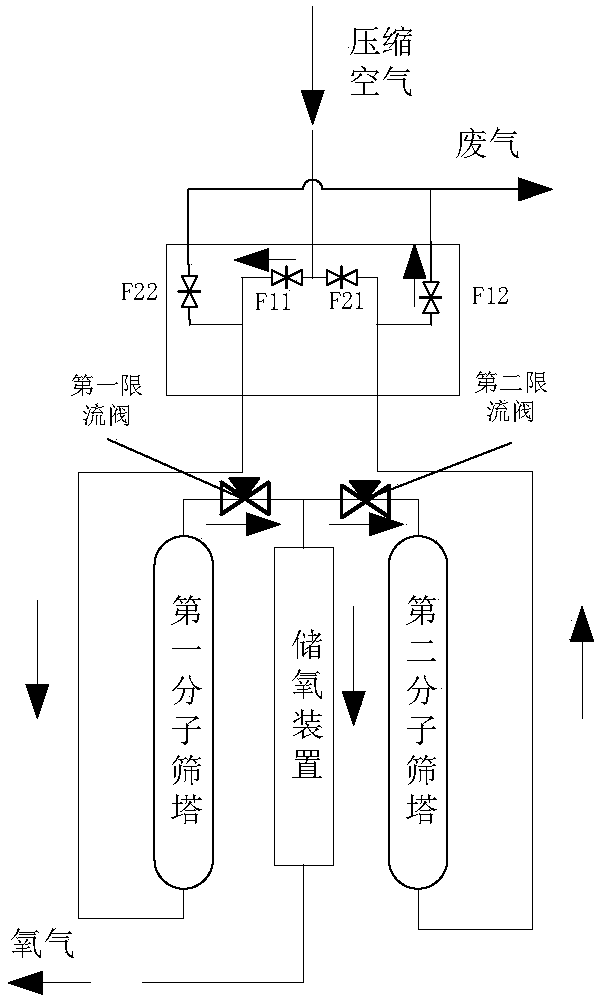

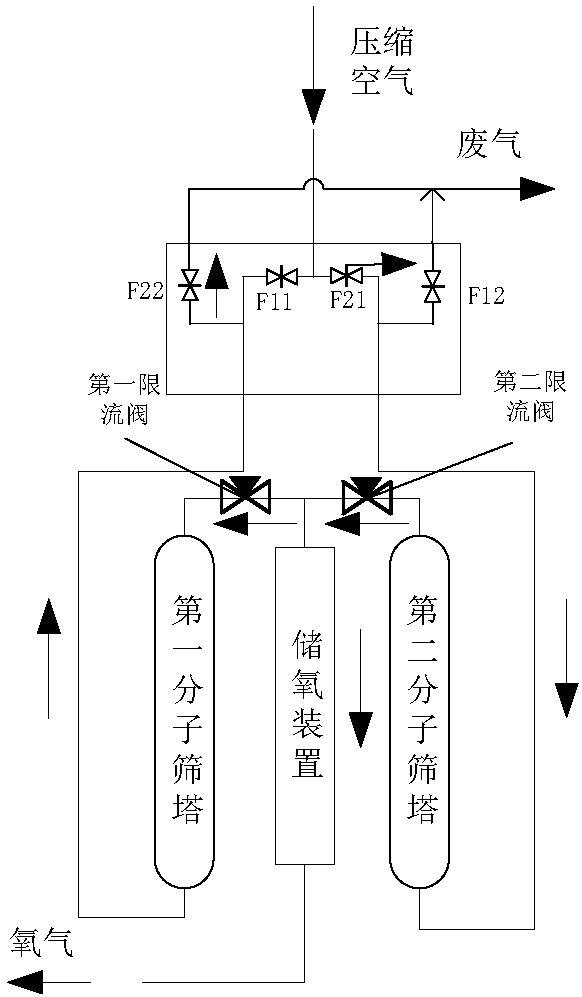

A digital intelligent oxygen production system and its control method

ActiveCN106292805BImprove protectionReduce shockSimultaneous control of multiple variablesOxygen preparationHigh concentrationOxygen system

The invention provides a digital intelligent oxygen generation system and control method. It can stably provide oxygen in high concentration, and realize a real-time control of oxygen concentration and oxygen flow. The method can real-time monitor and control the oxygen concentration and oxygen flow, provide an intelligent protection for the oxygen generation system, and increase the oxygen generation stability of the oxygen in high concentration.

Owner:重庆鬼谷子医疗器械科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com