Double-piston servo connecting-rod mechanism of dead-point-free internal combustion engine

A technology of connecting rod mechanism and internal combustion engine, which is applied in the direction of machine/engine, mechanical equipment, etc., can solve the problems of shortening the service life of the internal combustion engine, the piston cannot transmit thrust, and increasing the load of the crankshaft, and achieves a simple structure, convenient manufacturing, and extended service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

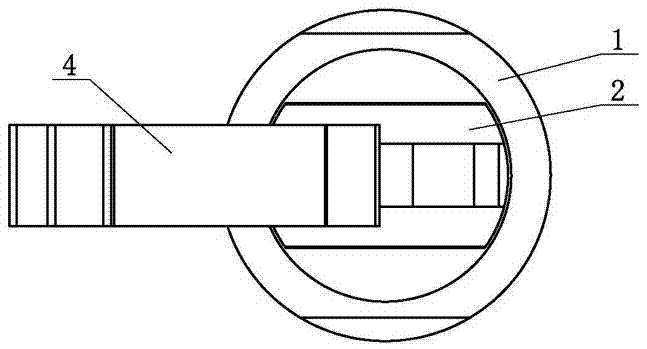

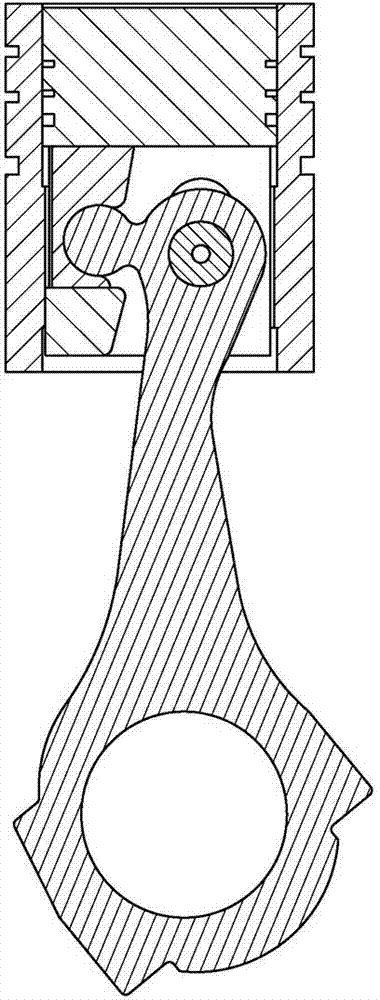

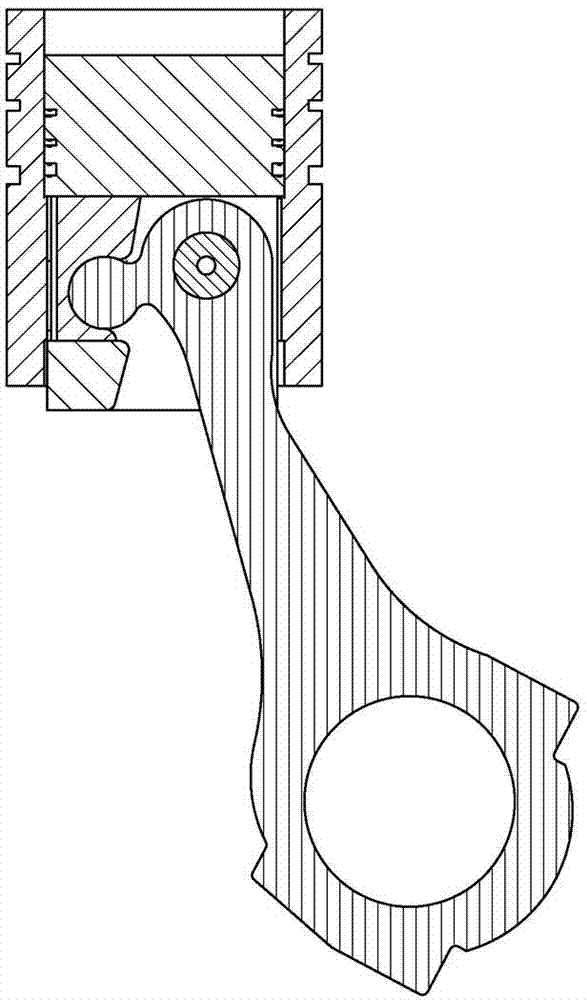

[0009] Such as figure 1 As shown, the double-piston follow-up link mechanism of the internal combustion engine without dead point in the present invention includes the main piston 1 . Such as image 3 As shown, an inner cavity 13 is provided in the main piston 1 along the direction of its central axis. Such as Figure 4 As shown, the main piston 1 is provided with a pin hole 15 perpendicular to its central axis, and the pin hole 15 communicates with the inner cavity 13 . Bearing pin 3 is installed in pin hole 15. The auxiliary piston 2 is installed in the inner cavity 13 , and the auxiliary piston 2 can move linearly along the central axis of the inner cavity 13 . Such as image 3 As shown, the lower end of the auxiliary piston 2 is provided with two fixed plates 5 side by side. A first sliding groove 6 is formed between the two fixing plates 5 . Such as Figure 6 and Figure 9 As shown, a guide block 12 is arranged between the two fixing plates 5 , the guide block 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com