Shear lifting mechanism producing large swing angle motion

A technology of lifting mechanism and large swing angle, which is applied in the direction of manual mechanism, wing leaf control mechanism, building structure, etc., and can solve the problems of inability to realize short strokes, inconvenient development of door and window automation, and the difference between the opening angle and the pushing angle. no problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing.

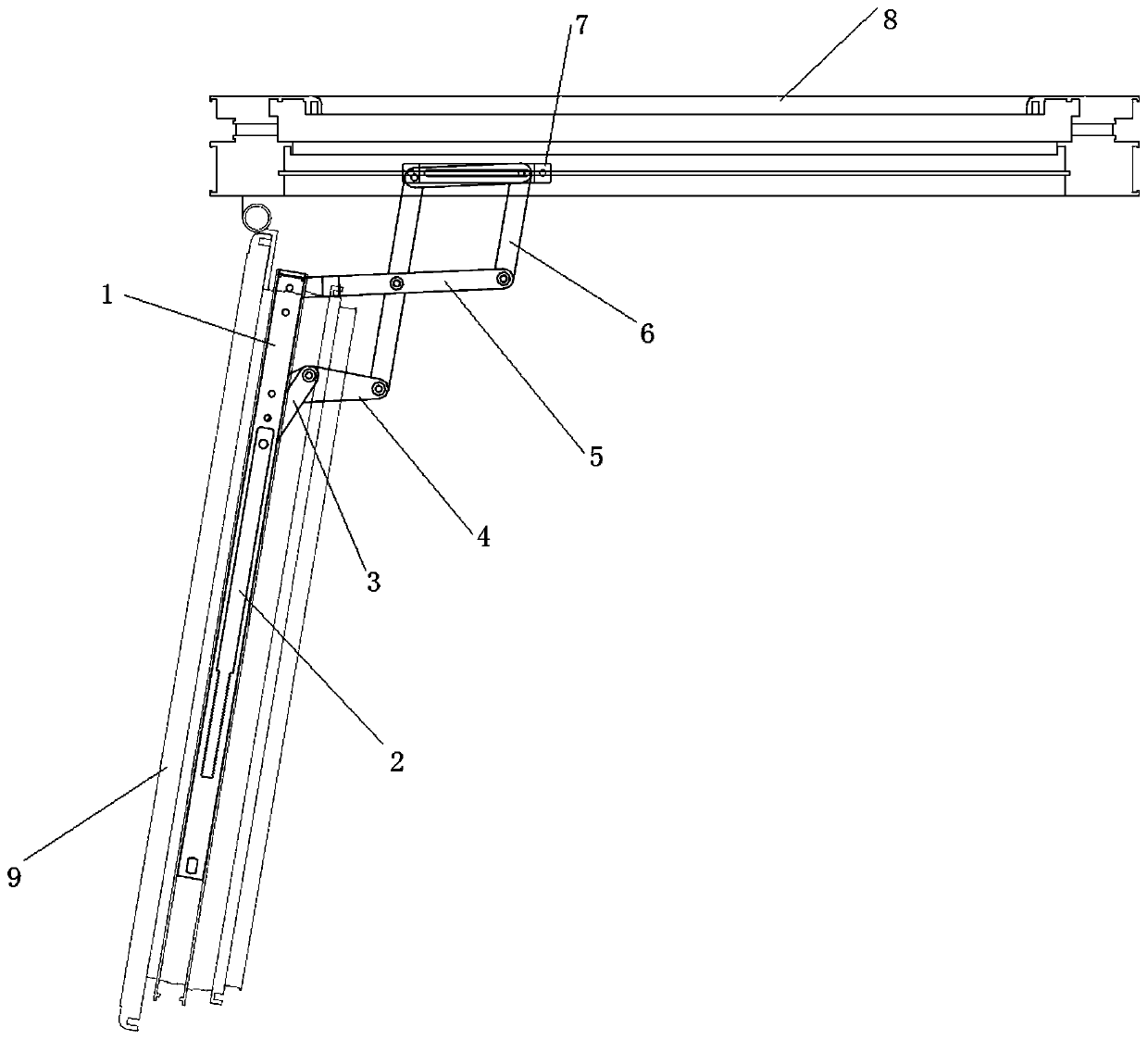

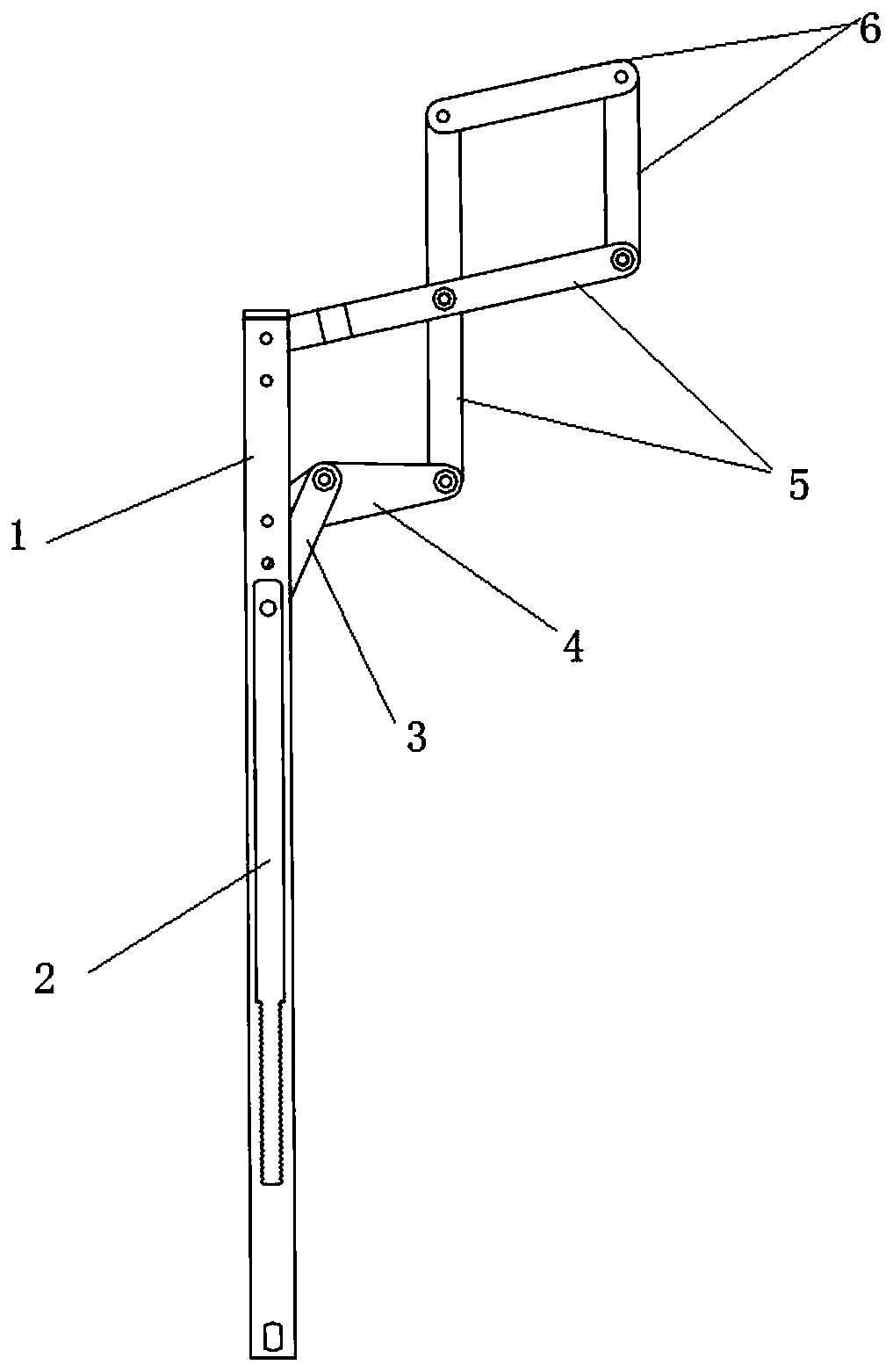

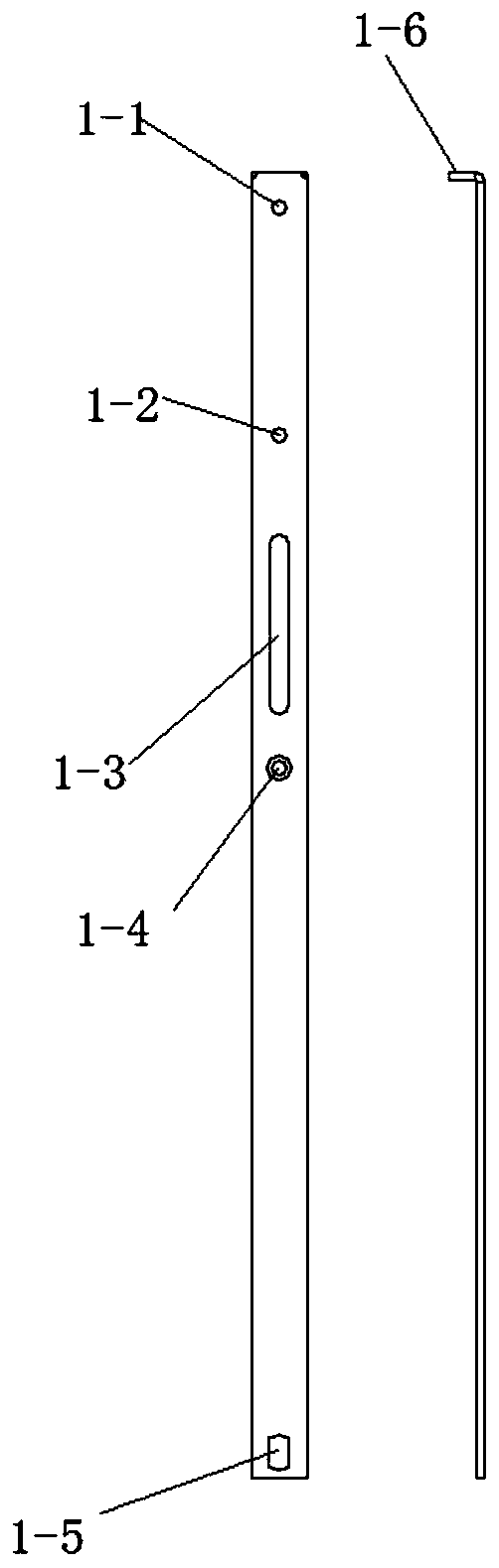

[0031] A scissors lifting mechanism that produces a large swing angle motion, comprising a fixed plate 1, a transmission rod 2, an active rod 3, an off-axis driven rod 4 and a shear rod group; the fixed plate 1 is installed on the door and window 9 ends, The transmission rod 2 is slidably arranged on the fixed plate 1, one end is connected with the driving actuator, and the other end is hinged to one end of the active rod 3 on the fixed plate 1; the other end of the active rod 3 is hinged to the The middle part of the off-axis driven rod 4; one end of the shear rod group is respectively hinged on the top of the fixed plate 1 and one end of the off-axis driven rod 4; the other end is hinged on the door and window frame 8 ends; The other end of the off-axis driven rod 4 is hinged on the fixed plate 1 .

[0032] Based on the function of traditional scissor lift to realize str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com