Rice transplanter

The technology of a rice transplanter and a rack is applied in the agricultural field to achieve the effects of simplifying the transmission structure, accelerating the falling speed and avoiding the dragging of seedlings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

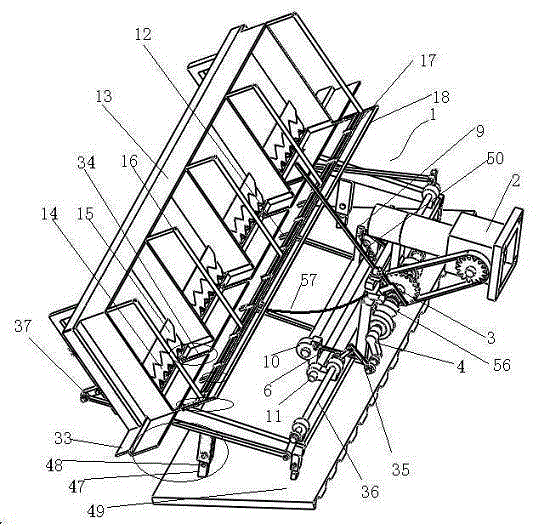

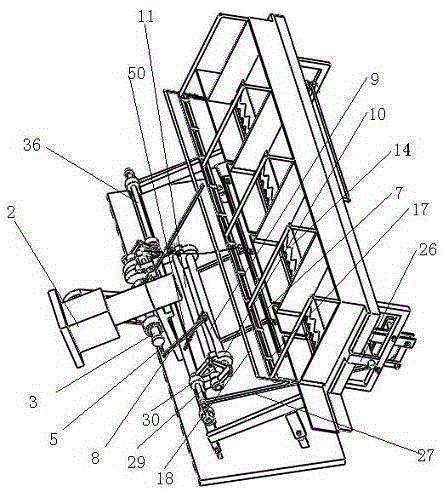

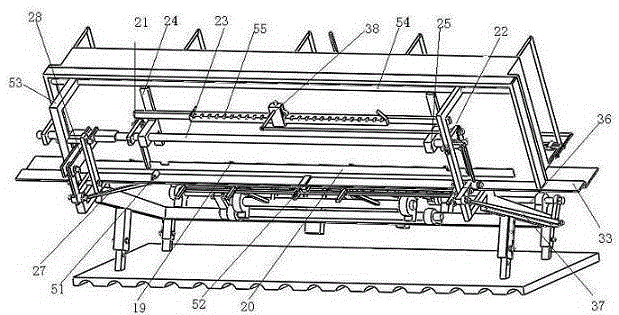

[0032] Such as Figure 1~Figure 7 A rice transplanter shown includes a frame 1, a power input box 2 is provided on the frame 1, and the power input box 2 is connected to a rotating shaft 3 in a chain drive. A rod A4, a rocker B5, the rocker A4 is connected to one side of the seedling pawl frame 7 through a connecting rod E6, and the rocker B5 is connected to the vertical rod 9 on the seedling pawl frame 7 through a connecting rod F8. Bearing seats 10 are installed at both ends. The bearing seats 10 are fixed on the drive shaft B11 on the frame 1, and the seedling claw frame 7 is provided with a seedling claw 12, and the rotating shaft 3 drives the seedling claw 11 from The seedling box 13 is grabbed and inserted into the soil. The seedling box 13 reciprocates along the track 33 on the frame 1. The track 33 is provided with a seedling opening 34, and the seedling box 13 is provided with a reciprocating movement. The seedling box 13 is provided with a layer of seedling blocking ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com