Patents

Literature

75results about How to "Avoid dead spots" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

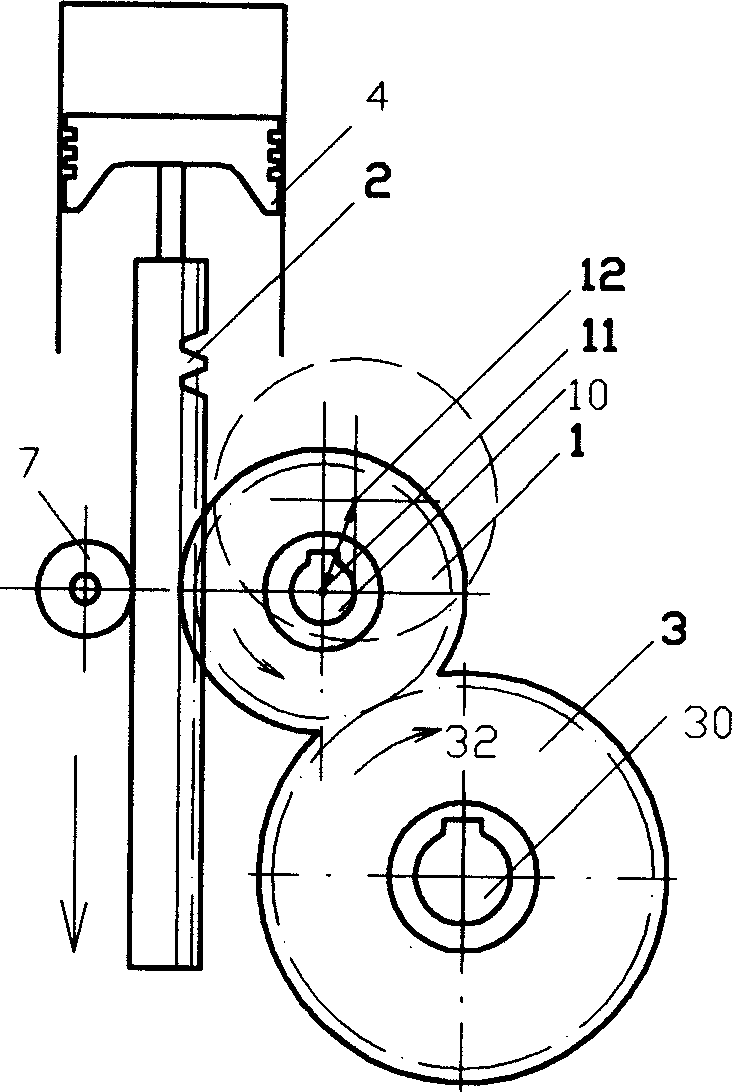

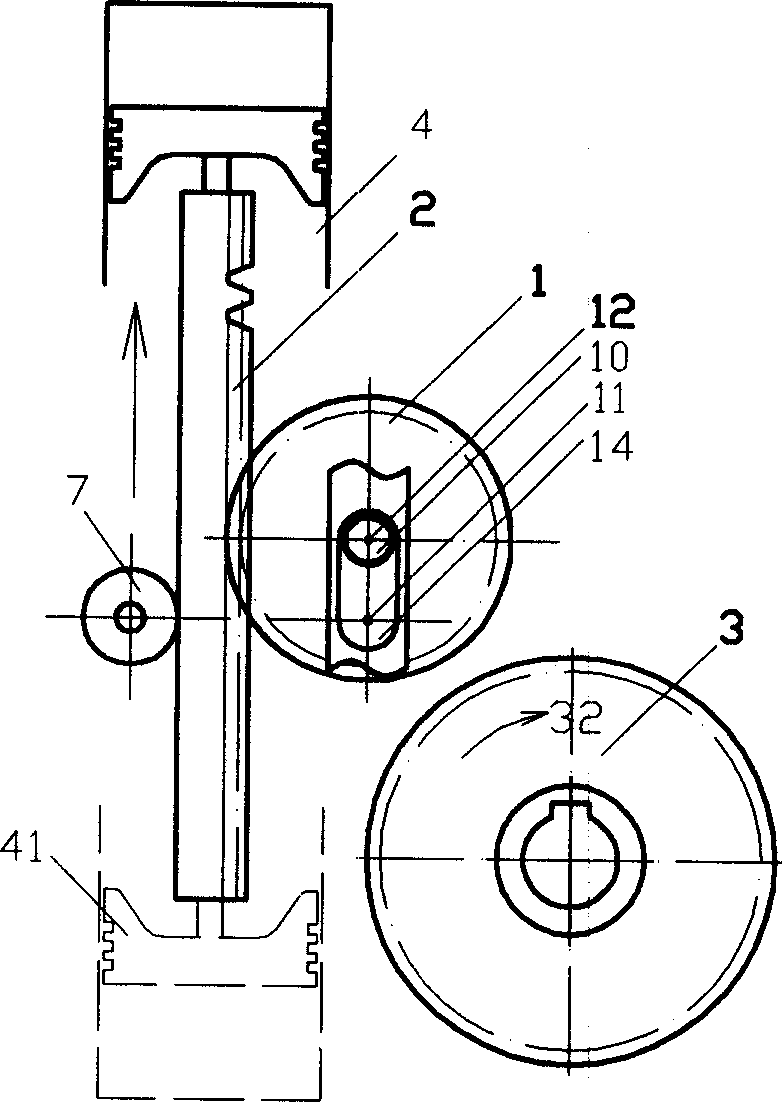

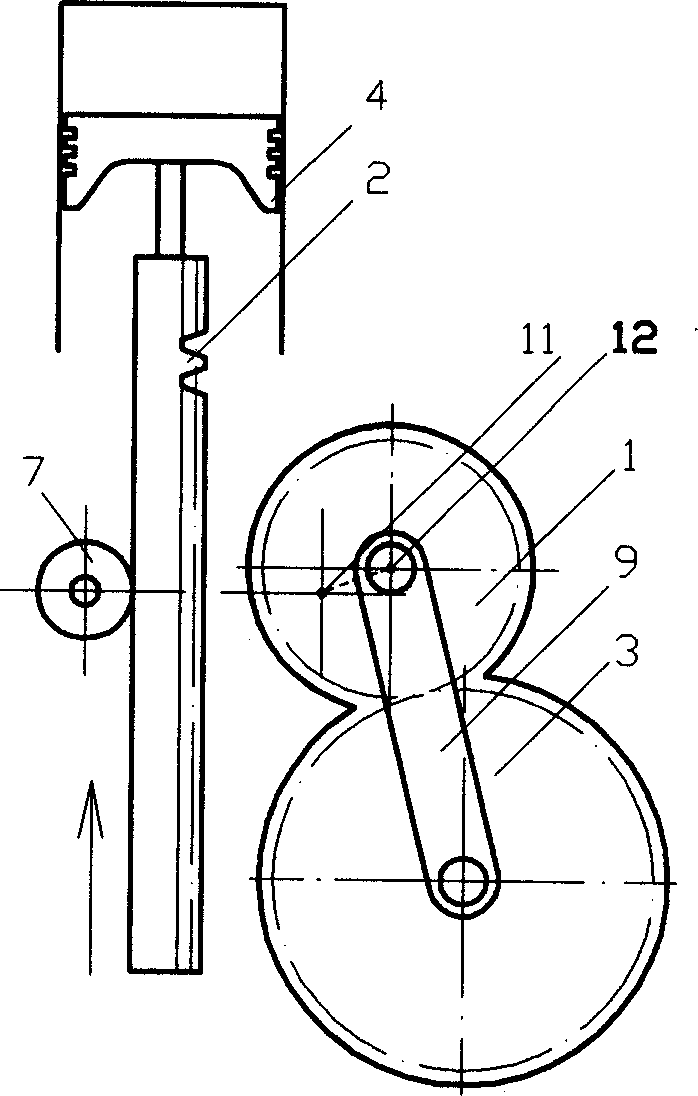

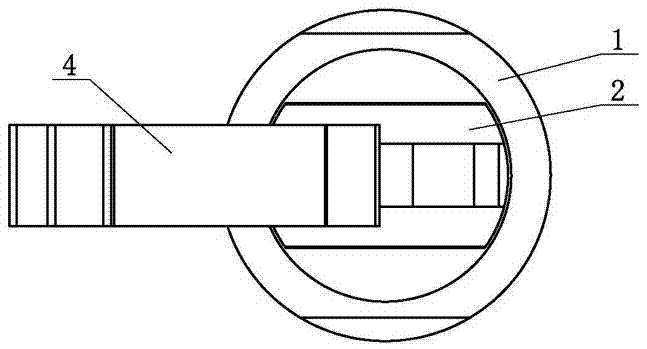

Piston crankshaftless engine

InactiveCN1529045ASimplify the constituent elementsSimple designMachines/enginesLine shaftGear wheel

The invention discloses a kind of piston engine without crank, a power converting mechanism made up of mobile gear, gear rack connected to the piston and the driving gear fixed on the straight output main shaft replaces traditional crank link mechanism, and it overcomes the deficiency of current crank-less engine; the mobile gear can move between the connection position and the non-connection position, thus the dynamic force device between the gear rack and the driving gear can be in on / off state; in the exposure distance of the piston, it can transmit force to the main shaft through the force transmitting chain; the back movement of piston doesn't affect the movement of the output main shaft; along with the joining movement of mobile gear, by mating with the other assistant system, the reciprocate straight movement can be changed into the power output with continuous single direction rotation of main shaft. The converter can be used in gasline, diesel, gas inner combustion machine.

Owner:程远

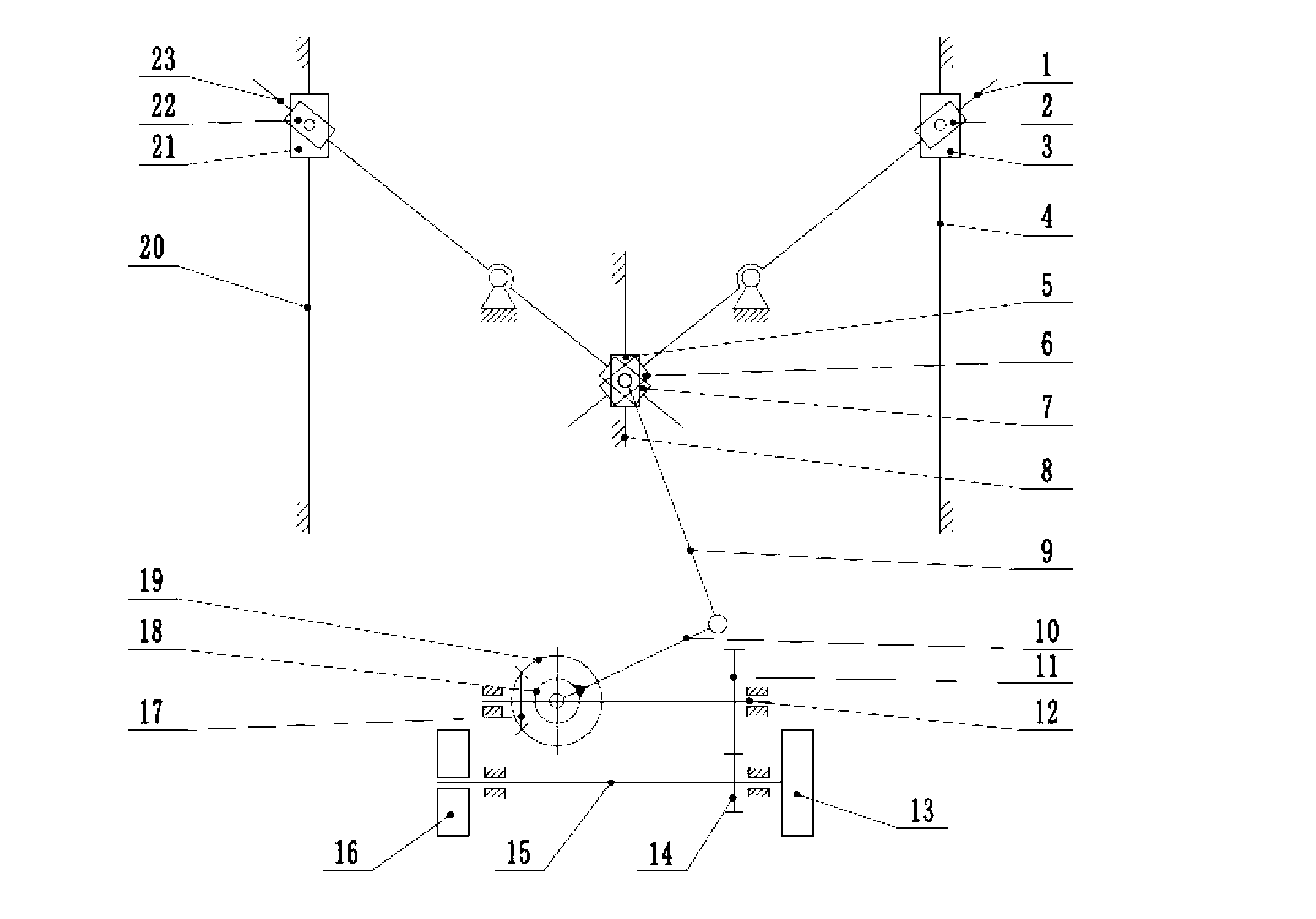

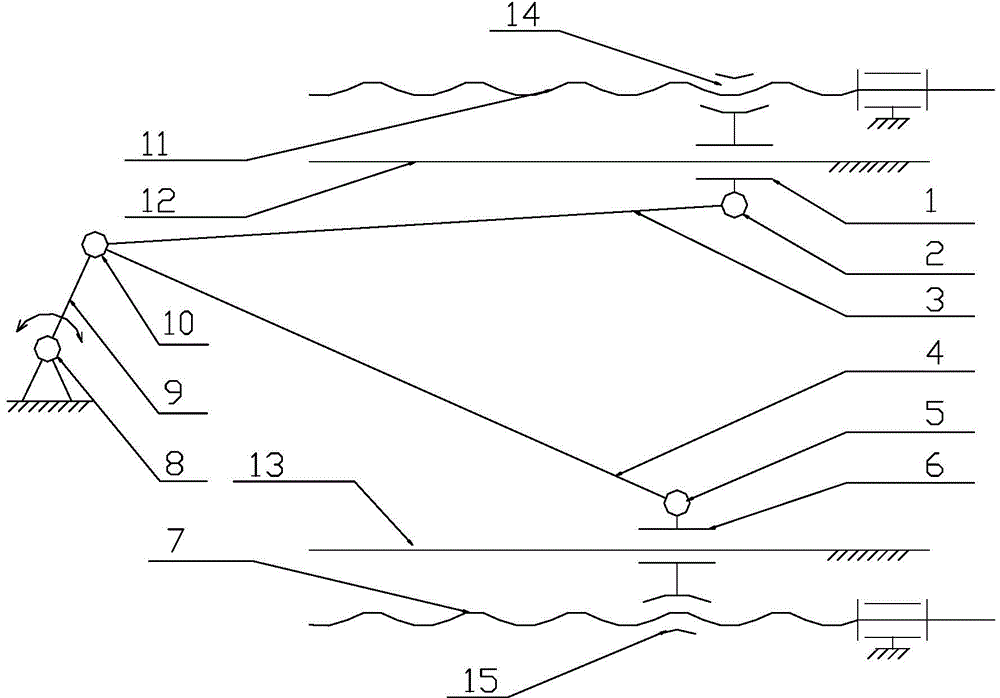

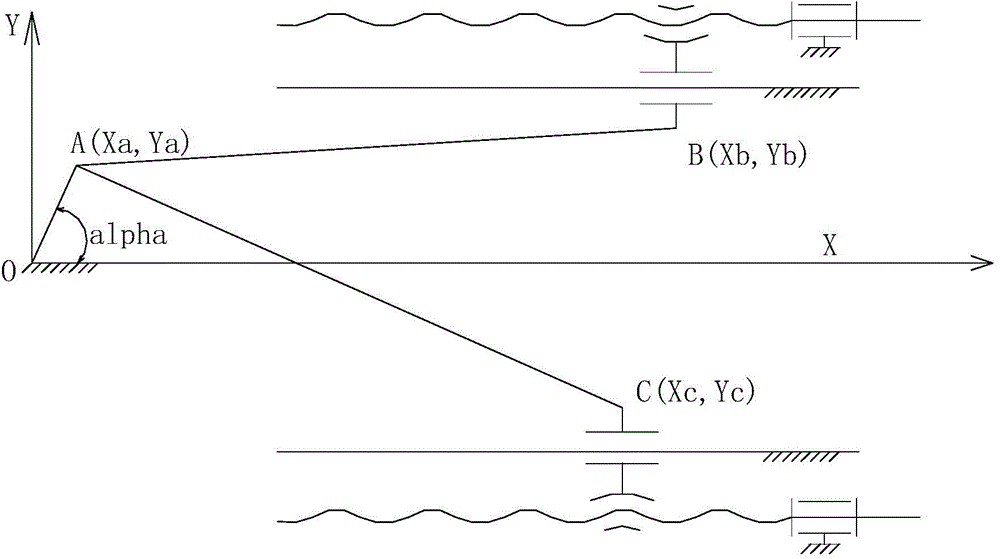

Transmission device for changing straight reciprocating motion into rotary motion

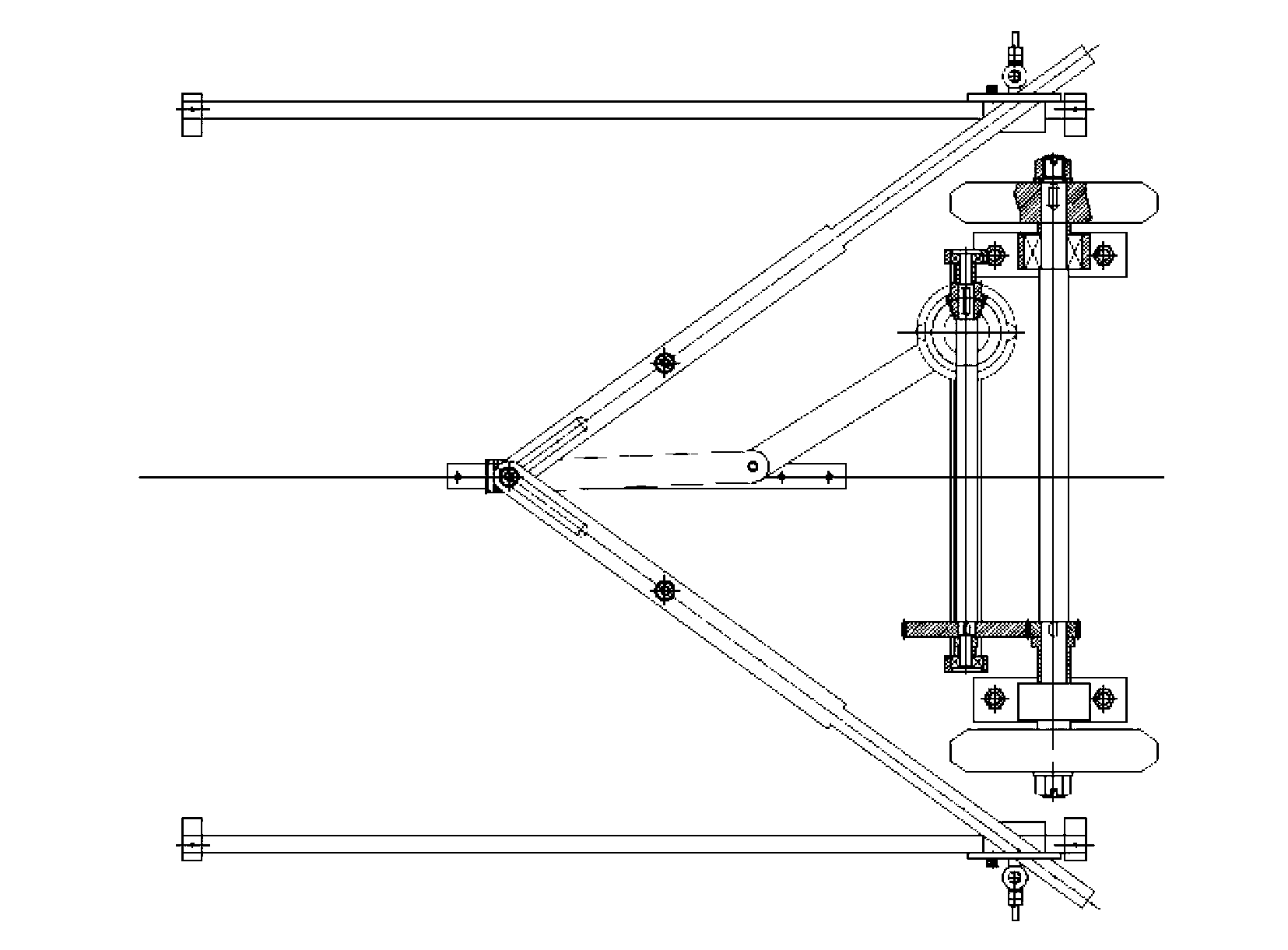

The invention discloses a transmission device for changing straight reciprocating motion into rotary motion. The transmission device for changing the straight reciprocating motion into the rotary motion comprises a first lever mechanism, a second lever mechanism, a rocker sliding block mechanism, a one-way clutch, a bevel gear mechanism and a spur gear mechanism. The first lever mechanism comprises a first transmission lever, a first sliding block and a sixth sliding block, the second lever mechanism comprises a second transmission lever, a second sliding block and a seventh sliding block, the rocker sliding block mechanism comprises a fifth sliding block, a connecting rod and a rocker, the bevel gear mechanism comprises a driving bevel gear and a driven bevel gear, and the spur gear mechanism comprises a driving spur gear and a driven spur gear. The transmission device for changing the straight reciprocating motion into the rotary motion can change the straight reciprocating motion into the rotary motion in a small space and is adjustable in rotation speed.

Owner:ZHEJIANG UNIV OF TECH

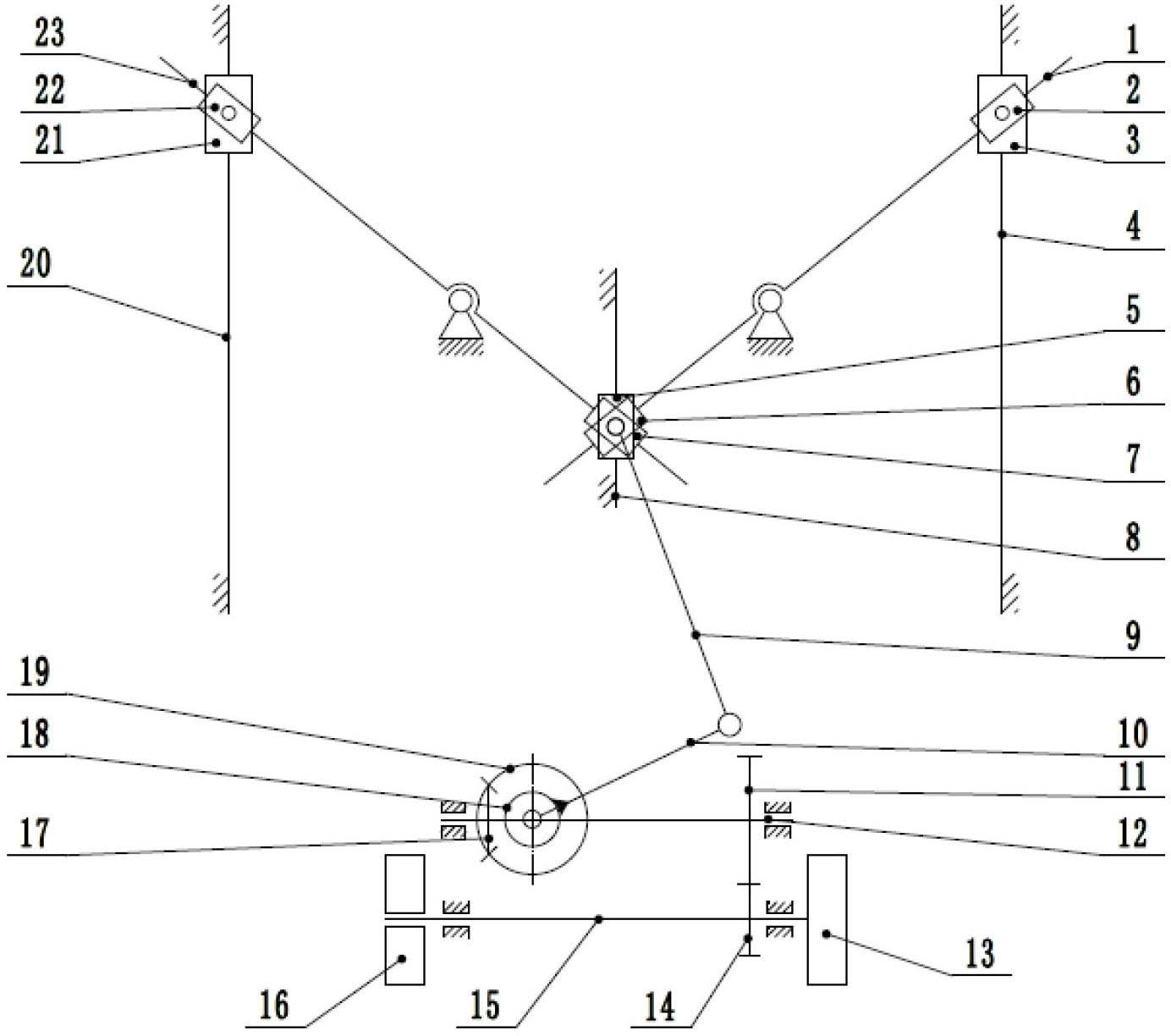

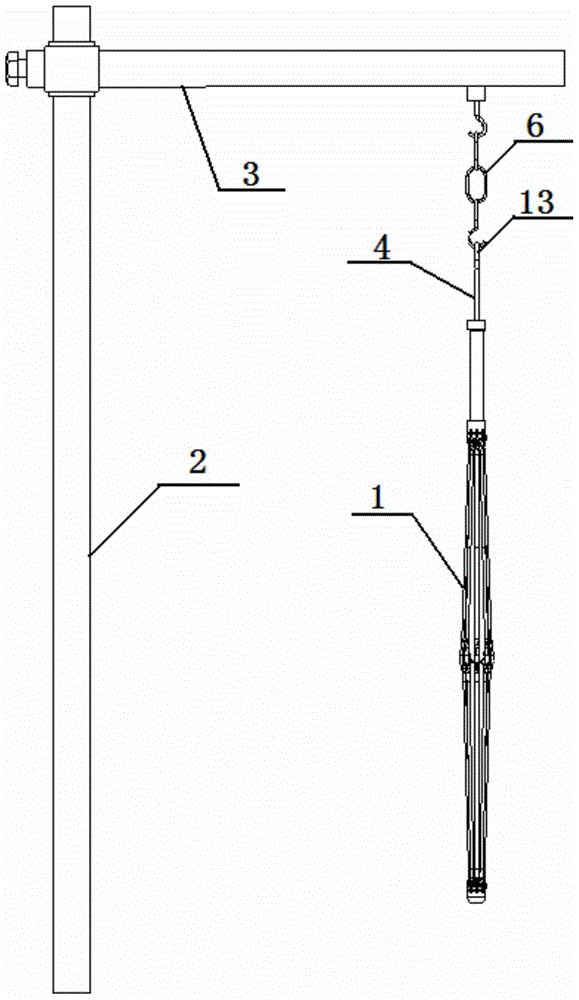

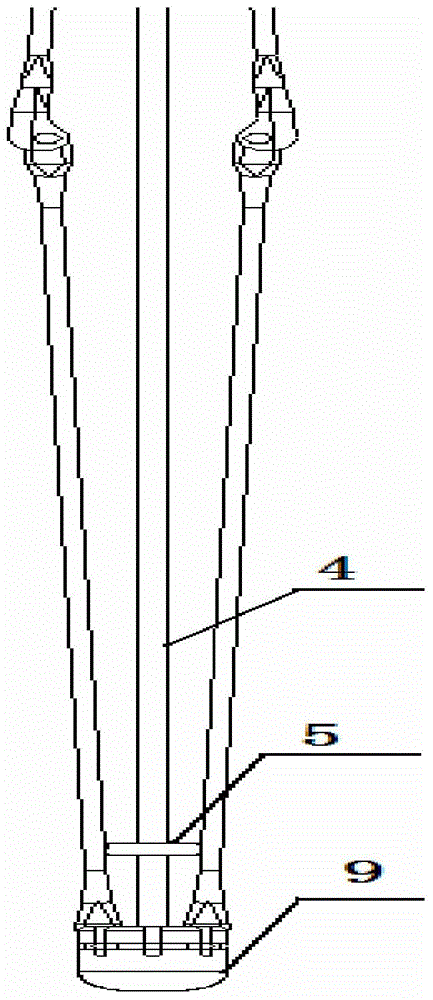

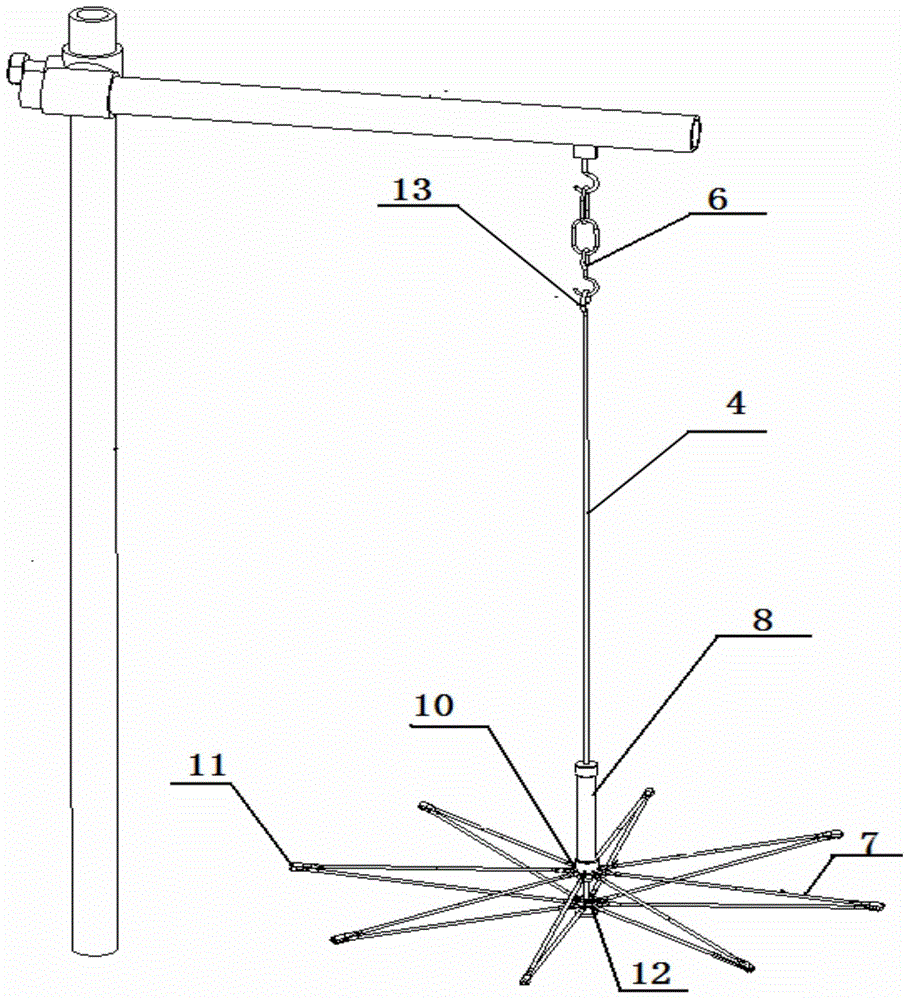

Umbrella-type abdominal wall hanging device used in laparoscopic operation

An umbrella-type abdominal wall hanging device used in a laparoscopic operation comprises a hanging umbrella, a mechanical arm and a fixing rod, wherein the hanging umbrella is hung on the mechanical arm; the mechanical arm is mounted on the fixing rod; the hanging umbrella comprises a casing pipe, a needle core, a dead point ring and a hanging chain, wherein the casing pipe comprises spokes and a push-and-pull pipe; when the push-and-pull pipe slides downwards, the spokes slide to the center through proximal end joints, remote end joints and middle joints, and the umbrella-type abdominal wall hanging device is folded to be an umbrella. Due to the structure of the dead point ring, the dead point problem of the spokes during the unfolding process is solved, so that the spokes can be unfolded smoothly; spokes on the left and right sides are elastic, so that the umbrella-type abdominal wall hanging device can adapt to the arch-shaped structure of an abdominal wall well relatively, and wound of the abdominal wall can be reduced; spokes in the front and back directions are high in rigidity so as not to deform easily while bearing abdominal wall resistance. Therefore, the front part of the abdominal wall can be pulled upwards adequately to create a relatively large operation space.

Owner:THE PEOPLES HOSPITAL OF GUANGXI ZHUANG AUTONOMOUS REGION

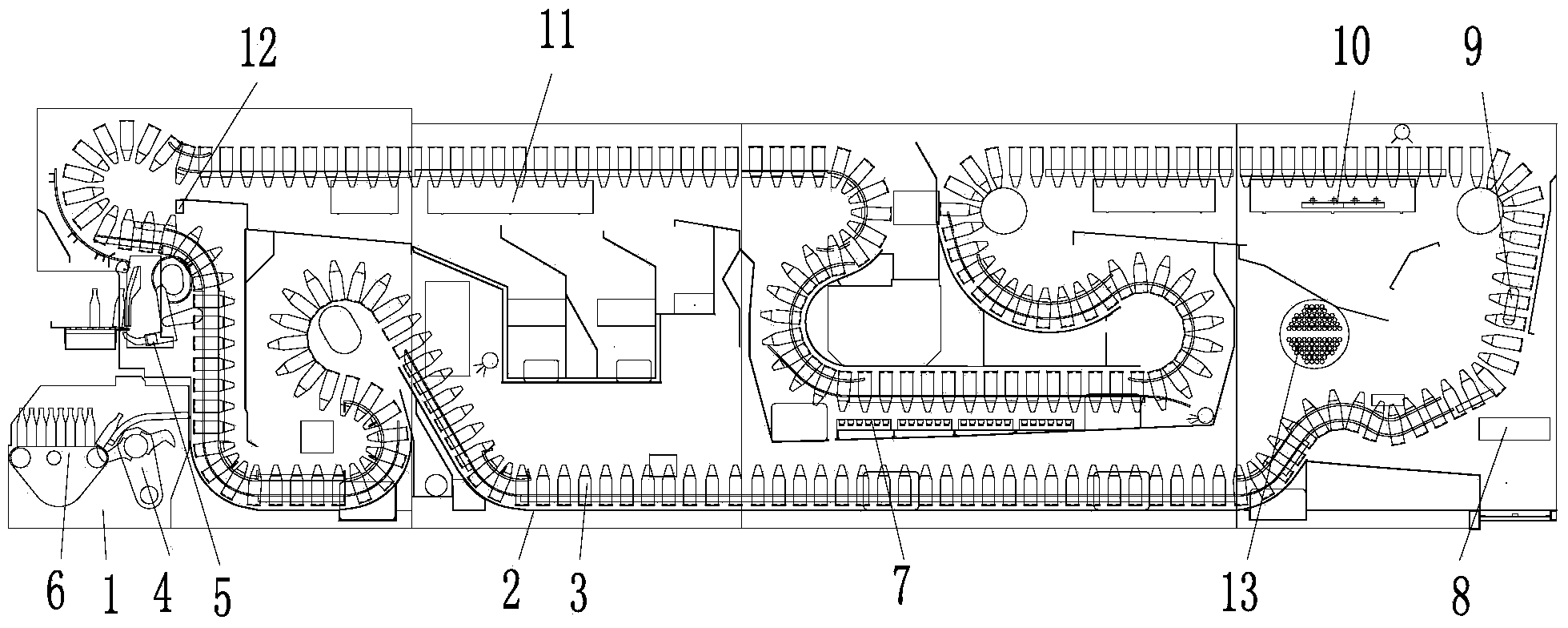

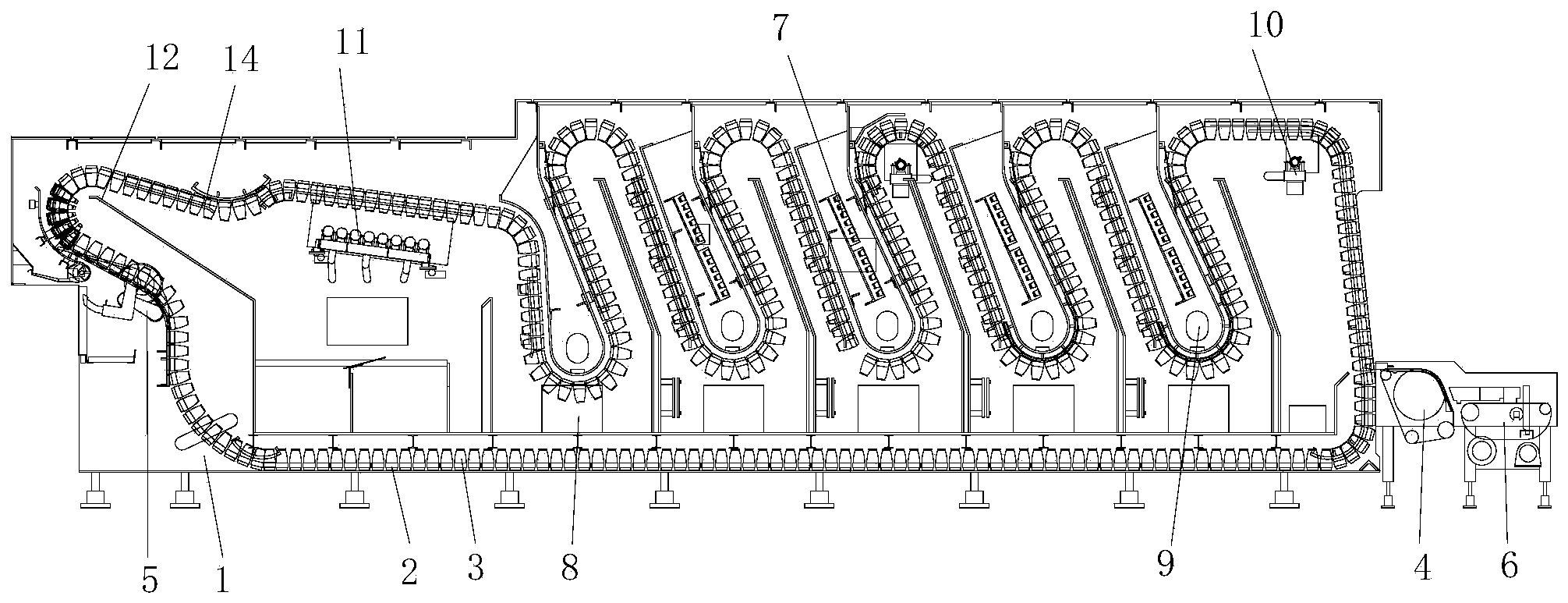

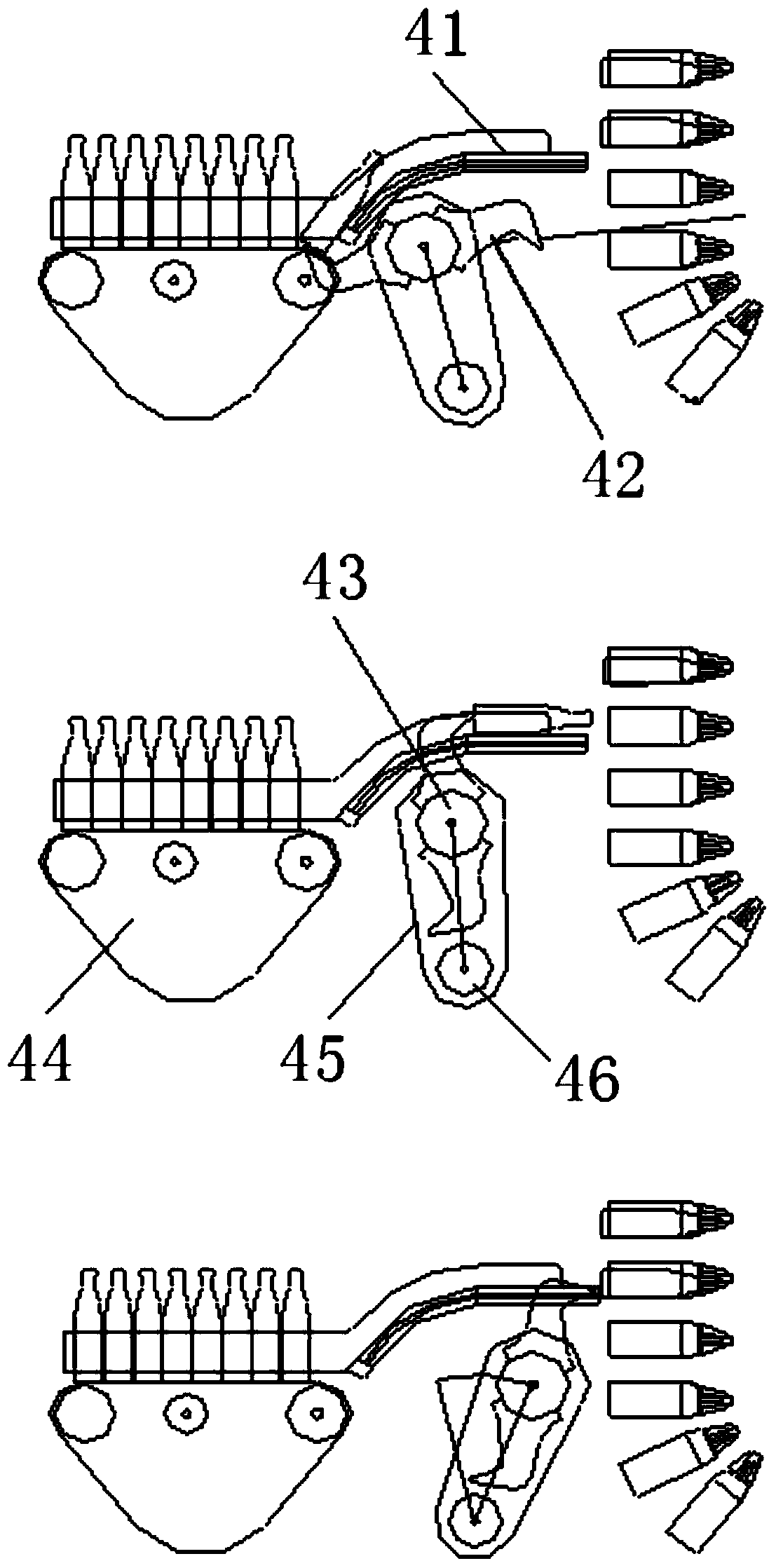

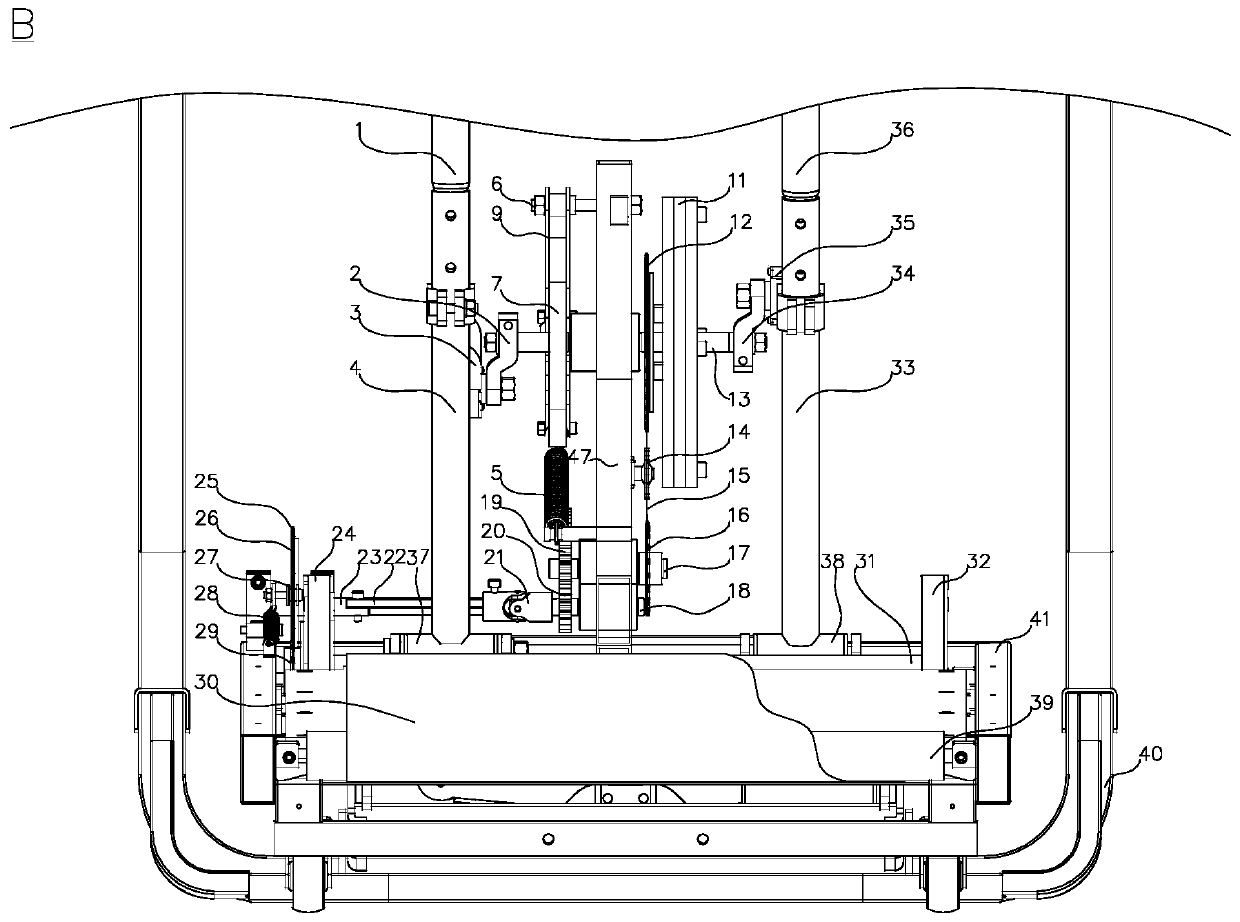

Tunnel type ultrasonic bottle cleaning machine

InactiveCN104338708AAvoid dead spotsBottle feeding is stable and reliableHollow article cleaningCleaning using liquidsCrankEngineering

The invention relates to the technical field of cleaning machines, in particular to a tunnel type ultrasonic bottle cleaning machine. The tunnel type ultrasonic bottle cleaning machine comprises a machine case filled with a cleaning fluid, wherein a bottle inlet and a bottle outlet are formed in the machine case; a transmission device capable of circulating rotation is arranged in the machine case; a plurality of bottle carrying boxes are arranged on the transmission device; a bottle feeding mechanism for pushing bottles to be cleaned into the bottle carrying boxes is arranged at the bottle inlet; a bottle discharging mechanism for pushing the cleaned bottles out of the bottle carrying boxes is arranged at the bottle outlet. The bottle feeding device adopts a crank and rocker mechanism, movement dead points of a four-bar mechanism are overcome, the bottles are stably and reliable fed, a bottle discharging device adopts a connecting rod to receive the bottles, and the bottles are firstly discharged by a cushion pad and then fed by a bottle receiving claw, so that the tunnel type ultrasonic bottle cleaning machine works stably. A plurality of cleaning working procedures are set in the machine case, the cleaning requirement of the bottles is met, and the work efficiency is high.

Owner:张家港市贝奇尔机械有限公司

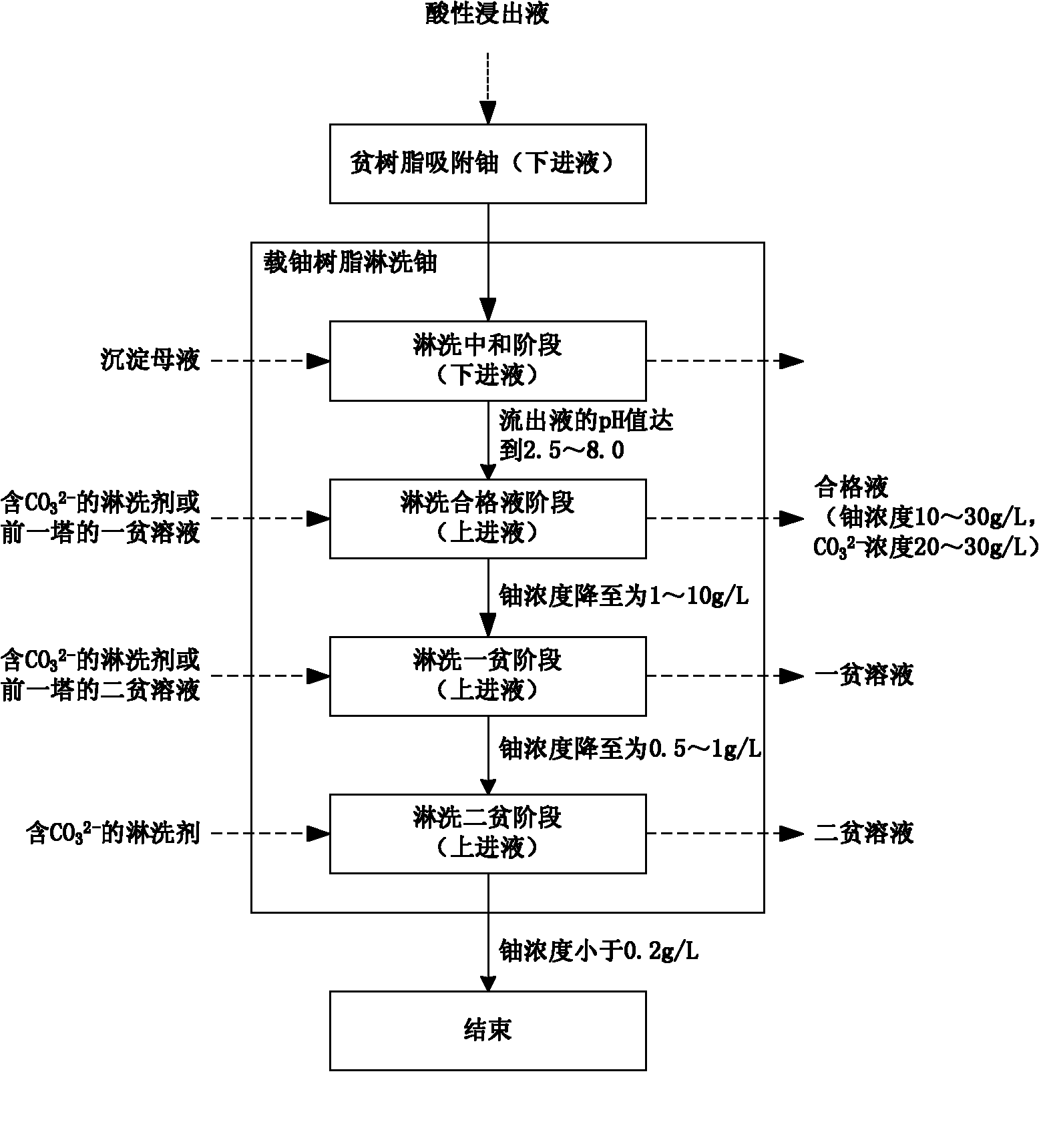

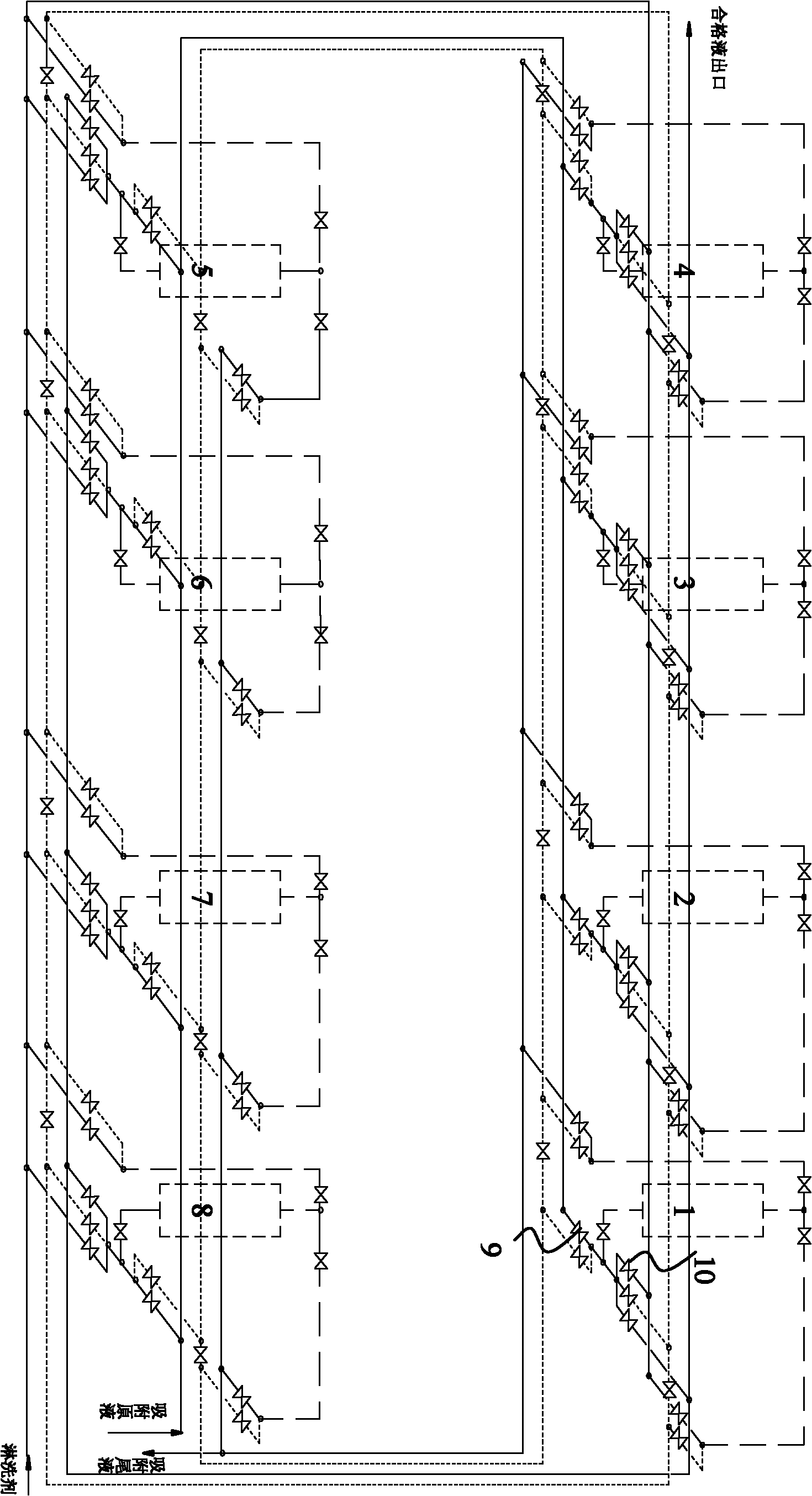

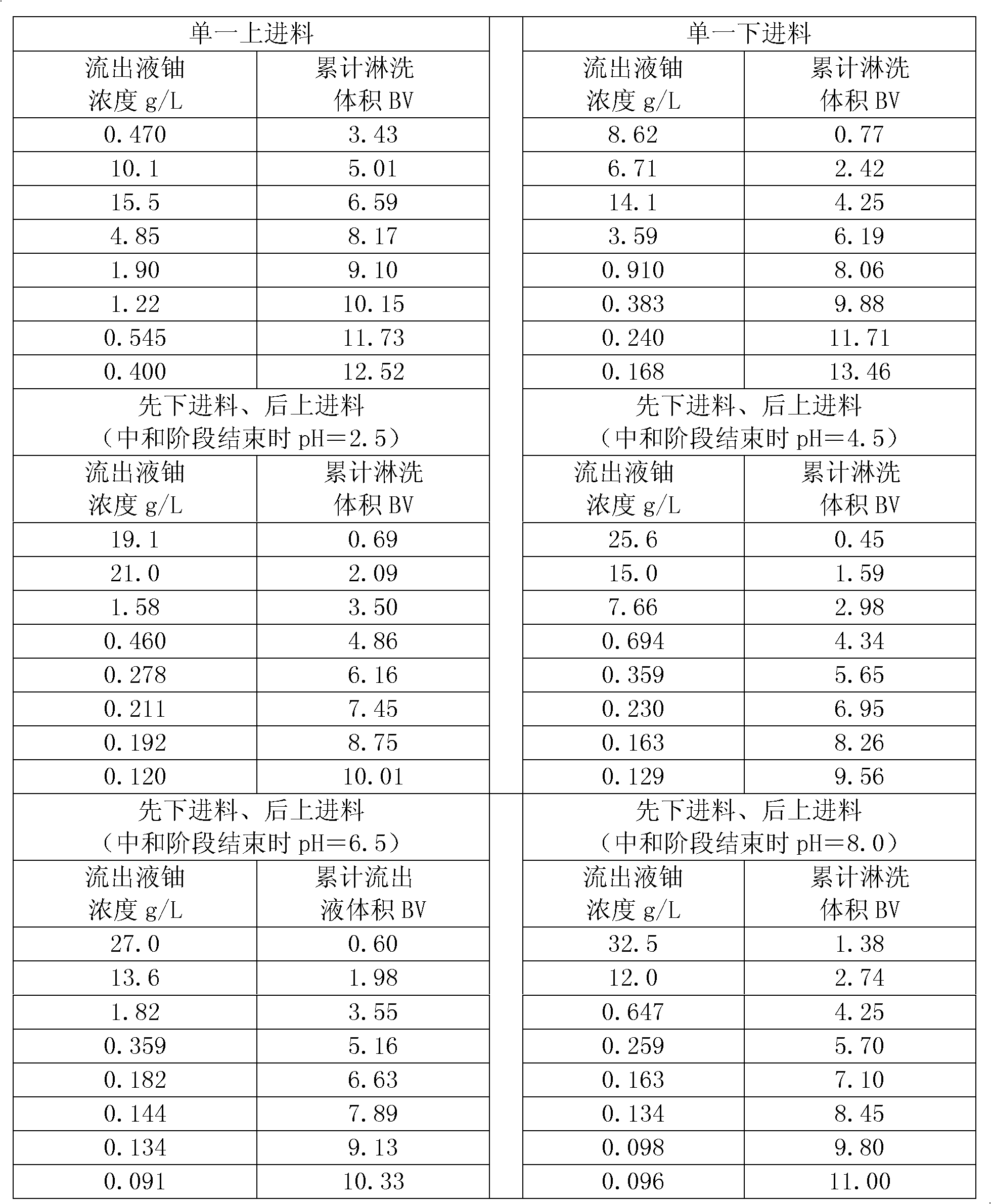

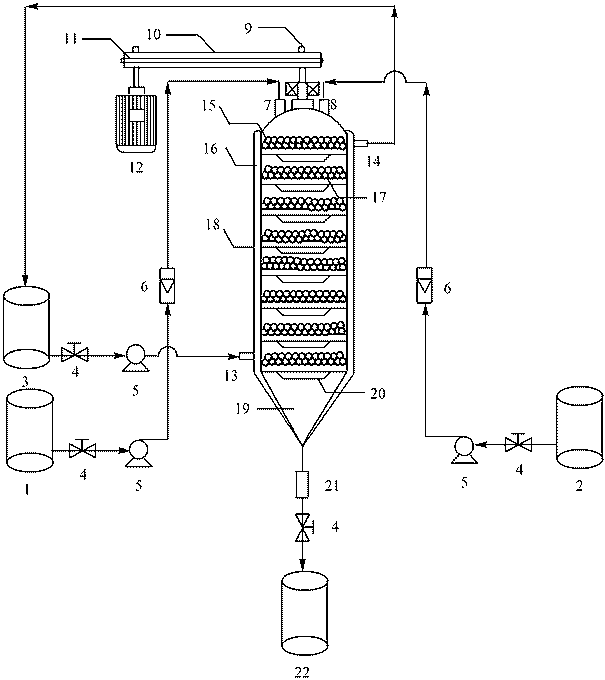

Method for extracting uranium by using ion exchange fixed tower under alternate Ph condition

InactiveCN102031369AUnobstructed dischargeAvoid "dead spots"Process efficiency improvementIon exchangeElution

The invention relates to a method for extracting uranium by using an ion exchange fixed tower, in particular to a method for extracting uranium by using an ion exchange fixed tower under the alternate Ph condition. The method comprises the steps of absorbing uranium by barren resin and eluting the uranium-carried resin to obtain uranium, wherein the step of eluting the uranium-carried resin to obtain uranium also comprises the following stages of elution neutralization, qualified liquid elution, first barren elution and second barren elution. In the stage of elution neutralization, an alkali eluent is used to neutralize residual acid in the uranium-carried resin, and the feeding mode is lower liquid feeding; in the stage of qualified liquid elution, the feeding mode is upper liquid feeding; in the stage of first barren elution, the feeding mode is upper liquid feeding, and the effluent liquid is a first barren solution; and in the stage of second barren elution, the feeding mode is upper liquid feeding, and the effluent liquid is a second barren solution. The invention increases elution efficiency and shortens elution volume by dividing the step of eluting the uranium-carried resin to obtain uranium into the stages of elution neutralization and qualified liquid elution and by respectively using the upper liquid feeding mode and the lower liquid feeding mode.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

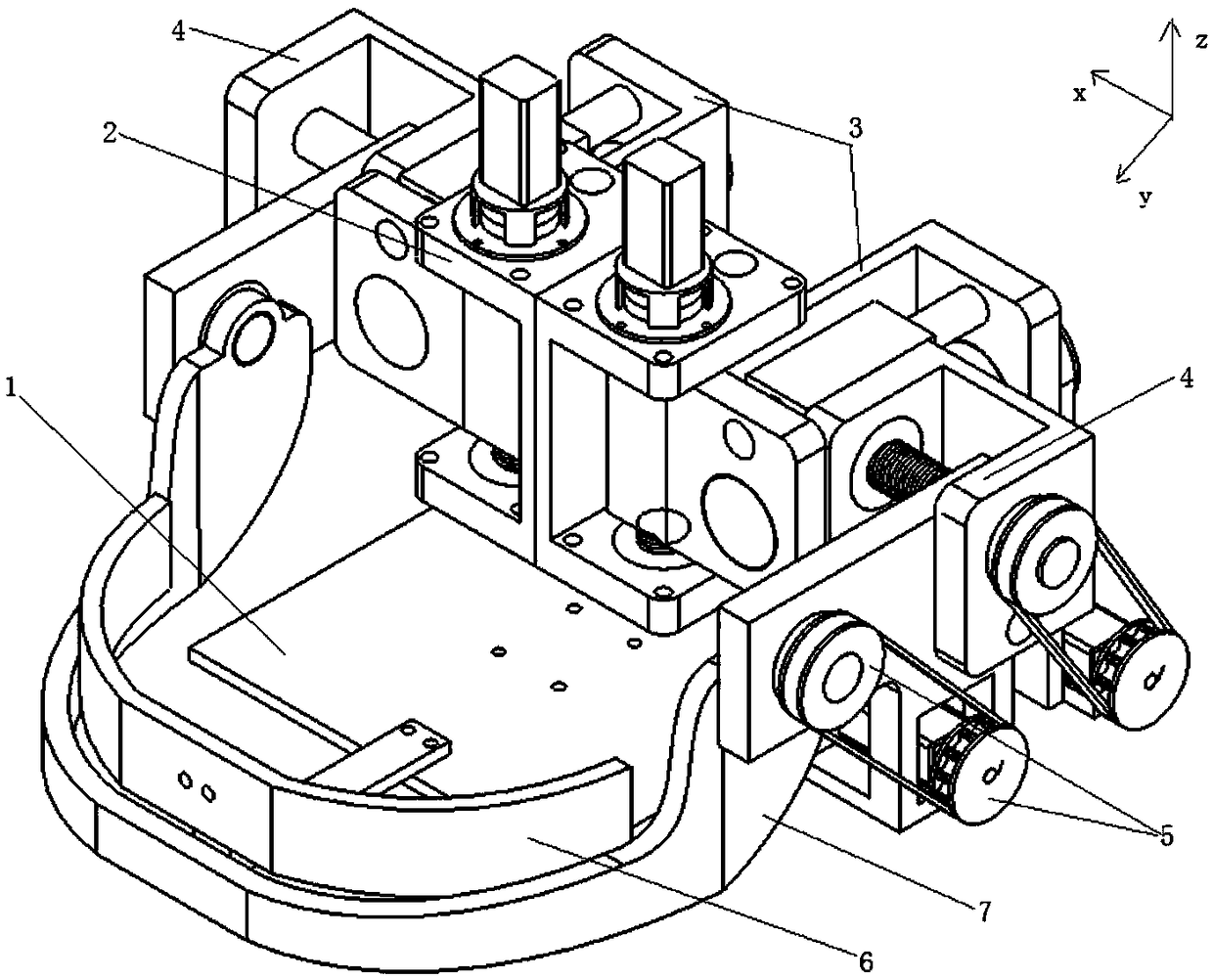

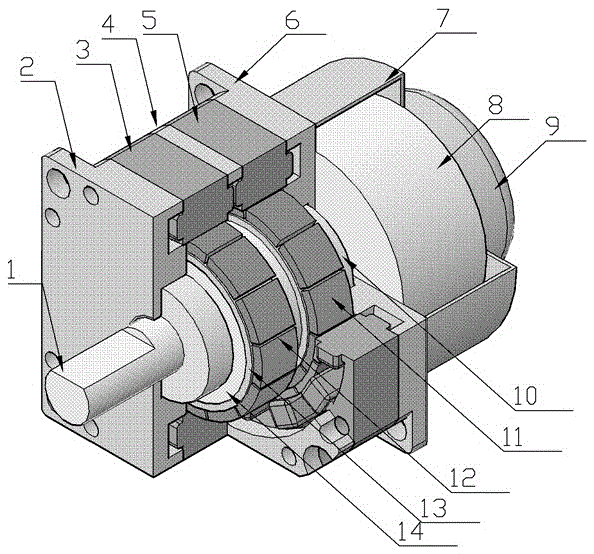

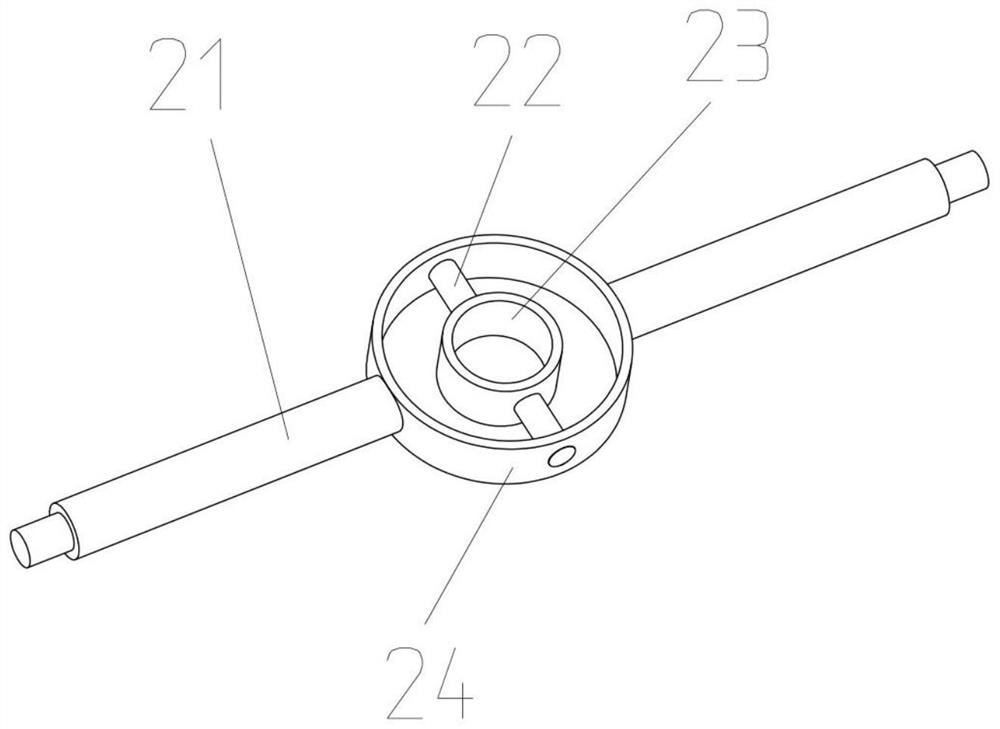

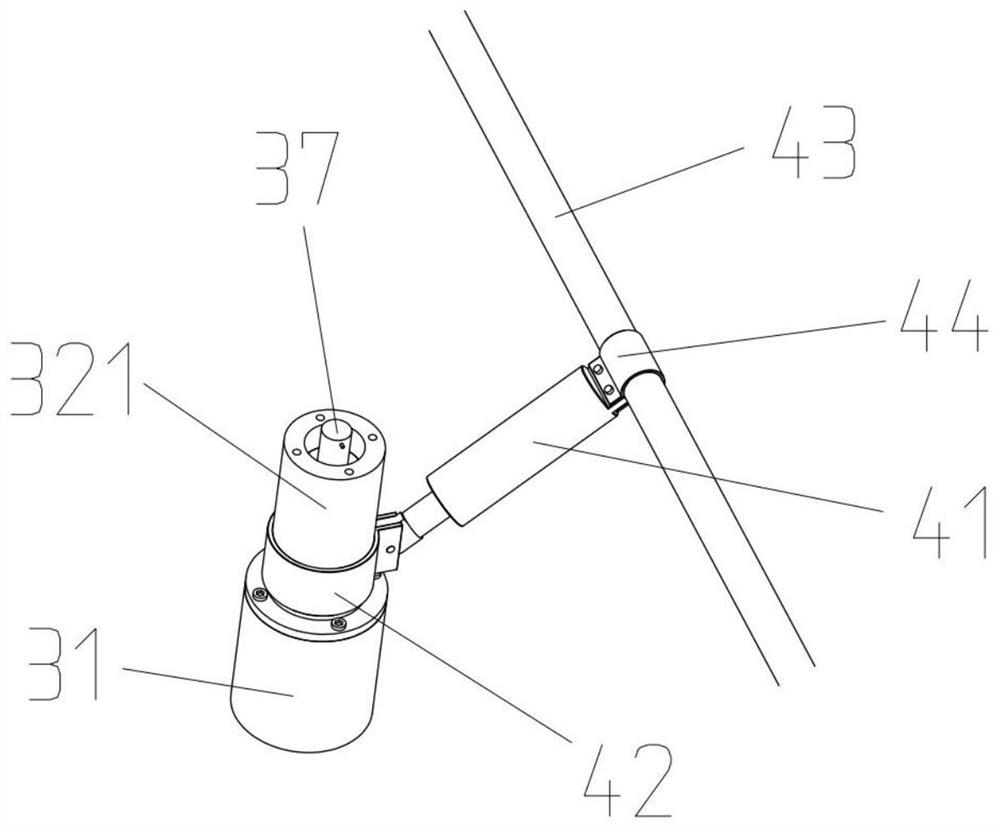

Six-freedom-degree humanoid chewing mechanism

ActiveCN108748103AEasy to moveAvoid dead spotsProgramme-controlled manipulatorService robotHuman–computer interaction

The invention discloses a six-freedom-degree humanoid chewing mechanism. The six-freedom-degree humanoid chewing mechanism comprises a base plate, an up-down moving platform, a front-back moving platform, a left-right moving platform, a rotary driving mechanism, a humanoid upper jaw and a humanoid lower jaw. The six-freedom-degree humanoid chewing mechanism is driven by six direct-current motors,the direct-current motors are large in starting torque and good in speed adjusting performance, smooth speed adjusting can be achieved, and the humanoid head requirements can be met. The humanoid upper jaw is fixed to a base plate, and the humanoid lower jaw is connected with the left-right moving platform. According to the up-down moving platform and the front-back moving platform, through motionof the different direct-current motors at the same speed or the different speeds, the effects of moving along the z axis, rotating along the z axis, moving along the y axis and rotating along the y axis can be achieved; and according to the left-right moving platform, the effects of moving along the x axis and rotating along the x axis can be achieved through two of the direct-current motors, thus, fix freedom degrees of the lower jaw is completed, and high-degree humanoid chewing motion is achieved. The six-freedom-degree humanoid chewing mechanism can be applied to food detection, tooth testing and other occasions, or a humanoid head robot, a service robot and other man-machine interaction situations.

Owner:NORTHEASTERN UNIV

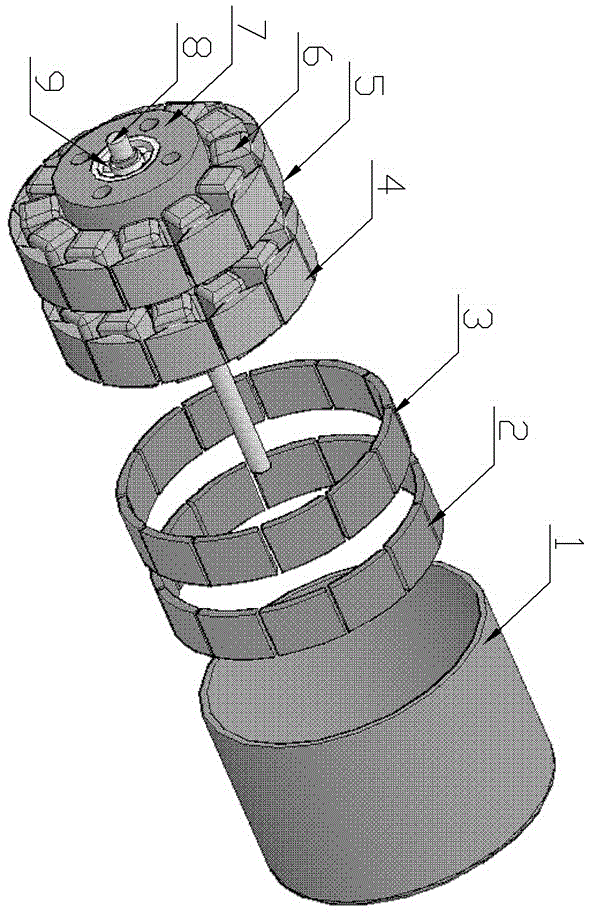

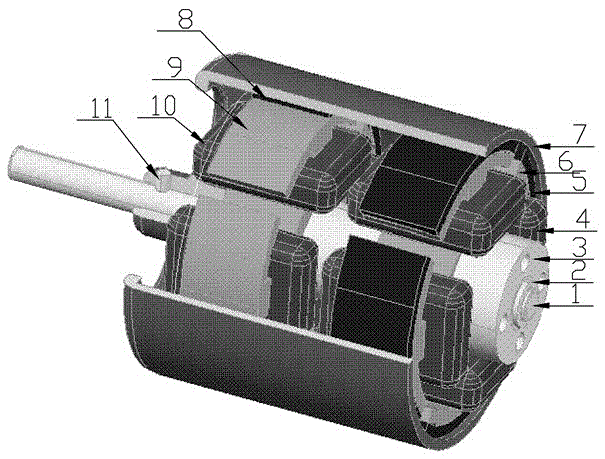

Permanent magnet stepping servo motor

InactiveCN105610258ASmall step angleHigh torque/volume ratioMagnetic circuit rotating partsSingle phaseEngineering

M double-salient-pole single-phase brushless direct current motors possessing 2n stator poles and a rotor magnetic pole or disc-type motors are installed on a same shaft. Stators and rotors of all the sub-motors form one integral stator and an integral rotor. If starting dead points of at least one or more sub-motors are not overlapped, each sub-motor operates independently so that a m-phase brushless direct current motor without dead point is formed. If each sub-motor successively rotates 360 / 2mn degree respectively, a stepping motor is formed. There are operation modes of 2m and 4m steps, and continuous stepping operation. A stepping angle is a 360 / 2mn degree or a 360 / 4mn degree. The m equals to 2. One angle sensor and one motor brake are added so that the stepping servo motor is formed. A continuous stepping operation mode is used to start the operation till that the motor is operated at a position which makes an assigned step pitch difference is less than one step, and then current sizes and directions of two phases are adjusted so that the rotor is rotated to an assigned position, and power off is performed after braking so that a function of the servo motor is realized.

Owner:JINHANSHU TECH COMPANY LTD HUNAN CHINA

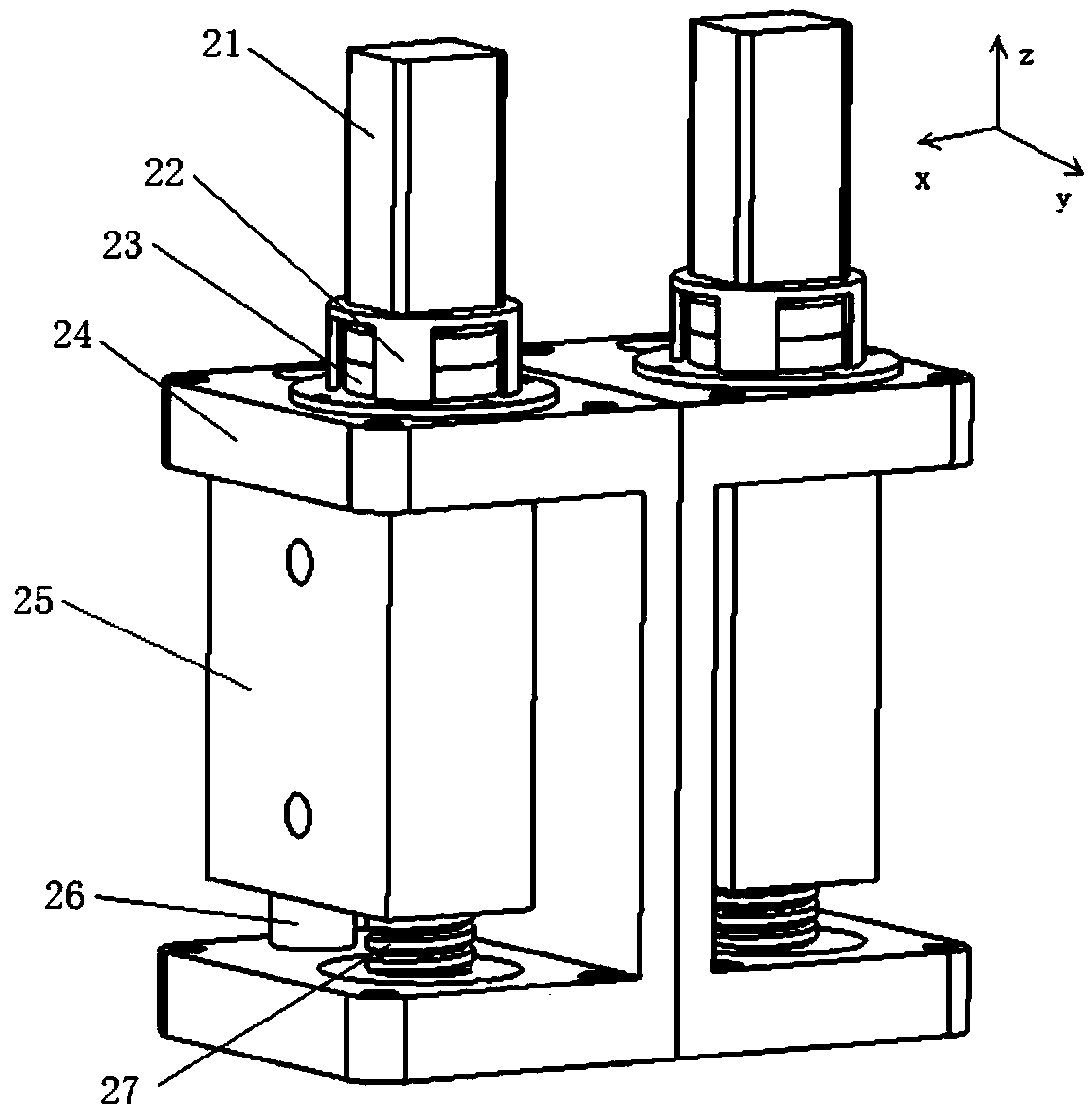

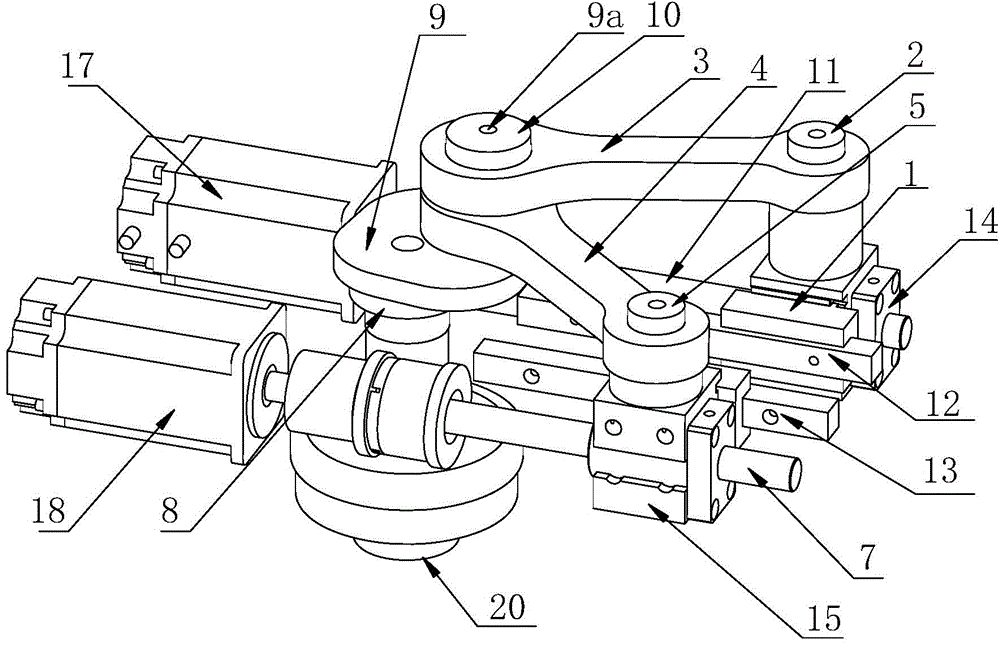

Precise numerical-control spindle system

ActiveCN104148976ASimple structureAvoid dead spotsElectric motor controlGearingNumerical controlControl theory

The invention discloses a precise numerical-control spindle system. The precise numerical-control spindle system comprises a frame, an output shaft and a driving system, wherein the output shaft is rotationally mounted on the frame through a main bearing, and the driving system comprises two driving devices. Each driving device comprises a crank slider mechanism and a screw nut mechanism. Guide rails of sliders of the crank slider mechanisms are fixed on the frame, cranks are fixed with the hinged end of the frame and the output shaft, and dead points of the crank slider mechanisms are mutually staggered relative to rotation angle of the output shaft; screws of the screw nut mechanisms are mounted on the frame through screw bearings, nuts are connected with the sliders of the crank slider mechanism, the screws of the driving devices rotate together, the nuts drive the sliders to translate, and the cranks of the crank slider mechanisms jointly drive the output shaft to rotate. The driving devices together drive the output shaft to rotate, possible dead points of one crank slider mechanism can be effectively avoided, and 360-degree rotation and positioning can be realized.

Owner:SHENZHEN LLMACHINECO LTD

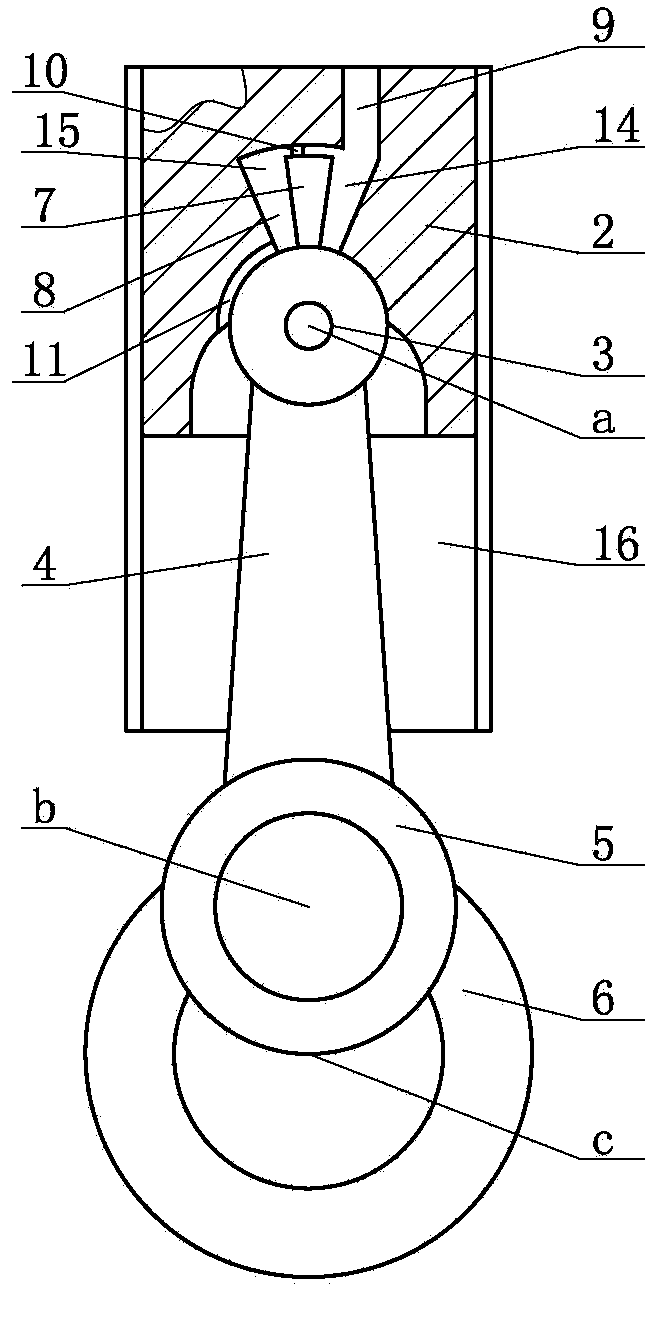

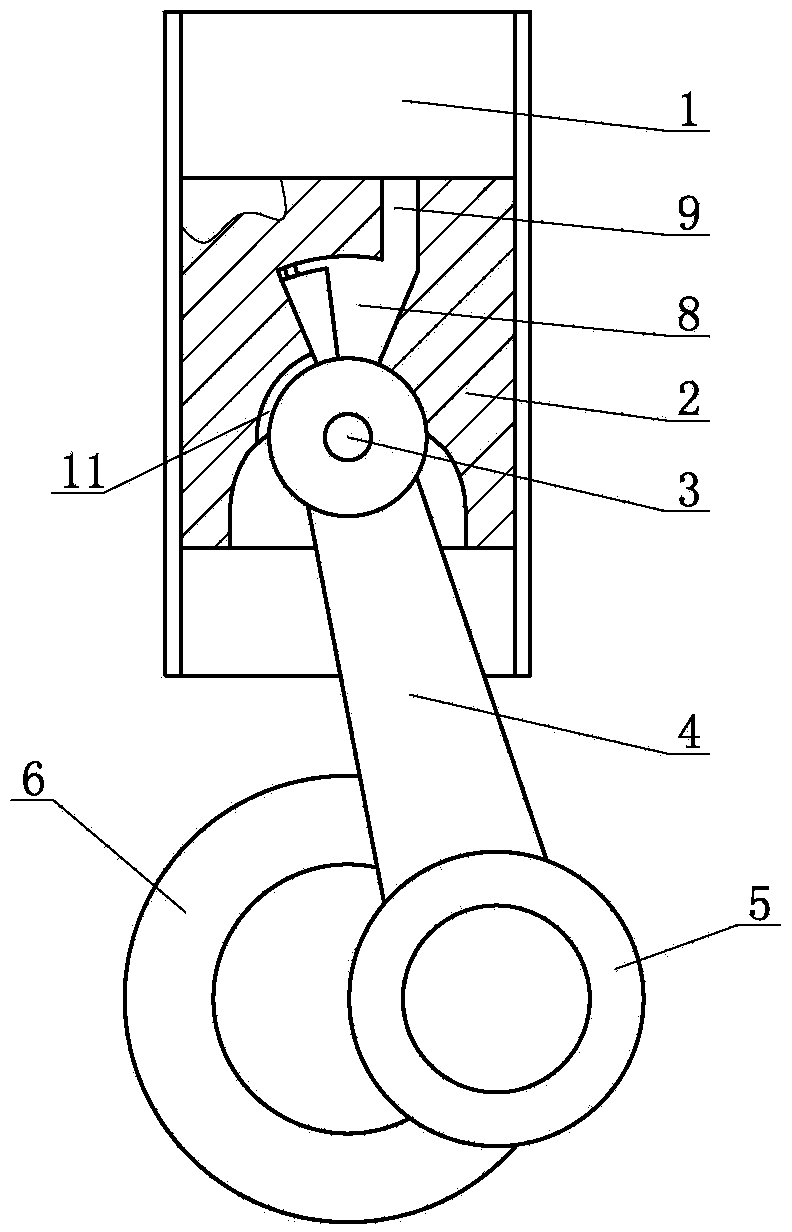

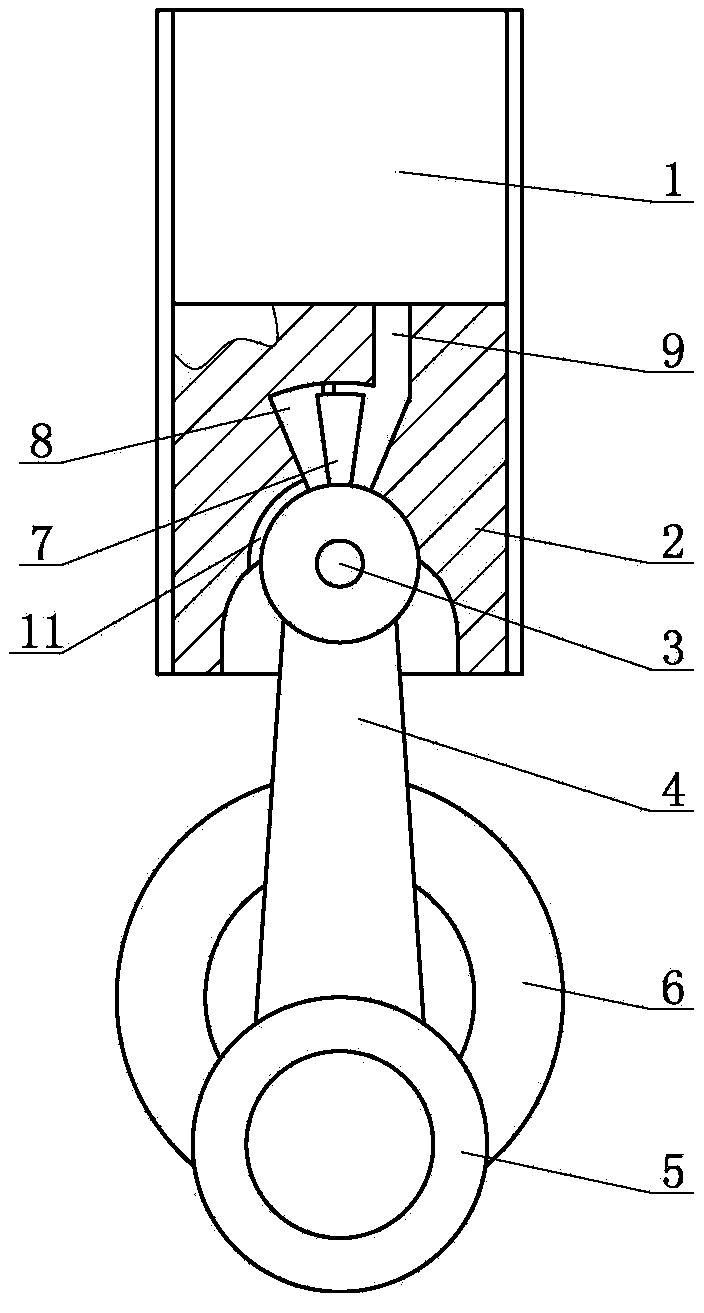

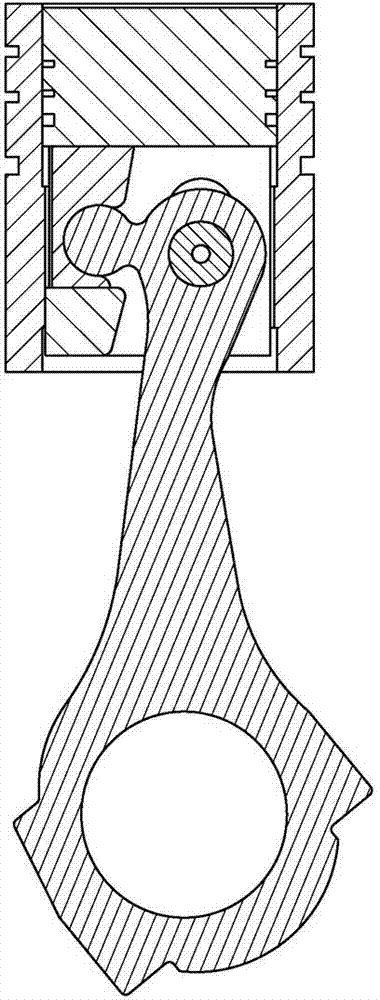

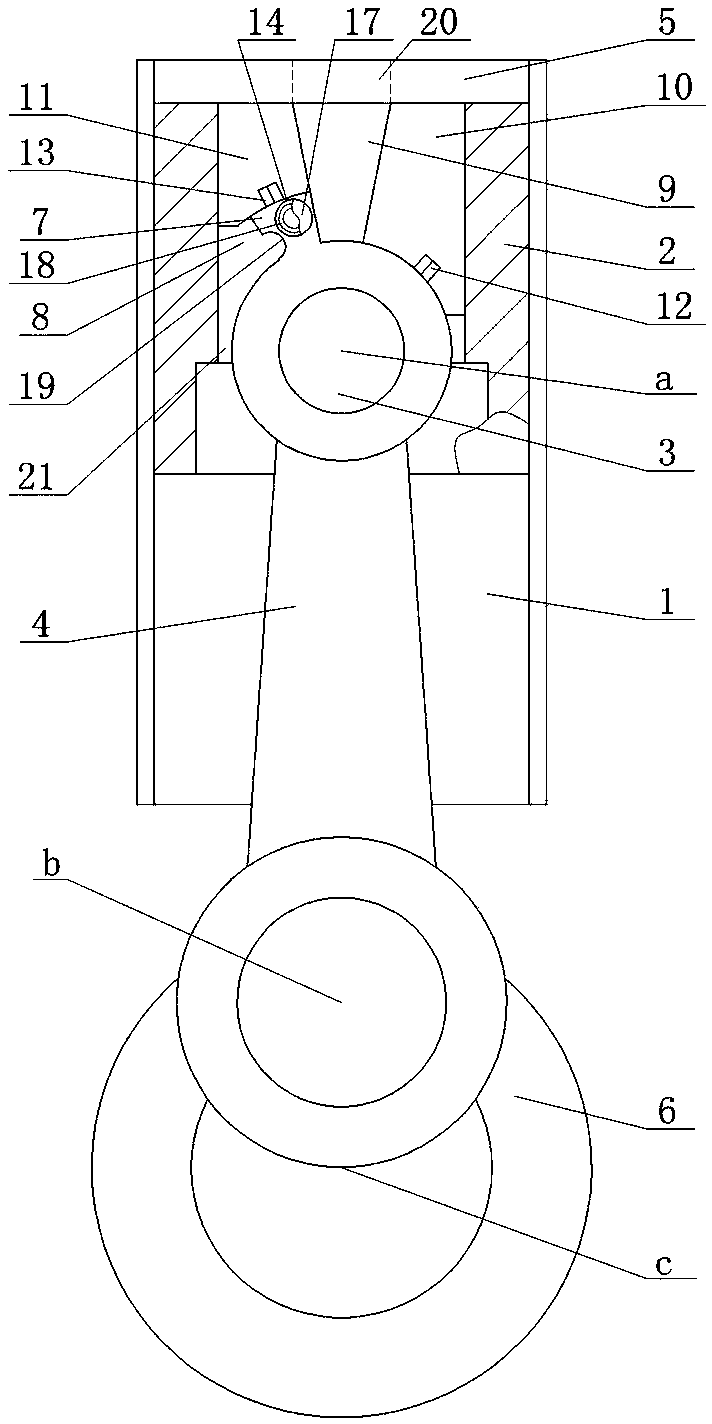

Connecting rod piston type combustion chamber combined dead-center-free reciprocating internal combustion engine

InactiveCN103742263AExtended service lifeIncreased thrust areaCombustion enginesPistonsTop dead centerExternal combustion engine

The invention discloses a connecting rod piston type combustion chamber combined dead-center-free reciprocating internal combustion engine which comprises a shell, a connecting rod, a crank and a crankshaft. A cylinder is arranged in the shell, a piston head is mounted in the cylinder, an inner cavity and a piston pin hole are formed in the piston head, the piston head is hinged to the connecting rod through a piston pin which is matched with the piston pin hole, and the connecting rod is located in the inner cavity. Smoothness of the internal combustion engine can be effectively improved, and service life of the internal combustion engine is prolonged. The dead center distance with the top dead center position about 15-25 degrees of an original internal combustion engine is utilized, working stroke of an original conventional piston is elongated, and thrust area of the piston is increased, so that the internal combustion engine is ensured to output power under maximum pressure. The piston head, the piston pin and the connecting rod can act for power output at an angle more than 180 degrees, particularly power output with piston running top and bottom dead centers of crankshaft 180 degrees + piston block output thrust angle of crank angle 90 degrees more than and equal to crank angle 180 degrees. Dead centers are eliminated, and the connecting rod piston type combustion chamber combined dead-center-free reciprocating internal combustion engine further has the advantages of simple structure and simplicity in manufacturing.

Owner:尹建

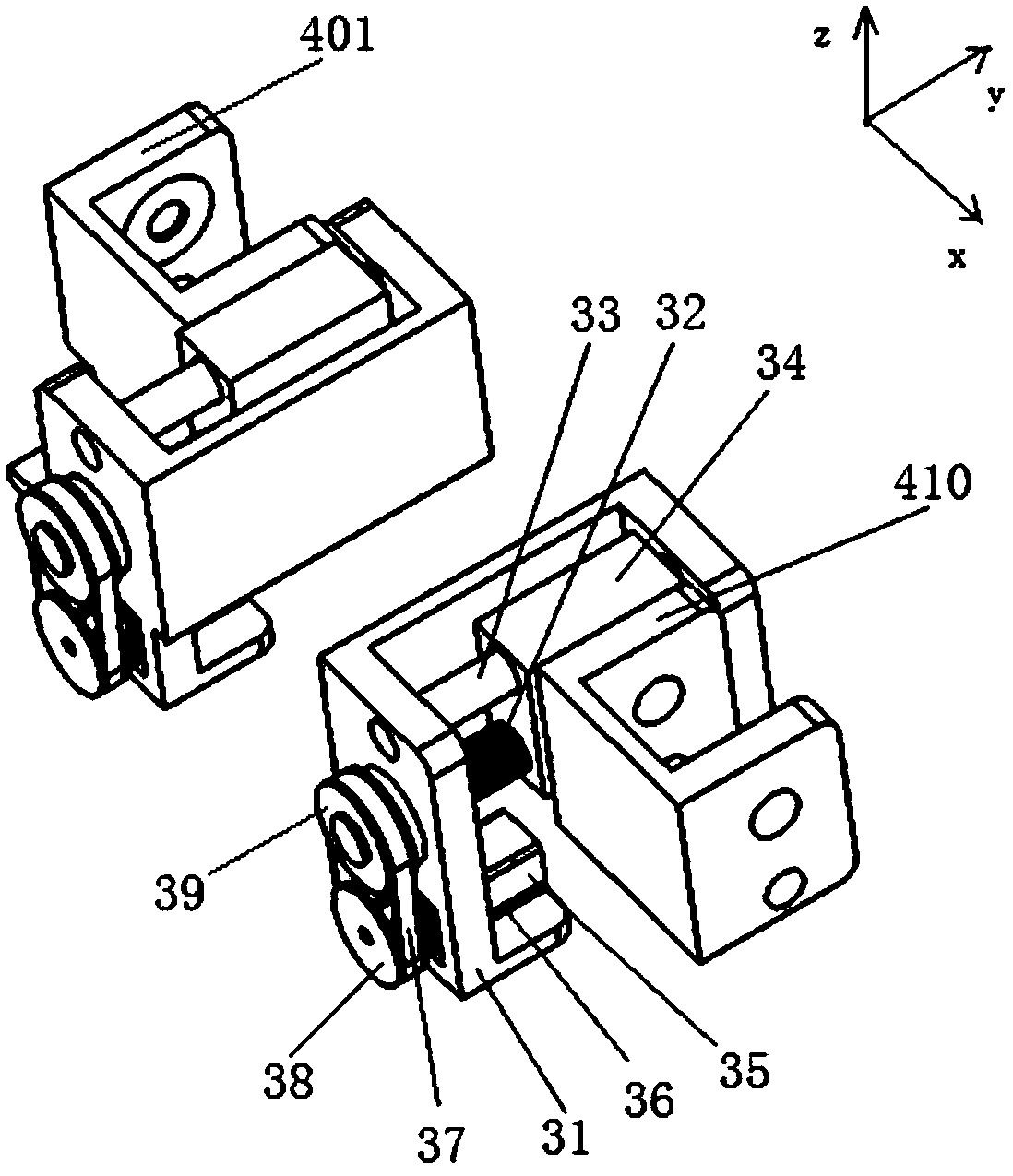

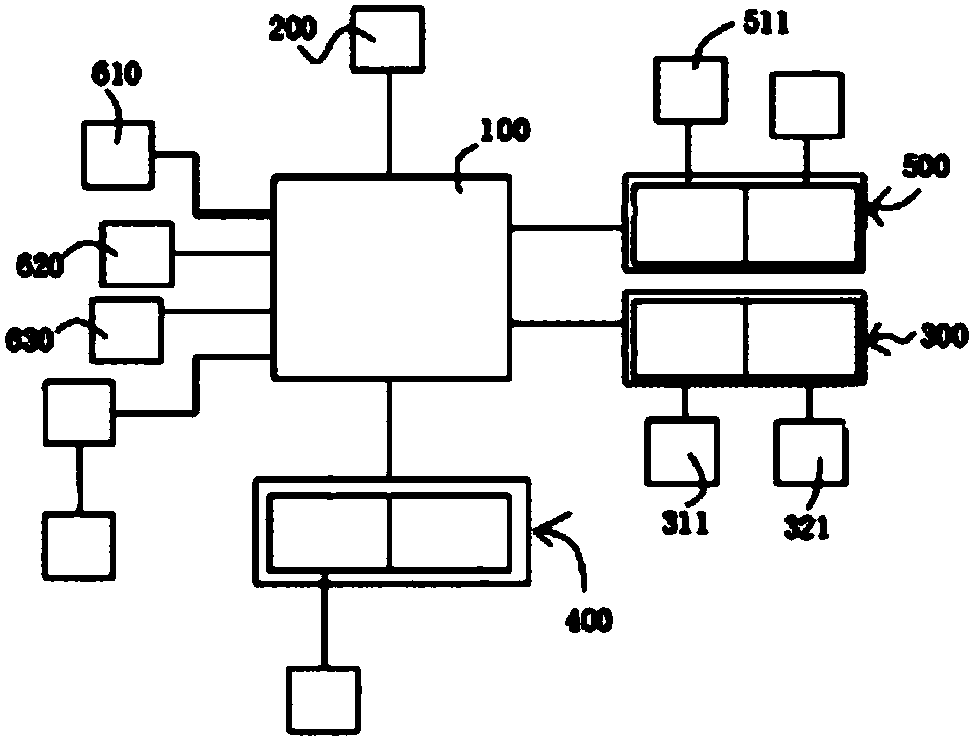

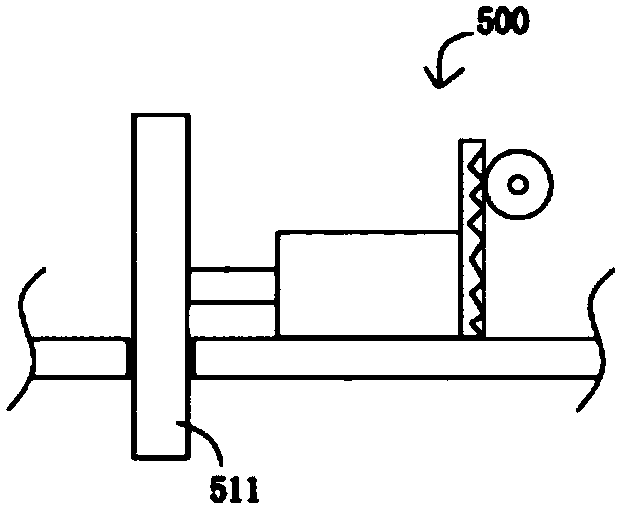

Self-removing robot

The invention discloses a self-removing robot. The self-removing robot comprises a moving robot body (1000) as well as a control unit and a primary drive wheel assembly (200) which are arranged on theself-removing robot body (1000), and further comprises a secondary drive wheel assembly (300) and a trigger mechanism connected with the secondary drive wheel assembly, wherein the primary drive wheel assembly comprises a drive motor (100) and a drive wheel (201); the secondary drive wheel assembly comprises a connecting rod assembly (400) and a secondary drive wheel (301) arranged at one end ofthe connecting rod assembly; the connecting rod assembly can be movably arranged on the body or the primary drive wheel assembly; the trigger mechanism at least comprises a trigger end (401); in a forward direction, the trigger end is positioned before the primary drive wheel; after the trigger end encounters an obstacle and is lifted, downward acting force is generated on the secondary drive wheel, and the secondary drive wheel performs descending motion relative to the body under downward acting force or increases positive pressure on the travelling surface. The self-removing robot effectively avoids a dead point phenomenon, is adjustable in height, is suitable for obstacle crossing requirements of various complicated terrains, is compact in structure, and is reasonable in layout.

Owner:ECOVACS ROBOTICS (SUZHOU ) CO LTD

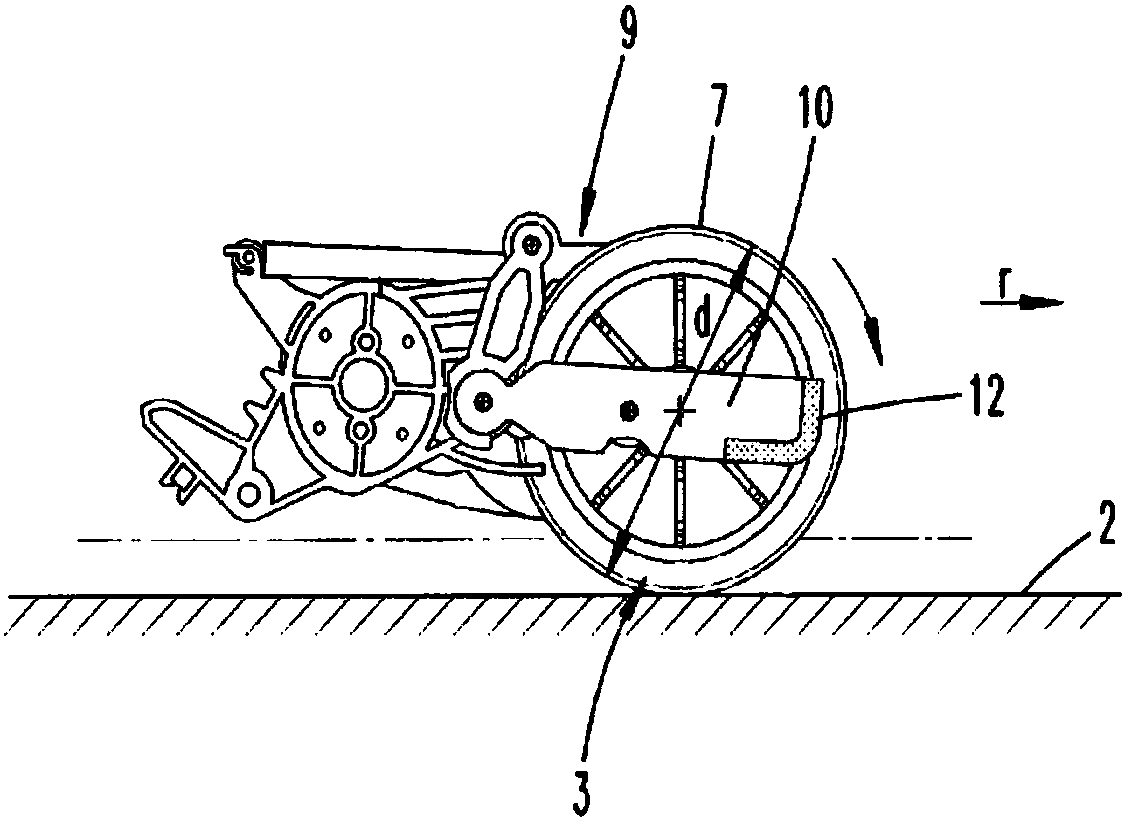

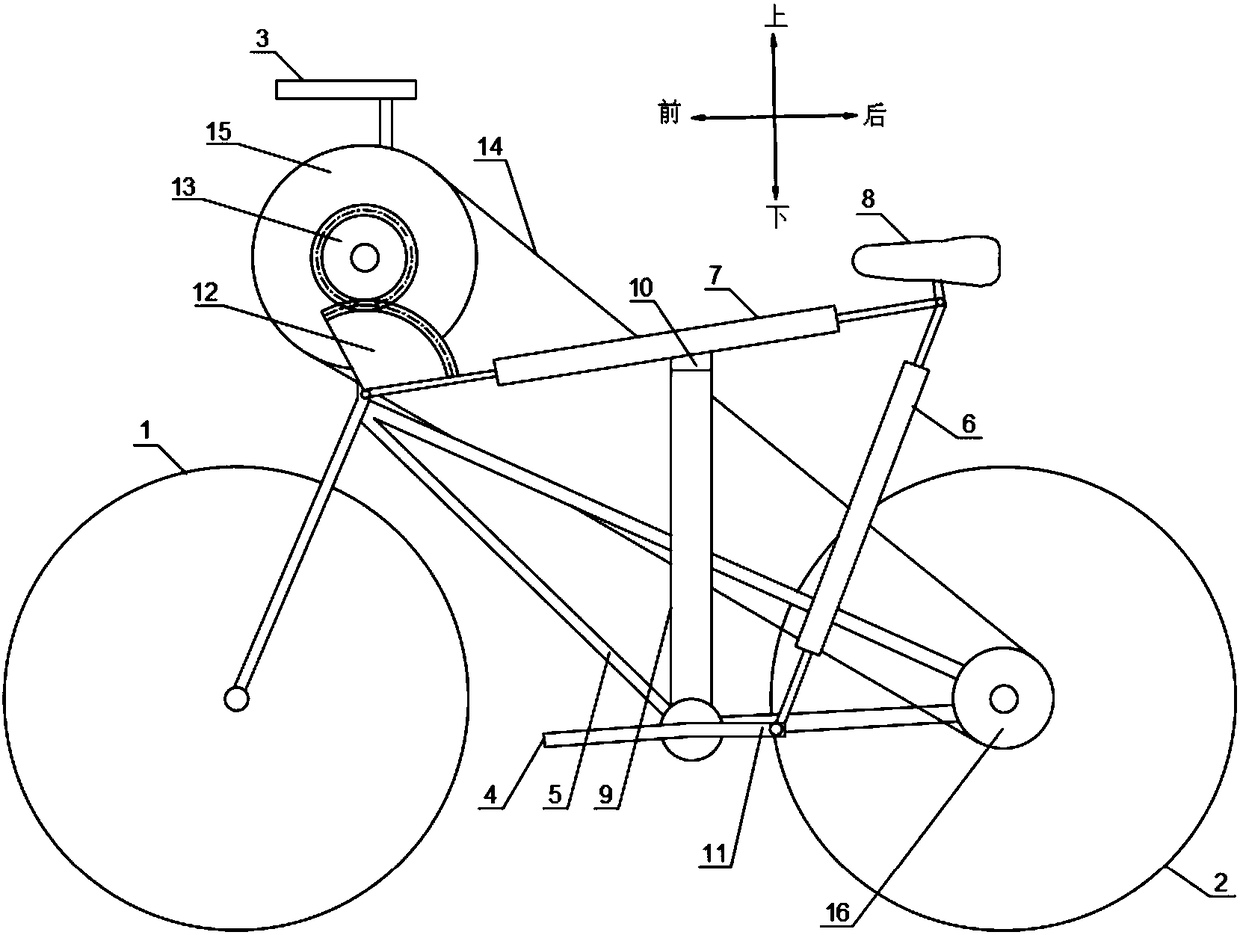

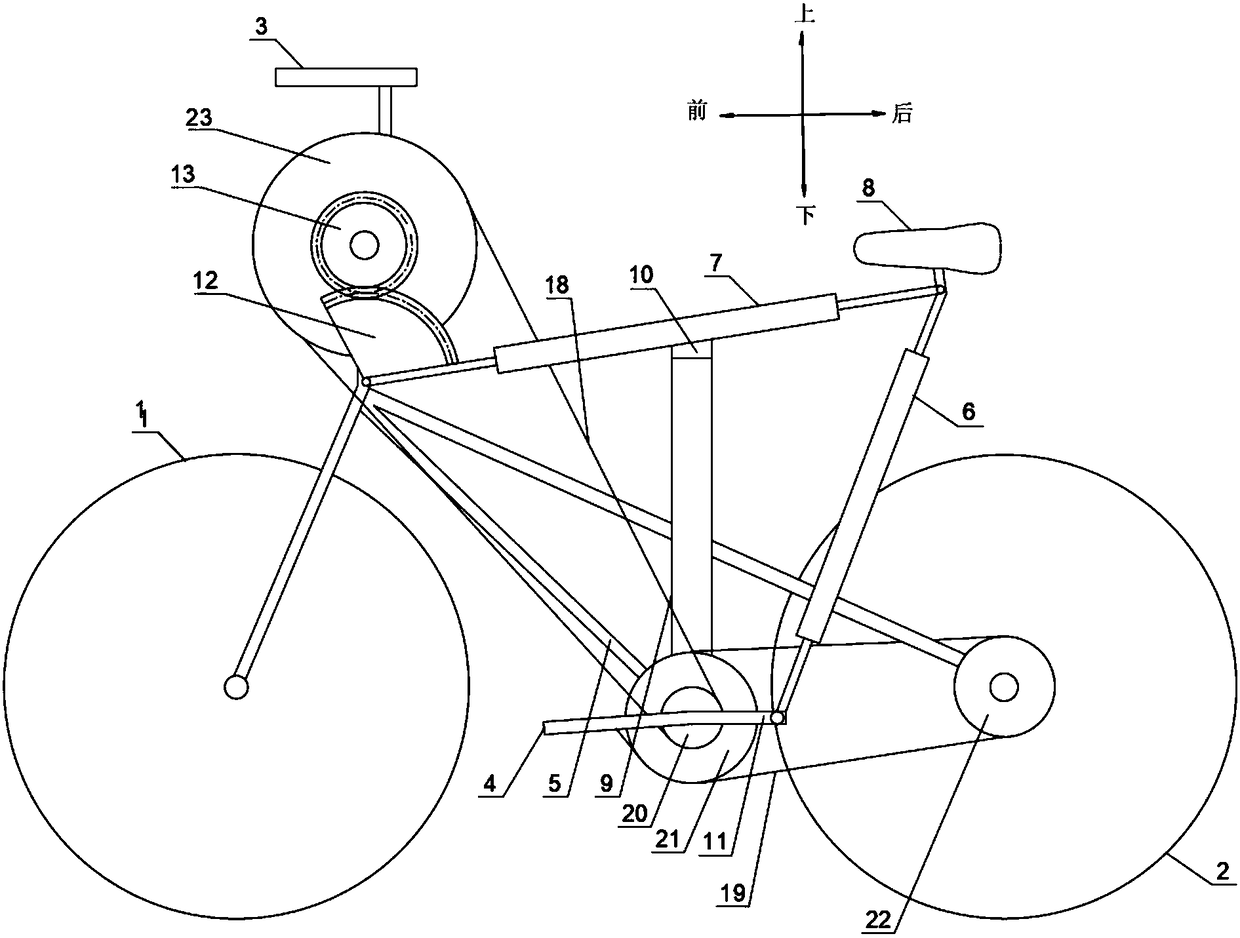

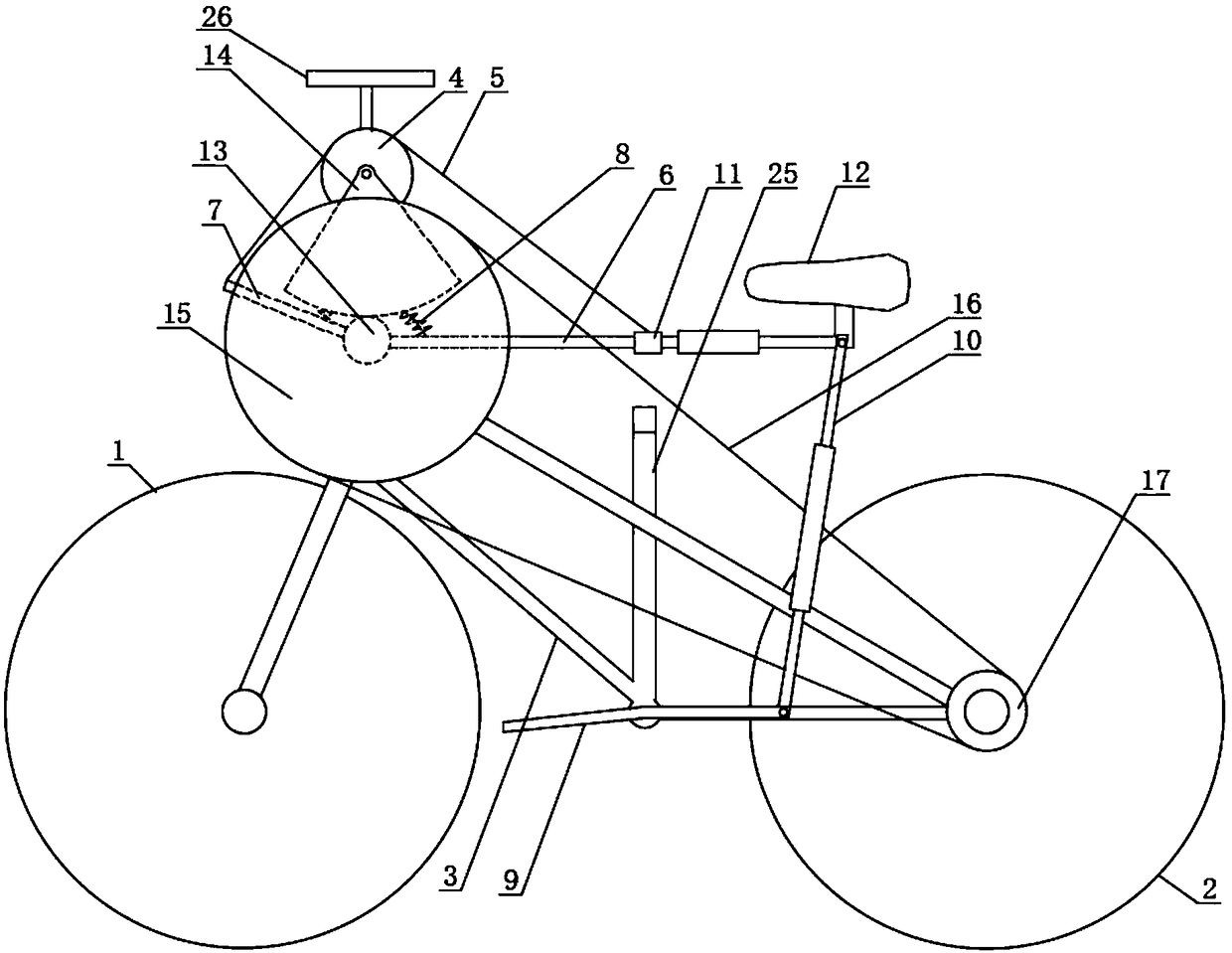

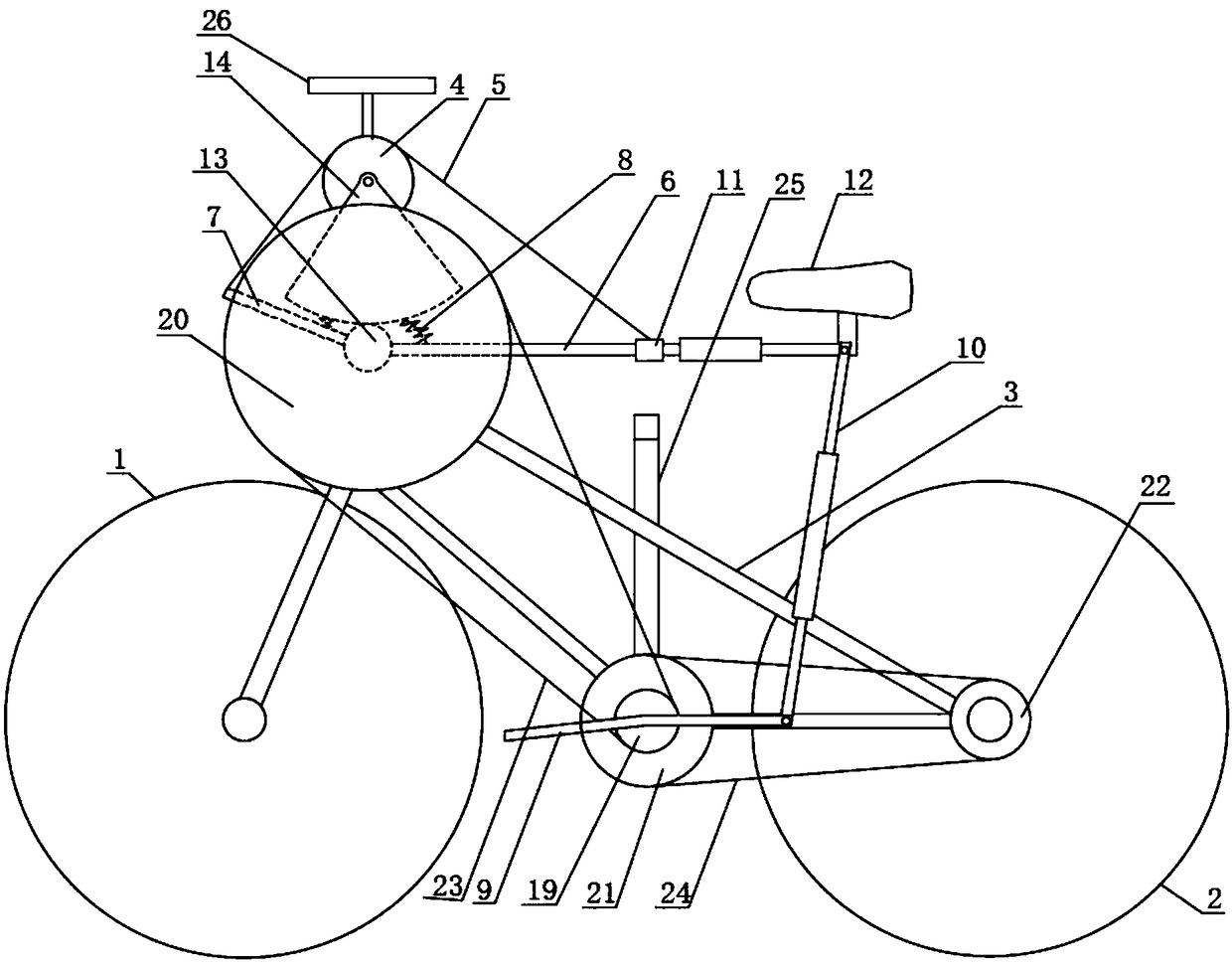

Super-labor-saving bicycle

InactiveCN108454769AEffort-saving ridingImprove exercise effectCycle saddlesRider propulsionVehicle frameWhole body

The invention discloses a super-labor-saving bicycle which comprises a front wheel assembly, a rear wheel assembly, a handle, pedals, a frame, a connecting rod, a swinging rod, a seat and a transmission mechanism, wherein the transmission mechanism is used for transferring swinging force of the swinging rod to the rear wheel assembly. The front wheel assembly and the rear wheel assembly are mounted at the front end and the rear end of the frame, the pedals are rotatably mounted at the lower end of the middle of the frame, the swinging rod and the pedals are hinged to two ends of the connectingrod, the seat is fixed at a hinging end of the connecting rod and the swinging rod, and one end, far away from the seat, of the swinging rod is hinged to the front end of the frame and in transmission connected with the rear wheel assembly through the transmission mechanism. According to the bicycle, force is generated by the weight of a human body, so that the bicycle is easily ridden, long-timemovement of feet is omitted, the bicycle is ridden by movement of a whole body, and good exercising effects can be achieved.

Owner:曾东斌

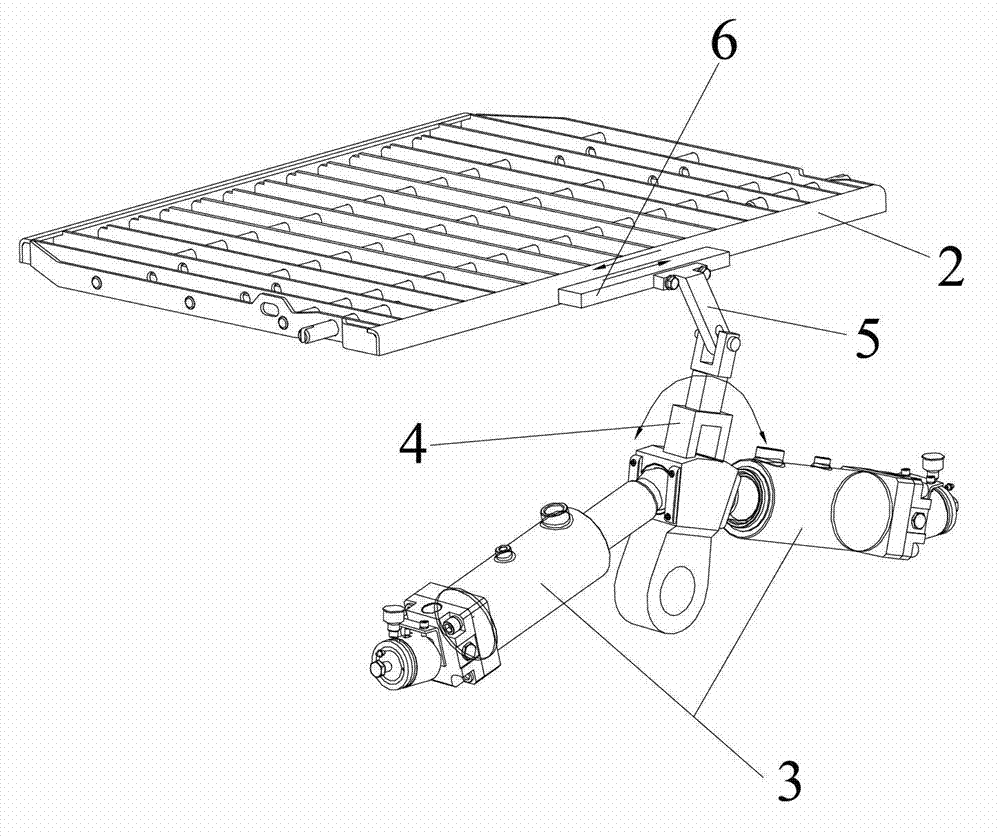

Pumping system and engineering machinery

ActiveCN102852336ALow costReduce procurement costsBuilding material handlingElectric machineryEngineering

The invention provides a pumping system; the pumping system comprises a hopper, a distribution valve and a swinging oil cylinder, wherein the hopper comprises a hopper body and a screen; the pumping system further comprises an earing; the screen is mounted at a material inlet of the hopper body; the screen is connected with a hopper body moving pair; the distribution valve is mounted in the hopper body; one end of the swinging oil cylinder is hinged on the hopper body and the other end of the swinging oil cylinder is used for driving the distribution valve to rotate; one end of the earing is connected with the other end of the swinging oil cylinder; the other end of the earing is connected with the screen in a rotating way; and while driving the distribution valve to rotate, the swinging oil cylinder can be used for driving the screen to move through the earing. The invention further provides engineering machinery. According to a technical scheme provided by the invention, the screen can be directly supplied with power by the swinging oil cylinder instead of a motor to vibrate; and as a vibrating device for swinging the screen is positioned behind the hopper and a swinging protective cover is arranged outside the hopper for protection, the whole hopper is simpler, beautiful and elegant.

Owner:SANY AUTOMOBILE MFG CO LTD

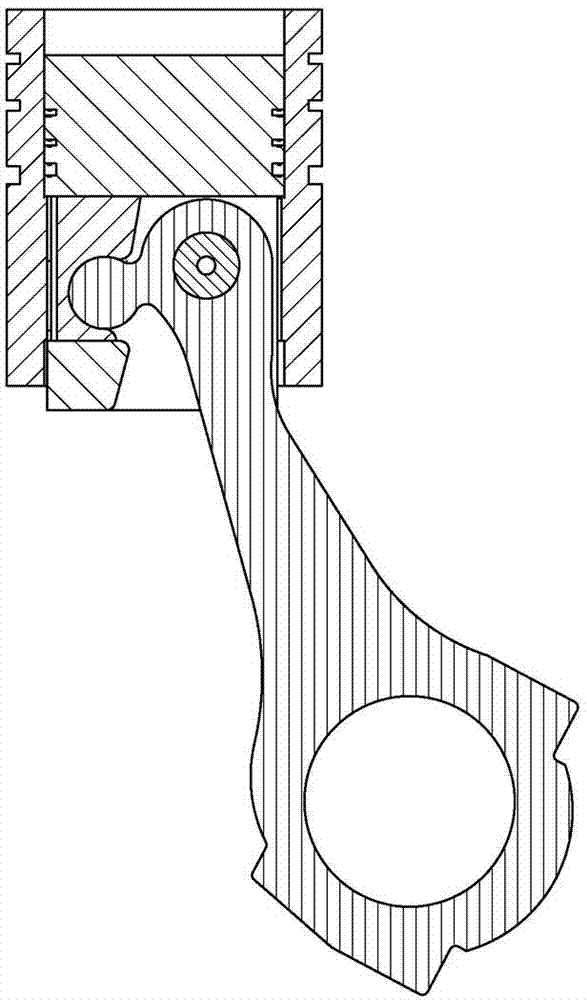

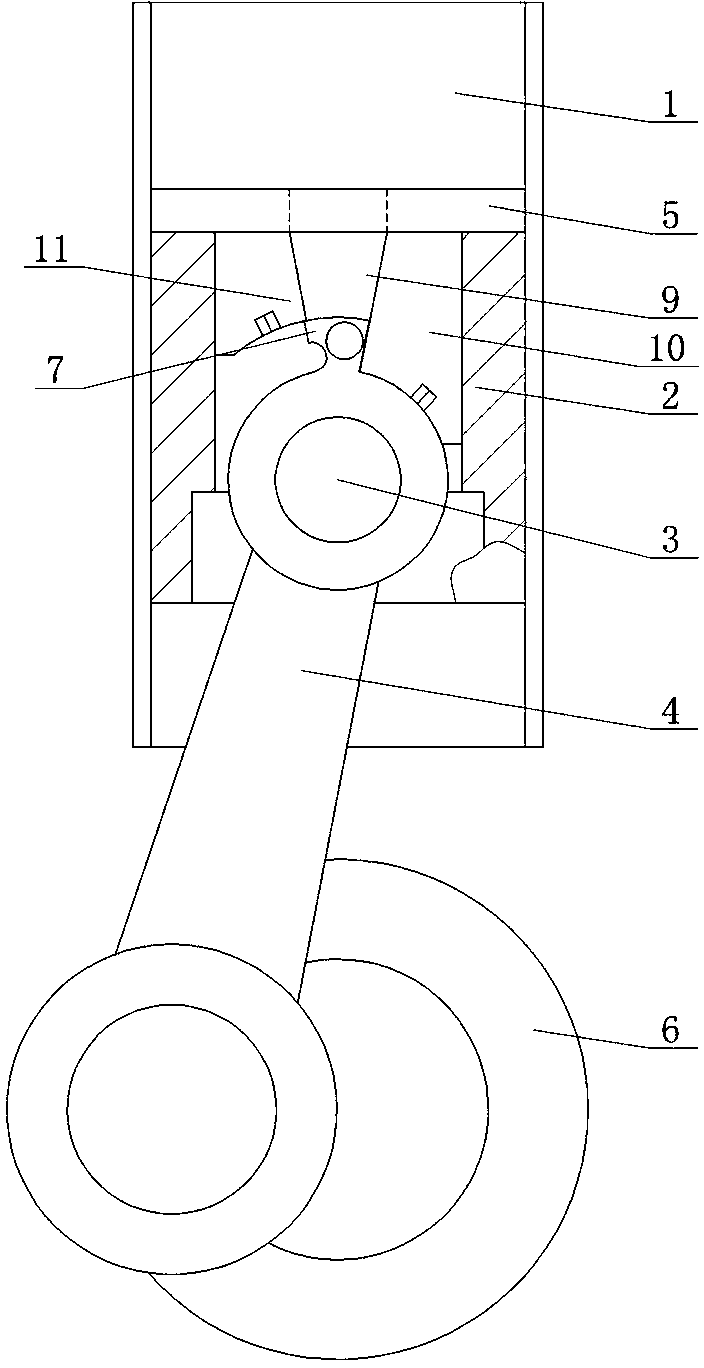

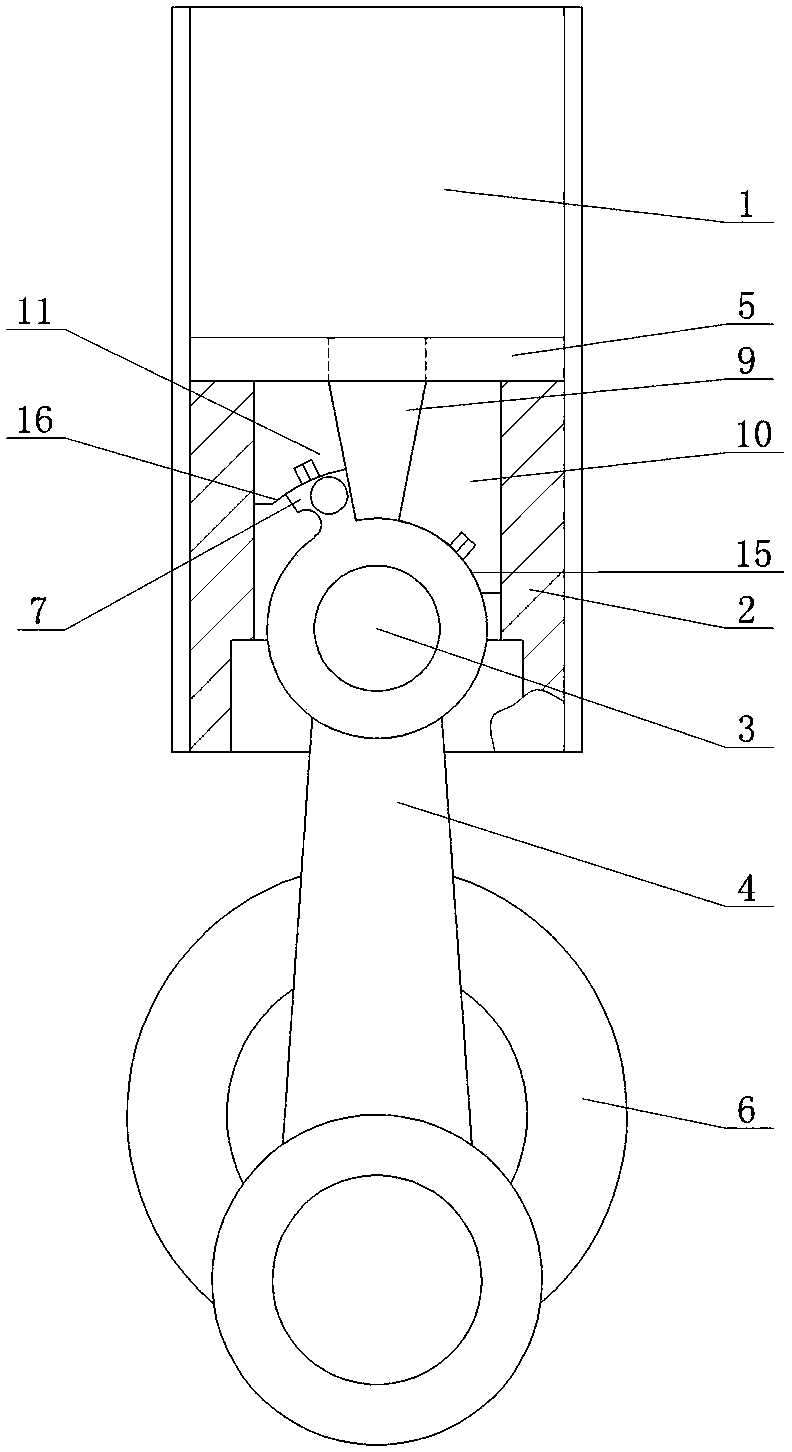

Double-piston servo connecting-rod mechanism of dead-point-free internal combustion engine

InactiveCN104265453AAvoid dead spotsEliminate dead spotsMachines/enginesEngineeringInternal combustion engine

A double-piston servo connecting-rod mechanism of a dead-point-free internal combustion engine comprises a main piston. An inner cavity is formed in the main piston along the axis direction of the same, a pin hole is formed in the main piston and perpendicular to the axis direction of the same and is communicated with the inner cavity, a pin shaft is mounted in the pin hole, an auxiliary piston is mounted in the inner cavity, two fixing plates are arranged at the lower end of the auxiliary piston side by side, a first sliding chute is formed between the two fixing plates, a guide block is arranged between the fixing plates and is located on the lower portions of the fixing plates, a space in the upper portion of the guide block is a second sliding chute, a slider is mounted in the second sliding chute, an arc groove is arranged in the slider, the guide block guides the slider, the pin shaft is connected with the upper end of a connecting rod which is hinged with the main piston through the pin shaft, the connecting rod is capable of swinging relative to the main piston by taking the pin shaft as an axis, and a single-cylinder internal combustion engine can be promoted and applied more sufficiently. The double-piston servo connecting-rod mechanism has the advantages of simple structure and convenience in manufacture.

Owner:尹建

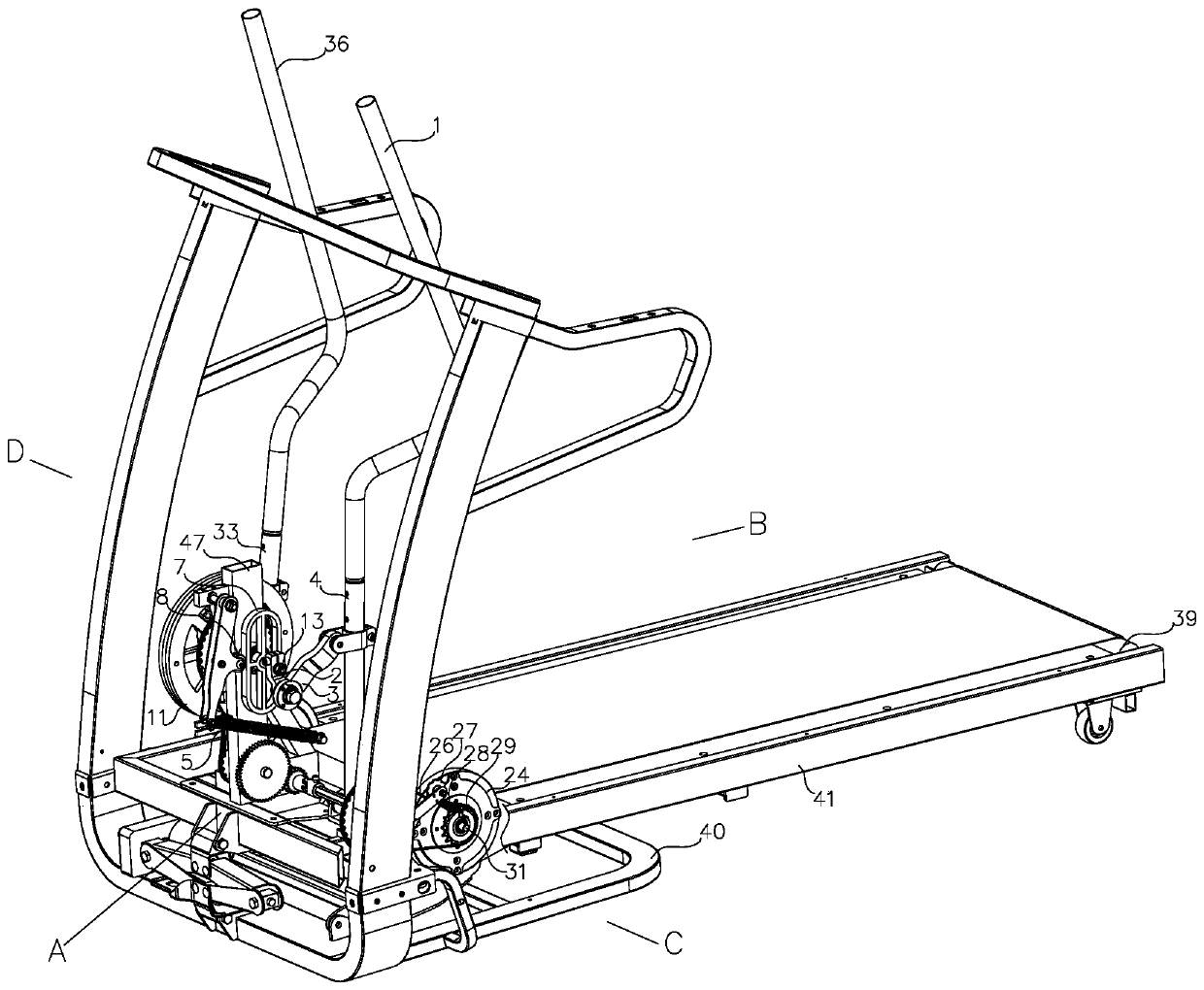

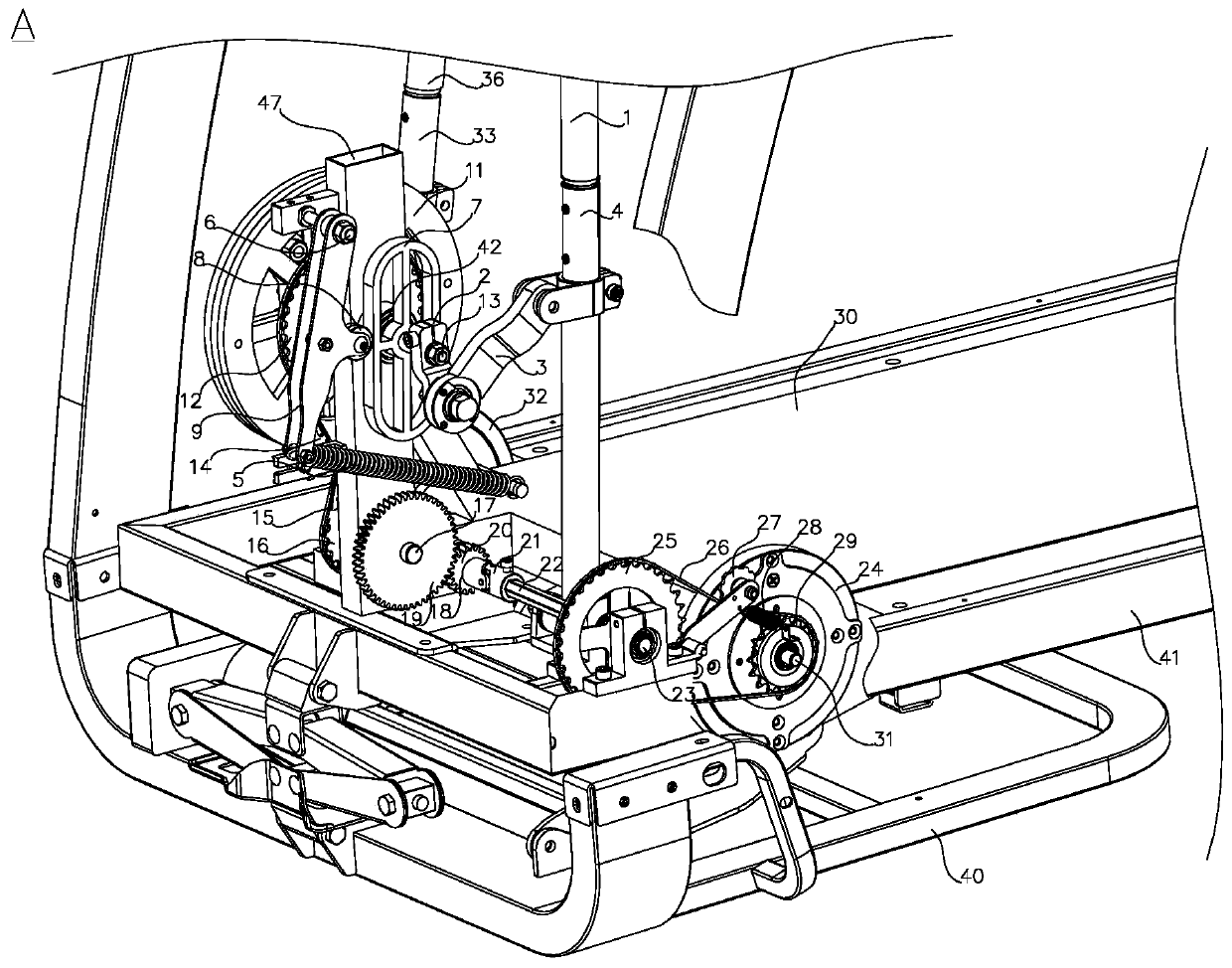

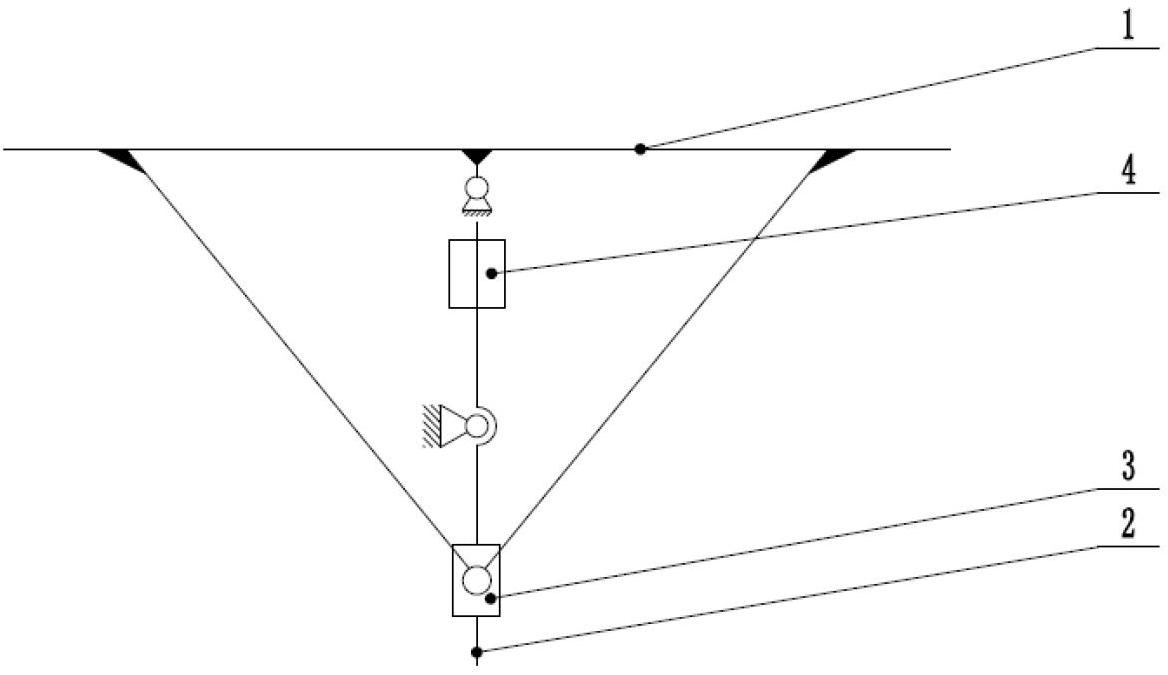

Driving mechanism depending on manpower and fitness equipment driven by manpower

ActiveCN110538422AAvoid dead spotsAvoid accidentsMovement coordination devicesCardiovascular exercising devicesReciprocating motionEngineering

The invention provides a driving mechanism depending on manpower. The driving mechanism comprises an operation part, a transmission part and an energy storage part, wherein the operation part is usedfor a user to apply driving force; the transmission part is used for transmitting driving force to a rotating shaft; the operation part performs a reciprocating motion in a certain range under the effect of the user; the transmission part is used for converting force applied by the user into driving force that the rotating shaft rotates continuously along a direction; the energy storage part is used for storing energy in the reciprocating motion process of the operation part, and the energy storage part is used for releasing energy when the operation part moves until approaching a dead point so that the energy storage part gets over the dead point. The invention also provides fitness equipment driven by manpower, and a running belt is driven to move through the driving of the hands of theuser, so that the running belt can stop instantly when an accident occurs on the user, and the possibility that a safety accident occurs on a running machine is reduced.

Owner:严辉

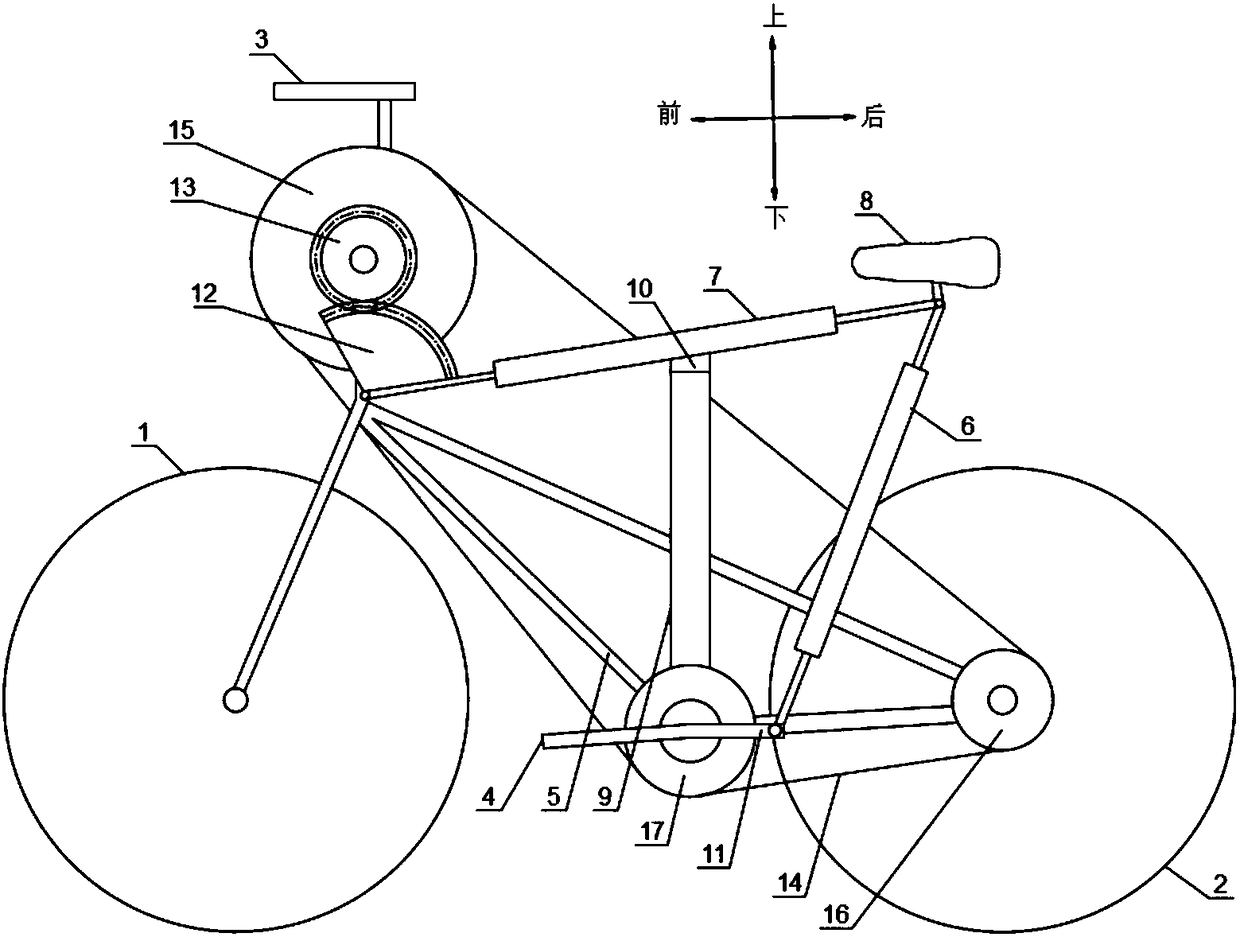

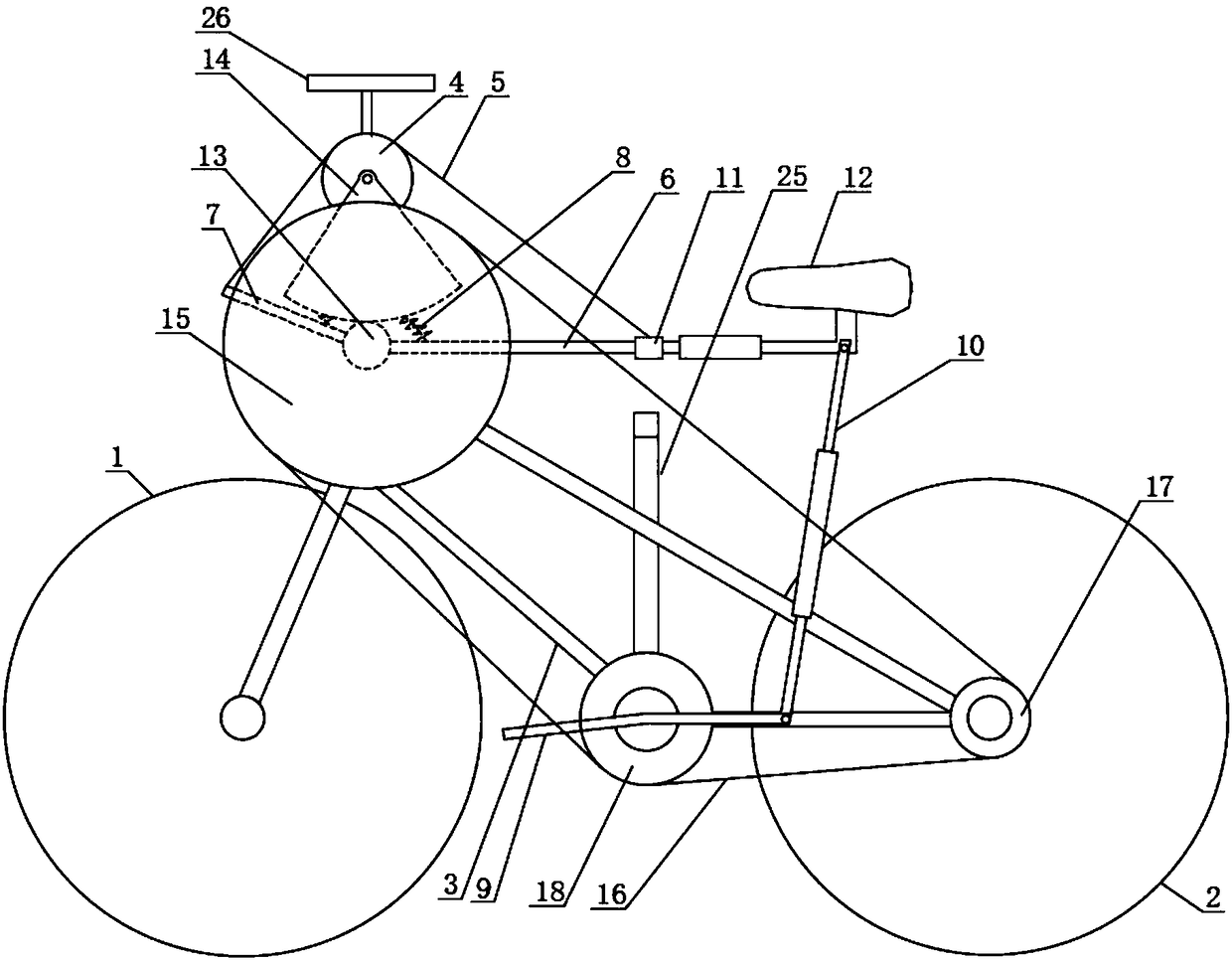

Labor-saving bicycle with adjustable speed

PendingCN108502081AChange the torqueSpeed adjustment is simple and fastChain/belt transmissionRider propulsionVehicle frameEngineering

The invention discloses a labor-saving bicycle with adjustable speed. The labor-saving bicycle with the adjustable speed comprises a front wheel assembly, a rear wheel assembly and a frame; the frontwheel assembly and the rear wheel assembly are correspondingly mounted at the front and rear ends of the frame; the labor-saving bicycle with the adjustable speed is characterized by further comprising a four-connecting-rod mechanism used for converting the deadweight of a rider into a swinging force, a chain wheel, a chain A and a transmission mechanism; the four-connecting-rod mechanism is mounted on the frame; the chain wheel is mounted on the frame in a rotatable manner and engaged with the middle part of the chain A; the chain wheel is connected with the rear wheel assembly through the transmission mechanism in a transmission manner; one end of the chain A is connected to an output connecting rod of the four-connecting-rod mechanism in a sliding manner; one end, connected with the frame, of the output connecting rod extends to form a bending part; the other end of the chain A is connected with the bending part; and a tensioner for tensioning the chain A is arranged between the bending part and the output connecting rod. According to the labor-saving bicycle with the adjustable speed, the speed can be simply and rapidly adjusted to protect physical and psychological health of the rider.

Owner:曾东斌

Reciprocating internal combustion engine without dead point

InactiveCN103850790AExtended service lifeIncreased thrust areaMachines/enginesPistonsExternal combustion engineInternal combustion engine

The invention discloses a reciprocating internal combustion engine without a dead point. The reciprocating internal combustion engine without dead point comprises a shell, a connecting rod and a crankshaft, wherein a piston cavity is arranged in the shell; a piston head is mounted in the piston cavity; a piston head is formed by connecting a piston head main body with a sealing end cover; an inner cavity and a piston pin hole are formed in the piston head main body; the inner cavity is communicated with the piston pin hole; an air inlet is formed in the center of the sealing end cover; a second sealing block and a first sealing block are arranged on the inner side of the sealing end cover; the first sealing block and the second sealing block are respectively located at two sides of the air inlet. According to the reciprocating internal combustion engine without the dead point, the about 15-25-degree dead point distance of the upper dead point position of the original internal combustion engine is utilized, the working stroke of the traditional piston is lengthened, the thrust area of the piston is increased, the power is enabled to be output when the pressure of the internal combustion engine is maximum, the working efficiency is improved, the energy consumption is reduced, and the power performance and the economy of the internal combustion engine are effectively improved.

Owner:尹建 +1

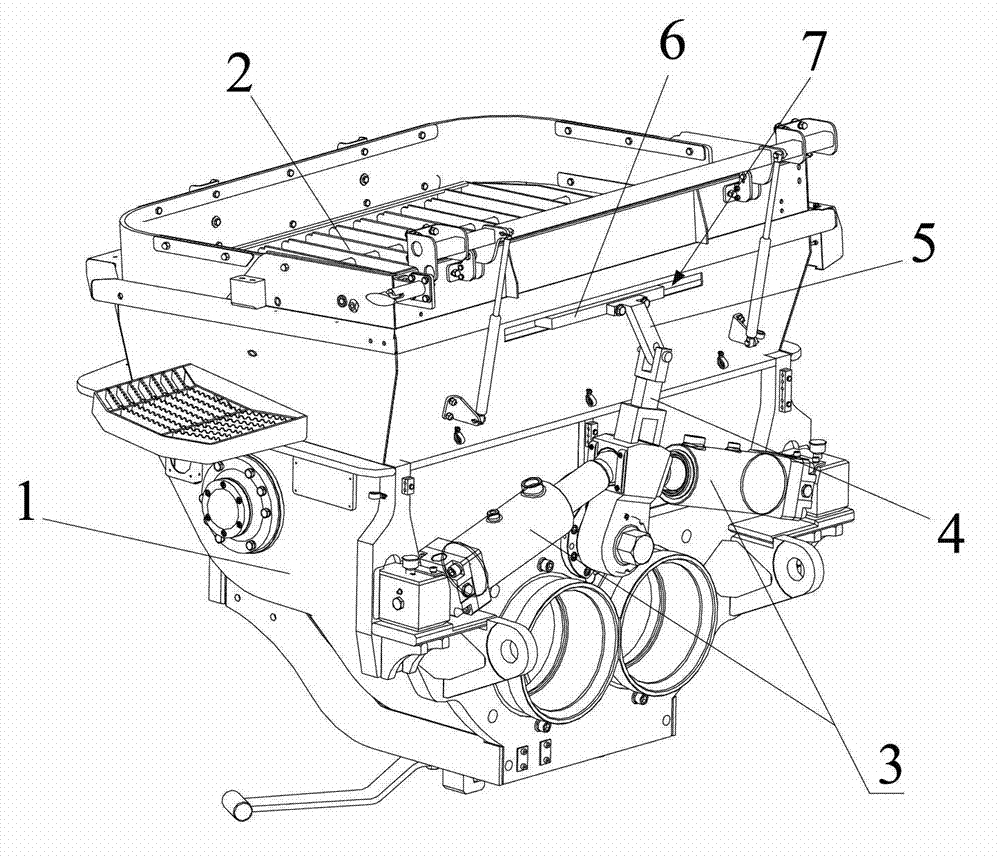

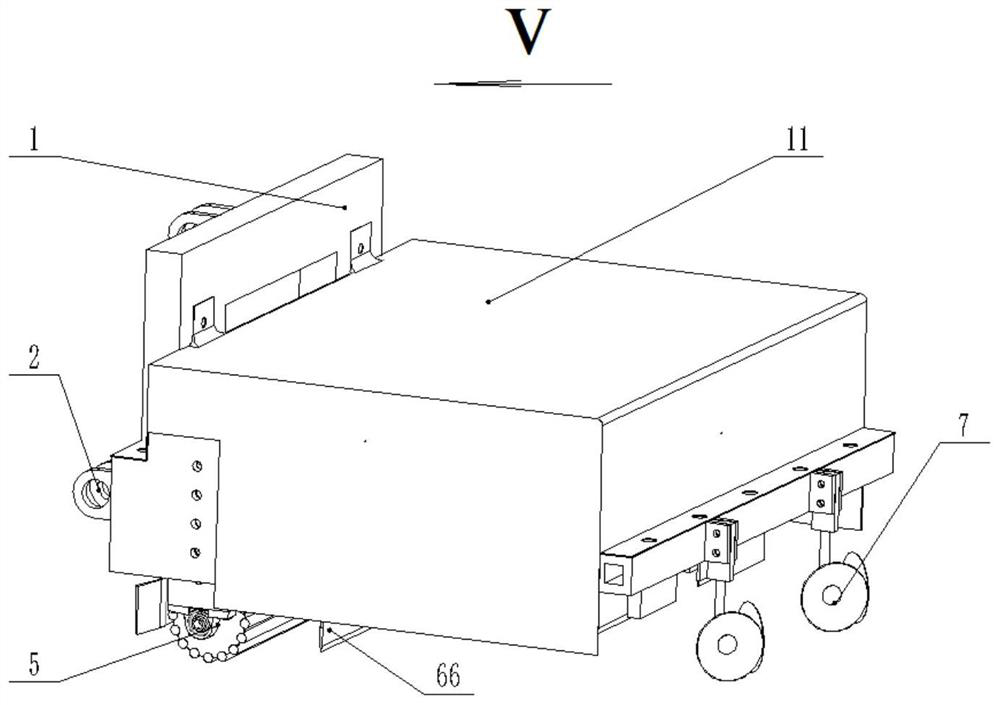

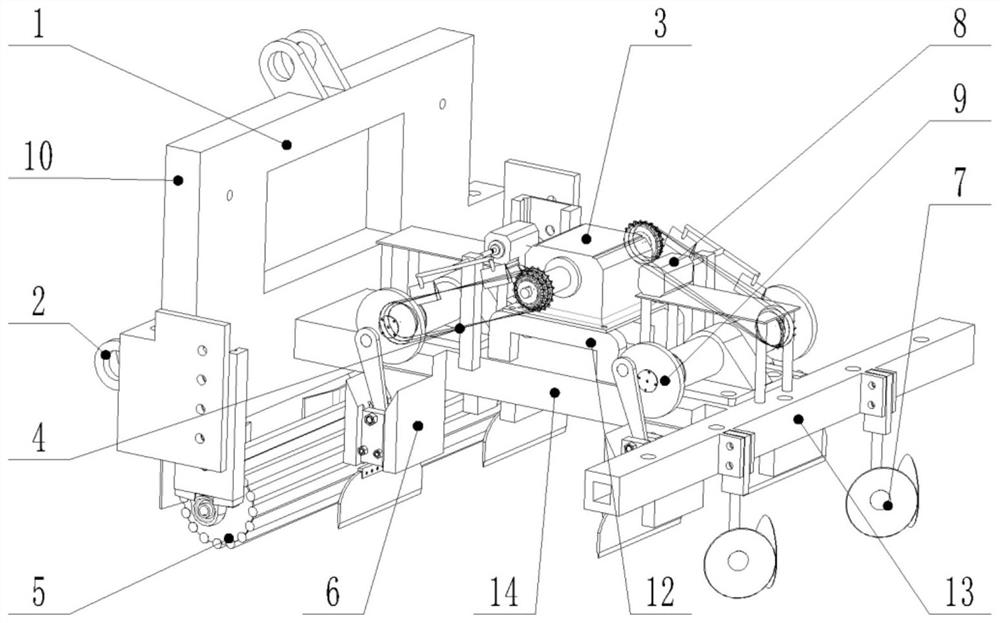

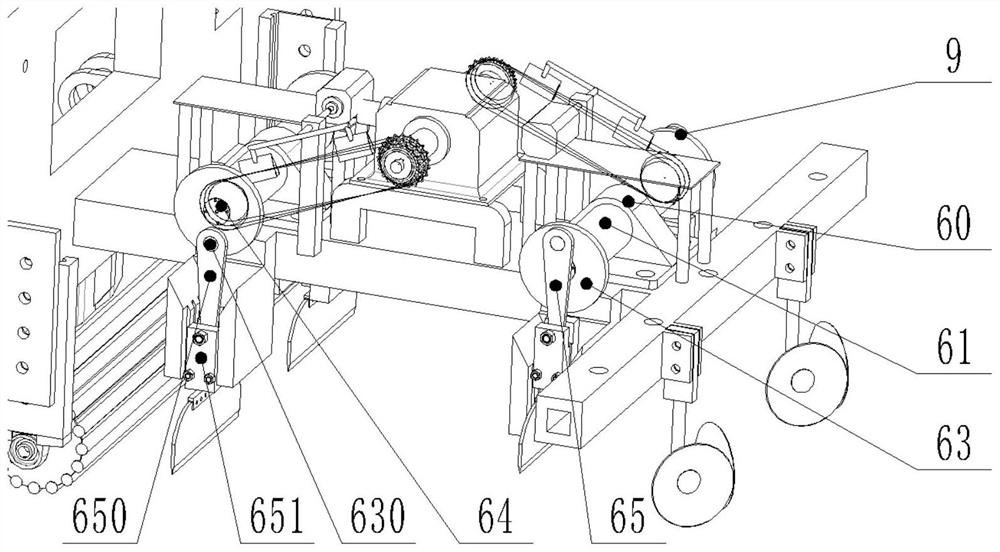

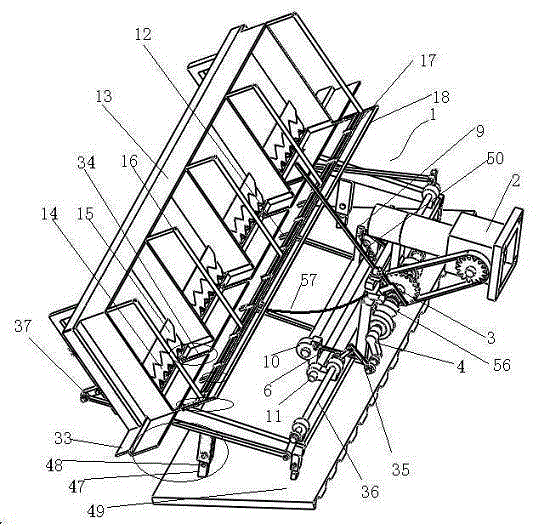

Speed-adjustable asynchronous opposite-cutting type straw smashing device

ActiveCN113711783AShorten the lengthImprove crushing efficiencyCuttersMachining vibrationsDynamic balance

The invention belongs to the field of agricultural machinery, and particularly relates to a speed-adjustable asynchronous opposite-cutting type straw smashing device which comprises a rack assembly (1), a three-point suspension device (2), a gearbox (3), a transmission assembly (4), a comb rod pressing device (5), a smashing device (6), a stubble cleaning device (7), a speed changing device (8) and a smashing device assembly (9). According to the speed-adjustable asynchronous opposite-cutting type straw smashing device, the initial phase difference between a front smashing cutter and a rear smashing cutter is 170-190 degrees, the front smashing cutter and the rear smashing cutter are in an asynchronous staggered motion mode in the working process, the length of smashed straw is effectively reduced, and the smashing efficiency is improved. The speed-adjustable asynchronous opposite-cutting type straw smashing device is arranged in a bilateral symmetry mode, dynamic balance can be achieved in the working state, machine vibration is reduced, and a chain wheel set is arranged, so that different chain wheels can be replaced conveniently to achieve the speed changing effect.

Owner:CHINA AGRI UNIV

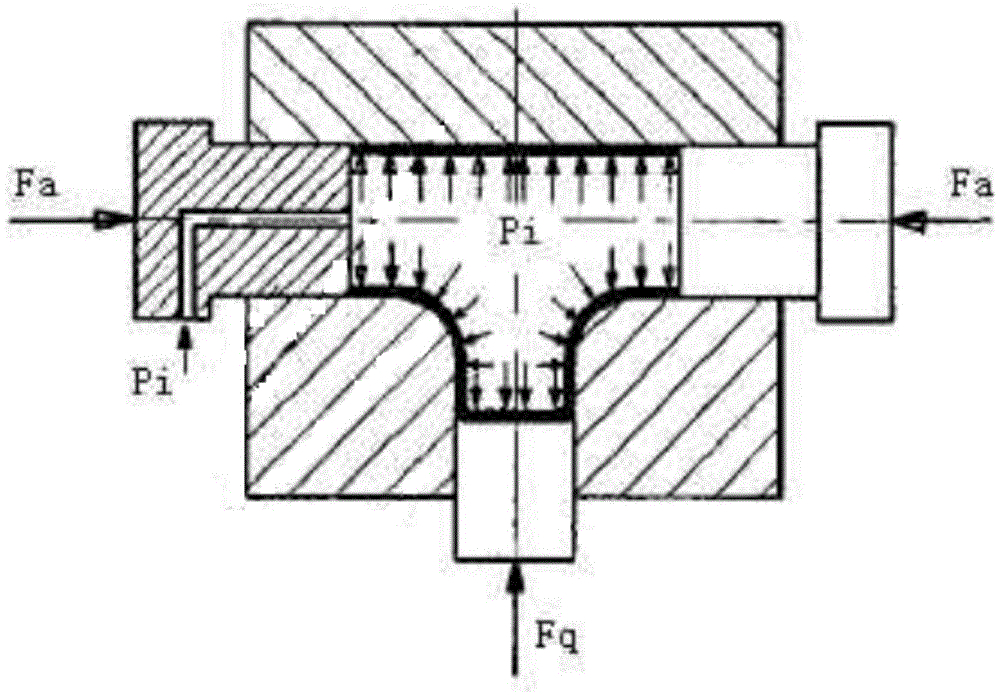

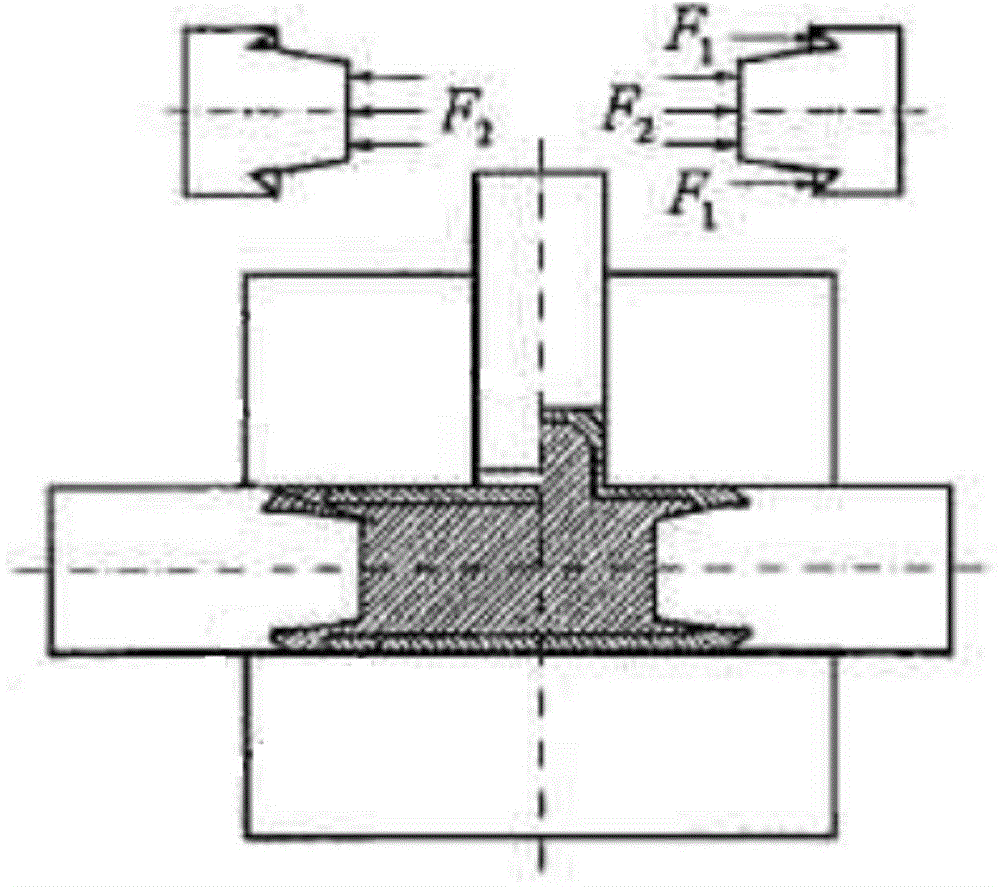

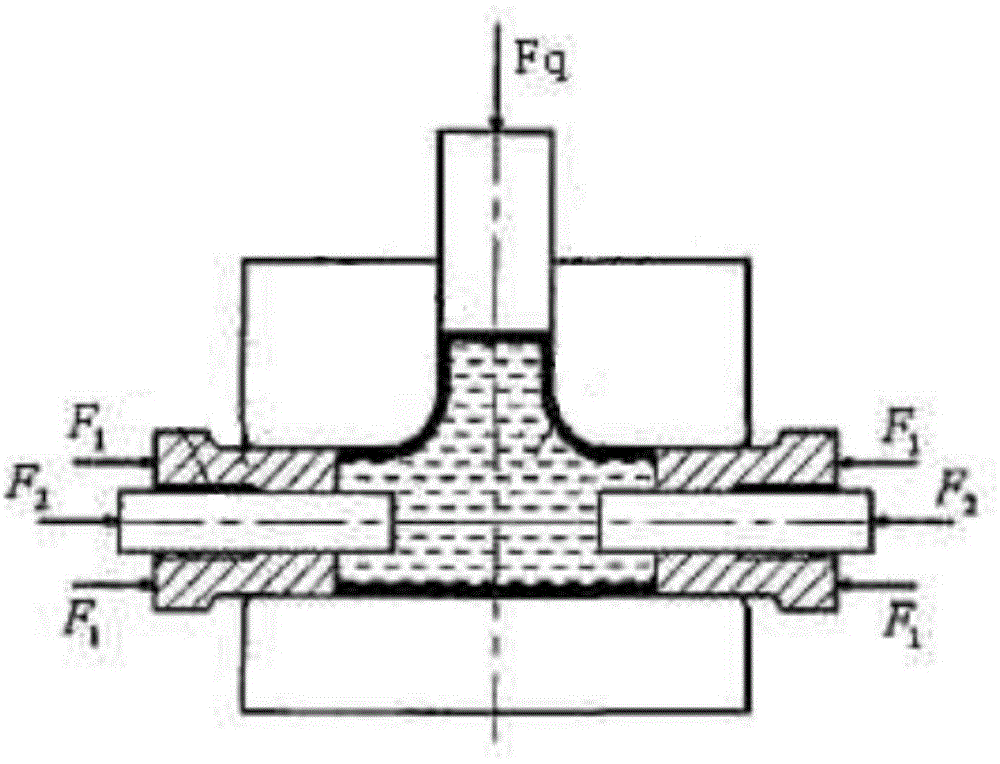

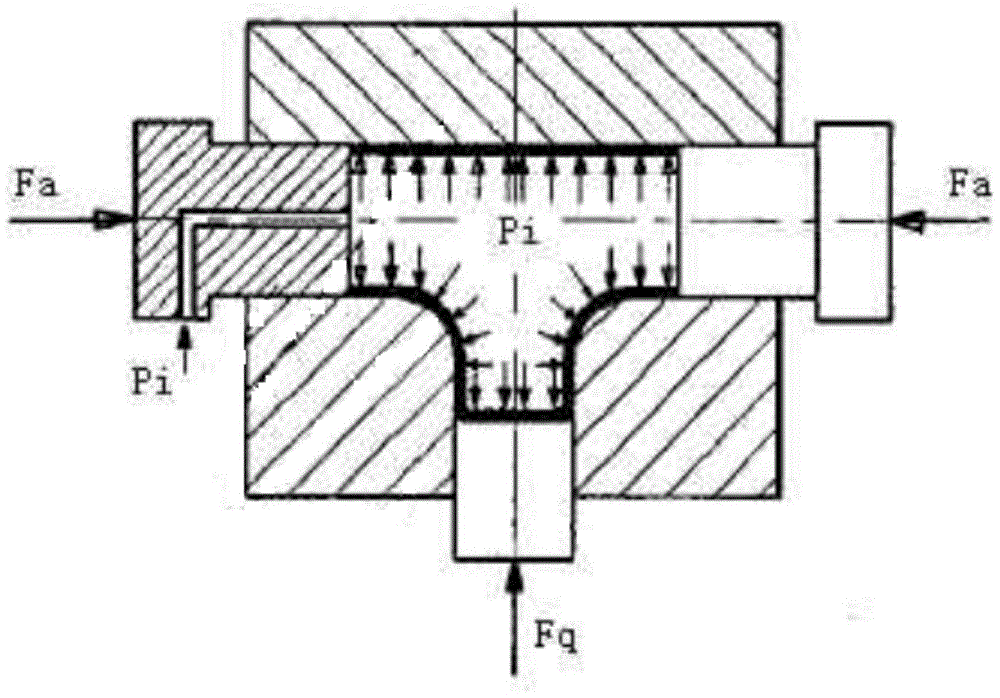

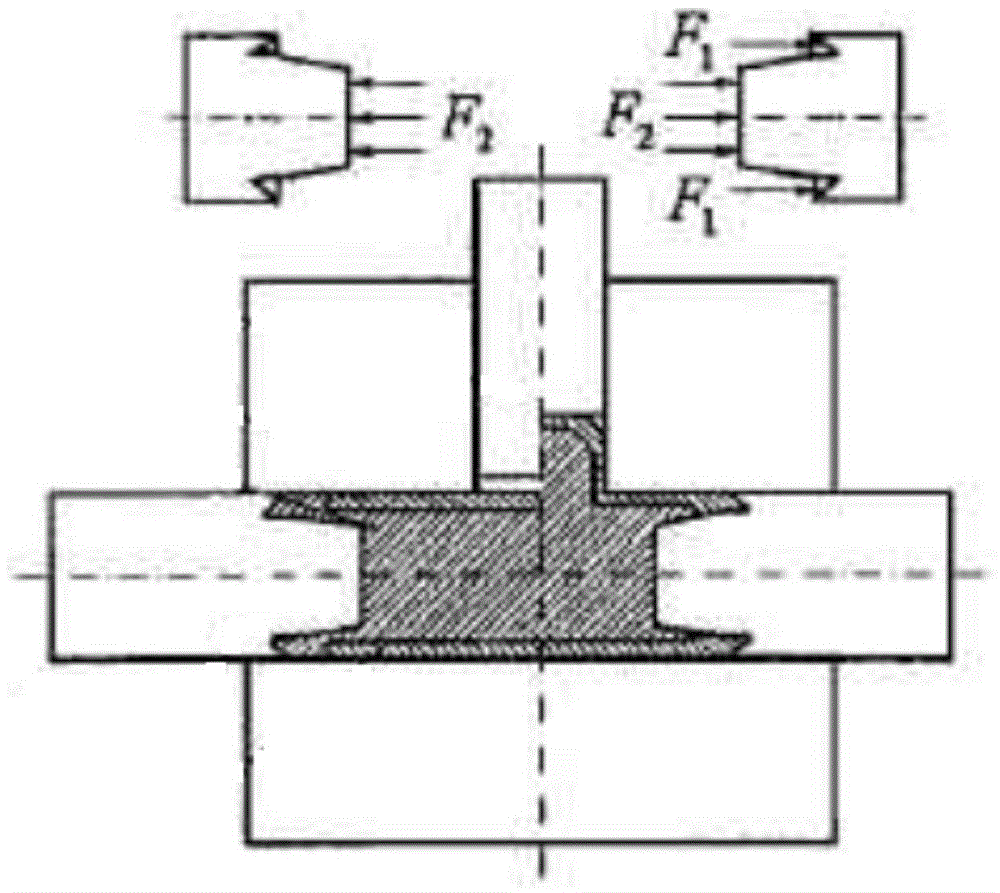

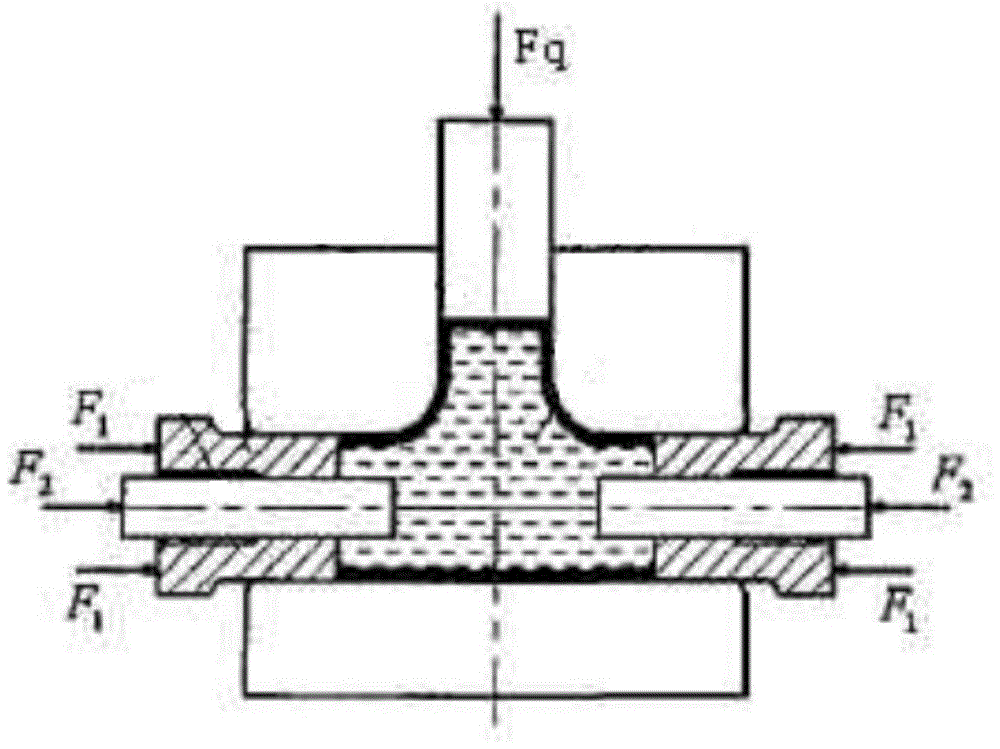

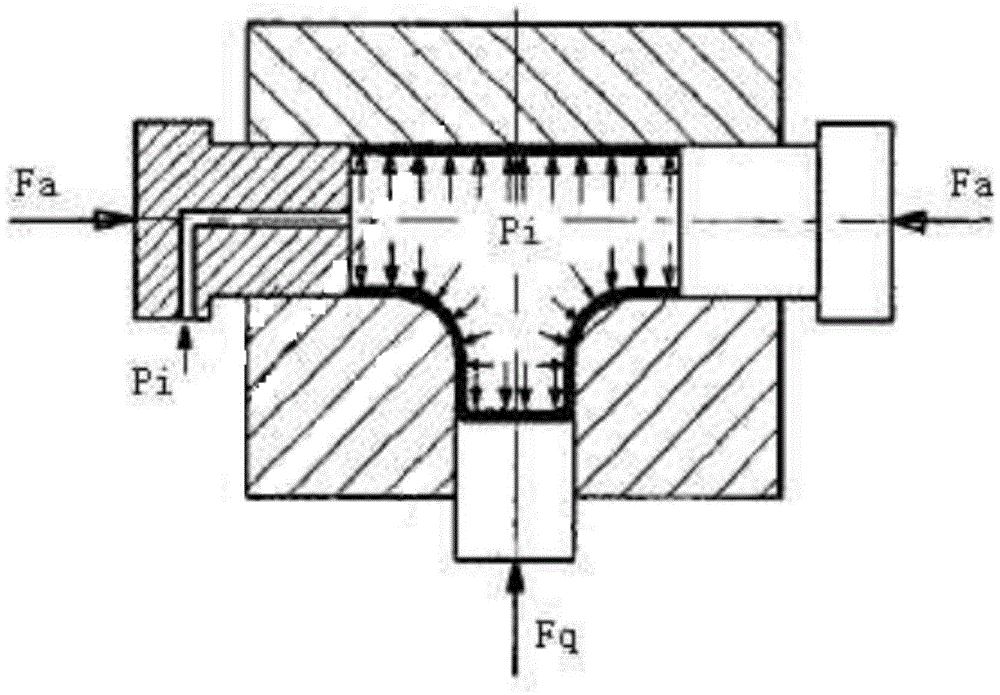

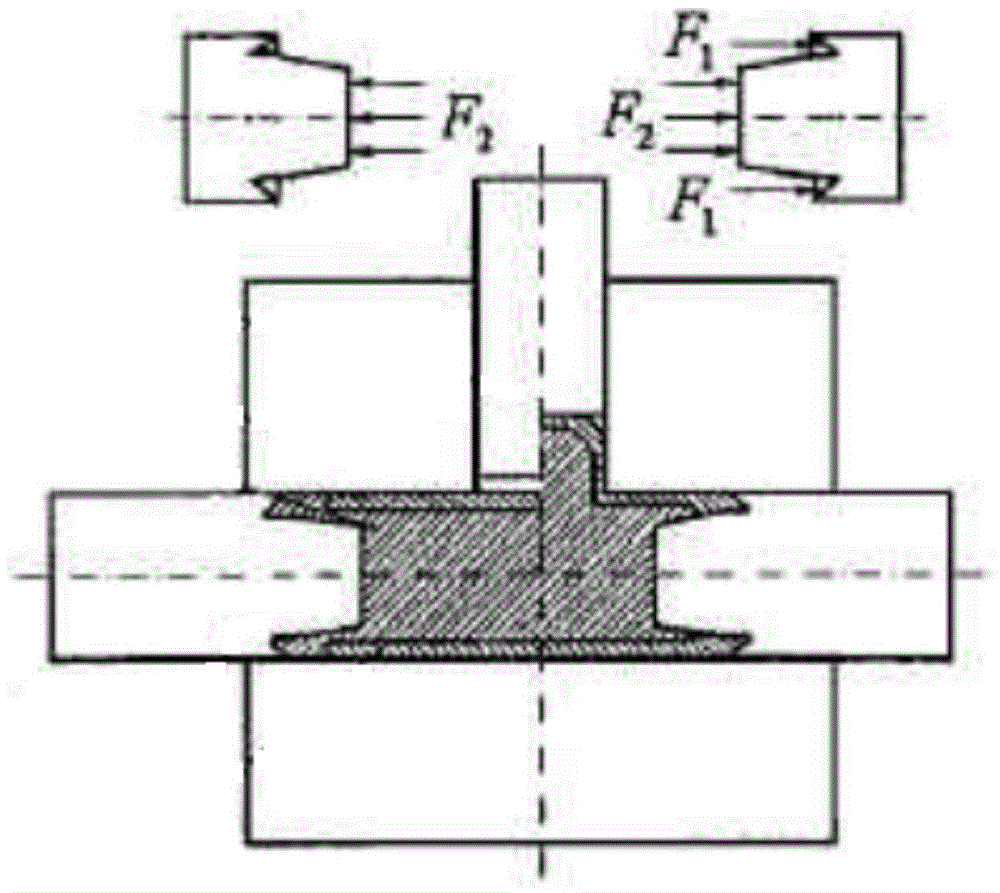

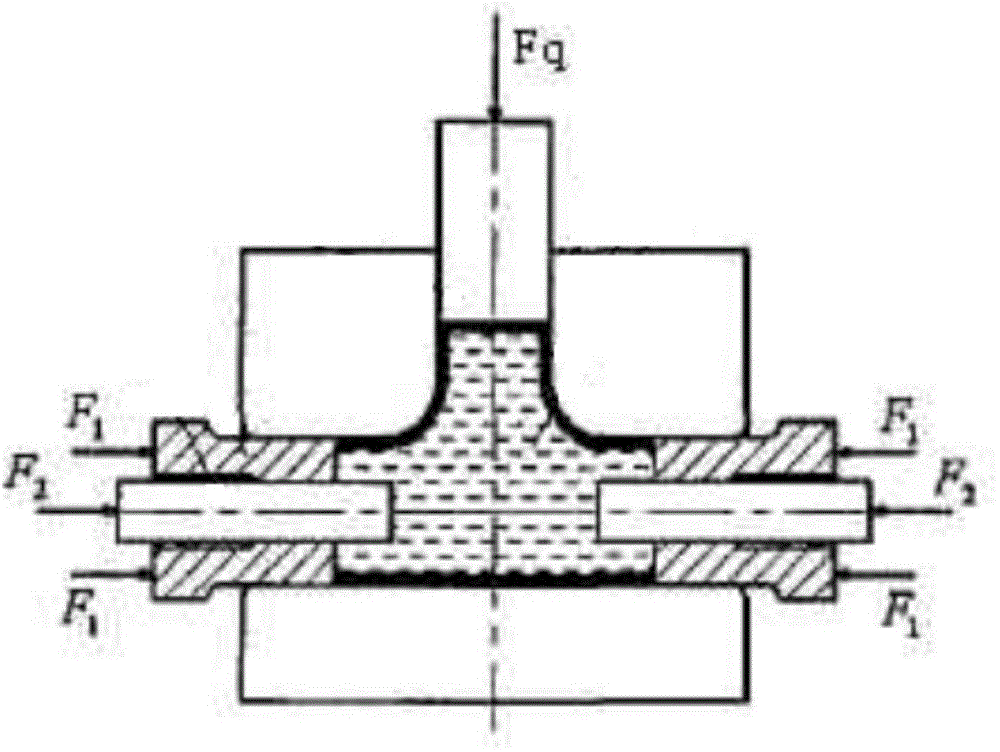

Tee-joint pipe rigid and plastic composite bulging device

The invention discloses a tee-joint pipe rigid and plastic composite bulging device. The tee-joint pipe rigid and plastic composite bulging device comprises an upper half die and a lower half die. A forming cavity is formed between the upper half die and the lower half die. Bulging extrusion punches are arranged at the two ends of the forming cavity respectively. The lower half die is provided with an axis branch pipe forming cavity. A balance punch is arranged in the branch pipe forming cavity. A rigid bulging inner die is arranged between the two bulging extrusion punches. The rigid bulging inner die comprises push rods located at the two ends respectively. A forming inner die block which is matched with the branch pipe forming cavity and used for driving a pipe blank for bulging deformation is arranged between the two push rods. The forming inner die block is connected with the two push rods through double hinged connecting rods. Connecting grooves facing an opening of the branch pipe forming cavity are formed in the opposite ends of the two push rods, and limiting structures are arranged in the connecting grooves. The push rods are arranged in the corresponding bulging extrusion punches in a sliding fit manner respectively. One push rod is provided with a rapid dismounting connecting structure. Push force devices are arranged at the two ends of the forming cavity respectively and comprise composite hydraulic cylinders.

Owner:XINCHANG HANGDA MACHINERY MFG

Device and method for preparing biodiesel through rotary fixed bed fast reaction

ActiveCN105713734AAvoid the uneven distribution of rotation and centrifugal forceAvoid uneven distributionFatty acid esterificationBiofuelsAlcoholCentrifugation

The invention provides a device and method for preparing biodiesel through a rotary fixed bed fast reaction. The device is mainly composed of a fixed bed reactor with a rotary shaft (9). Firstly, the fixed bed reactor filled with a solid catalyst is added to reactant methyl alcohol, and meanwhile a motor (12) is started to enable a reaction still to rotate. The dropping speed of raw material oil is controlled, and the oil and excessive methyl alcohol are subjected to the fast reaction. The contact chance of the reactant and the catalyst can be increased through rotating, more active point locations can be occupied, and sinking and separation of fatty acid methyl ester can be promoted. By means of a liquid redistributor, the phenomenon that liquid is unevenly distributed due to rotary centrifugation is avoided. The layering condition of sight glass (21) is observed, and products are removed in time. A forward reversible reaction can be accelerated through excessive methyl alcohol, timely removal of the products and the rotary reaction still. The advantages of being easy to operate, high in raw material utilization rate, high in esterification efficiency and the like are achieved, and the device and method can be used for fast and continuous preparation of the biodiesel.

Owner:SHANDONG UNIV OF TECH

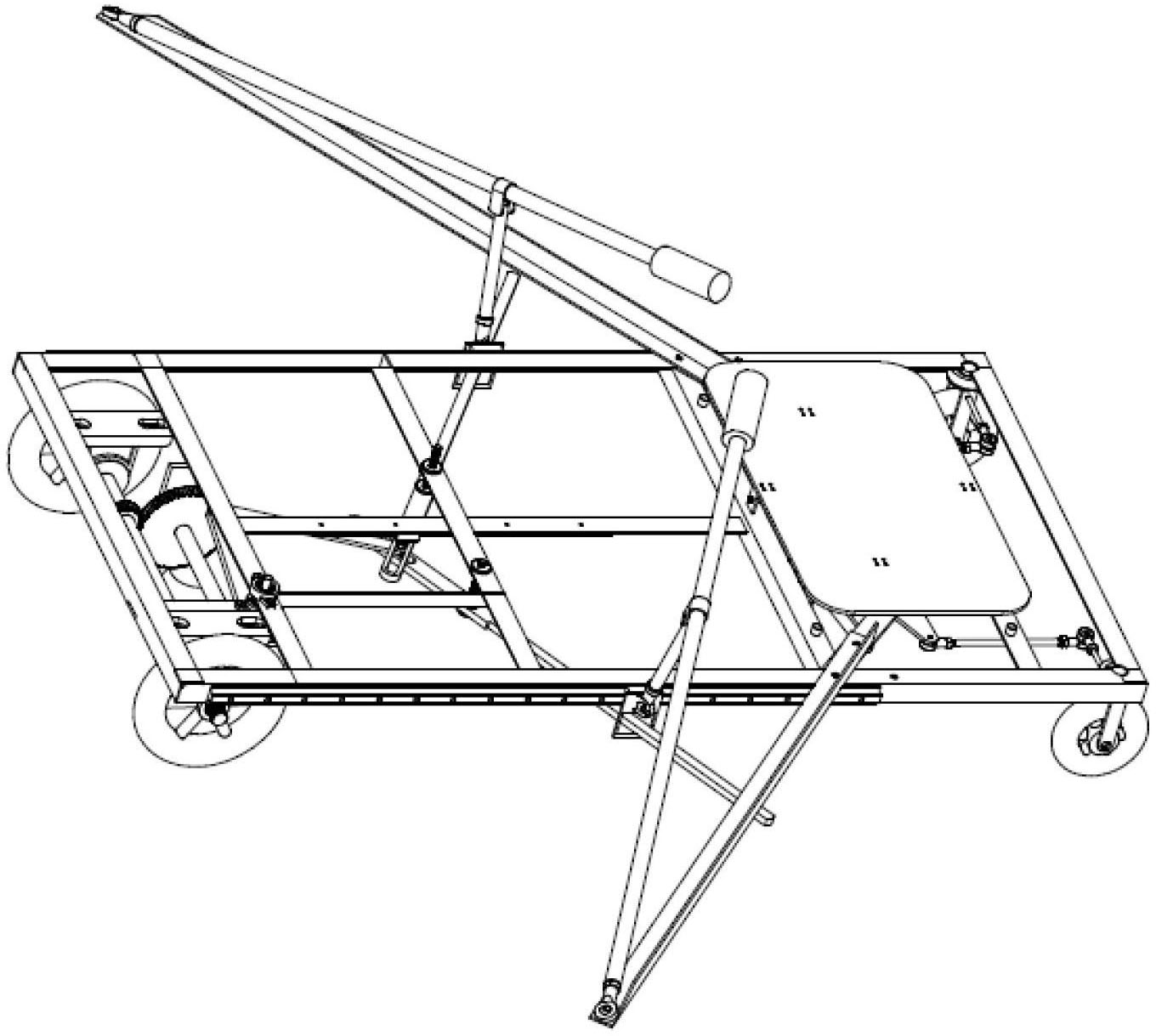

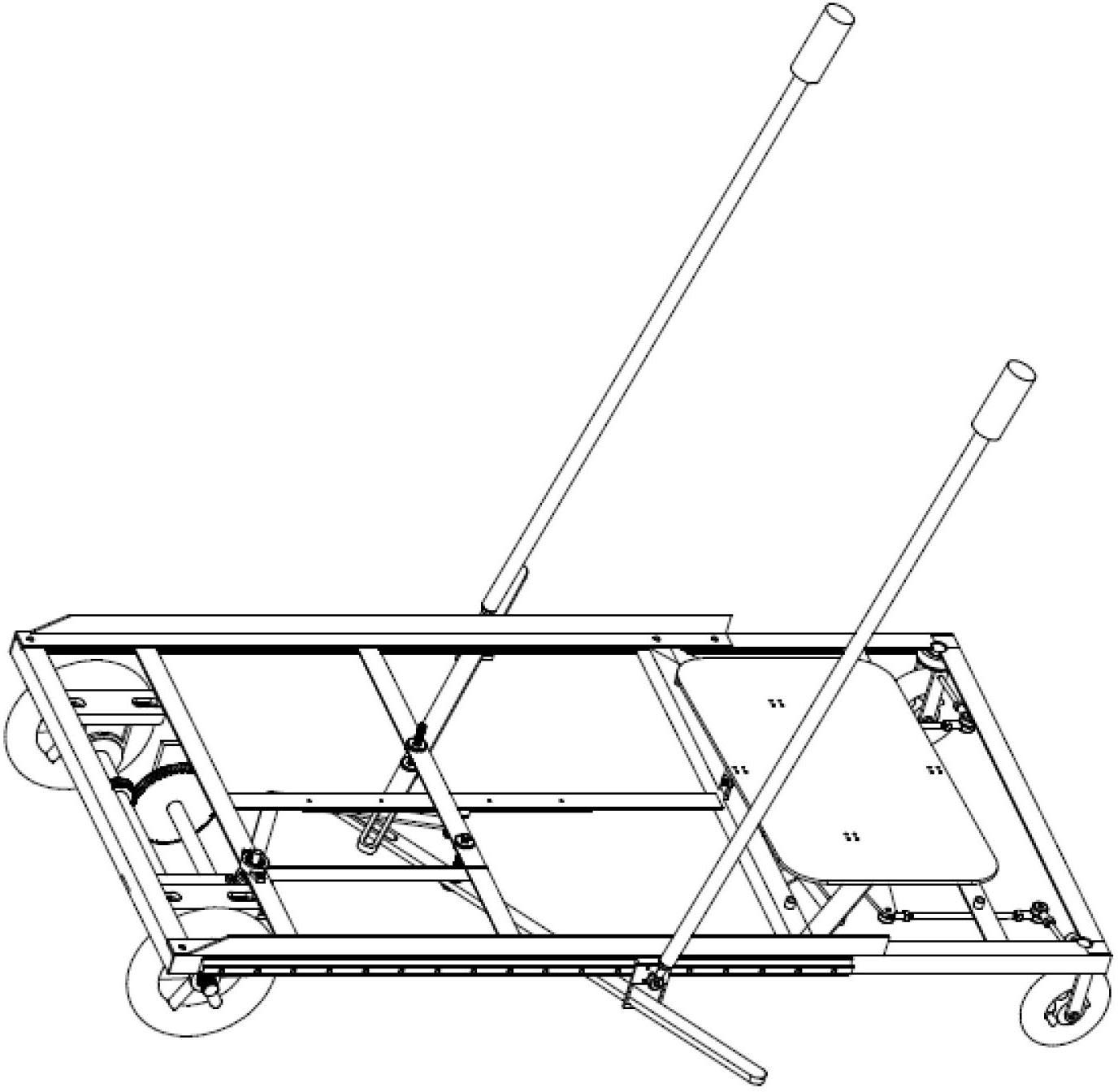

Integrated skiing and rowing simulated motion purely mechanical multifunctional recreational vehicle

InactiveCN102673728AIn line with basic habitsIncrease authenticityRider propulsionReciprocating motionGravity center

The invention discloses an integrated skiing and rowing simulated motion purely mechanical multifunctional recreational vehicle which comprises a vehicle body, a steering module, auxiliary modules and an advancing drive module, wherein the front end of the vehicle body is connected with the steering module, the rear end of the vehicle body is connected with the advancing drive module, and the auxiliary modules are respectively arranged at both sides of the vehicle body. The vehicle realizes the simulation of two motions of skiing and rowing under simple variation; the vehicle is driven by manpower to advance and steered by the centrobaric offset or angle motion, so the real experience of maintaining balance during the skiing and rowing is realized; a lever is additionally arranged on an original connecting rod steering mechanism to be connected with a steering pedal, so the centrobaric offset direction is consistent with the steering direction; a drive mechanism adopts a rocker and sliding block mechanism, so linear reciprocating motion is converted into rotary motion, the power is output, dead points are avoided, and the operation stroke is not limited; and the recreational vehicle is used without geographical limitations, and has a wide popularization scope.

Owner:吉林艾瑞环保技术有限公司

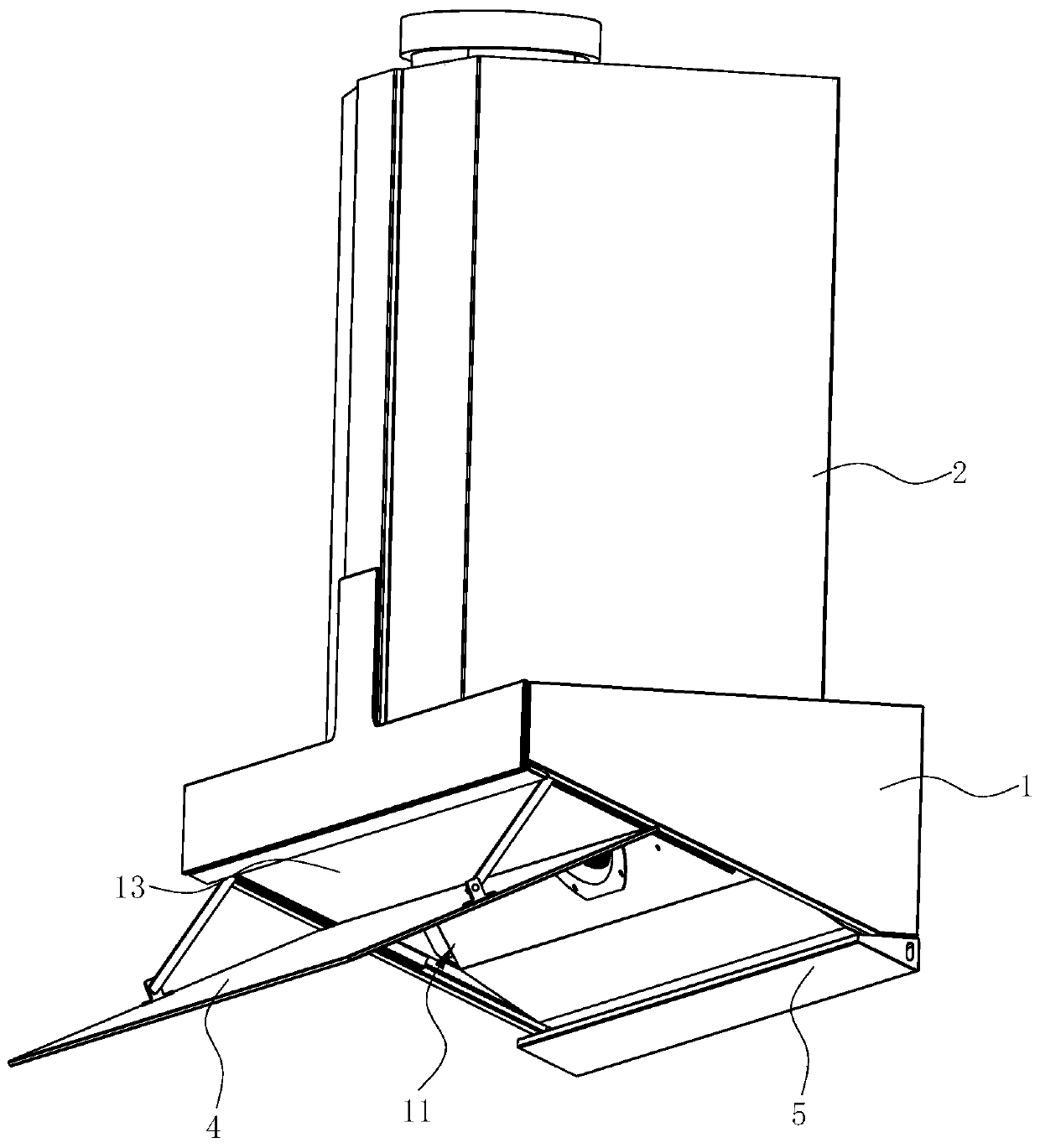

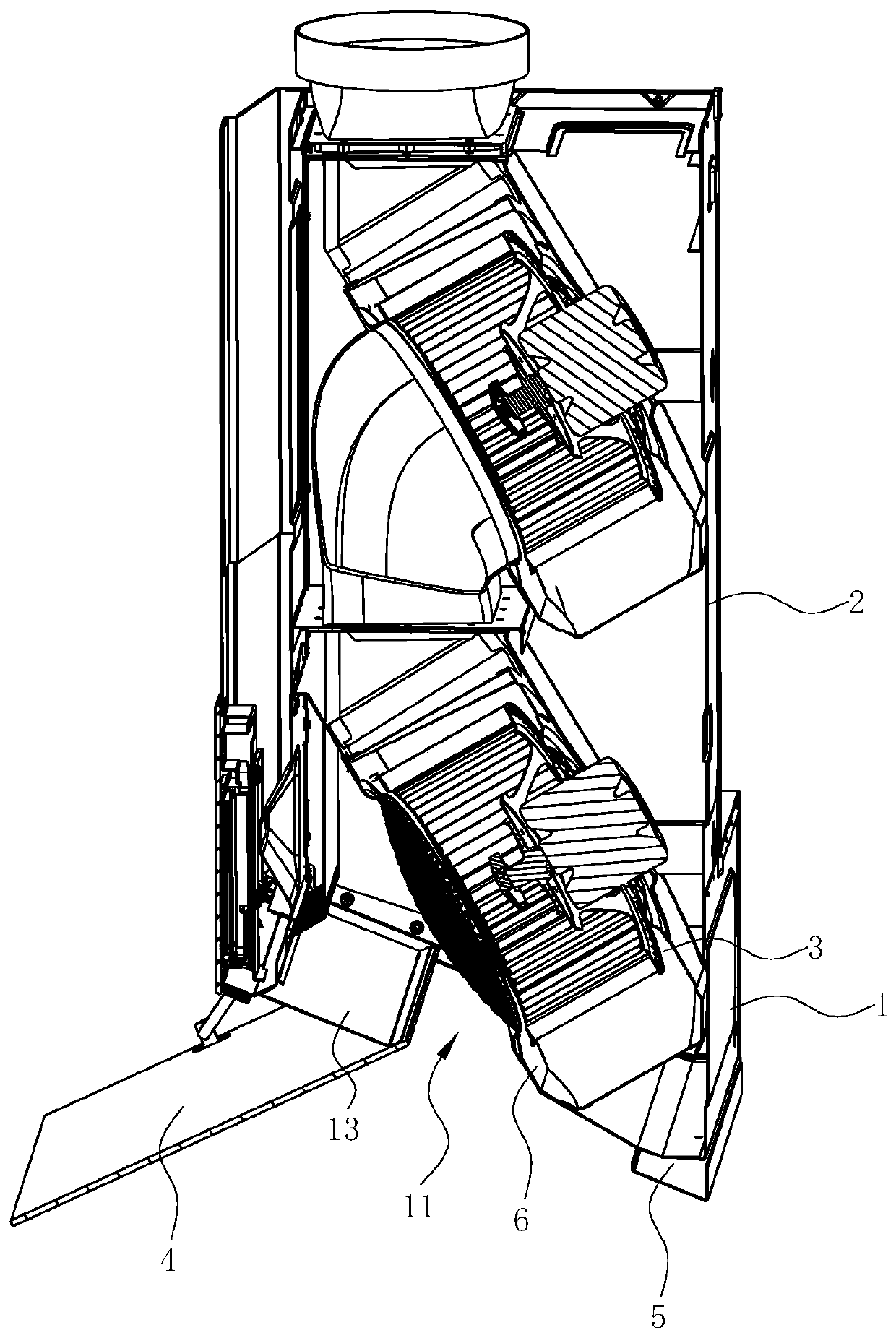

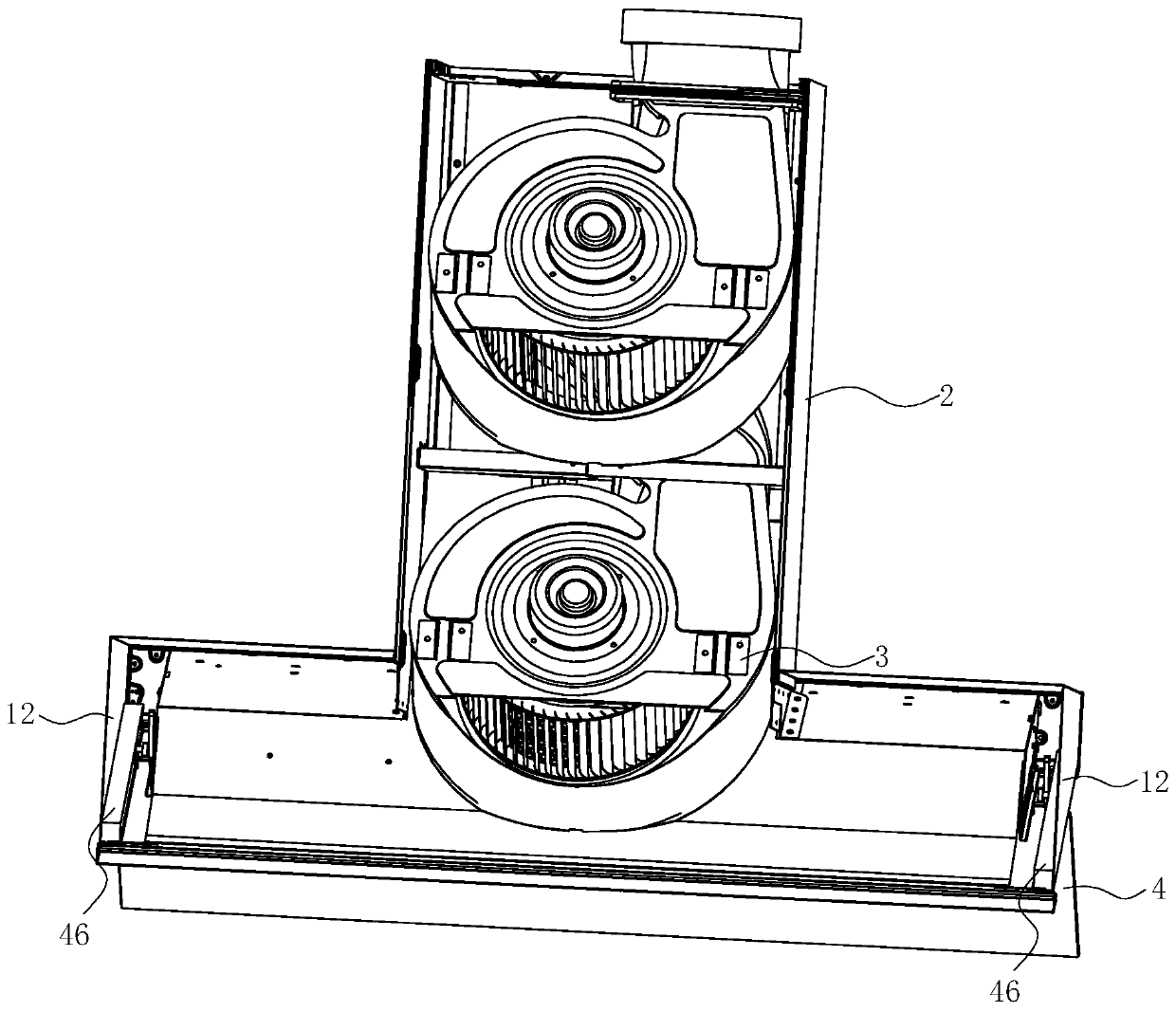

Range hood

ActiveCN110375358AOpen smoothlyGuaranteed to workDomestic stoves or rangesLighting and heating apparatusEngineeringLinear drive

The invention discloses a range hood which comprises a case and an oil cup arranged at the bottom of the rear side of the case, wherein an air inlet is formed in the case; a smoke deflector capable ofopening or closing the air inlet in an overturning manner is arranged at the air inlet of the case; the rear end of the smoke deflector extends above the oil cup; the range hood further comprises a moving mechanism capable of driving the smoke deflector to overturn; the moving mechanism comprises a linear driving module and a transmission mechanism; the transmission mechanism comprises a rockingbar and a sliding block; the sliding block is driven by the linear driving module to move in the front-and-back direction; one end of the rocking bar and the case are relatively fixed in position; theother end of the rocking bar is hinged to the smoke deflector; the sliding block is hinged to the smoke deflector; and the hinge joint part of the rocking bar and the smoke deflector is positioned onthe front side of the hinge joint part of the sliding block and the smoke deflector. Compared with the prior art, the range hood has the following advantages: through reasonably arranging the movingmechanism, the lower end of the smoke deflector overturns from bottom up when the smoke deflector is opened, so that interference between the smoke deflector and the oil cup is avoided to ensure normal operation of the smoke deflector.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

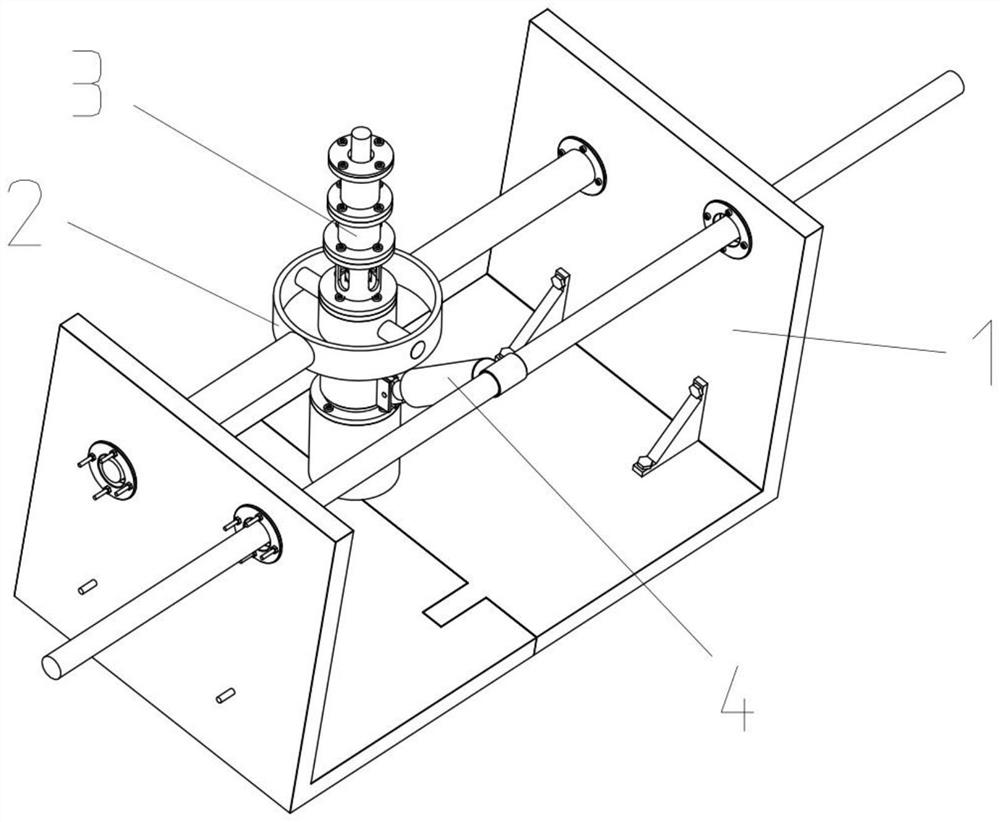

Tilt rotor testing device

ActiveCN114166496ARealize multi-degree-of-freedom rotationTilt controlMachine part testingSustainable transportationClassical mechanicsEngineering

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

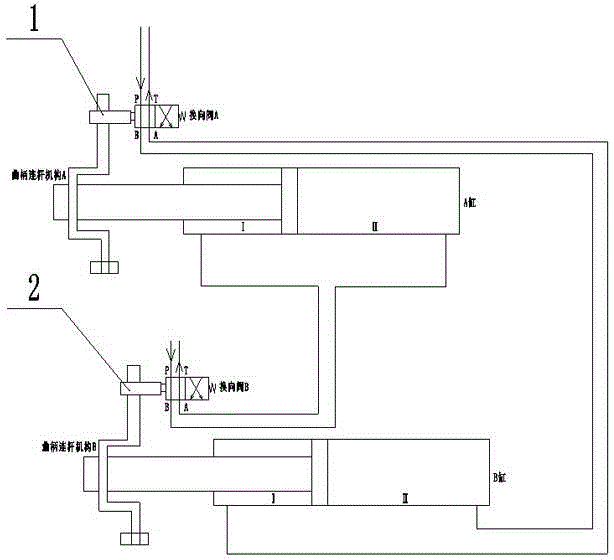

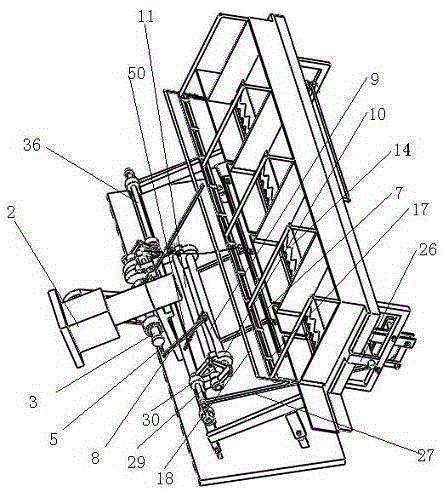

Mechanism for realizing automatic reversing through a distributing slide valve

InactiveCN103982483ATo achieve the purpose of reversingImprove stabilityServomotor componentsHydraulic cylinderEmulsion

The invention discloses a mechanism for realizing automatic reversing through a distributing slide valve, belongs to the technical field of oil cylinder automatic reversing, and aims to solve the technical problem by providing the mechanism for realizing automatic reversing through the distributing slide valve by adopting variant control and utilizing a crank and connecting rod mechanism to make the reciprocating movement into the rotating movement of a crank, so as to drive cams to rotate and enable the cams to drive reversing valves to reverse, as a result the reciprocating movement of each hydraulic cylinder piston is controlled and a dead point is prevented from being produced. The mechanism for realizing automatic reversing through the distributing slide valve adopts the technical scheme for solving the technical problem that the piston rods of cylinders A and B are connected with the connecting rods of crank and connecting rod mechanisms A and B; the ends of cranks of the crank and connecting rod mechanisms A and B are provided with a first cam and a second cam respectively; the working ports of the reversing valves A and B are communicated with the cavity I and the cavity II of the cylinder B and the cylinder A through emulsion pipelines. The mechanism for realizing automatic reversing through the distributing slide valve can be widely applied to the field of oil cylinder automatic reversing.

Owner:CHINA KIST VALVE GRP

Rigid-plastic compound multi-cylinder latch-type bulging device for three-way pipe

The invention discloses a rigid-plastic compound multi-cylinder latch-type bulging device for a three-way pipe. The device comprises an upper semi mold and a lower semi mold, wherein a forming cavity is formed between the upper semi mold and the lower semi mold; bulging extrusion punches are installed at two ends of the forming cavity respectively; a branch pipe forming cavity is formed in the lower semi cavity; a balancing punch is installed inside the branch pipe forming cavity; a rigid bulging inner mold is arranged between two bulging extrusion punches and comprises pushing rods located at two ends respectively; a forming inner mold block is arranged between two pushing rods; the forming inner mold block is connected with two pushing rods through double-hinge connecting rods; two connecting grooves facing towards the opening of the branch pipe forming cavity are formed in opposite ends of two pushing rods respectively; limiting structures are arrange in the connecting grooves; each pushing rod is installed inside corresponding bulging extrusion punch in a sliding fit mode, and a latch-type quick disassembly connection structure is arranged on one of the pushing rods; thrust devices are arranged at two ends of the forming cavity respectively; each thrust device comprises extrusion hydraulic cylinders and a central hydraulic cylinder; and at least three extrusion hydraulic cylinders distributed annularly and uniformly are arranged.

Owner:XINCHANG HANGDA MACHINERY MFG

Method for retaining freshness of boiled salted duck based on electronic beam radiation

ActiveCN102986823APrevent leakageSave labor costsMeat/fish preservation by irradiation/electric treatmentBiotechnologyRadiation Dosages

The invention discloses a method for retaining freshness of a boiled salted duck based on electronic beam radiation. The method is characterized by comprising the following steps of: 1, processing a boiled salted duck semi-finished product by the conventional boiled salted duck production line, and splitting the boiled salted duck along the spinal column or the belly; then performing vacuum packaging; putting the vacuum packaged boiled salted duck into an electronic beam radiation device, and fixing the boiled salted duck, wherein the total thickness of the boiled salted duck is not more than 3.85cm; performing electronic beam radiation processing, wherein the energy is 10 Mev, the beam power is not less than 10 kW, and the radiation time is controlled to be shorter than 3 seconds, the radiation dosage is 3.5 to 4.55 Gy, and the absorption amount non-uniformity is less than 1.3; and bagging and storing. By the method, the boiled salted duck does not need to turn around during radiation, so that leakage radiation is prevented, and labor cost is reduced; and the fresh time is longer than 6 months.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

Rice transplanter

The invention provides a rice transplanter. The rice transplanter comprises a rack, wherein a power input box is arranged on the rack and connected with a rotating shaft in a chain transmission manner; a rocker A and a rocker B are respectively arranged at the two ends of the rotating shaft; the rocker A is connected with one side of a seedling claw carrier through a connecting rod E; the rocker B is connected with a vertical rod on the seedling claw carrier through a connecting rod F; bearing pedestals are respectively mounted at the two ends of the seedling claw carrier and fixed on a driving shaft B on the rack; the seedling claw carrier is provided with seedling taking claws; the rotating shaft drives the seedling taking claws to grab seedlings in a seedling box and insert the seedlings into soil; the seedling box reciprocates along a track on the rack; seedling taking openings are formed in the track; reciprocating seedling stirring sheets are arranged in the seedling box; a layer of seedling stop plate is arranged above and below the seedling stirring sheets in the seeding box respectively; seedling gathering racks are arranged on the open side of the seedling box; seedling limiting blocks are arranged on the lower frameworks of the seedling gathering racks; seedling supporting subframes extend from the outer sides of the lower frameworks of the seedling gathering racks.

Owner:SUQIAN CHANGFENG MACHINERY CO LTD

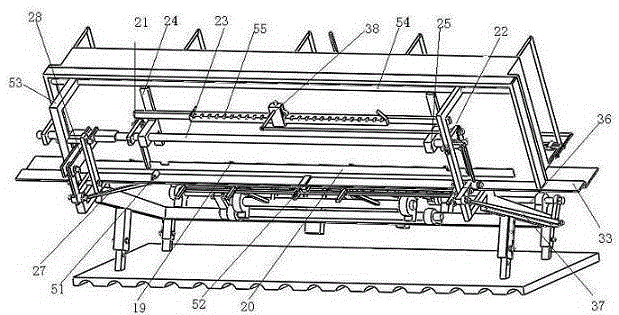

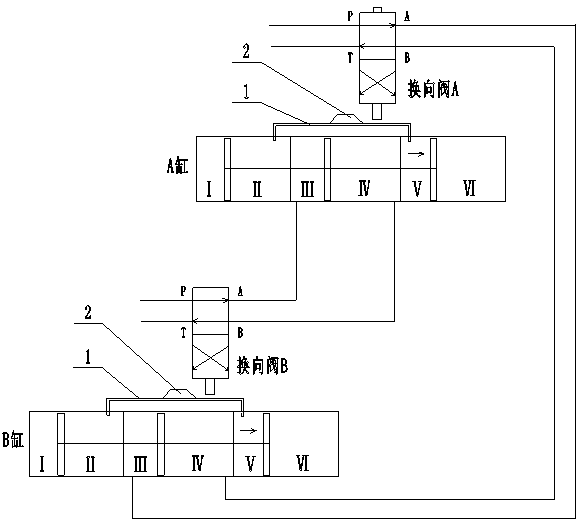

Cavity type automatic special-shaped body reversing mechanism

The invention discloses a cavity type automatic special-shaped body reversing mechanism and belongs to the technical field of automatic reversing of oil cylinders. According to the cavity type automatic special-shaped body reversing mechanism, a special-shaped body is adopted for reversing, a dead point is prevented from being generated, a connecting rod makes a boss move under the control of a hydraulic cylinder piston, and then a two-position four-way reversing valve is controlled to act. According to the technical scheme, the cavity type automatic special-shaped body reversing mechanism is characterized in that an A cylinder and a B cylinder are respectively provided with a cavity I, a cavity II, a cavity III, a cavity IV, a cavity V and a cavity VI in sequence, the cavities II and the cavities V are all hollow, pistons of three cylinder bodies of the A cylinder are connected through a piston rod, so that linkage of the three pistons is achieved, and pistons of three cylinder bodies of the B cylinder are connected through a piston rod, so that linkage of the three pistons is achieved; sliding blocks are arranged on the A cylinder and the B cylinder, protrusions are arranged on the tops of the sliding blocks, the sliding blocks are pushed by the pistons located on the two sides of the A cylinder and the B cylinder to move leftwards and rightwards, and the protrusions move leftwards and rightwards to shift a reversing valve A and a reversing valve B to achieve reversing. The cavity type automatic special-shaped body reversing mechanism can be widely applied to the field of hydraulic automatic reversing.

Owner:南通新兴机械制造有限公司

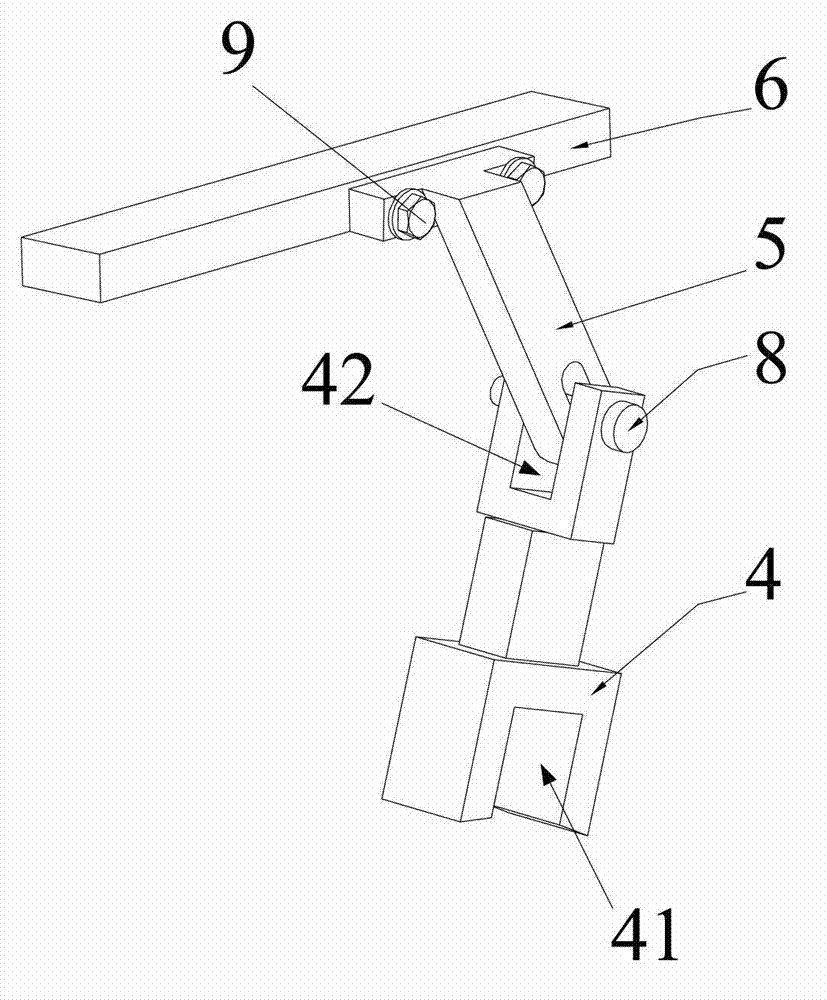

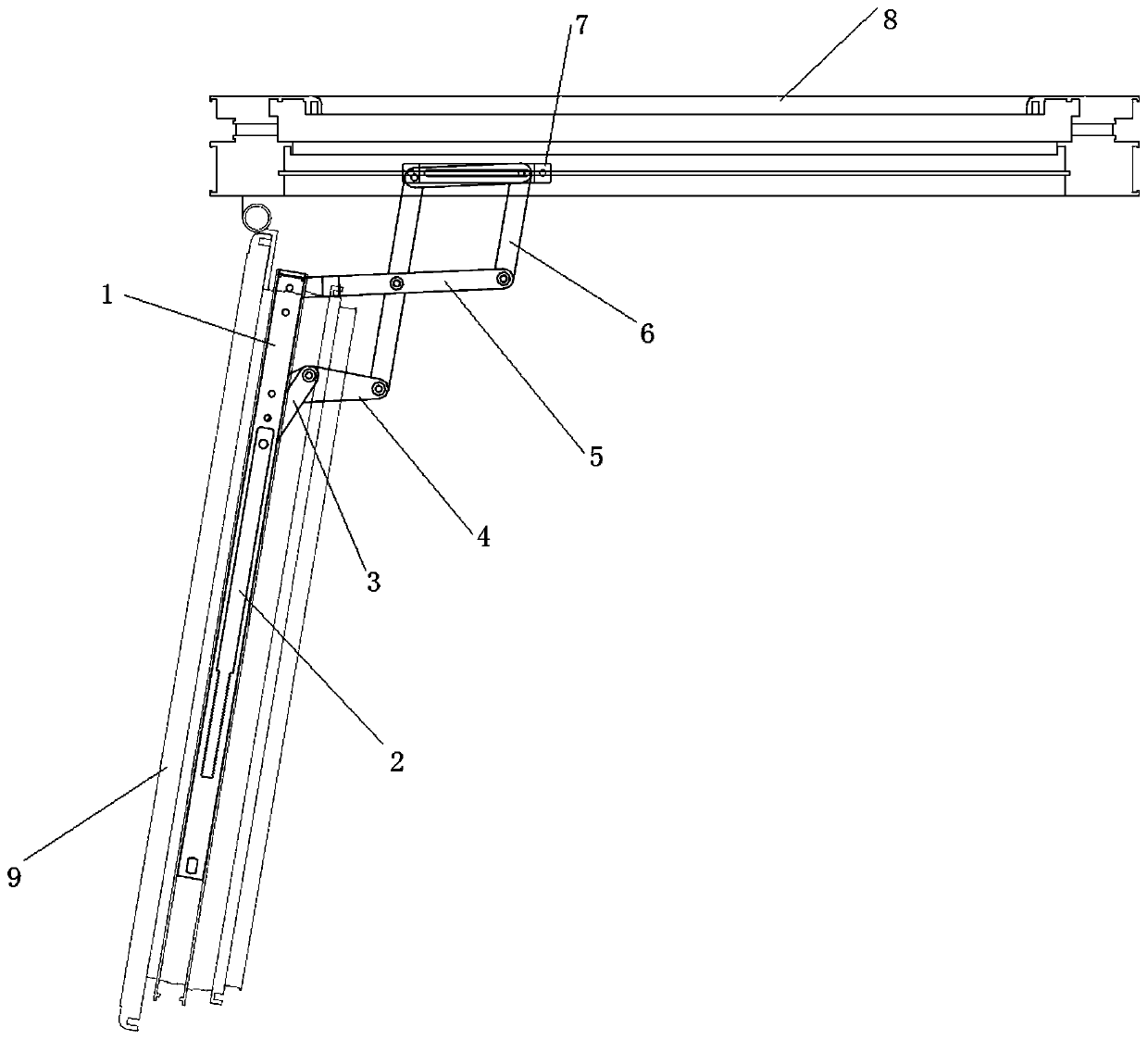

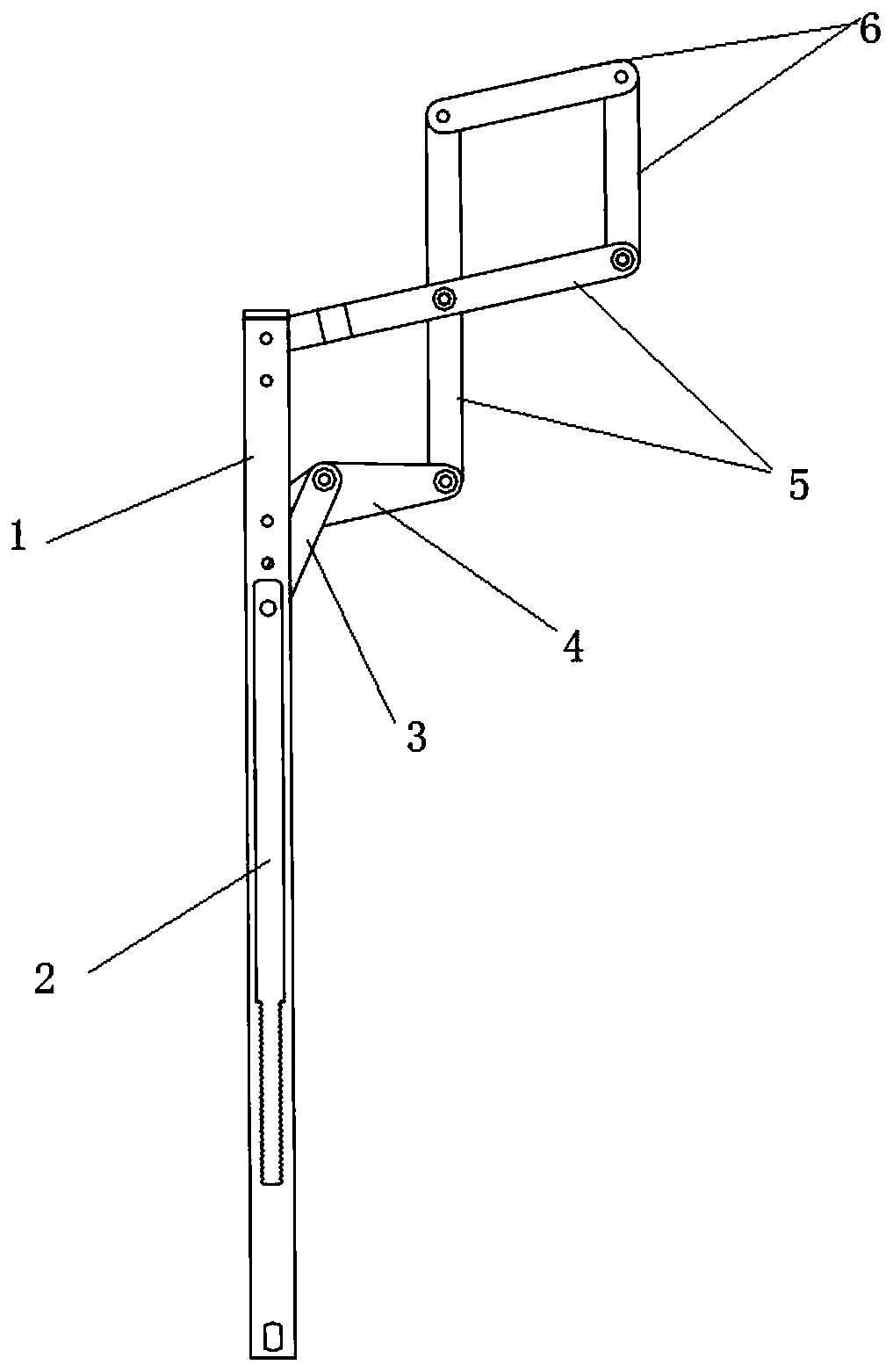

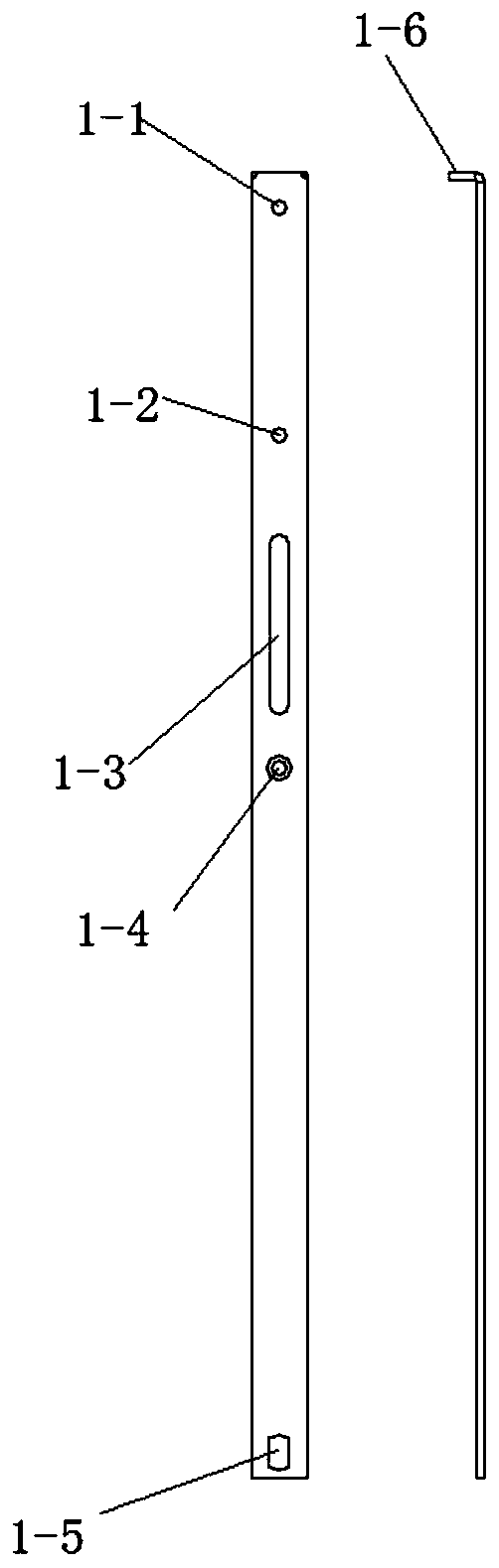

Shear lifting mechanism producing large swing angle motion

InactiveCN111075298ARealize the fan motionAvoid dead spotsMan-operated mechanismWing suspension devicesReciprocating motionShear force

The invention relates to a shear lifting mechanism producing large swing angle motion. The shear lifting mechanism comprises a fixing plate, a transmission rod, a driving rod, an off-axis driven rod and a shear force rod group, wherein the fixing plate is mounted at a door and window sash end, the transmission rod is arranged on the fixing plate in a sliding manner, one end of the transmission rodis connected with a drive execution mechanism, and the other end and one end of the driving rod are hinged to the fixing plate; the other end of the driving rod is hinged to the middle of the off-axis driven rod; one end of the shear force rod group is hinged to the top end of the fixing plate and one end of the off-axis driven rod; the other end is hinged to the door and window sash end; and theother end of the off-axis driven rod is hinged to the fixing plate. The shear lifting mechanism changes a drive force bearing point and a force output point on the basis of a linear lifting functionof traditional shear lifting, so that short-range linear reciprocation can be realized, large travel pushing and contraction motion can be produced, and sector motion at a large swing angle can be realized.

Owner:烟台执爱智能家居有限公司 +1

T-branch pipe locking type rigid-plasticity combined type bulging equipment

The invention discloses T-branch pipe locking type rigid-plasticity combined type bulging equipment. The T-branch pipe locking type rigid-plasticity combined type bulging equipment comprises an upper half die and a lower half die. A forming cavity is arranged between the upper half die and the lower half die, and the two ends of the forming cavity are provided with bulging squeezing punches respectively. The lower half die is provided with an axis branch pipe forming cavity and a balance punch is installed in the branch pipe forming cavity. A rigid bulging inner die is arranged between the two bulging squeezing punches and comprises push rods located at the two ends respectively, and a forming inner die block which is matched with the branch pipe forming cavity and used for driving a pipe blank to bulge and deform is arranged between the two push rods; the forming inner die block is connected with the two push rods through double-hinge connecting rods; the opposite ends of the two push rods are provided with connecting grooves opened towards the branch pipe forming cavity; a limiting structure is arranged in each connecting groove; the push rods are installed in the corresponding bulging squeezing punches respectively in a sliding matching mode, and one of the push rods is provided with a locking type rapid detaching and connecting structure. Thrust devices are arranged at the two ends of the forming cavity and comprise compound hydraulic cylinders.

Owner:XINCHANG HANGDA MACHINERY MFG

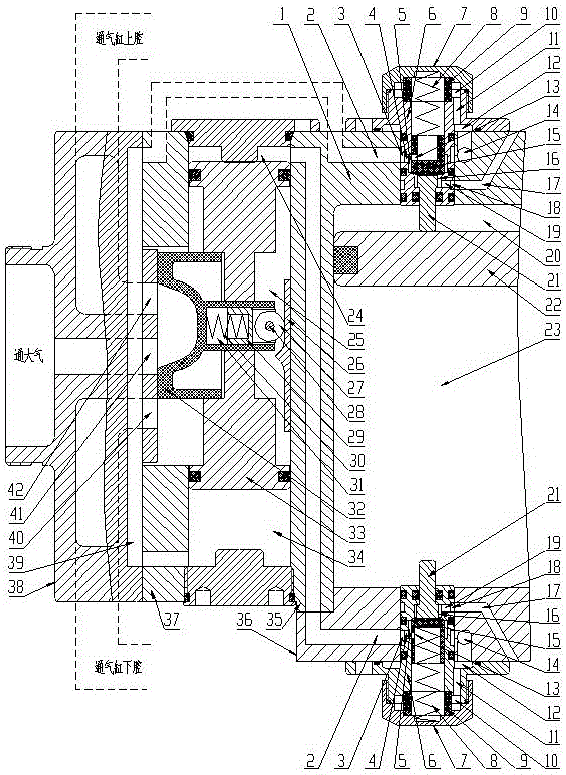

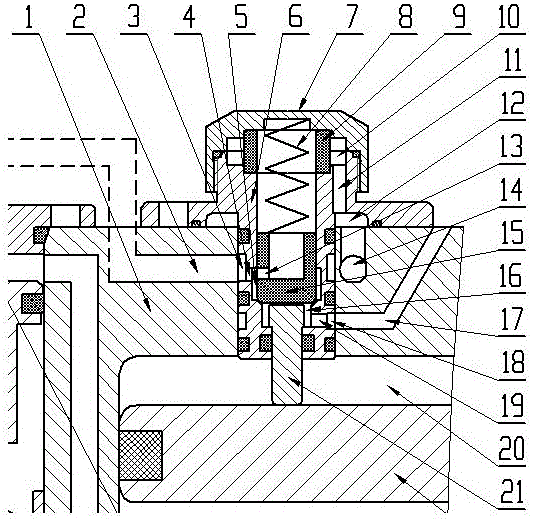

Air motor automatic reversing mechanism

ActiveCN104454013BReversing action is sensitiveReset in timeMachines/enginesSafety/regulatory devicesAtmospheric airEngineering

The invention discloses an automatic reversing mechanism for a pneumatic motor. The automatic reversing mechanism comprises an air cylinder; an air cylinder top wall and an air cylinder lower cover are arranged at the upper and lower ends of the air cylinder; pilot valves are arranged on the air cylinder top wall and the air cylinder lower cover respectively; a piston cavity is formed between the air cylinder top wall and the air cylinder lower cover; a piston is arranged in the piston cavity; a reversing valve is arranged on the air cylinder, and comprises a reversing valve body; a reversing piston cavity is formed in the reversing valve body; a reversing piston is arranged in the reversing piston cavity; a reversing piston upper cavity, an air distributing chamber cavity and a reversing piston lower cavity are formed between the reversing piston and the reversing piston cavity; control passages, air intake passages communicated with an air source and exhaust passages communicated with air are formed in the air cylinder top wall and the air cylinder lower cover respectively; the exhaust passages are formed in the inner sides, near the piston cavity, of the air intake passages; the control passage formed in the air cylinder top wall is communicated with the reversing piston lower cavity; the control passage formed in the air cylinder lower cover is communicated with the reversing piston upper cavity.

Owner:CHONGQING GUOLING MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com