Mechanism for realizing automatic reversing through a distributing slide valve

A sliding valve and flow distribution technology, which is applied to fluid pressure actuating devices, mechanical equipment, servo motor components, etc. point effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

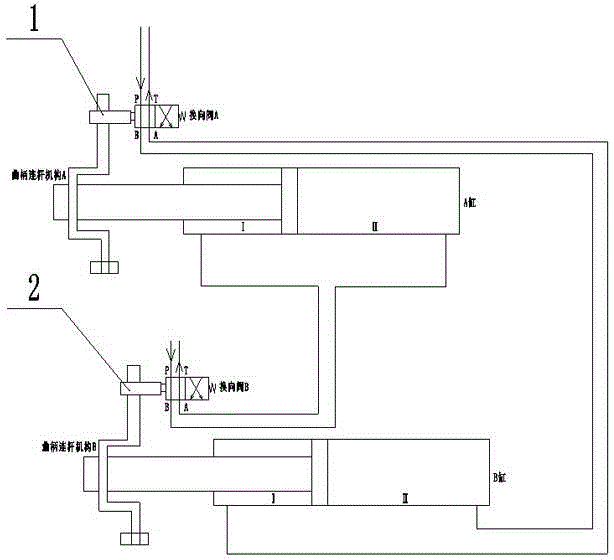

[0017] like figure 1 As shown, the present invention realizes the mechanism of automatic reversing with flow distribution slide valve, comprises A cylinder, B cylinder, reversing valve A, reversing valve B, crank connecting rod mechanism A and crank connecting rod mechanism B, described A cylinder and The structure of the B cylinder is the same, the reversing valve A and the reversing valve B are both mechanical reversing valves, one end of the valve body of the mechanical reversing valve is provided with a reversing lever, and the other end is provided with a return spring, The reversing valve A and the reversing valve B have the same structure, and the crank linkage mechanism A and the crank linkage mechanism B have the same structure;

[0018] The structure of the A cylinder is: including the cylinder body and the piston rod, and two chambers formed by the cylinder body and the piston rod, the chamber with the piston rod in the two chambers is the I chamber, and the other c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com