Motor control circuit and method

A motor control and circuit technology, which is applied in the direction of AC motor reduction gear, electric motor/converter plug, etc., can solve problems such as high cost and electrical safety risks, and achieve cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

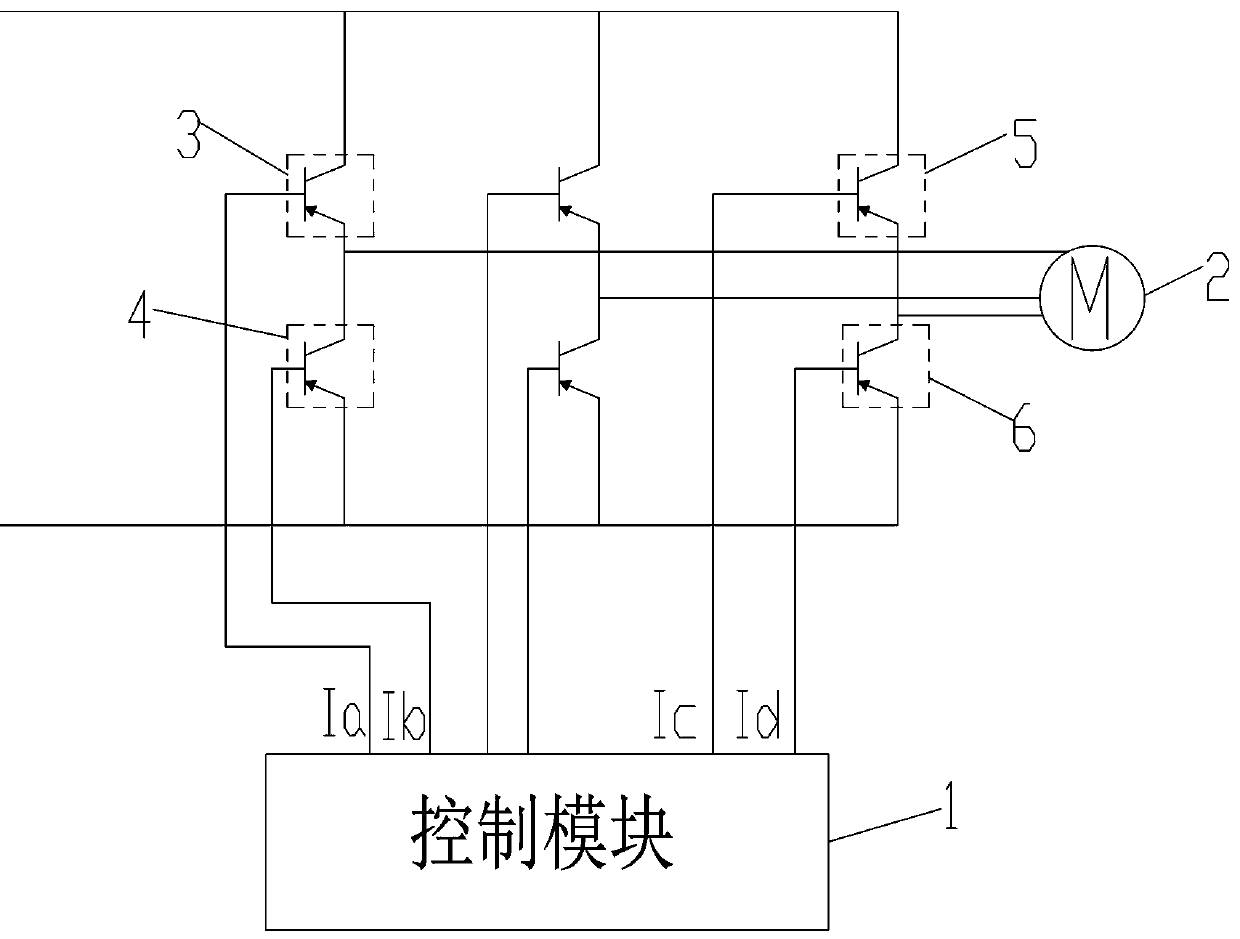

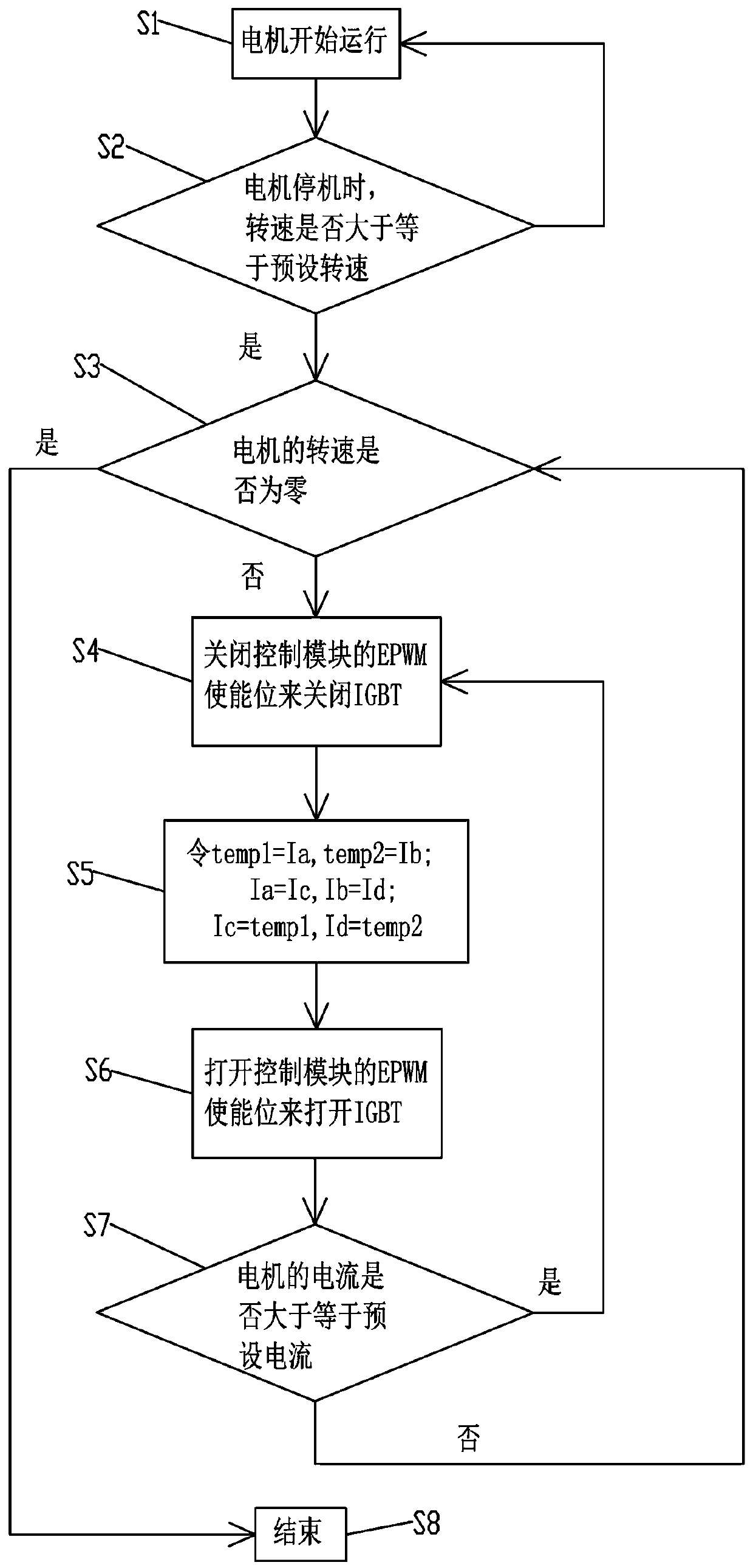

[0027] like figure 1 As shown, the motor control circuit proposed by the present invention is based on a frequency converter. The motor control circuit includes an IGBT connected to the control module 1 and the control module 1, the motor 2 is connected to the IGBT, and the duty of the IGBT is controlled by the control module 1. Compare and change. Swapping the duty cycle controlled by the IGBT through the control module is equivalent to swapping the three-phase power line of the motor, so as to achieve the purpose of "commutation", realize the reversal of the magnetic field, and exert force on the motor rotor by the reverse magnetic field. To achieve the purpose of zero motor speed. The control module is used to reverse the duty cycle of the IGBT control to achieve the purpose of "commutation" of the power supply, and then realize the purpose of stopping the motor at high speed, eliminating the need for relays or AC contactors, saving costs.

[0028] The IGBT has a first up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com