Multifunctional grinding machine and working method thereof

A working method and multi-functional technology, applied in the direction of grinding machine, grinding bed, grinding machine parts, etc., can solve the problems of reducing grinding efficiency, large fixed investment for putting green machine users, increasing production cost, etc., to achieve Moving and Stationary Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

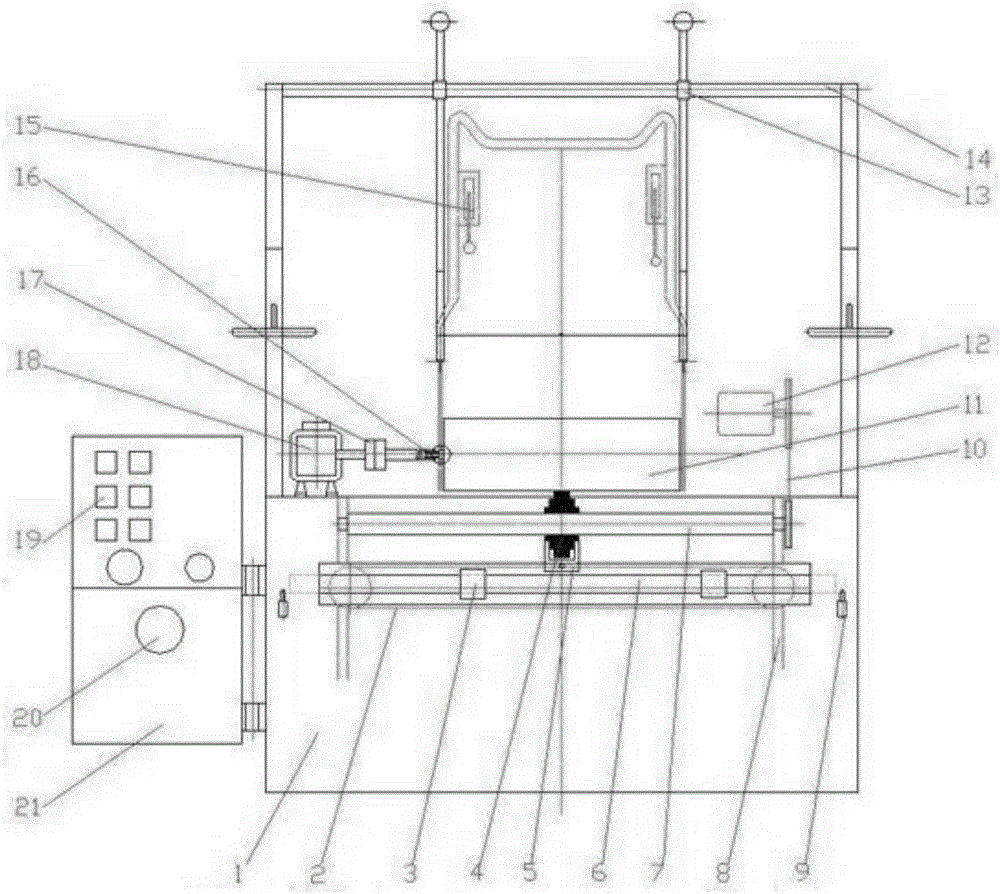

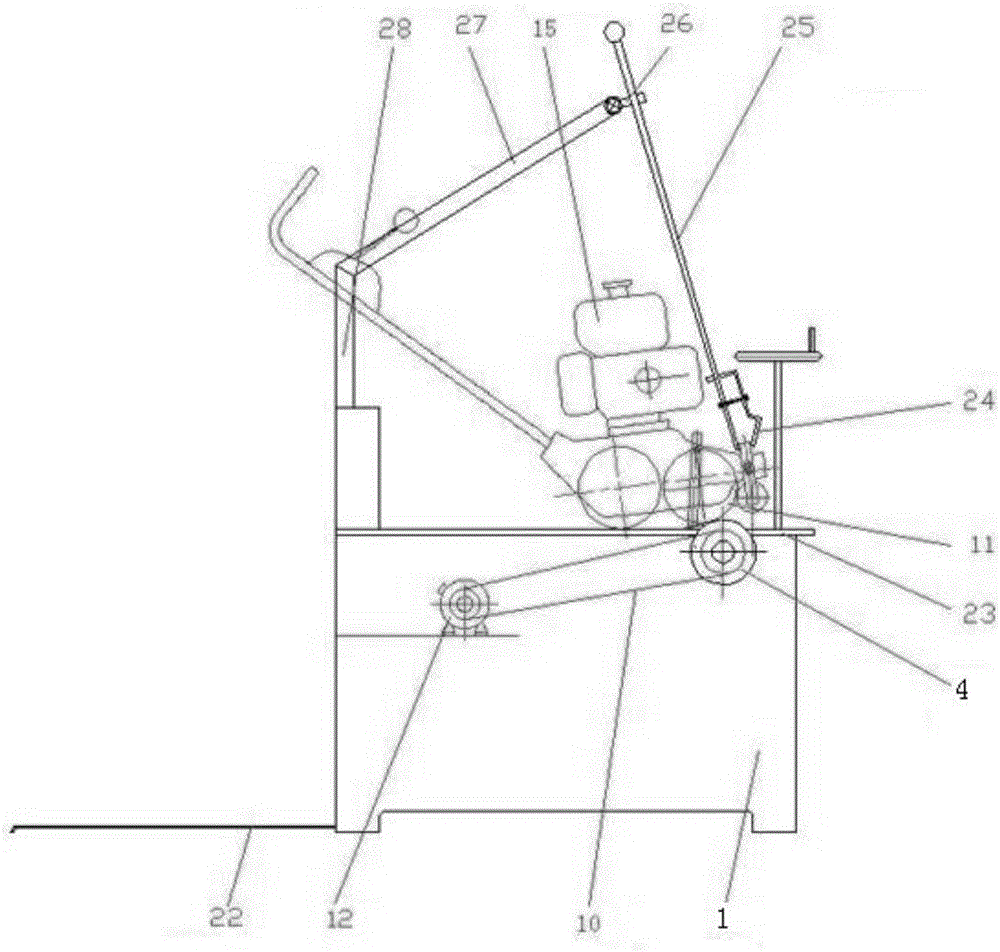

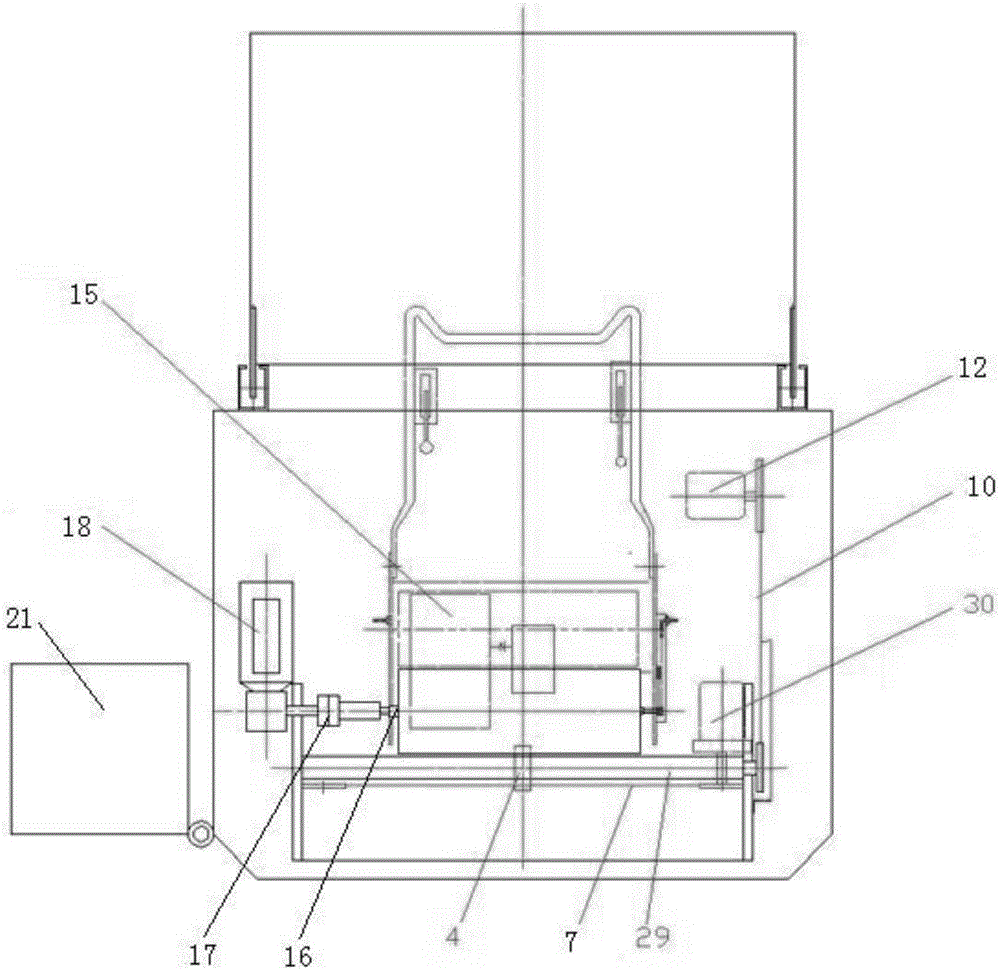

[0039] further as Figure 4 to Figure 21 As shown, to grind the outer circle of the hob of the putting green machine, first put the putting green machine 15 on the lifting platform 22 during operation, then lift the putting green machine 15 onto the bed panel 23 through the lifting mechanism, and use the clamping frame 24 Clamp the fixed ends on the left and right sides of the front end of the putting green machine, and then adjust the position of the putting green machine by adjusting the angle between the second clamping rod fixing sleeve 26 and the clamping frame crossbeam 14 and the length of the clamping rod 25 protruding out. One end of the sleeve shaft 16 is inserted into the output shaft of the hob 11 of the green machine 15, and the other end is connected with the coupling 17. After all adjustments are made, all bolts are locked, and finally the green machine 15 is fixed on the grinder; After the first reduction motor 18 is started, it drives the forward rotation of t...

Embodiment 2

[0041] further as Figure 4 to Figure 21 As shown, the hob of the putting green machine is automatically chamfered. During operation, the putting green machine 15 is first placed on the lifting table 22, and then the putting green machine 15 is lifted onto the bed panel 23 by the lifting mechanism, and clamped with the clamping frame 24. Hold the fixed ends on the left and right sides of the front end of the putting green machine, and then adjust the position of the putting green machine by adjusting the angle between the second clamping rod fixing sleeve 26 and the clamping frame crossbeam 14 and the length of the clamping rod 25 protruding out. One end of the cylinder shaft 16 is inserted into the output shaft of the hob 11 of the green machine 15, and the other end is connected with the coupling 17. After all adjustments are made, all bolts are locked, and finally the green machine 15 is fixed on the grinder; A motor 54 drives the linear bearing 58 to move laterally on the ...

Embodiment 3

[0043] further as Figure 4 to Figure 21 As shown, the bottom knife of the putting green machine is ground. During the operation, first put the putting green machine 15 on the lifting platform 22, then lift the putting green machine 15 onto the bed panel 23 through the lifting mechanism, and use the clamping frame 24 clamp the fixed ends on the left and right sides of the front end of the putting green machine, and then adjust the position of the putting green machine by adjusting the angle between the second clamping rod fixing sleeve 26 and the clamping frame crossbeam 14 and the length of the clamping rod 25 protruding out, and at the same time Insert one end of the sleeve shaft 16 into the output shaft of the hob 11 of the green machine 15, and connect the other end with the coupling 17. After all adjustments are made, all bolts are locked, and finally the green machine 15 is fixed on the grinder; After the second motor 78 is turned on, the lateral movement of the outer ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com