Woven bag flat silk winding machine

A woven bag and winder technology, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems of uneven winding of flat filaments, protect the tooth shape, prolong the life of the device, and improve the Even roll effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following is further described in detail through specific implementation methods:

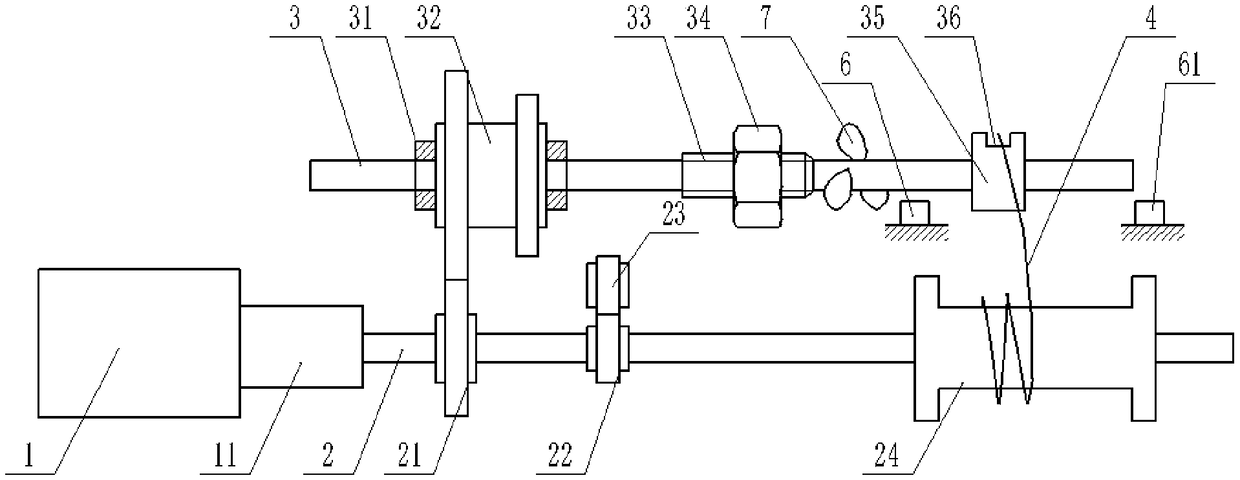

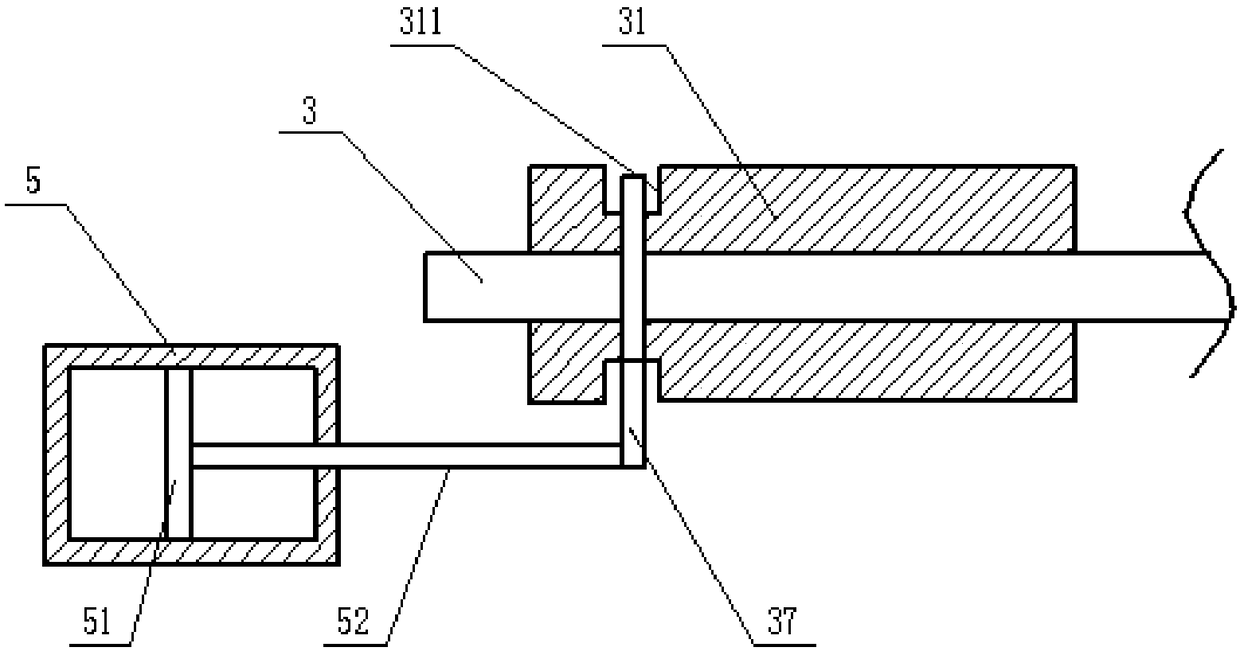

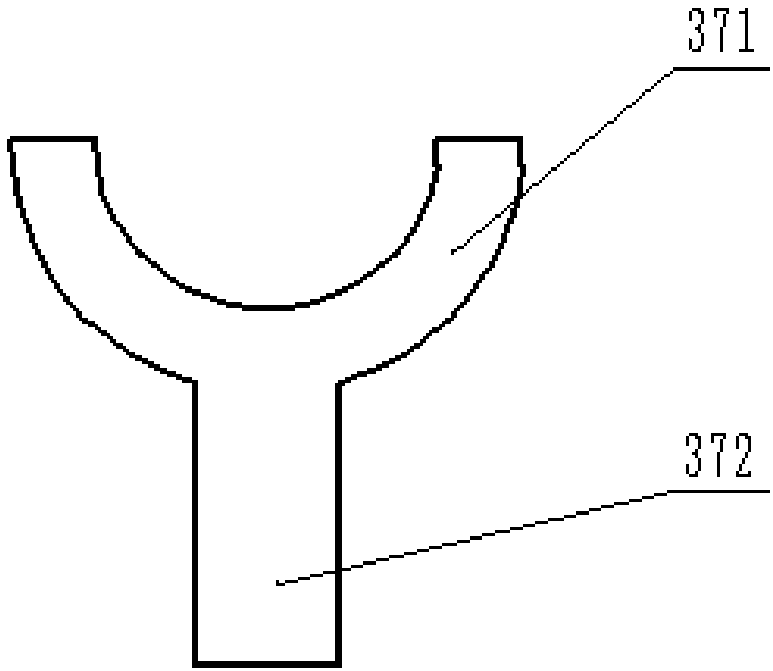

[0021] The reference signs in the accompanying drawings of the description include: rotating motor 1, output shaft 11, second rotating shaft 2, large gear 21, pinion 22, idler 23, reel 24, first rotating shaft 3, coupling sleeve 31, ring Card slot 311, double gear 32, thread section 33, nut 34, guide block 35, groove 36, shift fork 37, arc section 371, vertical section 372, flat wire 4, cylinder 5, piston 51, piston rod 52. The first limit switch 6, the second limit switch 61, and the fan blade 7.

[0022] Such as figure 1 and figure 2 As shown, the woven bag flat yarn winding machine includes a frame, on which a cylinder 5 and a rotating motor 1 are fixed, and a first rotating shaft 3 and a second rotating shaft 2 are vertically overlapped on the frame, and on the first rotating shaft 3, the A spline section and a thread section 33 are provided in sequence from left to right. An...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com