Pump turbine capable of rotating forwards and backwards

一种水泵水轮机、正反转的技术,应用在水轮机,水泵领域,能够解决水泵单方向抽水、成本高、水轮机使用效率低等问题,达到高效工作的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

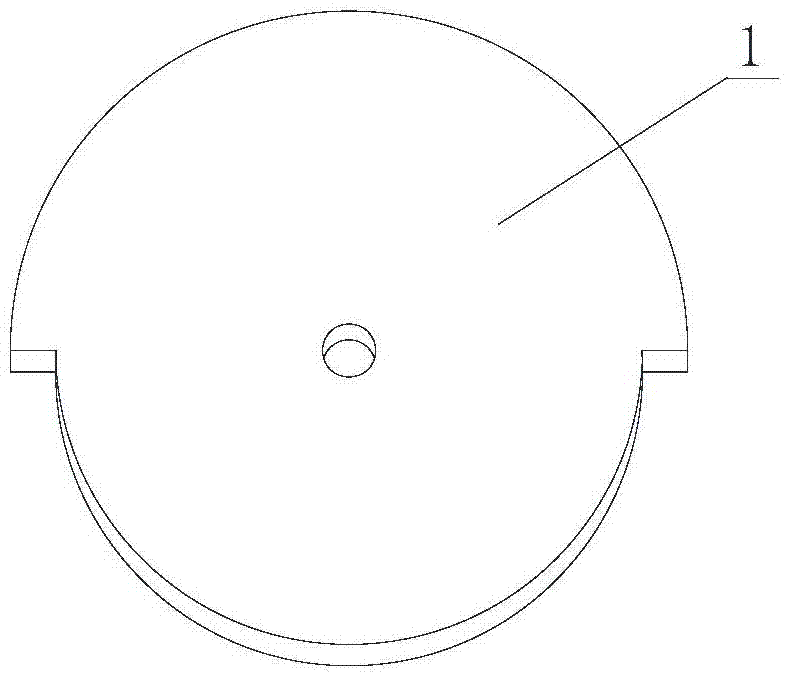

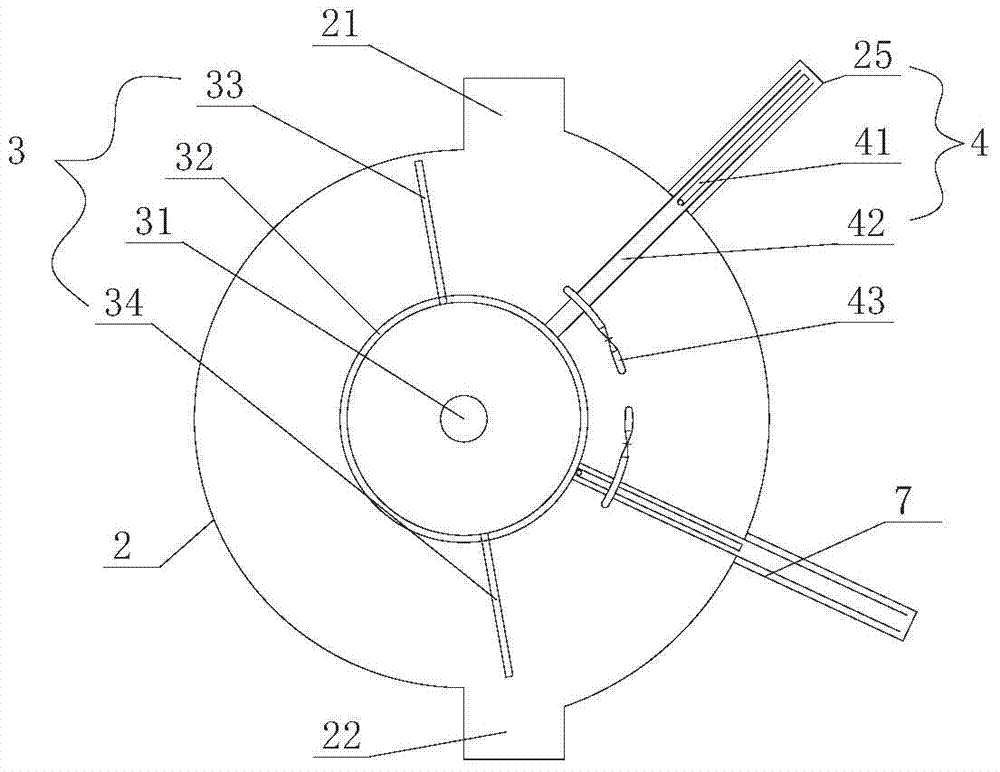

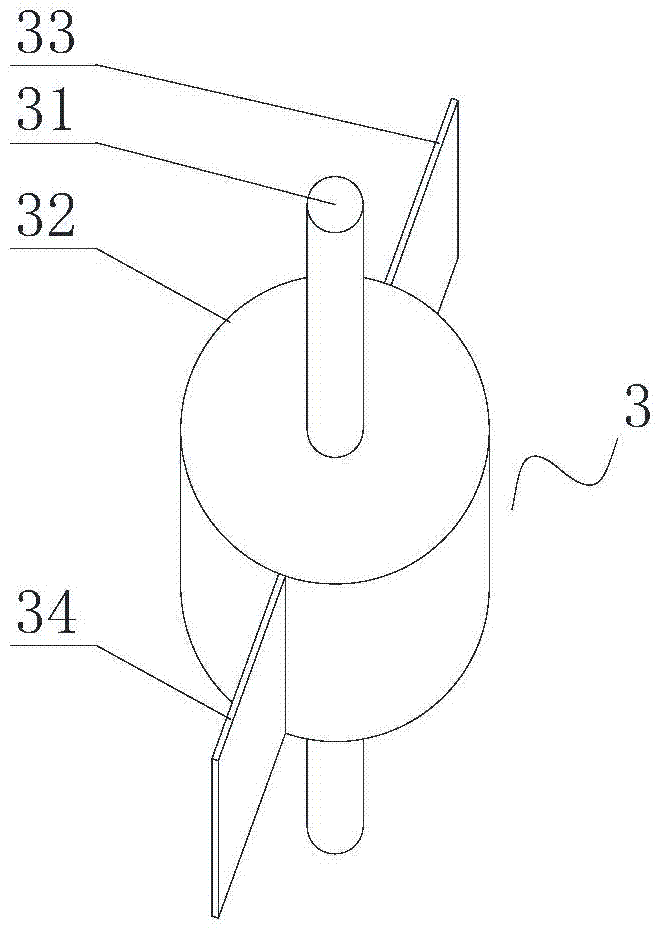

[0027] Such as Figure 1 to Figure 6 As shown, the reversible pump-turbine of the present invention includes a casing 2 and a rotor 3 movably arranged in the casing 2. The casing includes two end plates 1 oppositely arranged and of the same shape and used for The casing 2 connecting two end plates 1, the end plate 1 includes a large semi-circular plate and a small semi-circular plate coaxial but with different radii, the large semi-circular plate and the small semi-circular plate are connected together in the diameter direction, the large semi-circular plate The common axis position of the half-circle plate and the small half-circle plate is provided with an axis ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com