An on-track reversing multifunctional cargo transport vehicle

A multifunctional, conveying vehicle technology, applied in conveyors, mechanical conveyors, transportation and packaging, etc., to achieve stable performance, reasonable design, and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

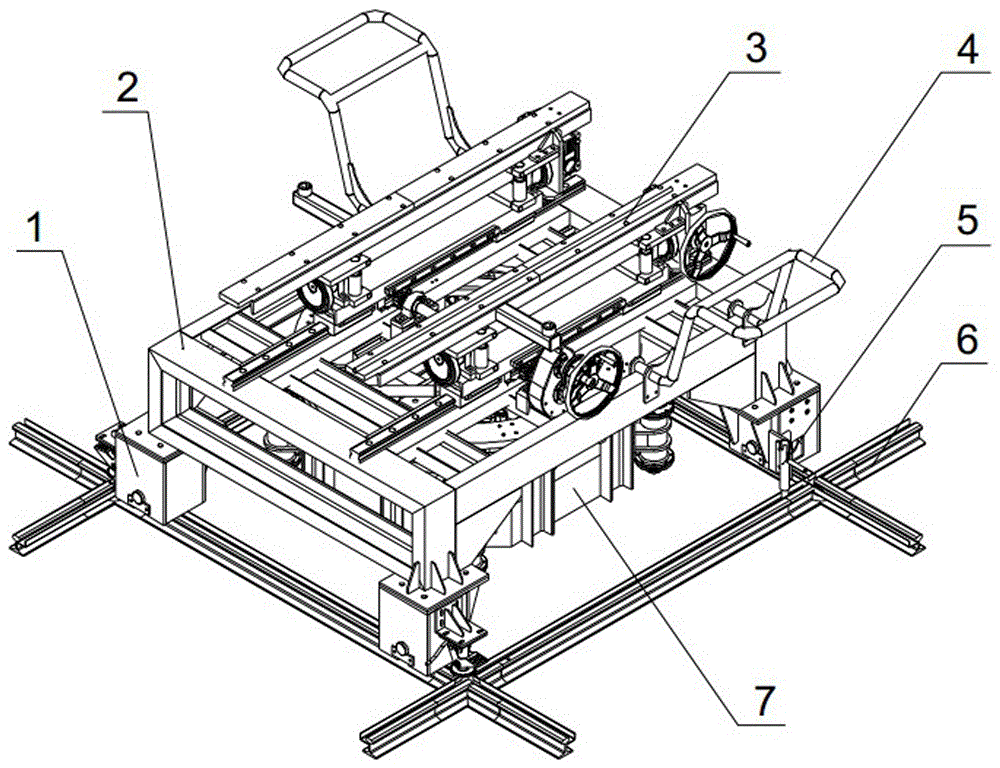

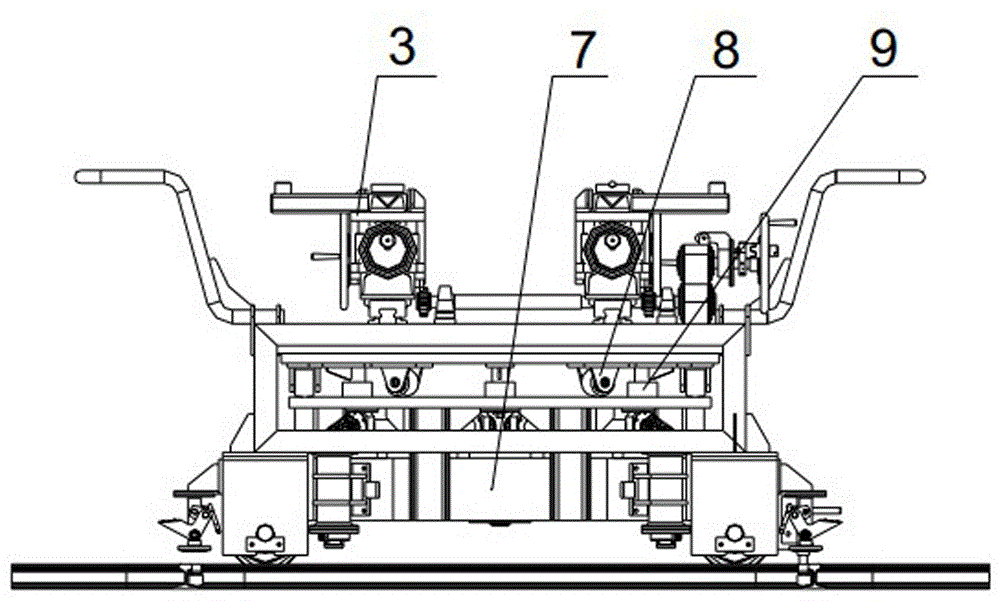

[0021] existfigure 1 , figure 2 Among them, the vehicle frame 2 is a rectangular frame structure, which is welded and assembled by steel structure. An annular fixed plate is arranged in the frame, and six rotating devices 9 for steering and six rotating rollers 8 are arranged on the lower end surface of the annular fixed plate. The rotating device 9 and the rotating roller 8 are arranged at intervals, and the lower end of the rotating device 9 is provided with a lifting device 7 for steering, and two handrails 4 are provided on both sides of the vehicle frame 2 length direction. Four corners are provided with 4 walking wheel sets 1, wherein a positioning device 5 is provided on a walking wheel set near the left side handrail 4.

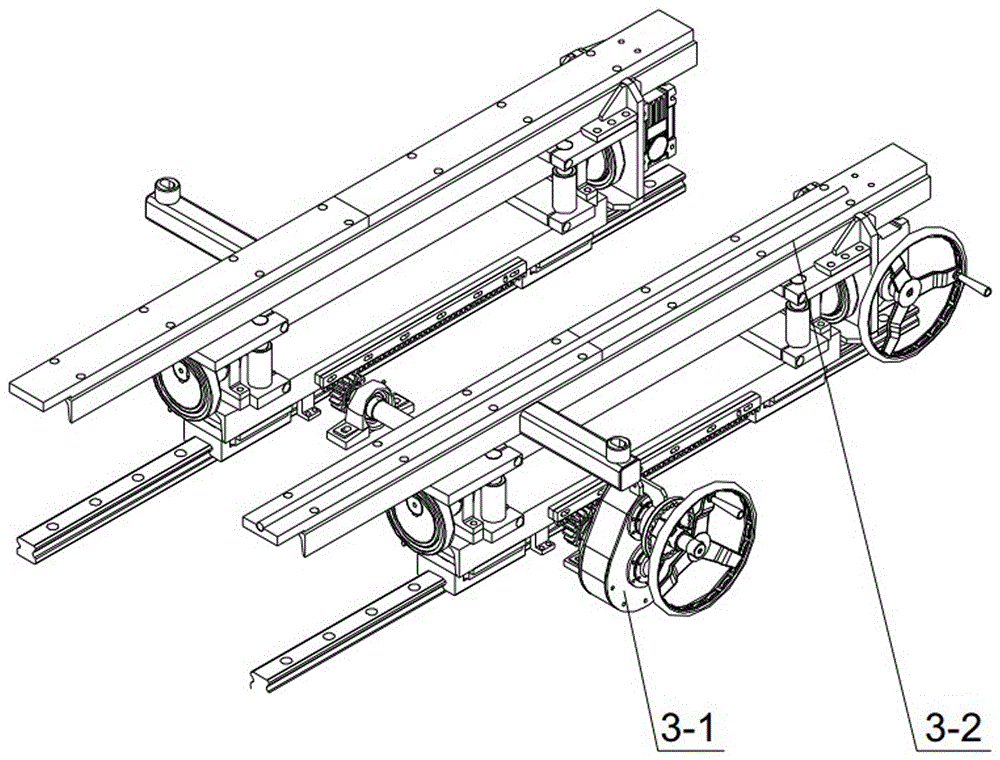

[0022] exist image 3 , Figure 4 , Figure 5 Among them, the horizontal telescopic device 3-1 is arranged under two se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com