Range hood

A technology of a range hood and a casing is applied in the field of range hood purification devices, which can solve problems such as oil cup interference, and achieve the effects of avoiding interference, ensuring normal work, and avoiding dead spots.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

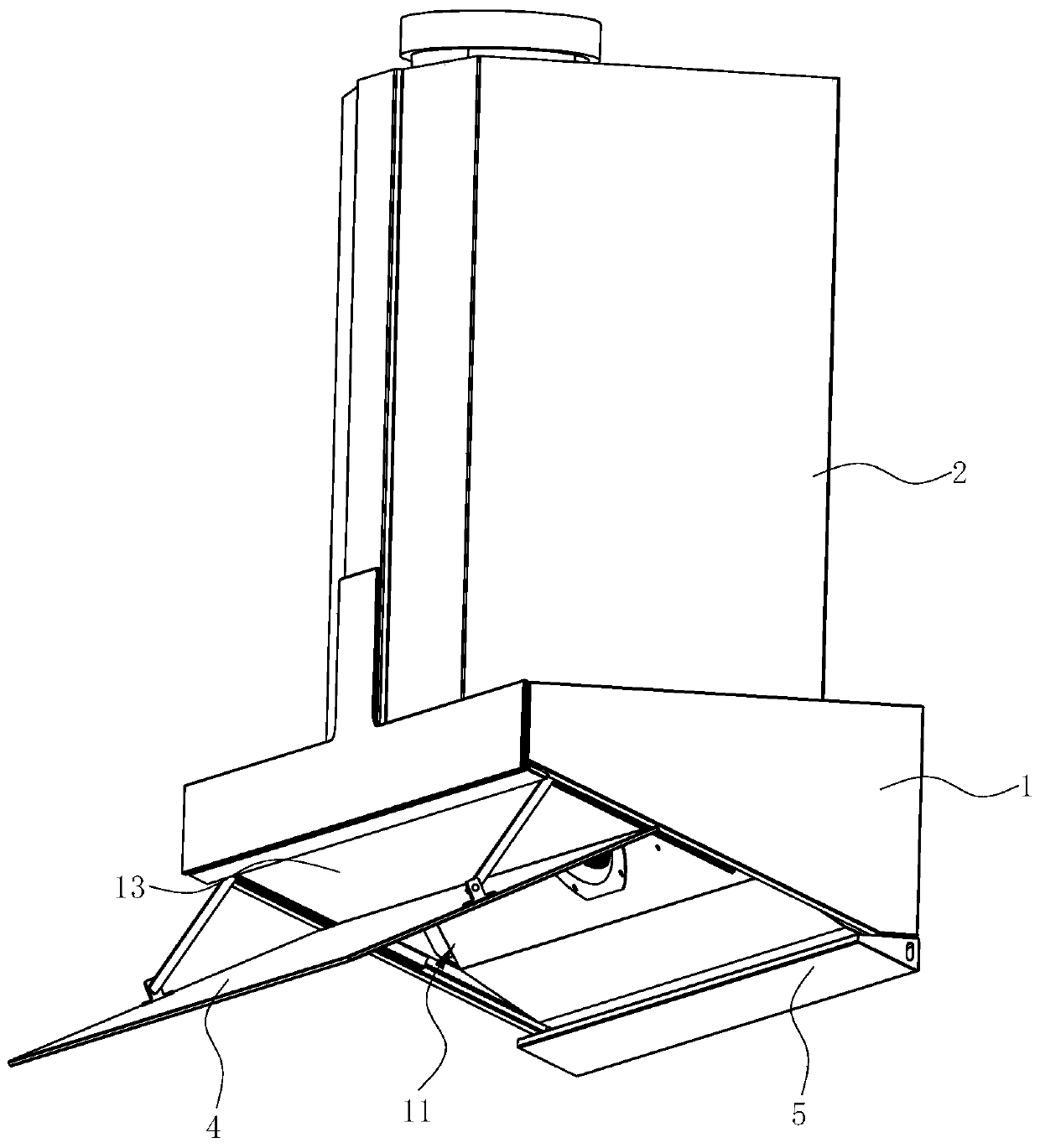

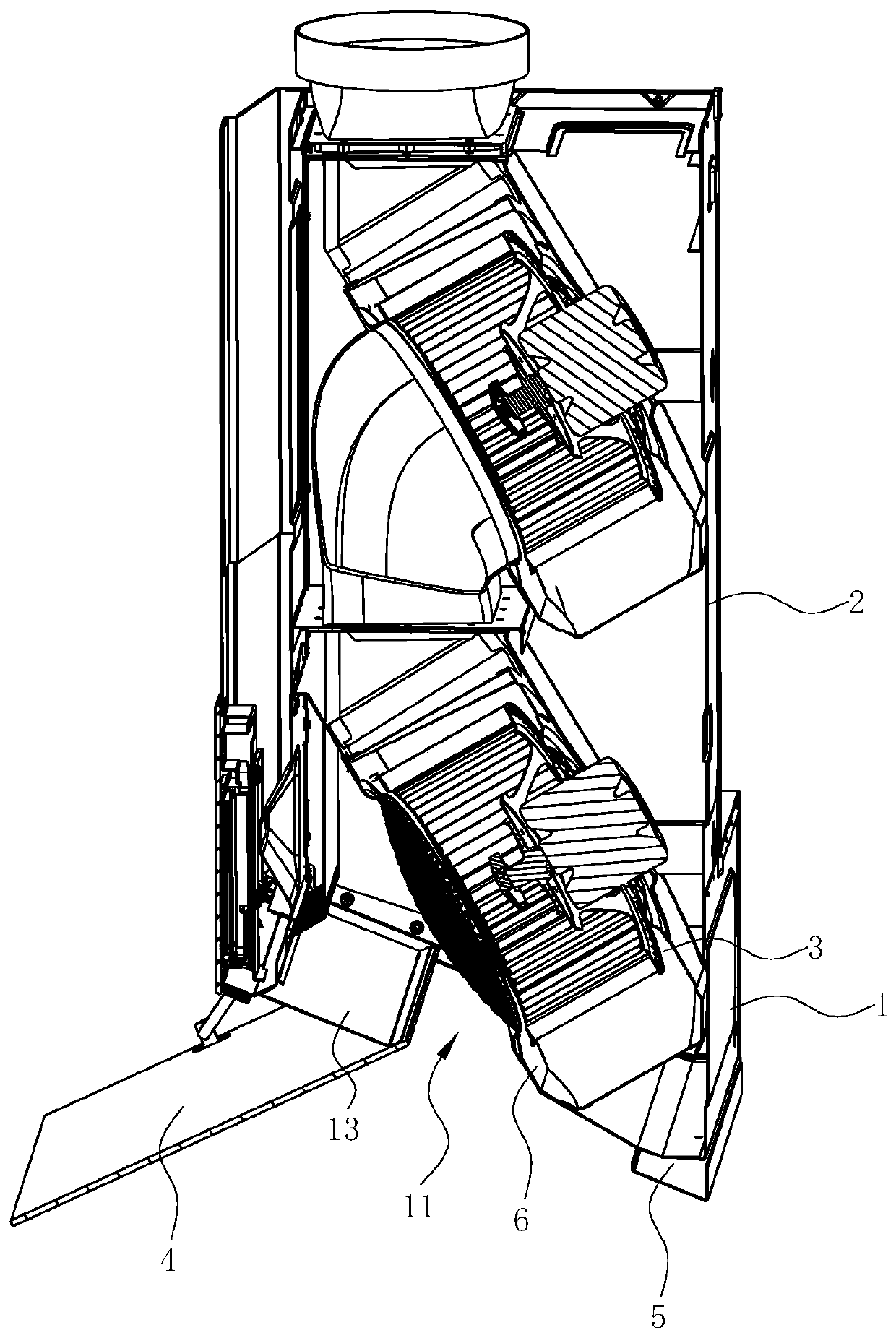

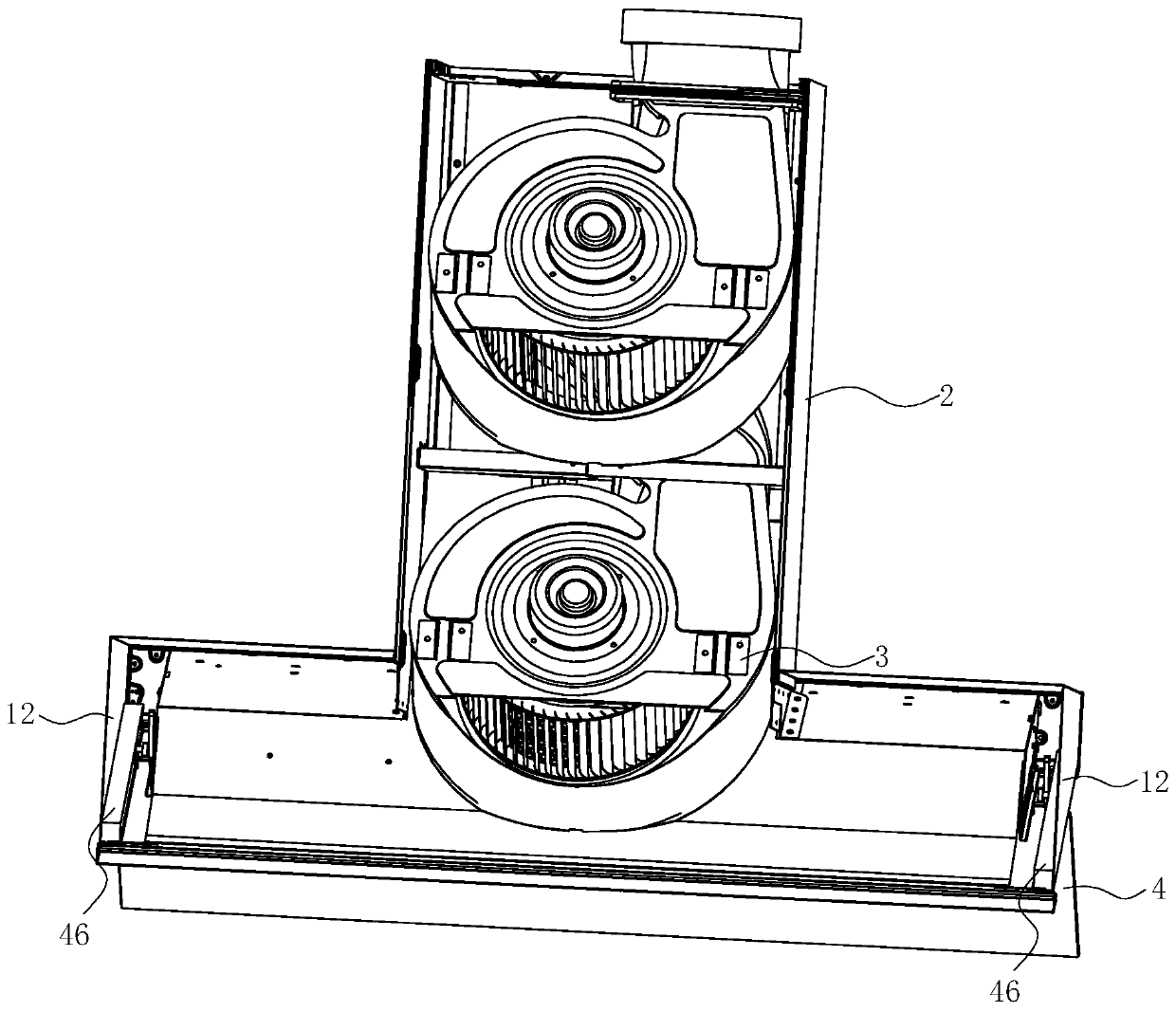

[0029] see Figure 1~5 , a range hood is a top-suction, side-suction integrated machine or side-suction type, including a casing 1, a casing 2 arranged above the casing 1, and a fan 3 arranged in the casing 2. For the convenience of description, in this specification, "front", "rear", "left", "right", "up", and "down" refer to the direction of the range hood relative to the user when in use.

[0030] In this embodiment, taking the top-suction and side-suction integrated machine as an example, the bottom of the cabinet 1 is open to form an air inlet 11 , which gradually slopes downward from front to back. The air inlet 11 is provided with a smoke baffle 4, which can be turned to open or close the air inlet 11 driven by its movement mechanism. When the range hood is a side suction type, the air inlet 11 is formed on the front side of the casin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com