Cavity type automatic special-shaped body reversing mechanism

A reversing mechanism and cavity technology, applied in mechanical equipment, fluid pressure actuators, servo motor components, etc., can solve problems such as poor stability, large pulses, and affecting the performance of the positioning machine, so as to improve stability, The effect of preventing dead spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

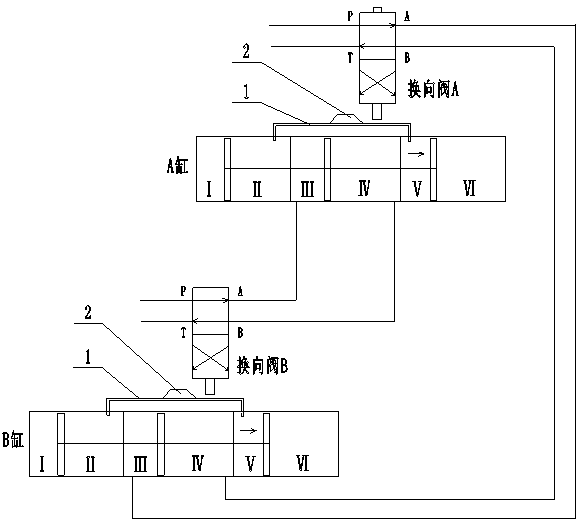

[0016] Such as figure 1 As shown, the cavity-type automatic different body reversing mechanism of the present invention includes A cylinder, B cylinder, reversing valve A and reversing valve B, and the structure of the A cylinder and B cylinder is the same, and the reversing valve A and the reversing valve B has the same structure;

[0017] The structure of cylinder A is as follows: it includes three cylinders, and the three cylinders are connected together in turn to form six chambers, which are chamber I, chamber II, chamber III, chamber IV, chamber V and chamber VI in sequence. Both chamber II and chamber V are hollow, and the pistons of the three cylinders are connected together by a piston rod, so that the three pistons are linked;

[0018] Both the A cylinder and the B cylinder are provided with a slide block 1, and the top of the slide block is provided with a protrusion 2, and the slide block 1 is pushed to move left and right by the pistons on both sides of the A cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com