Transmission device for changing straight reciprocating motion into rotary motion

A technology of linear reciprocating motion and rotary motion, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of high installation accuracy, difficult installation, high price, etc., and achieve the effect of adjustable speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

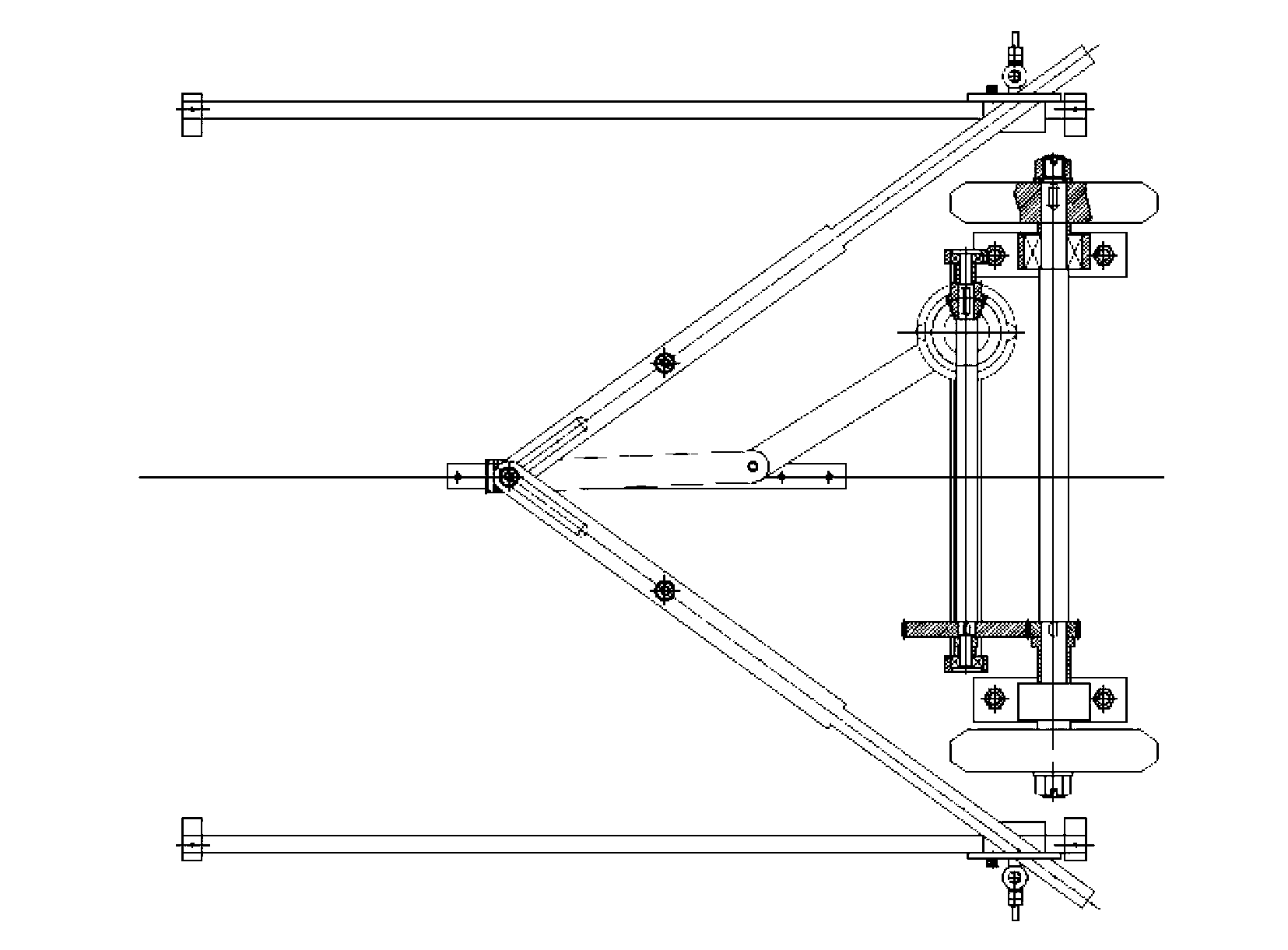

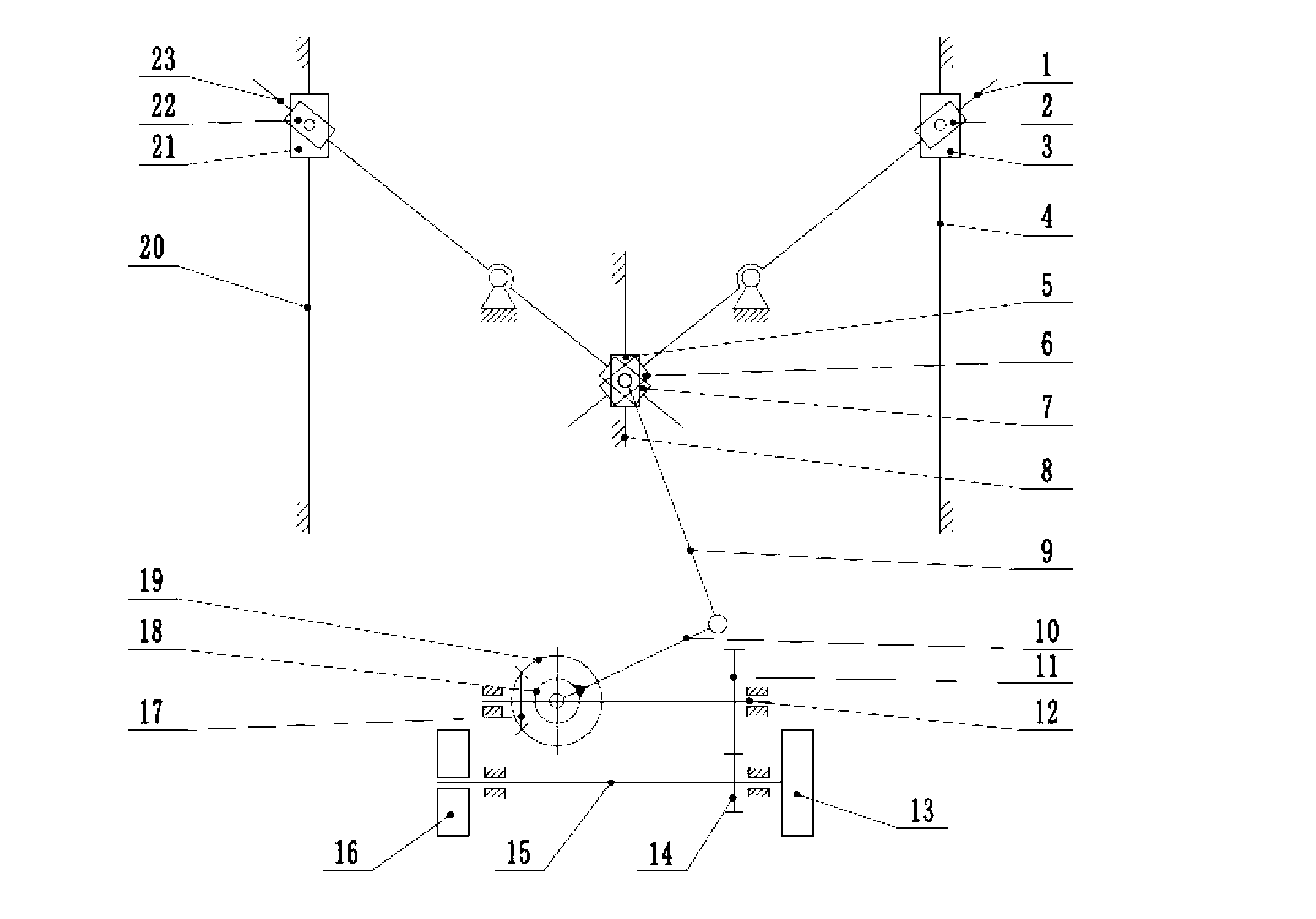

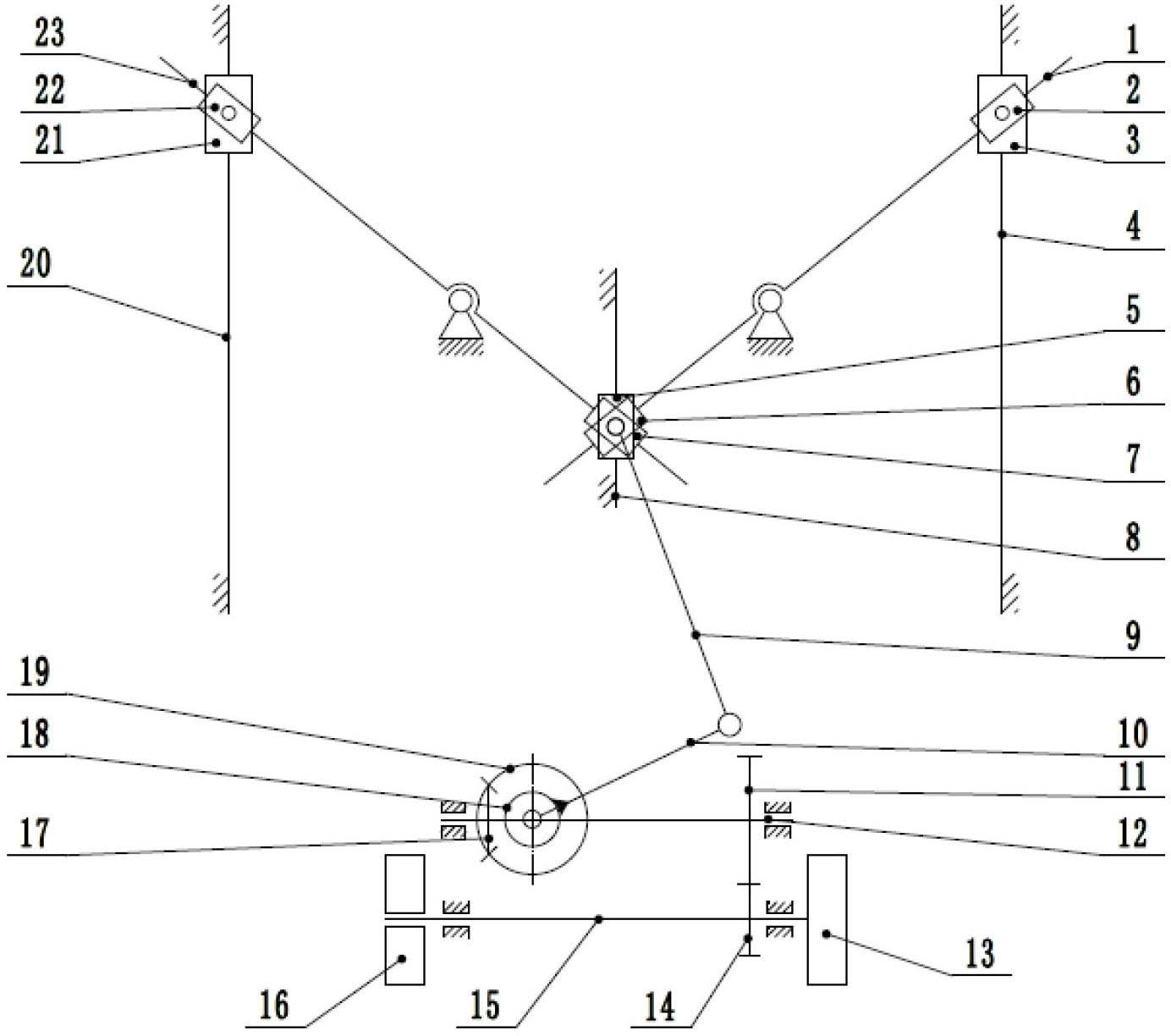

[0014] refer to figure 1 and figure 2 , the linear reciprocating motion is converted into a rotary motion transmission, including a first lever mechanism, a second lever mechanism, a rocker slider mechanism, a one-way clutch 18, a bevel gear mechanism and a spur gear mechanism; the first lever mechanism includes the first lever mechanism A transmission lever 1, the first slide block 2 and the sixth slide block 6, the second lever mechanism comprises the second transmission lever 23, the second slide block 22 and the seventh slide block 7, and the rocker slide block mechanism comprises The fifth slide block 5, connecting rod 9 and rocking bar 10, described bevel gear mechanism comprises driving bevel gear 19 and driven bevel gear 17, and described spur gear mechanism comprises driving spur gear 11 and driven spur gear 14;

[0015] The first slider 2 and a third slider 3 are hinged at the same point, and the second slider 22 and a fourth slider 21 are hinged at the same point;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com