Precise numerical-control spindle system

A precise numerical control and rotating shaft technology, applied in control systems, motor control, and mechanical energy control, etc., can solve problems such as expensive, difficult to meet precise positioning, unable to achieve 360-degree rotation positioning, etc., to avoid dead point problems and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

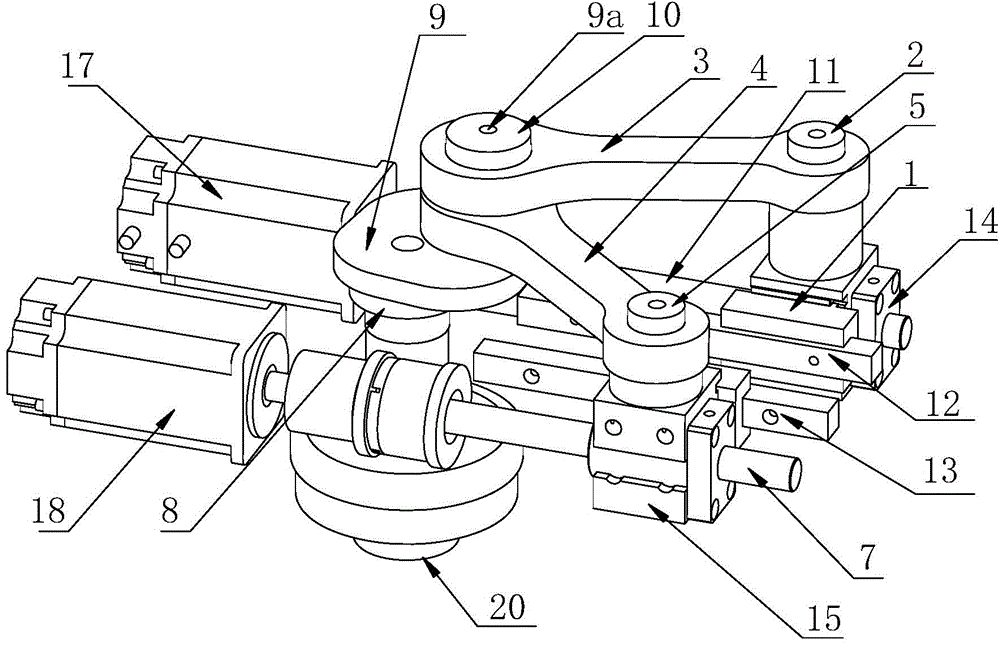

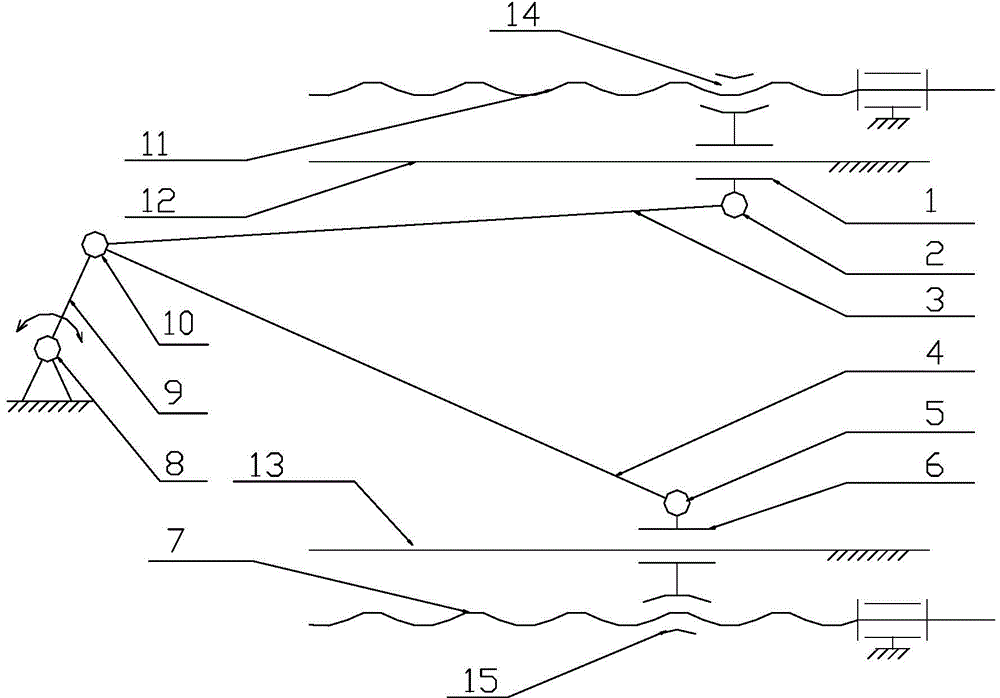

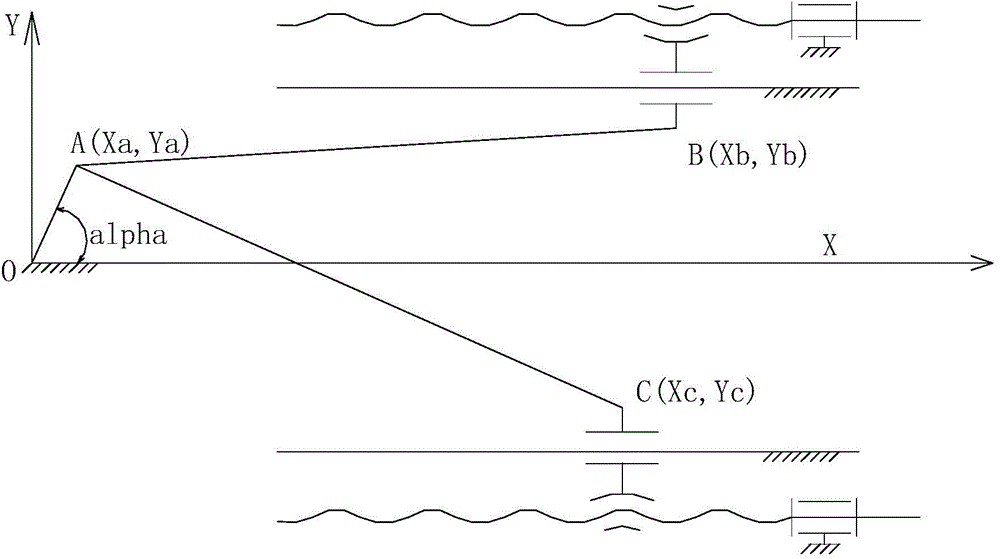

[0020] The structure of the precision numerical control rotating shaft system in the embodiment of the present invention is as follows: figure 1 shown, including the rack ( figure 1 Not shown in), output shaft 20, controller (not shown) and drive system, the drive system includes two sets of drive devices, each set of drive devices includes a set of slider crank mechanism and a set of screw nut mechanism. With respect to the rotation angle of the output shaft 20, the dead points of the two sets of crank-slider mechanisms are staggered from each other.

[0021] Two sets of slider crank mechanisms share the same crank 9 and the same crank pin 9a. Crank 9 is fixed on the upper end of output shaft 20, and rotating output shaft 20 is installed on the frame by main bearing 8, and output shaft 20 is driven by crank 9 and rotates synchronously by the constraint of main bearing 8.

[0022] The first set of slider crank mechanism comprises connecting rod 3, connecting rod slider beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com