Tunnel type ultrasonic bottle cleaning machine

An ultrasonic and tunnel-type technology, applied in the field of cleaning machines, can solve the problems of increasing labor intensity and production costs, increasing the alkali concentration of RB bottles, and difficult cleaning of bottles, etc., achieving convenient and quick bottle discharge, reducing alkali concentration and alkali energy consumption , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

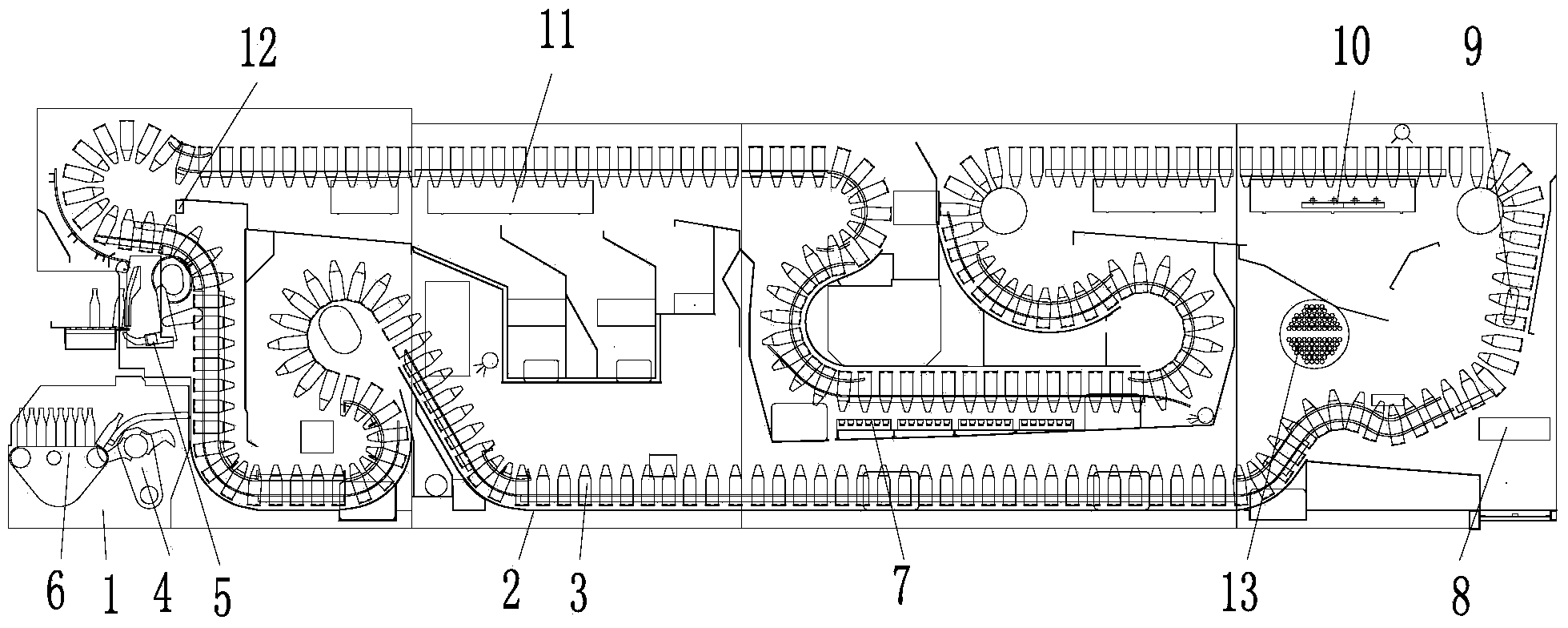

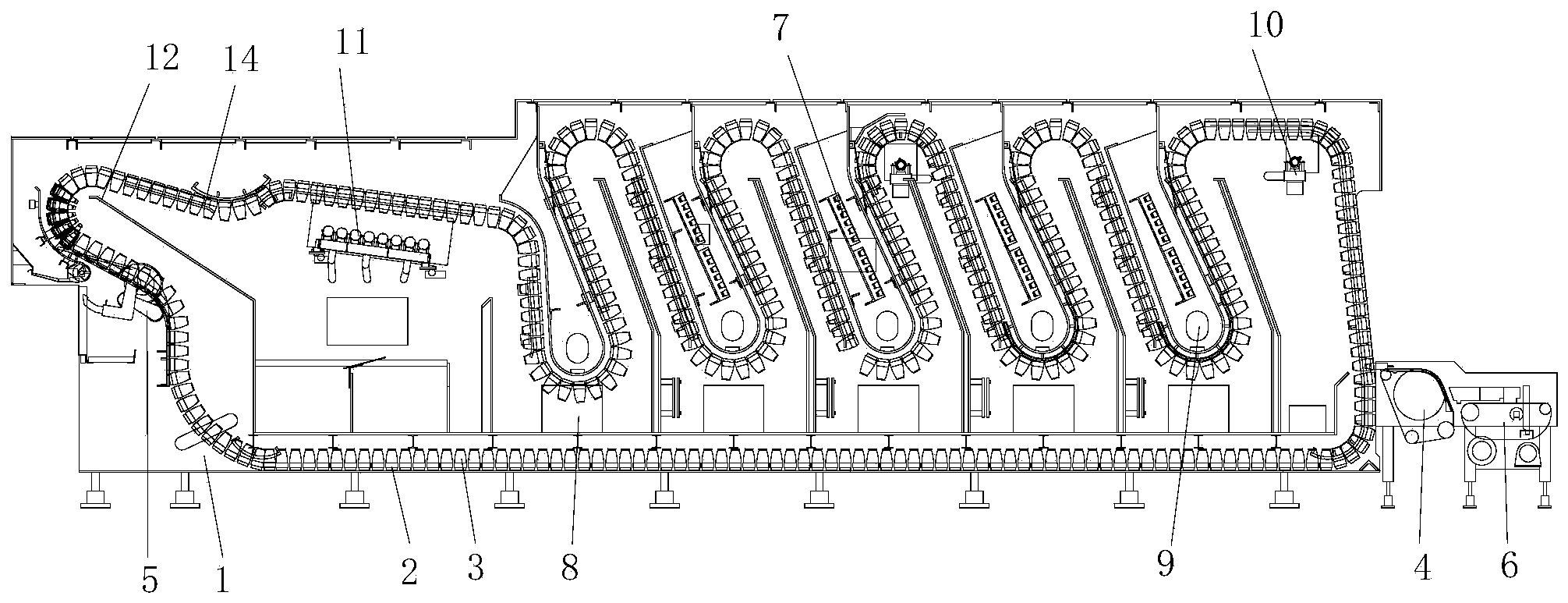

[0031] refer to figure 1 , image 3 and Figure 4 , the present embodiment is a single-ended tunnel type ultrasonic bottle washing machine, comprising a cabinet 1 filled with an alkali cleaning solution, a transmission device 2 that can rotate cyclically is arranged in the cabinet 1, and a number of bottle carrying boxes 3 are arranged on the transmission device 2. The same side of the cabinet 1 is provided with a bottle inlet and a bottle outlet.

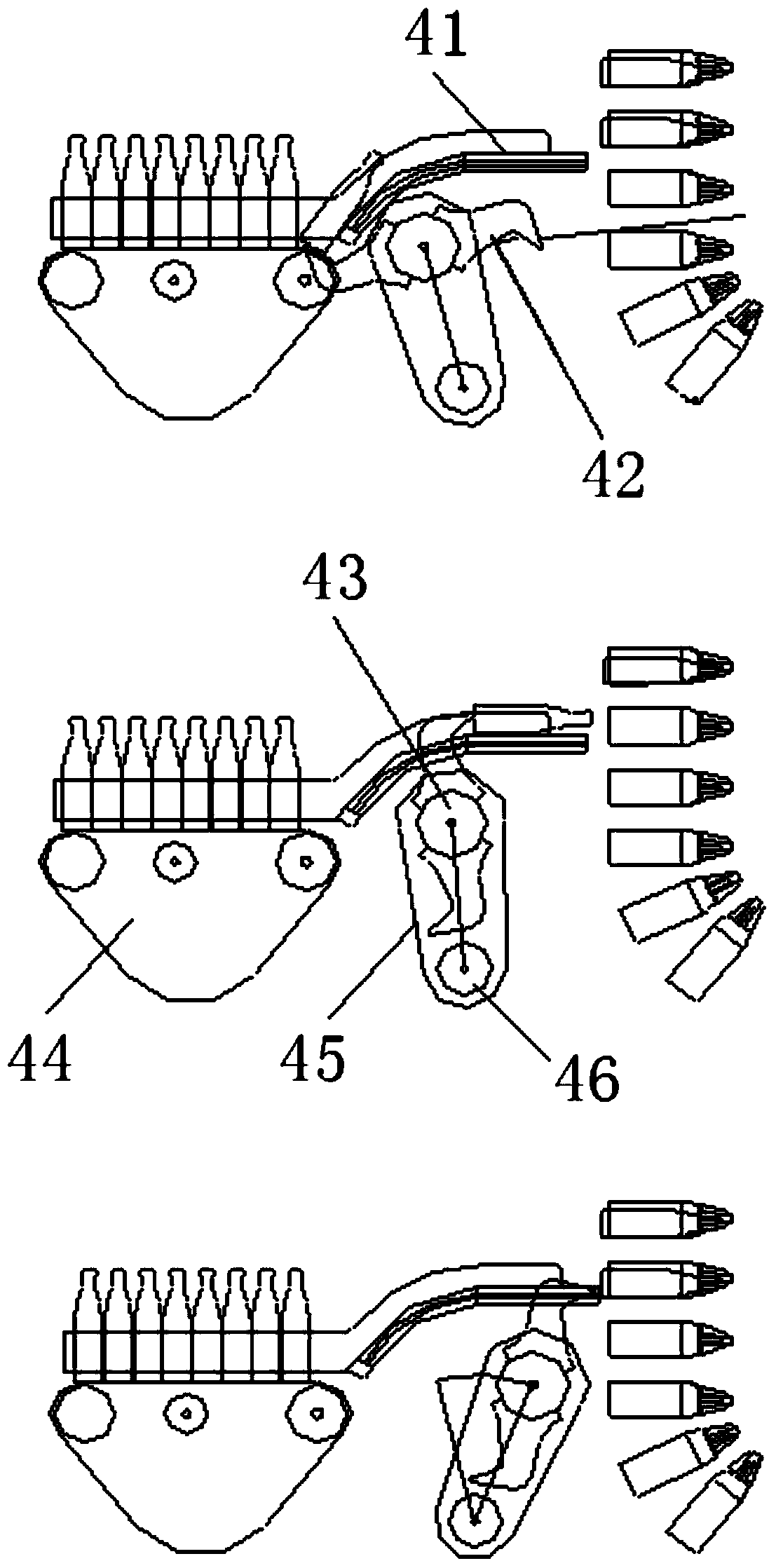

[0032] A bottle feeding mechanism 4 for pushing the bottle to be cleaned into the bottle loading box 3 is provided at the bottle inlet, and the bottle feeding mechanism 4 includes a conveying mechanism 44 for conveying the bottle to be cleaned, and a transition connected with the conveying mechanism 44 Plate 41 and a rocker 45 for swinging and conveying the bottle to be cleaned and a bottle-turning curved plate 42 arranged on the rocking rod 45 and rotatable, and two ends of the bottle-turning curved plate 42 are provided with cl...

Embodiment 2

[0042] refer to figure 2 , image 3 and Figure 4 , the present invention is a double-ended tunnel type ultrasonic bottle washing machine, which is different from Embodiment 1 in that: one side of the cabinet 1 is provided with the bottle inlet, and the opposite side is provided with the bottle outlet .

[0043] refer to Figure 5 , the lye spraying device of the present invention adopts the rotating spray pipe, and the rotating spray pipe is that each group is made up of two or three, and the shift fork on the bottle holder is pushed by the transmission device to drive the star wheel plate to drive the spray shaft 91 to rotate, There are two rows of high-pressure spray holes arranged vertically on the spray shaft 91. The spray shaft 91 is supported on the upper support and the lower support made of wear-resistant materials. The high-pressure injection hole and the square pipe of the drenching shaft 91, the spray water of the square pipe flushes the inside of the bottle 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com