Patents

Literature

253 results about "Wash bottle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A wash bottle is a squeeze bottle with a nozzle, used to rinse various pieces of laboratory glassware, such as test tubes and round bottom flasks. Wash bottles are sealed with a screw-top lid. When hand pressure is applied to the bottle, the liquid inside becomes pressurized and is forced out of the nozzle into a narrow stream of liquid.

Automatic sterilizing waste glass bottle recycling equipment

InactiveUS20200130031A1Remove old labelsAccurate removalSolid waste disposalHollow article cleaningForeign matterProcess engineering

The invention discloses an automatic sterilizing waste glass bottle recycling equipment, and includes a machine body, a left side of the upper end of the machine body is provided with a placement opening that opens upwards and opens to the left, a right wall of the placement opening communicates with a channel that opens to the right, and a bottle washing device is provided on the left side of the channel An infrared detection device is arranged in the channel and on the right side of the bottle body scrubbing device, the infrared detection device pushes out bottles with foreign objects or damage in the bottle, and an in-bottle flushing device is provided on the right side in the channel. The outer surface of the recovered glass bottle can be quickly cleaned and the old labels can be removed. By hot water cleaning, both the bottle body can be sterilized by high temperature and the glass bottle can be heated at the same time, so that the next infrared detection can be accurately removed.

Owner:LIN SHICHANG

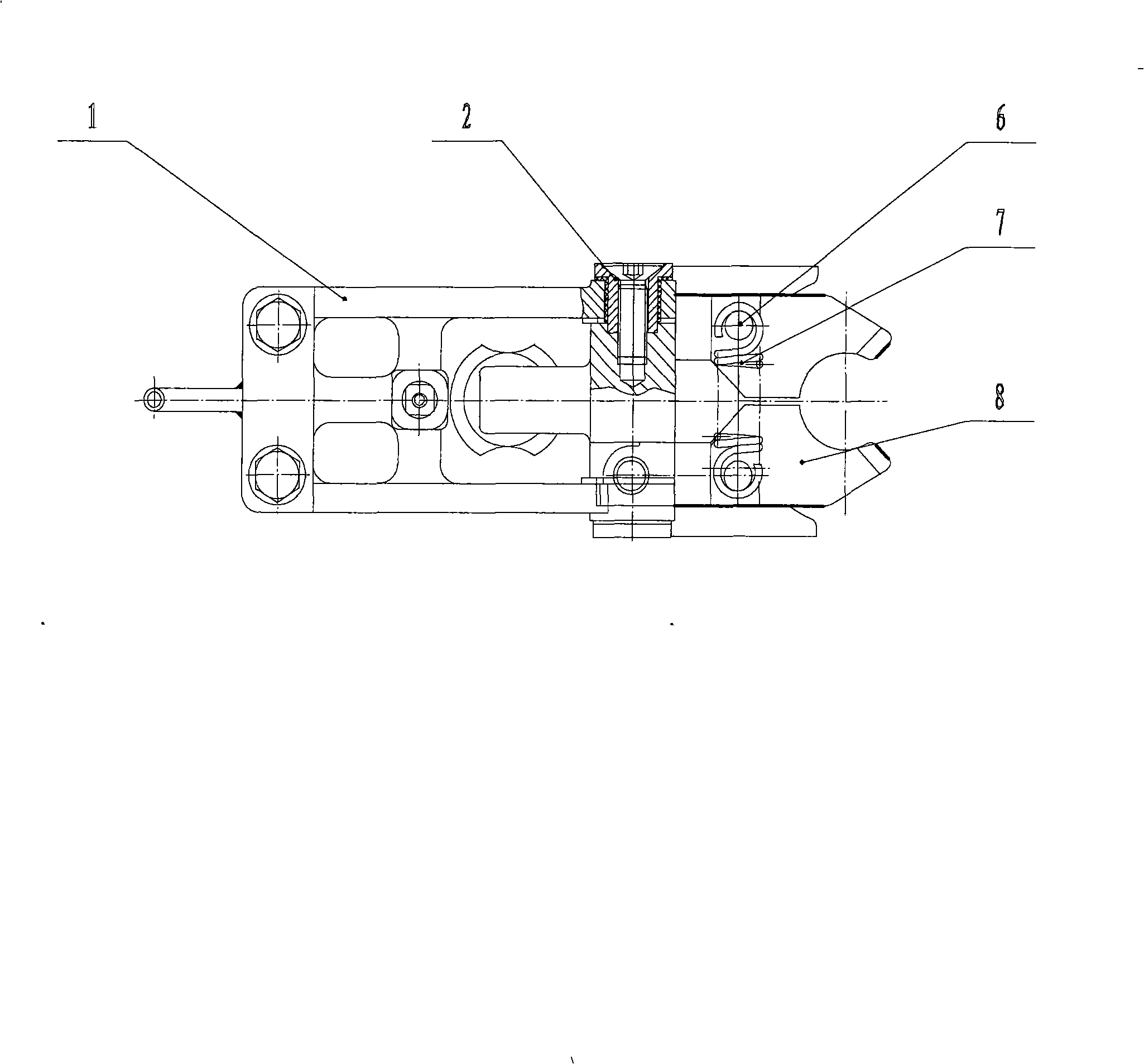

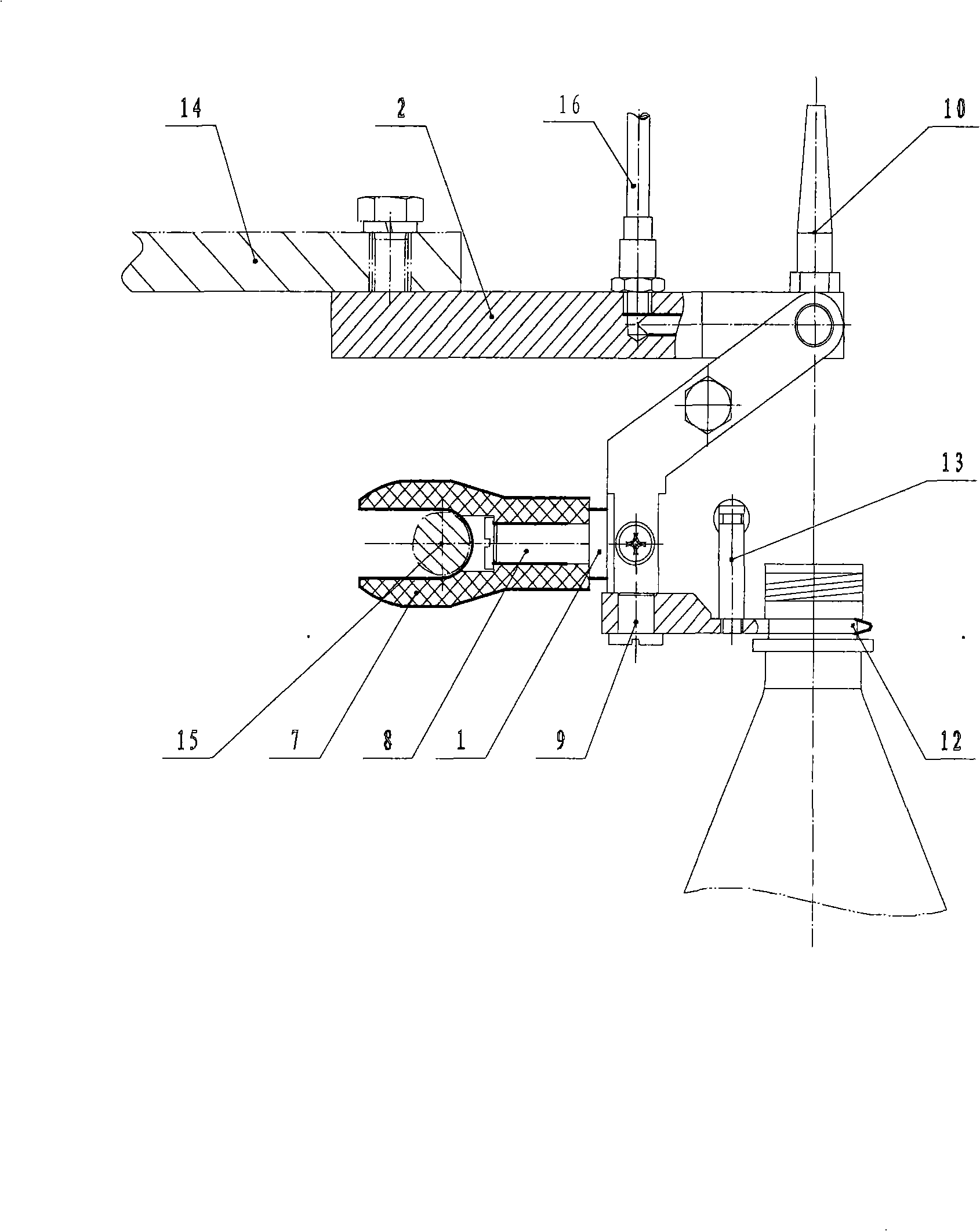

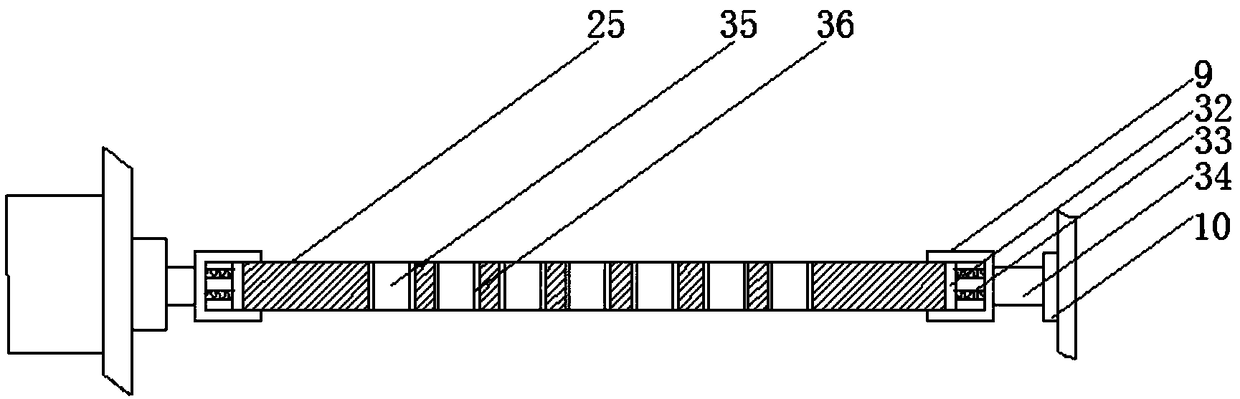

Clip for washing bottle

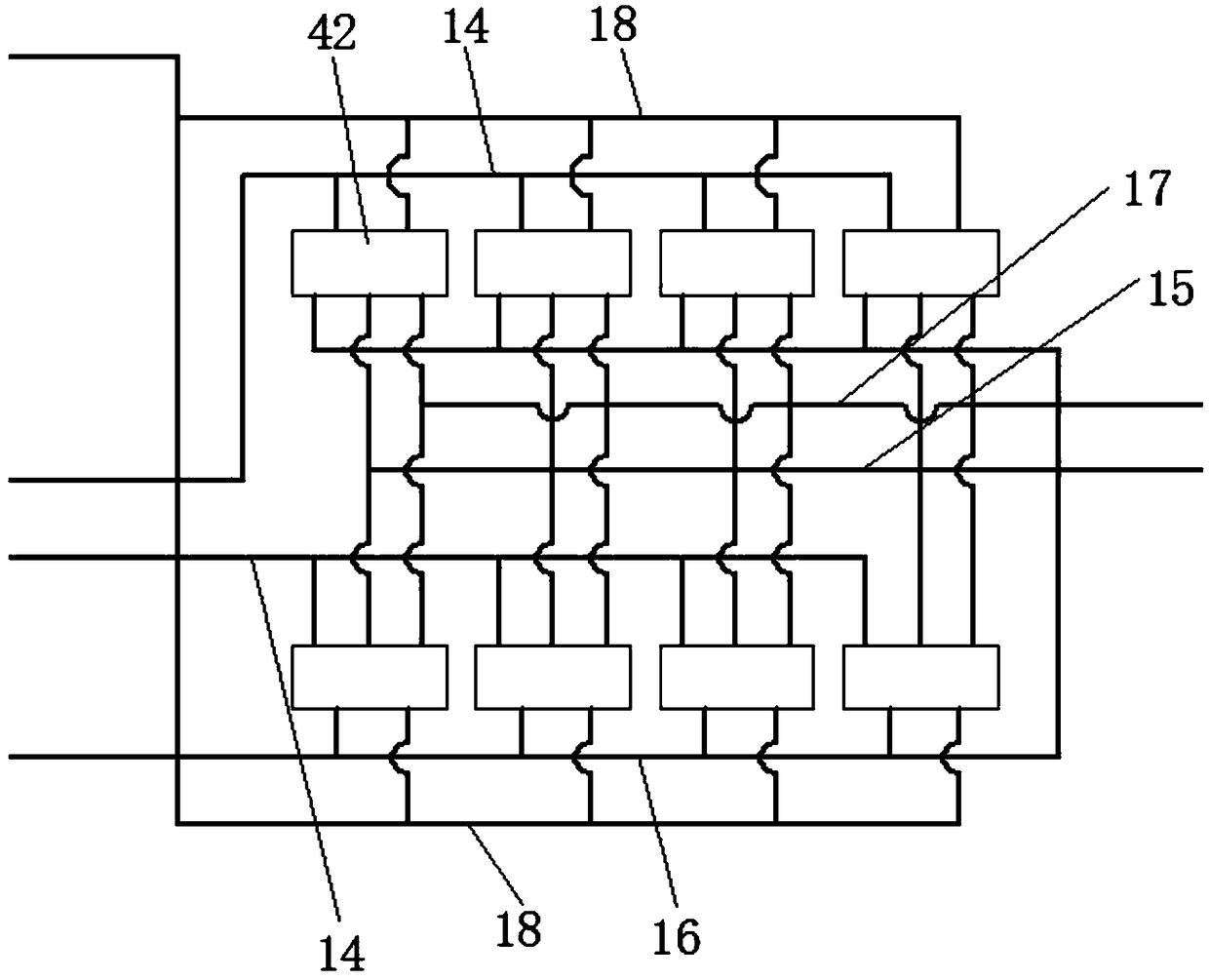

InactiveCN101347786ASave installation spaceReduce manufacturing costHollow article cleaningPunchingEngineering

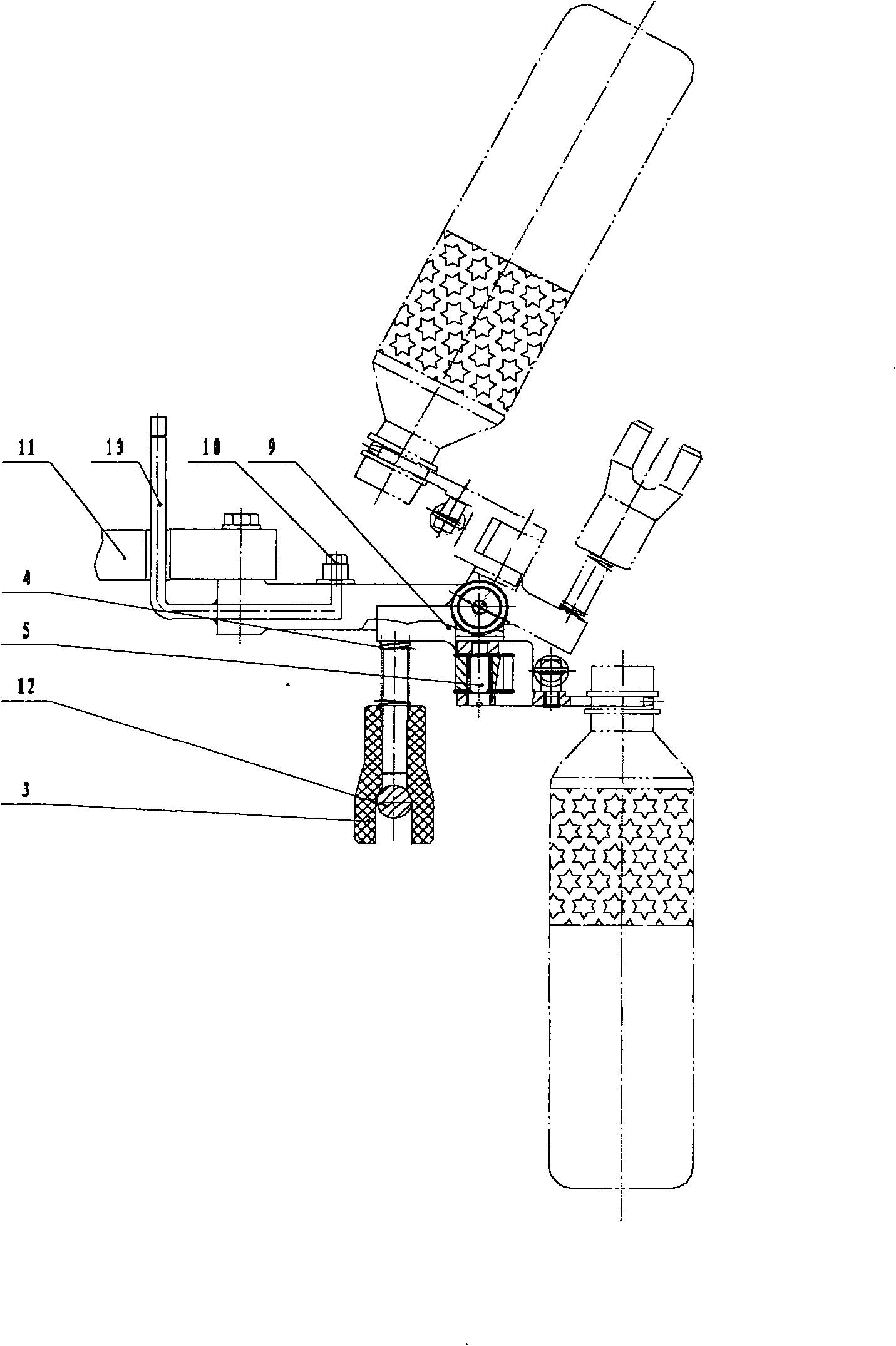

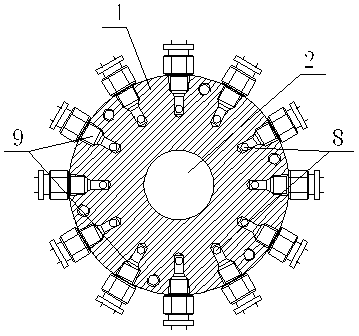

The invention provides a bottle punching clamp. A supporting block is fixed on a rotary disc; a left elbow rod and a right elbow rod are respectively arranged at the two sides of the supporting block by a small shaft; the two elbow rods can rotate around the small shaft; the two elbow rods are connected with each other by a fixed distance body; a left clamping sheet and a right clamping sheet are provided with pins which are used for fixing a pullback spring; a supporting body is fixed on the side surfaces of the two elbow rods; a sliding fork is connected on the supporting body by a retaining ring screw; the sliding fork is contacted with a turnover guideway and can slide along the turnover guideway, thus driving the elbow rods and the clamping sheets to turn over. After the bottle clamped by the left clamping sheet and the right clamping sheet is turned over by 180 degrees, the distance from the center of the bottle to the center of the rotary disc is kept unchangeable, and the distance of two adjacent bottles before and after the turnover of the bottle is also kept unchangeable; therefore, the bottle punching clamp can be applicable to large bottles without the necessary to consider the mutual interference of the two adjacent bottles after the turnover of the bottle. The bottle punching clamp saves the installation space and saves the production cost compared with the original bottle punching clamp.

Owner:JIANGSU ASG PACKAGING MACHINERY GRP

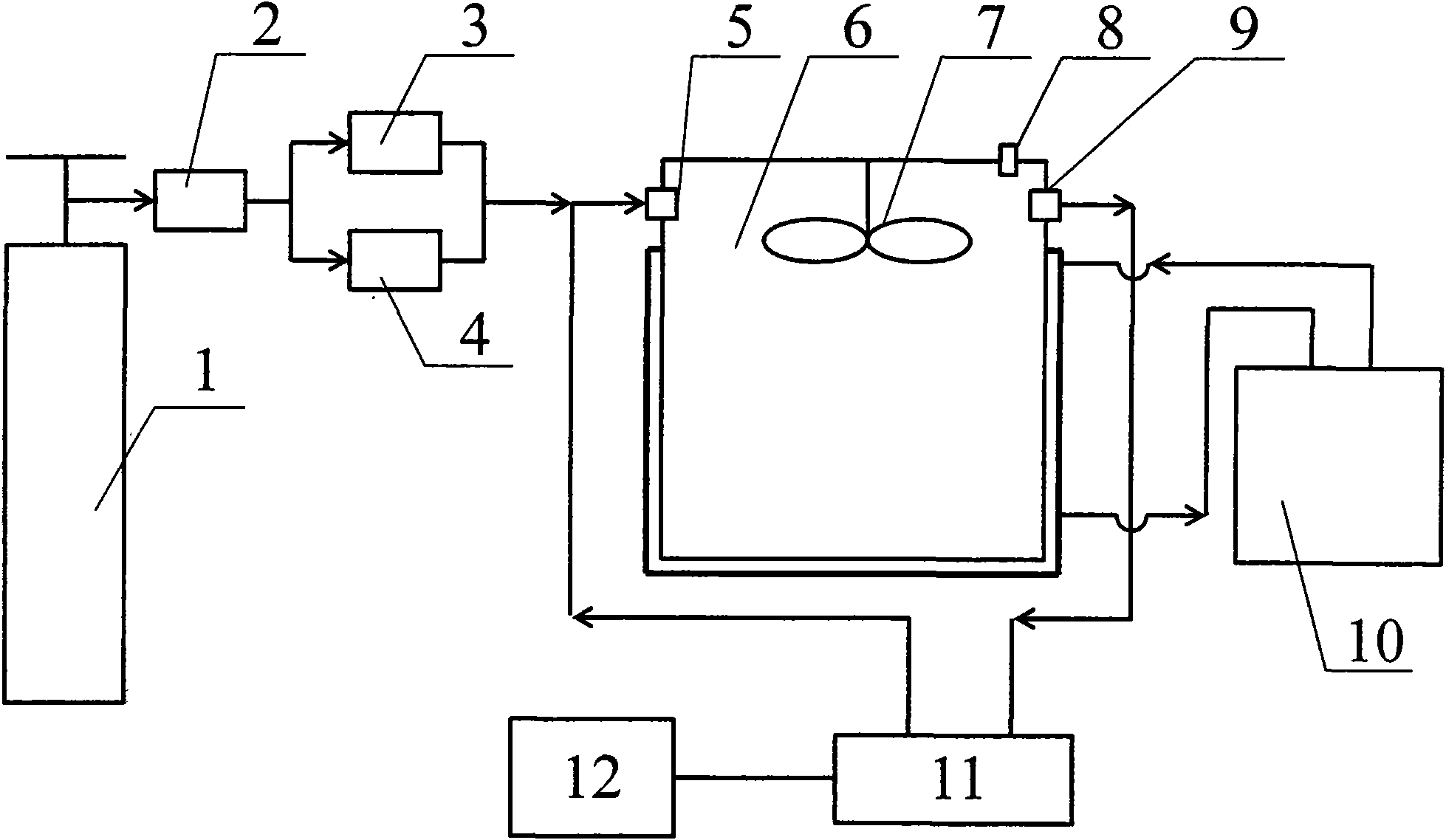

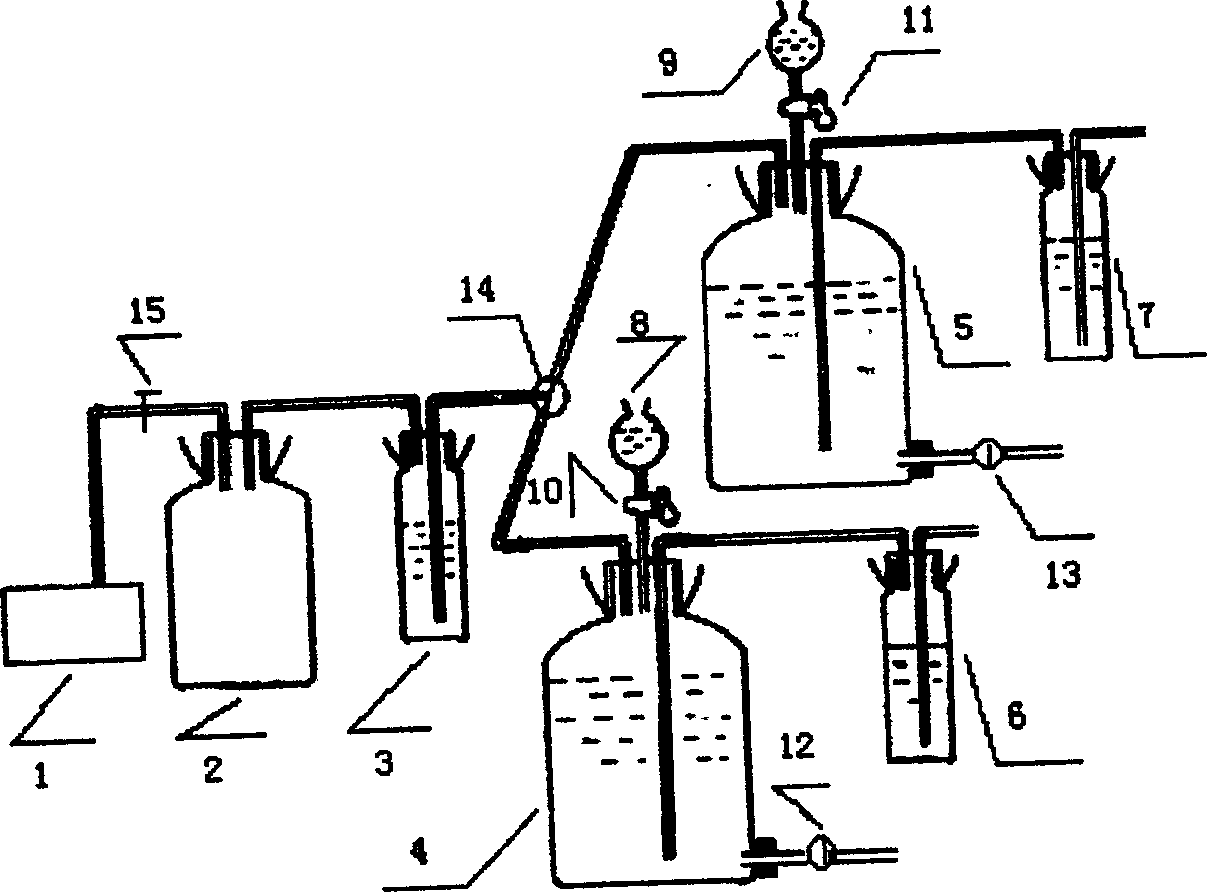

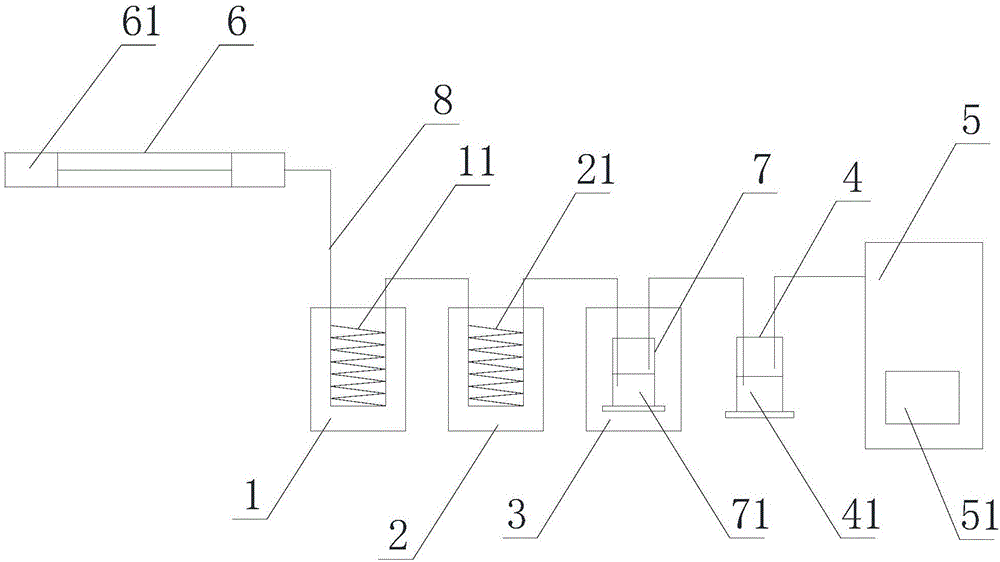

Experimental device for measuring formaldehyde adsorption property of adsorbent and measuring method thereof

ActiveCN101644666ASolve the problem of difficult determination of injection volumeAvoid destructionMaterial analysis by optical meansExperimental methodsSorbent

The invention relates to an experimental device for measuring the formaldehyde adsorption property of adsorbent and a measuring method thereof, belonging to the field of indoor environment measurement. The experimental device comprises a thermostatic waterbath being capable of setting the temperature, a compressed gas cylinder for providing carrier gas, a primary and bypass path flow controller for controlling and measuring air flow, a gas-washing bottle containing distilled water, an environmental chamber provided with an outer housing, an acousto-optical gas analyzer and a display; a gas inlet and a gas outlet are arranged on the opposite lateral walls of the environmental chamber, and a stirring fan and a sampling hole are arranged at the top of the environmental chamber. And the acousto-optical gas analyzer is connected with the gas inlet and the gas outlet through pipelines. An experimental method utilizes the acousto-optical gas analyzer to detect the formaldehyde equilibrium concentration in the blank environmental chamber without the adsorbent and the environmental chamber with the adsorbent on line at the real time and obtains the formaldehyde adsorption property of the adsorbent by calculation. The experimental device and the measuring method thereof can control the temperature and the moisture better, and has simple and convenient operation and higher precision and reliability.

Owner:TSINGHUA UNIV

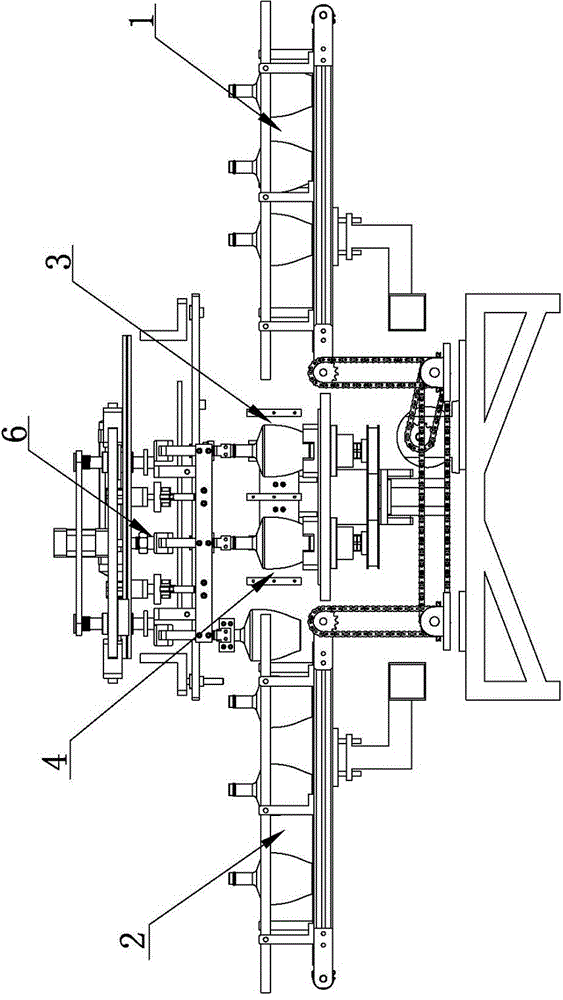

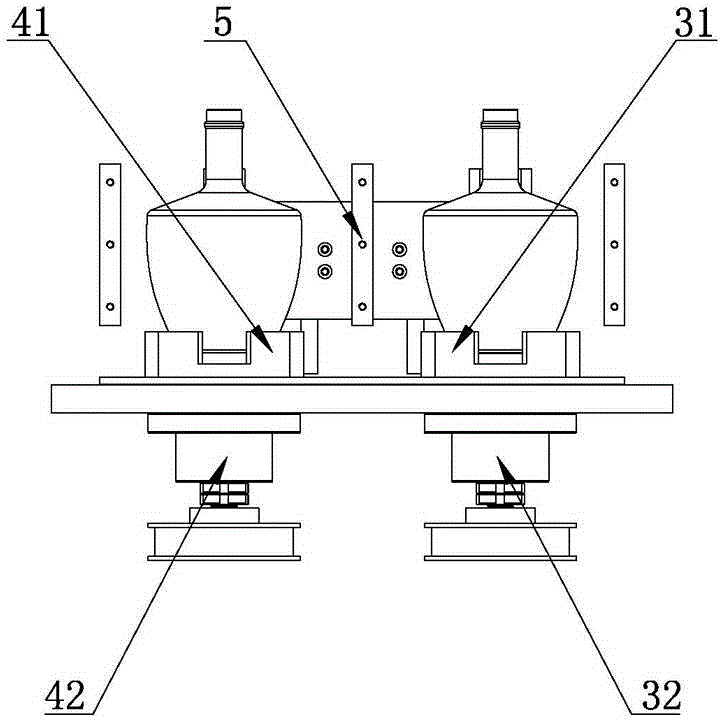

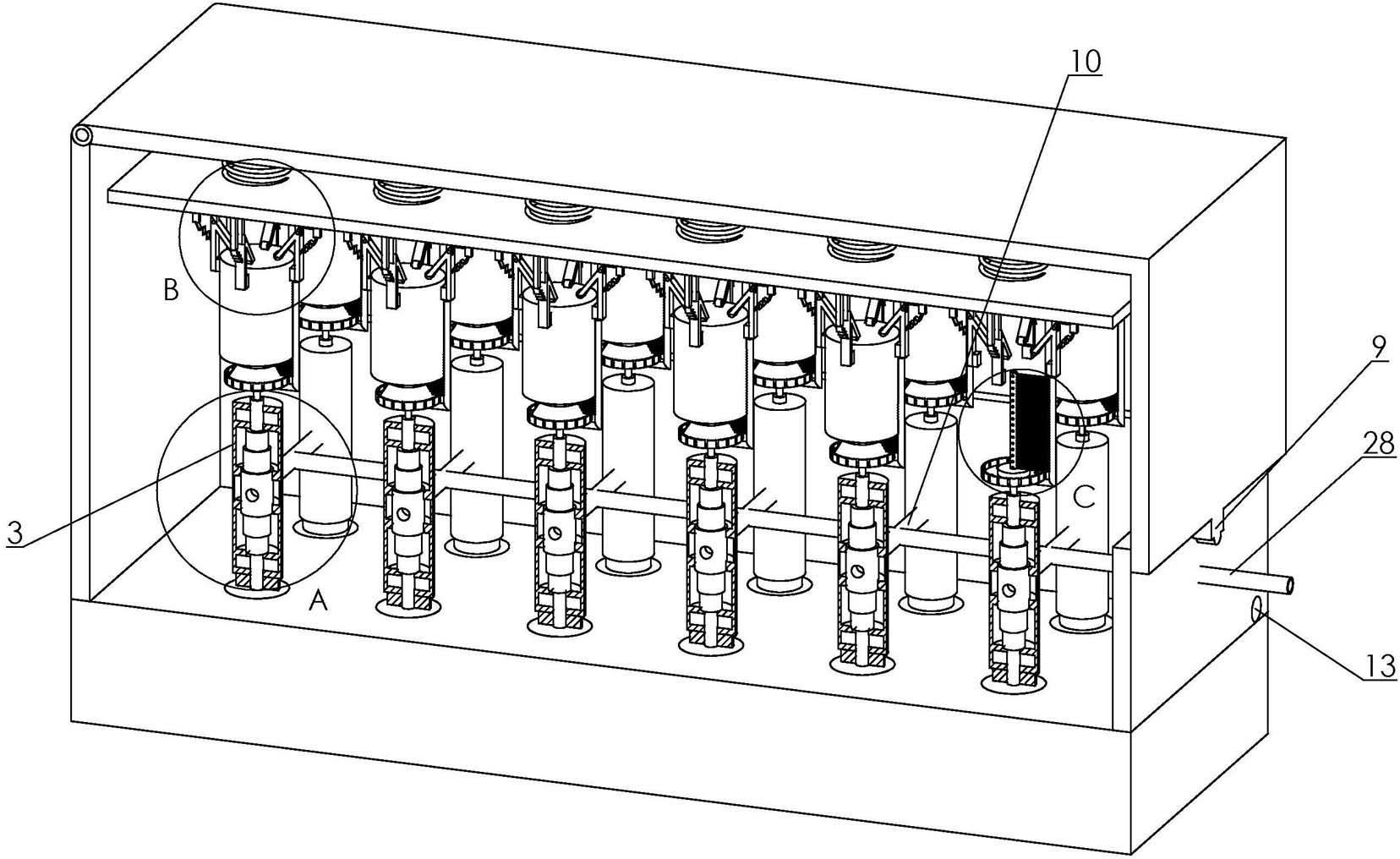

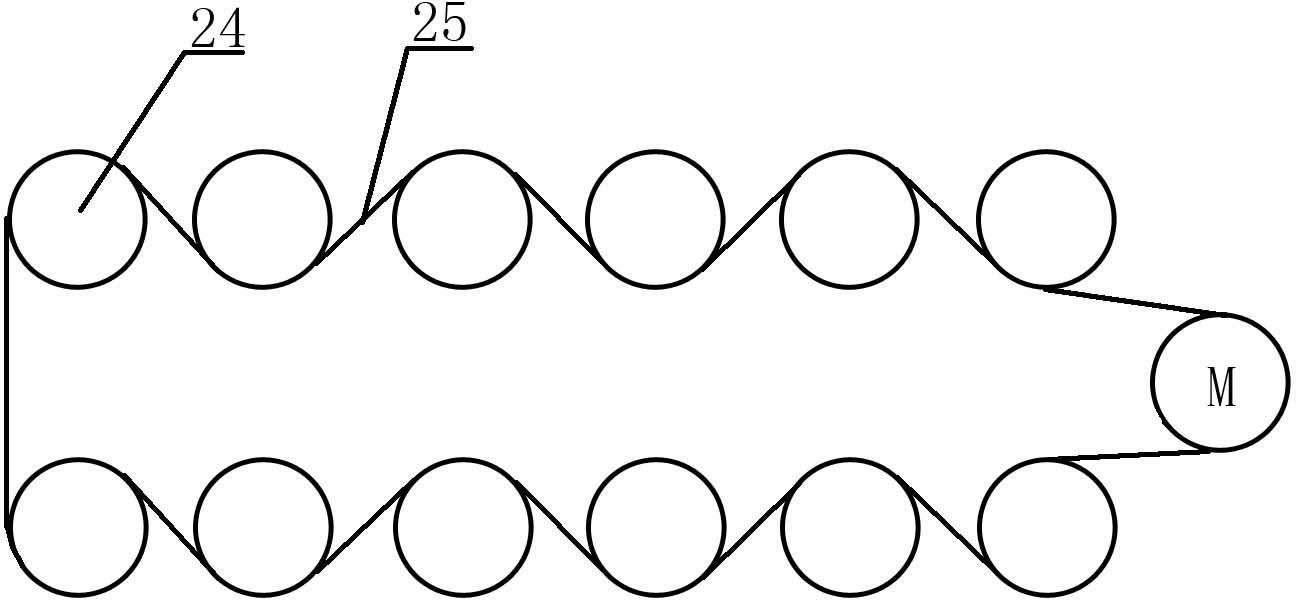

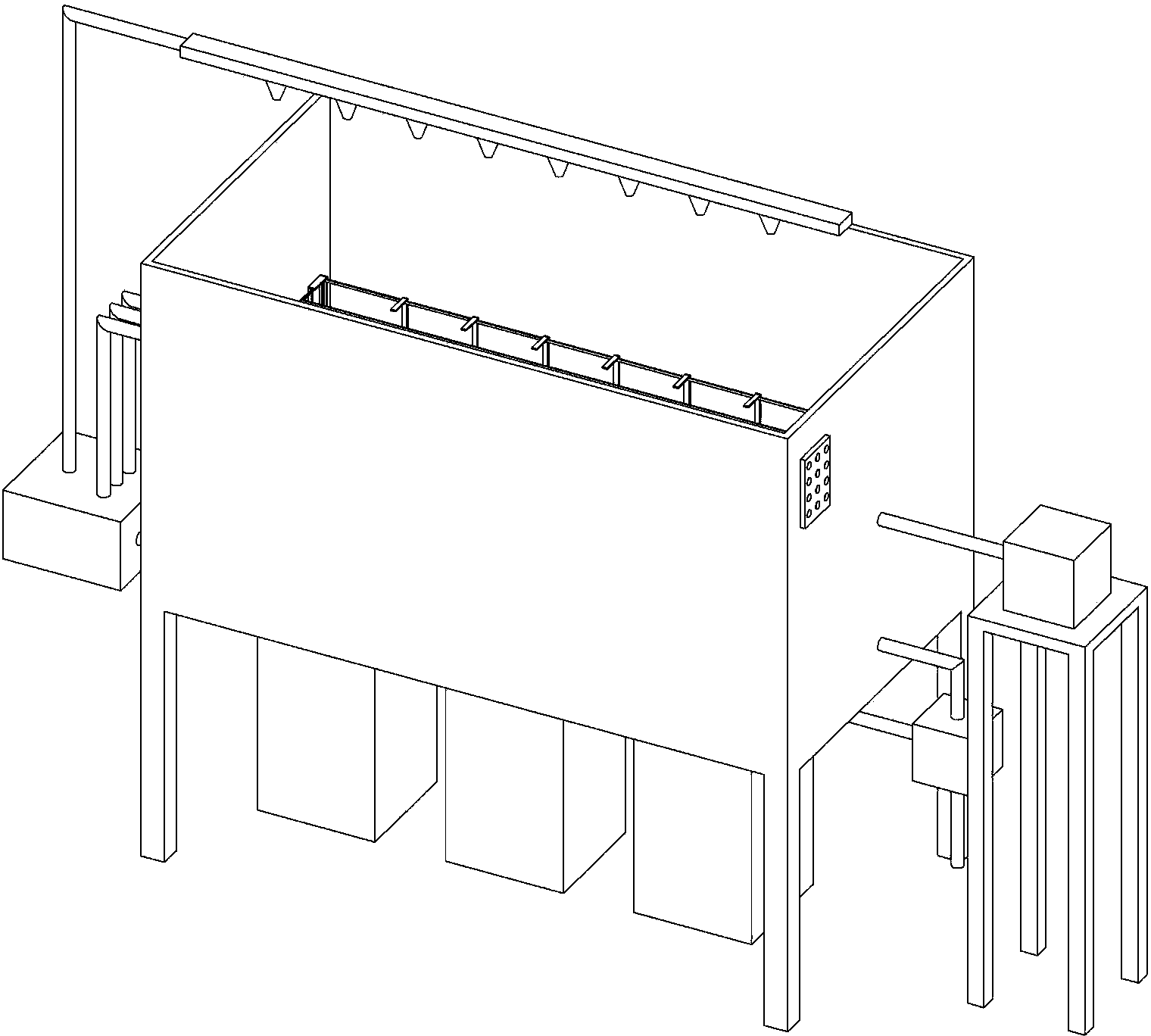

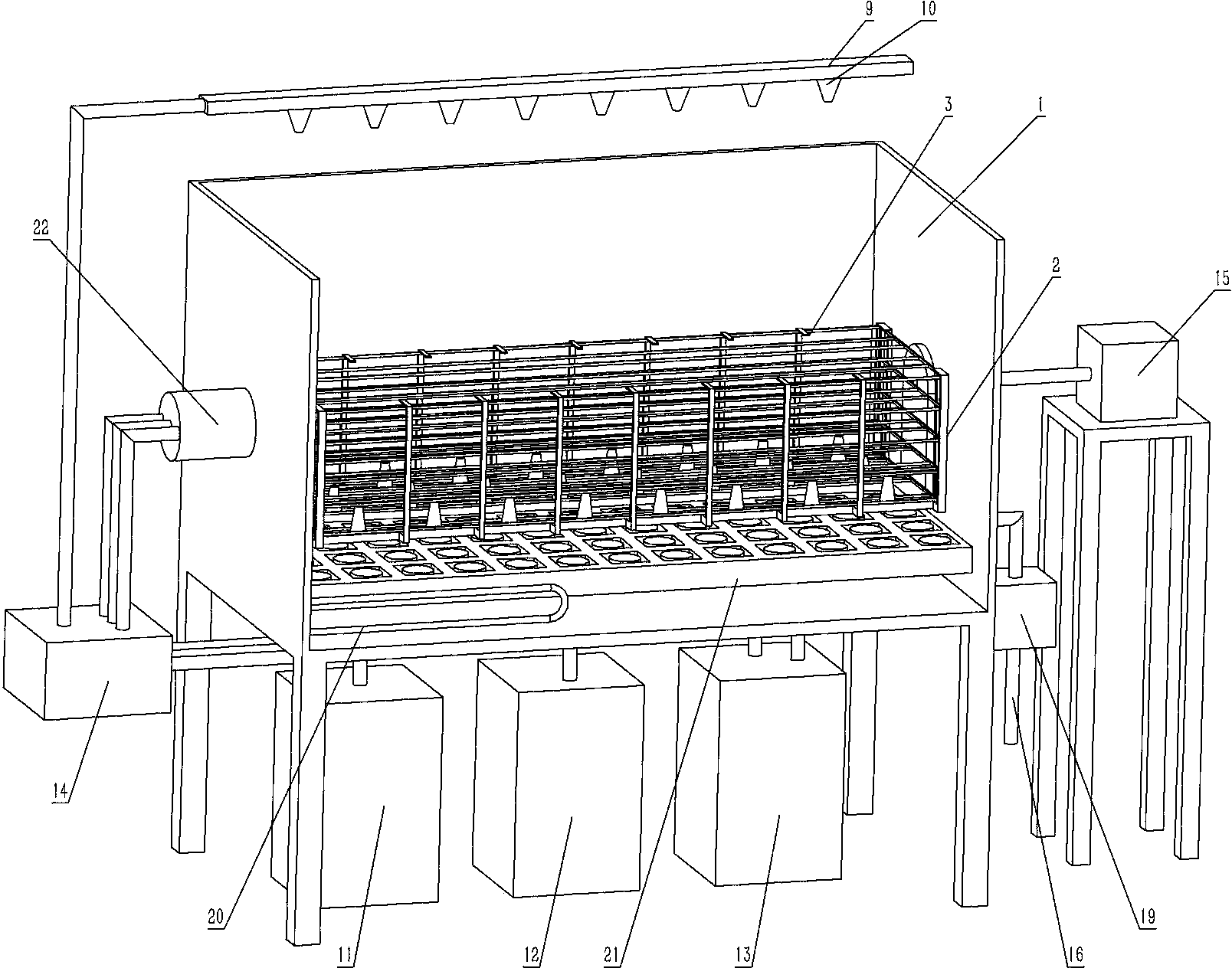

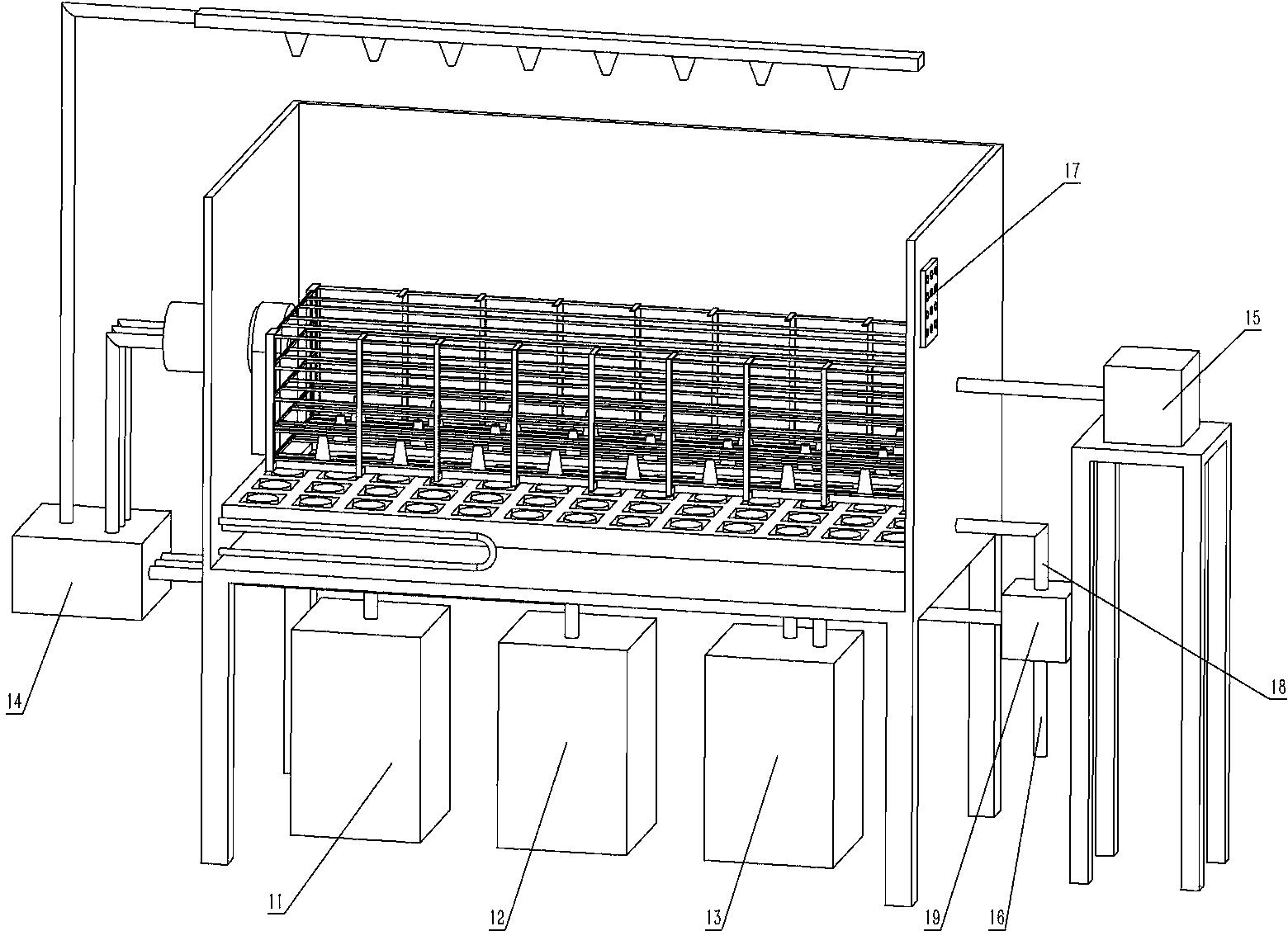

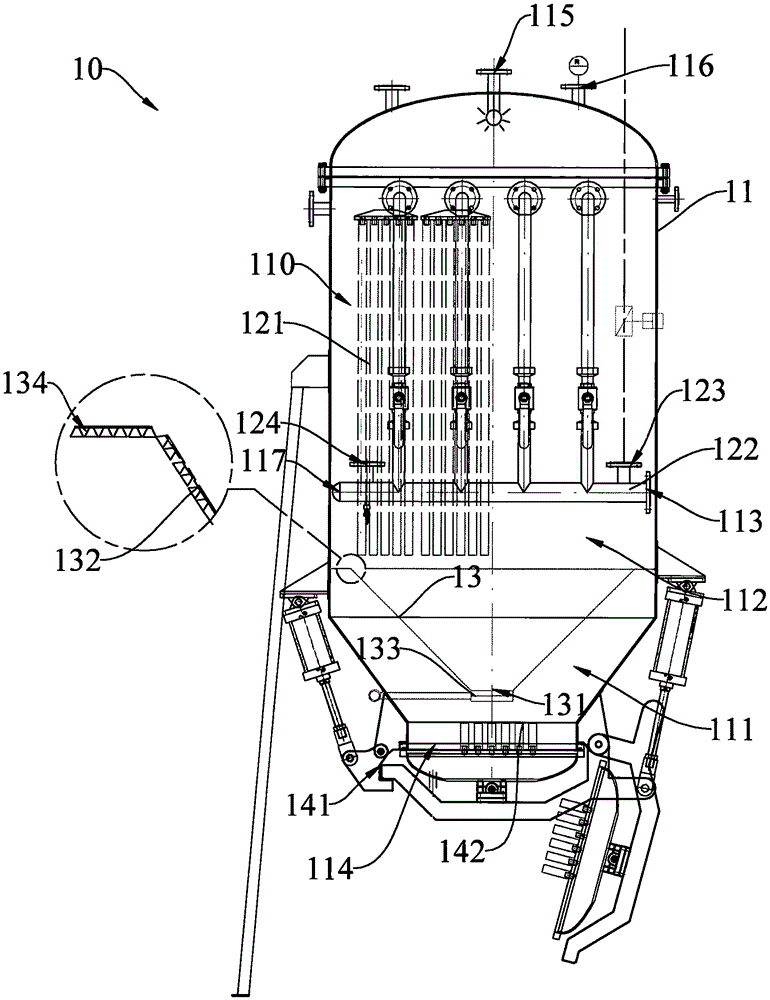

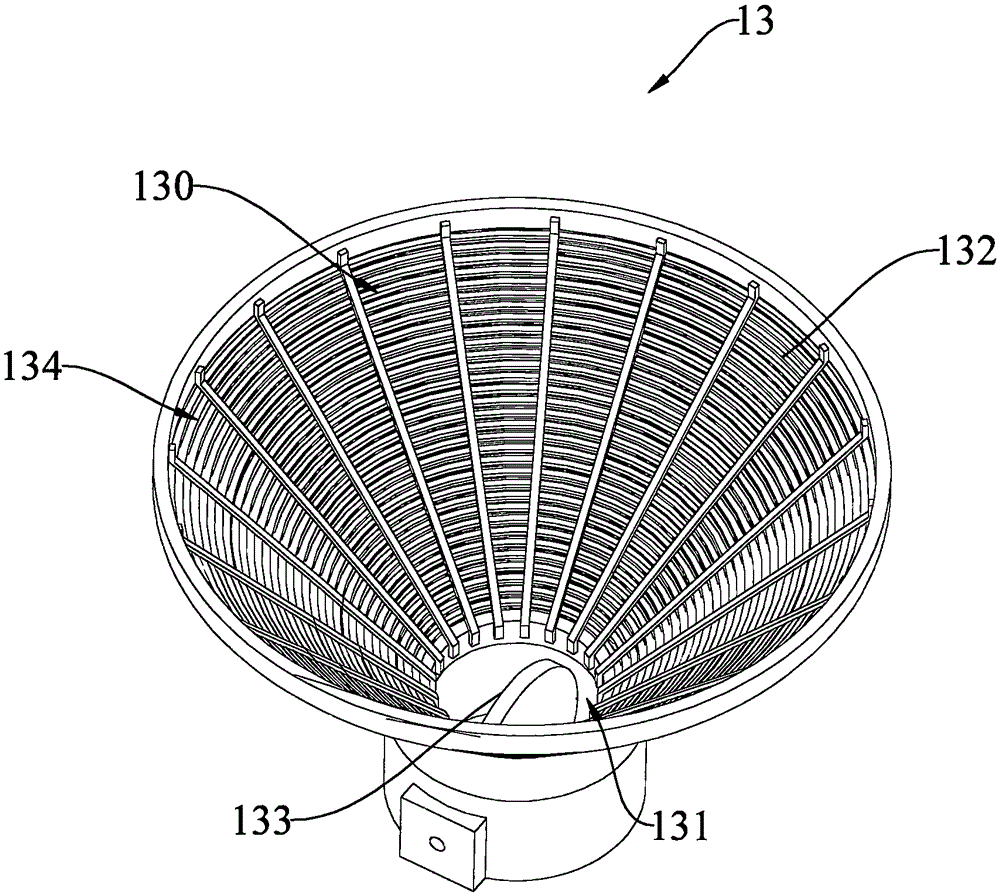

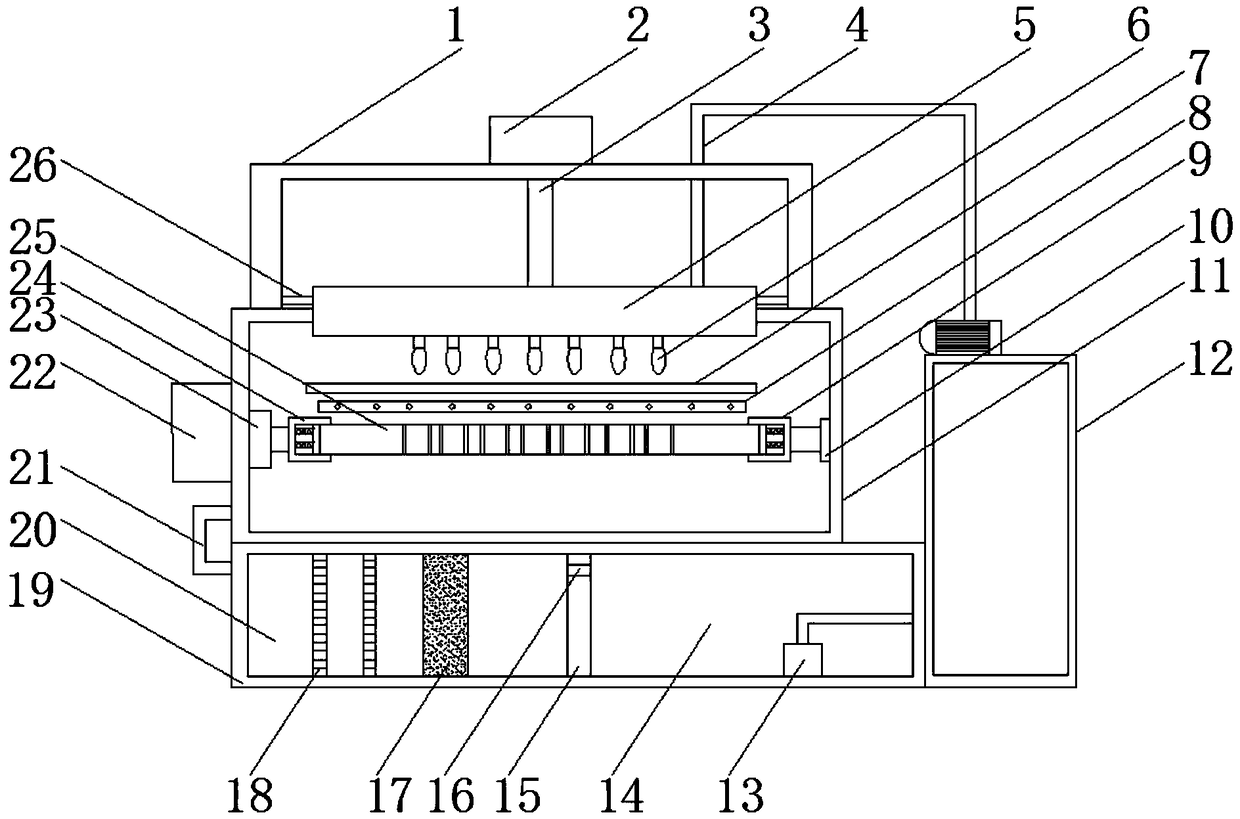

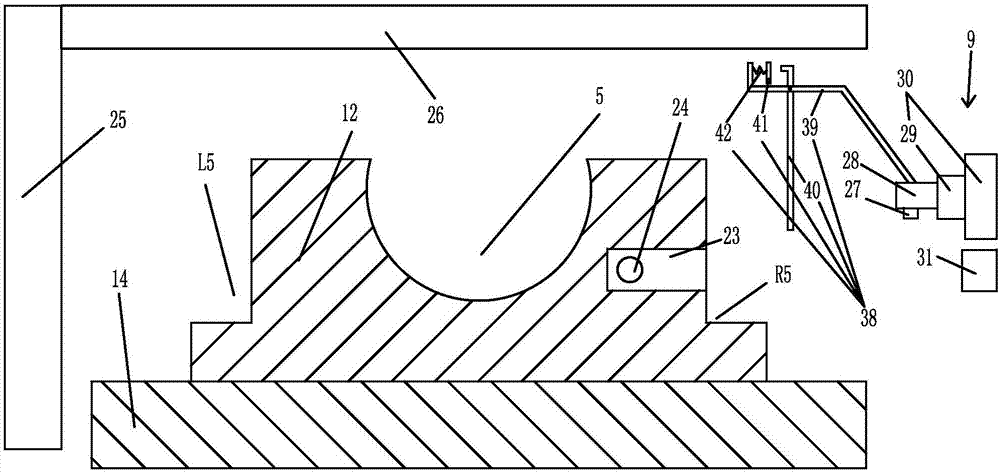

Full-automatic bottle washing machine

ActiveCN104307825AReduce labor costsImprove cleaning efficiencyHollow article cleaningWash bottleWaste management

The invention relates to the technical field of bottle washing equipment, in particular to a full-automatic bottle washing machine, which comprises a rack, wherein the rack is provided with a feeding and discharging device, wherein the feeding and discharging device comprises a feeding channel, a discharging channel and a transmission mechanism; a bottle washing device is arranged between the feeding channel and the discharging channel; a feeding hole of the bottle washing device is communicated with a discharging hole of the feeding channel; a discharging hole of the bottle washing device is communicated with a feeding hole of the discharging channel; the bottle washing device comprises a washing station and a wiping and absorbing station; a spacing board is arranged between the washing station and the wiping and absorbing station; a feeding device for clamping and feeding a bottle to the next station is arranged above the bottle washing station. The full-automatic bottle washing machine can be used for full-automatically washing bottles, replaces manual washing, is beneficial to reducing of the manpower cost, is high in washing efficiency and simple in structure, and can be used for cleaning any type of bottles.

Owner:DONGGUAN TINSHINE TIN BOX

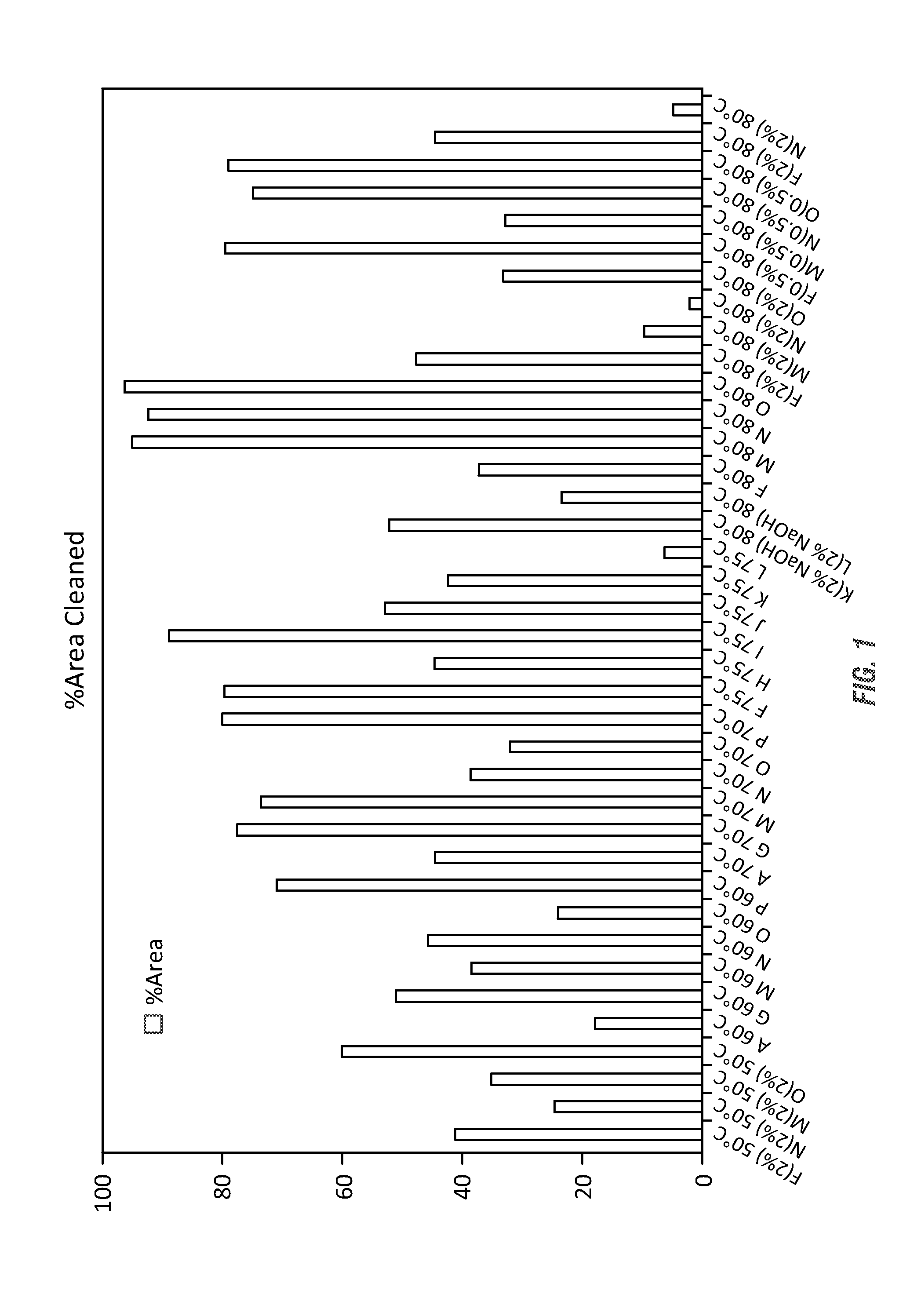

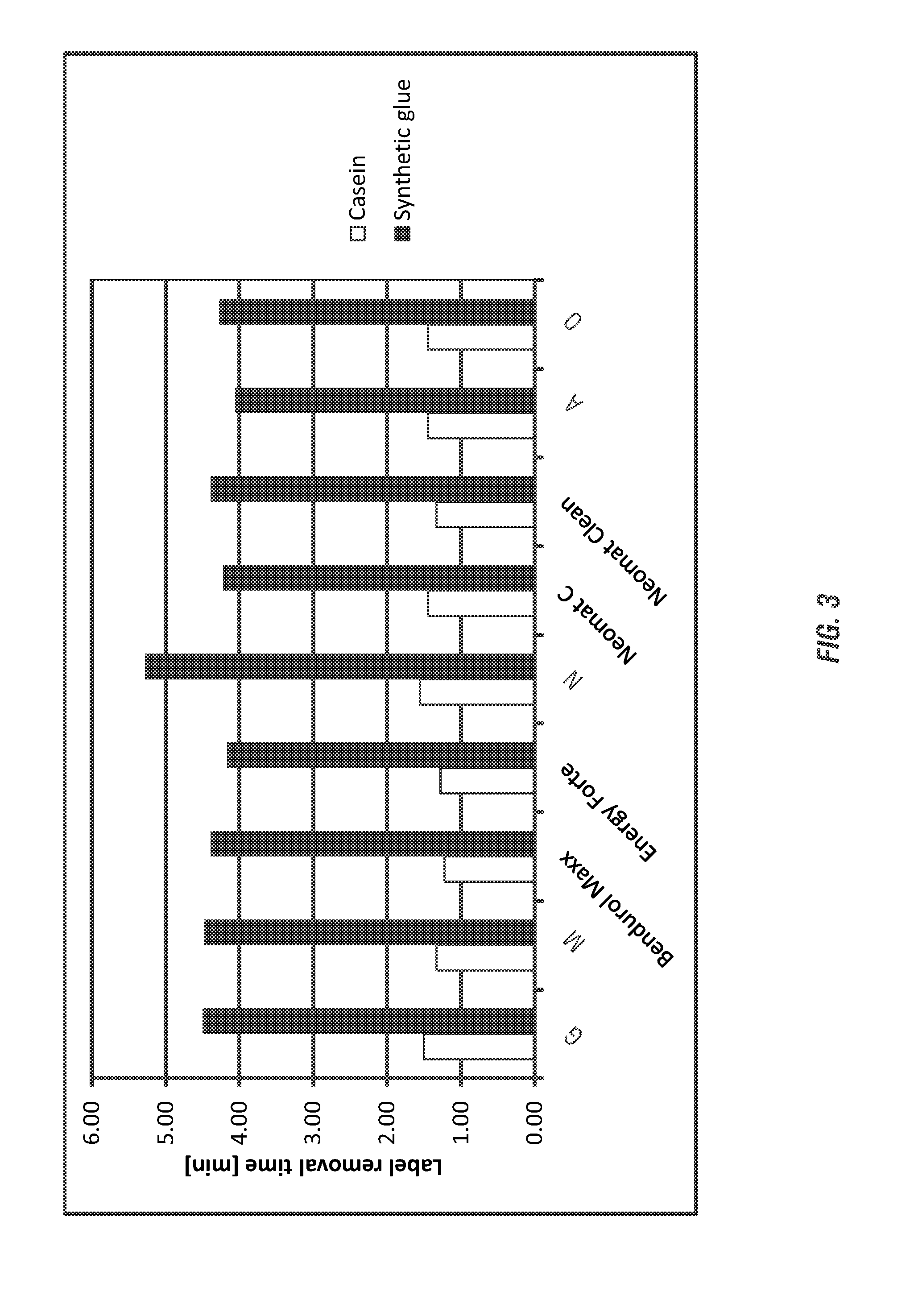

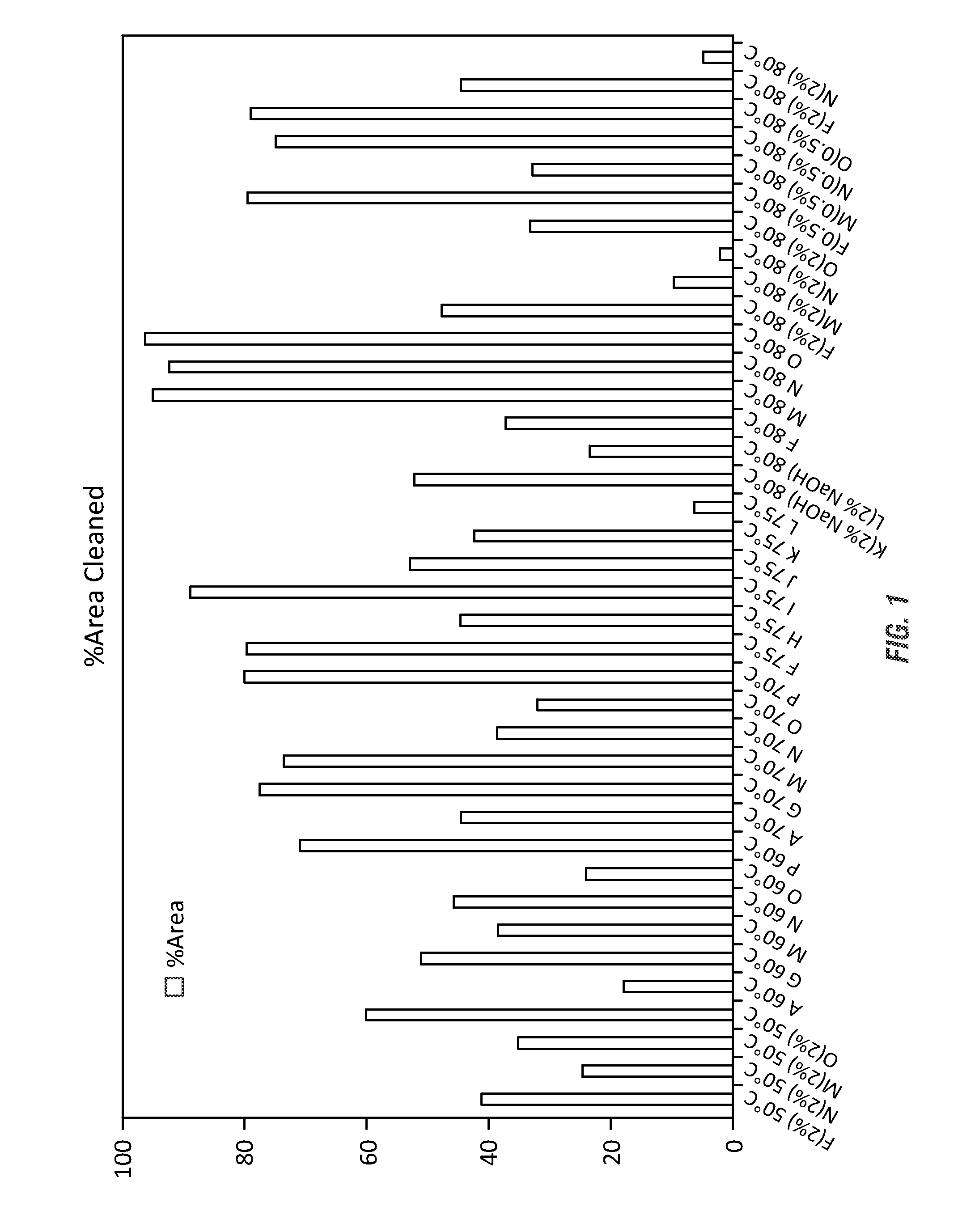

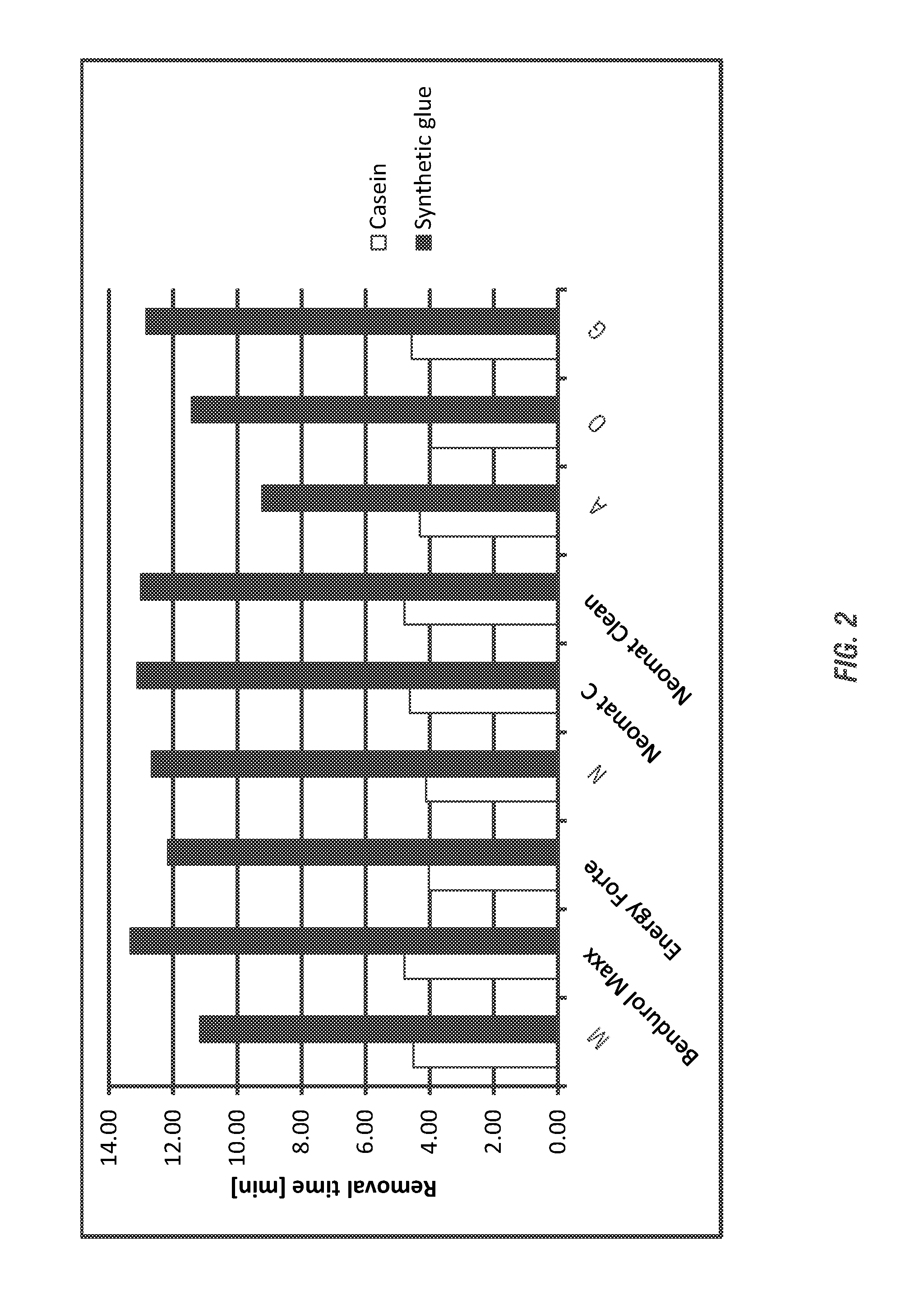

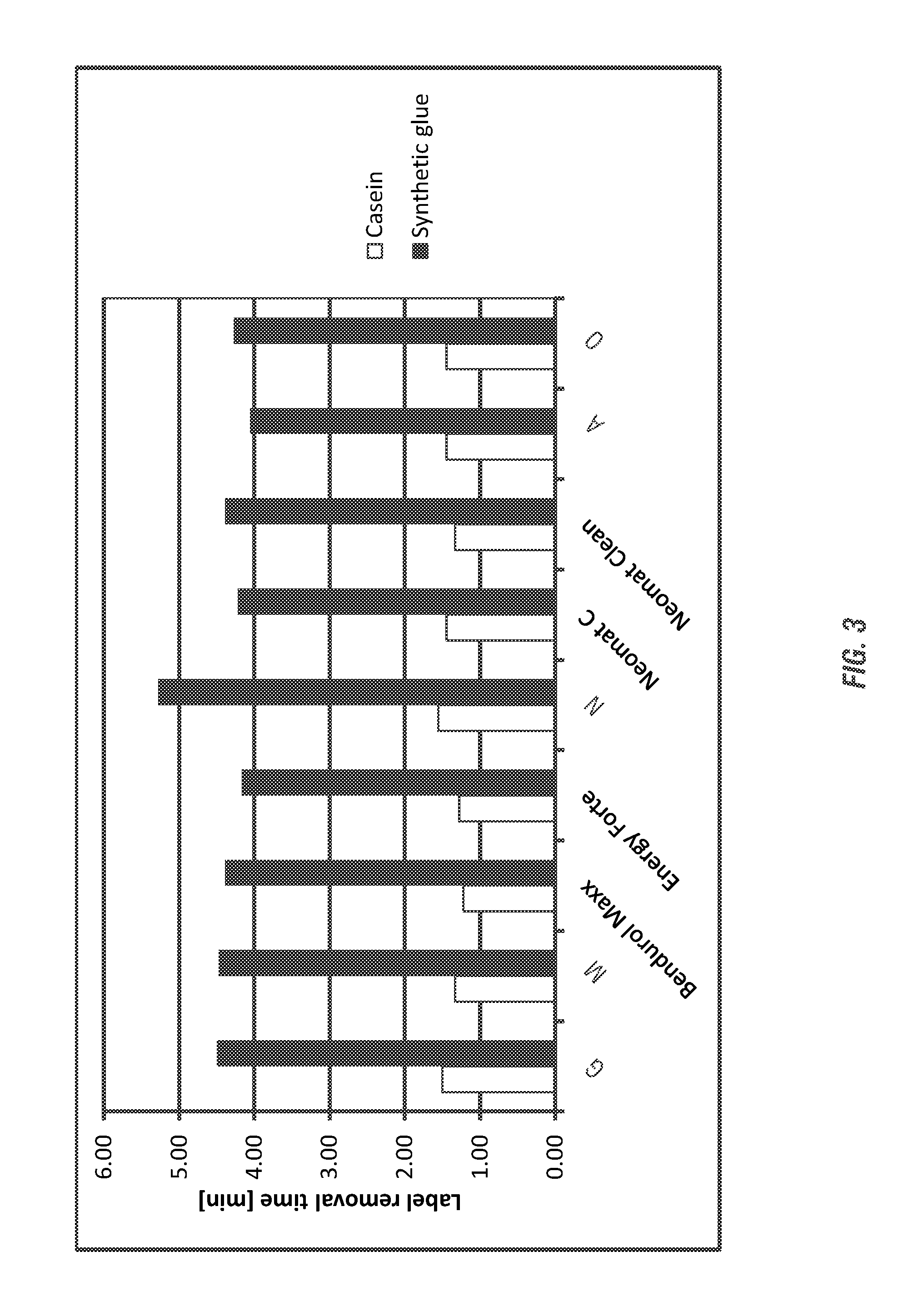

Label removal solution for low temperature and low alkaline conditions

ActiveUS20140352740A1Efficient removalExtension of timeOrganic detergent compounding agentsSurface-active detergent compositionsActive agentPhysical chemistry

According to the invention, the compositions and methods provide for the complete removal of synthetic glues or adhesives from a plurality of surfaces through the use of amide solvents in combination with surfactants, chelants, acidulants and / or additional bottle wash additives. Beneficially, the compositions and methods are suitable for use at lower temperatures, including below 35° C., and lower pH conditions, including from 5 to 10, from 6 to 9, and from 6 to 8, in comparison to conventional caustic-based adhesive removal compositions.

Owner:ECOLAB USA INC

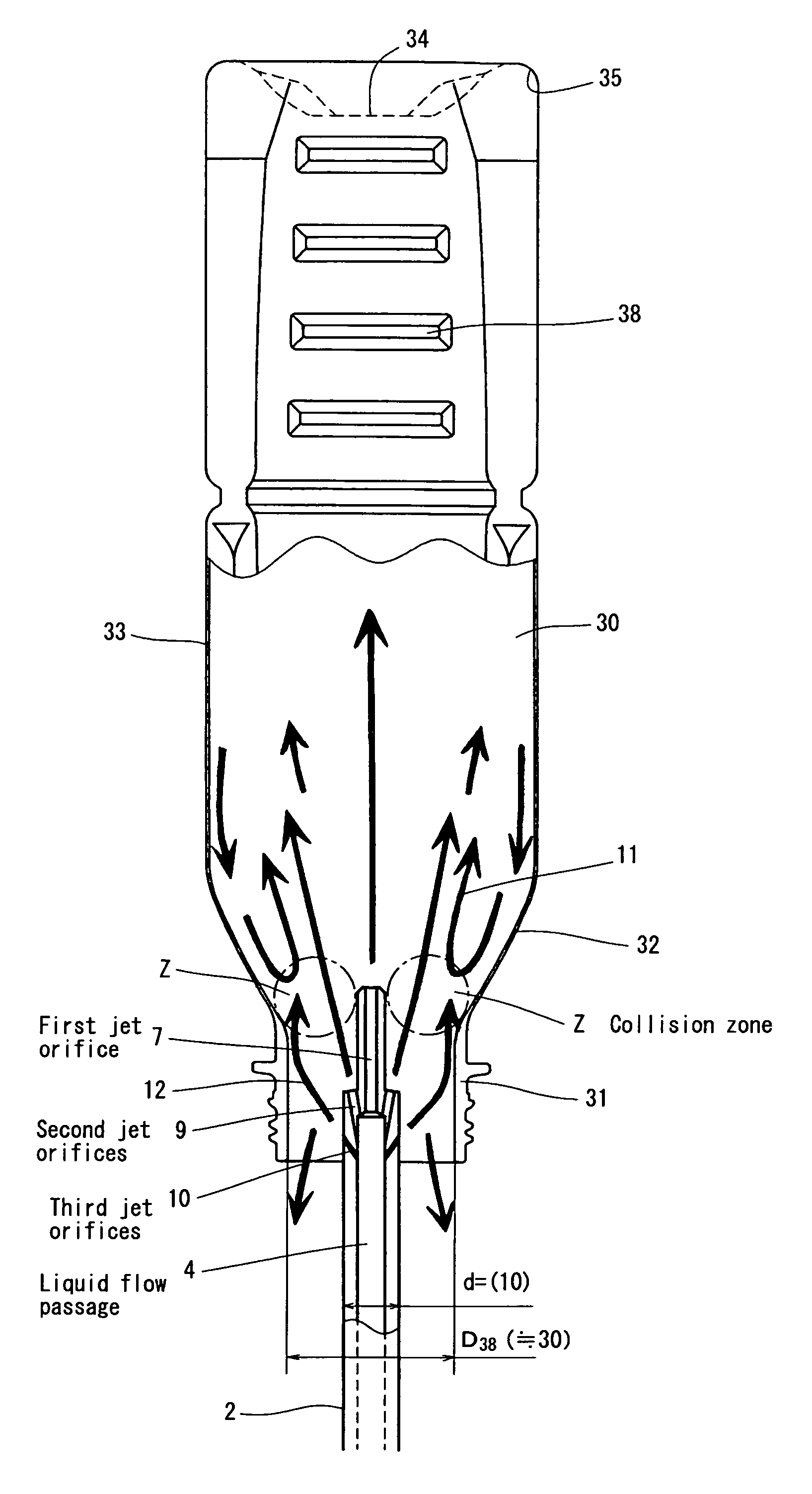

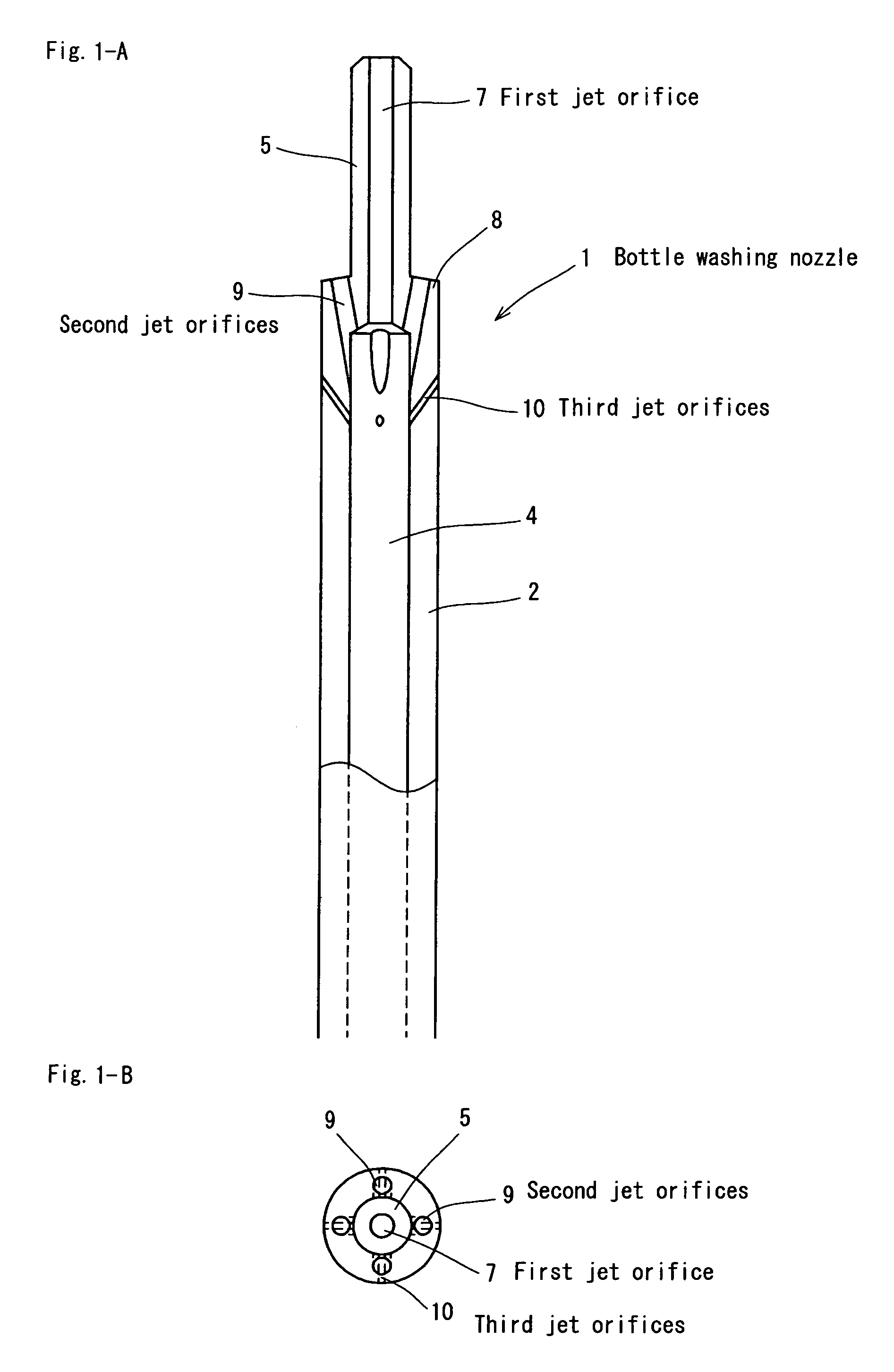

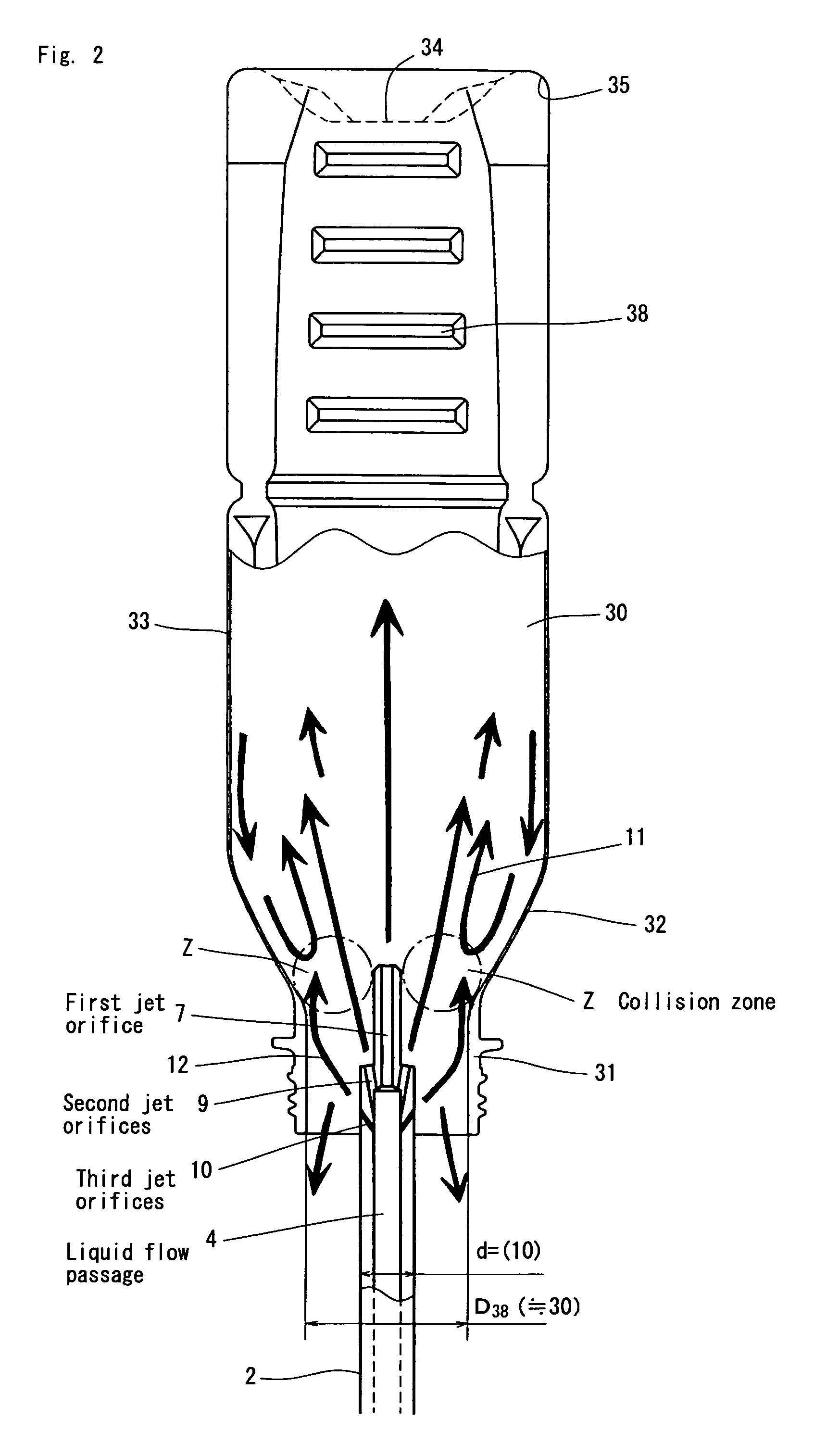

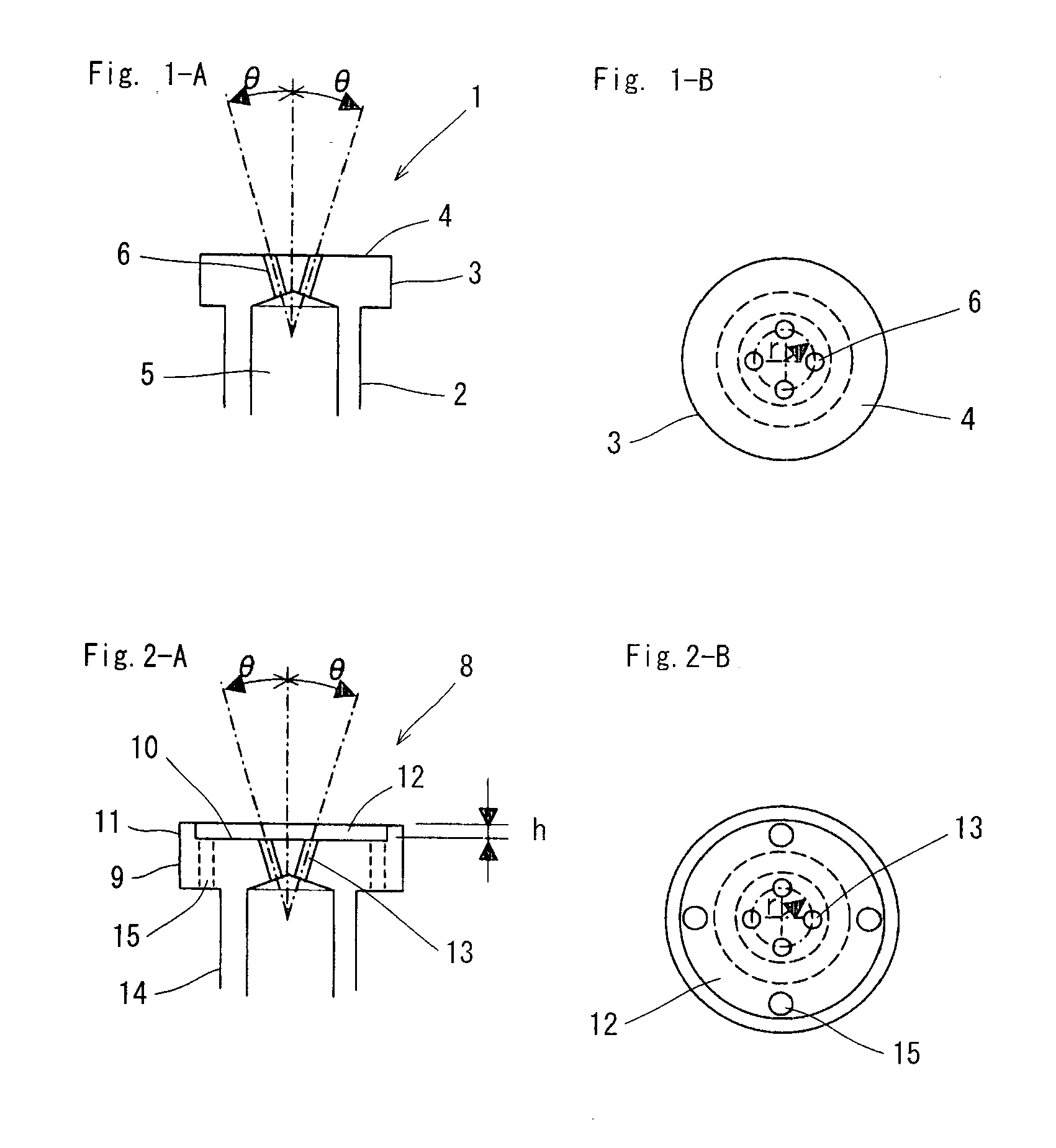

Bottle washing nozzle

ActiveUS7318555B1Wash evenlyLimited amountHollow article cleaningDust removalSquare cross sectionWash bottle

A bottle washing nozzle which is capable of washing bottles having openings of different diameters and which is capable of washing bottles having projections, indentations, and a square cross-section, or the like, with good efficiency. The nozzle includes a central jet tube a first jet orifice which jets in a vertical direction, second jet orifices which jet in an oblique upward direction in the base section of the central jet tube, and an discharge controlling means in the outer circumferential section of the nozzle main body, below the second jet orifices.

Owner:TOYO SEIKAN KAISHA LTD

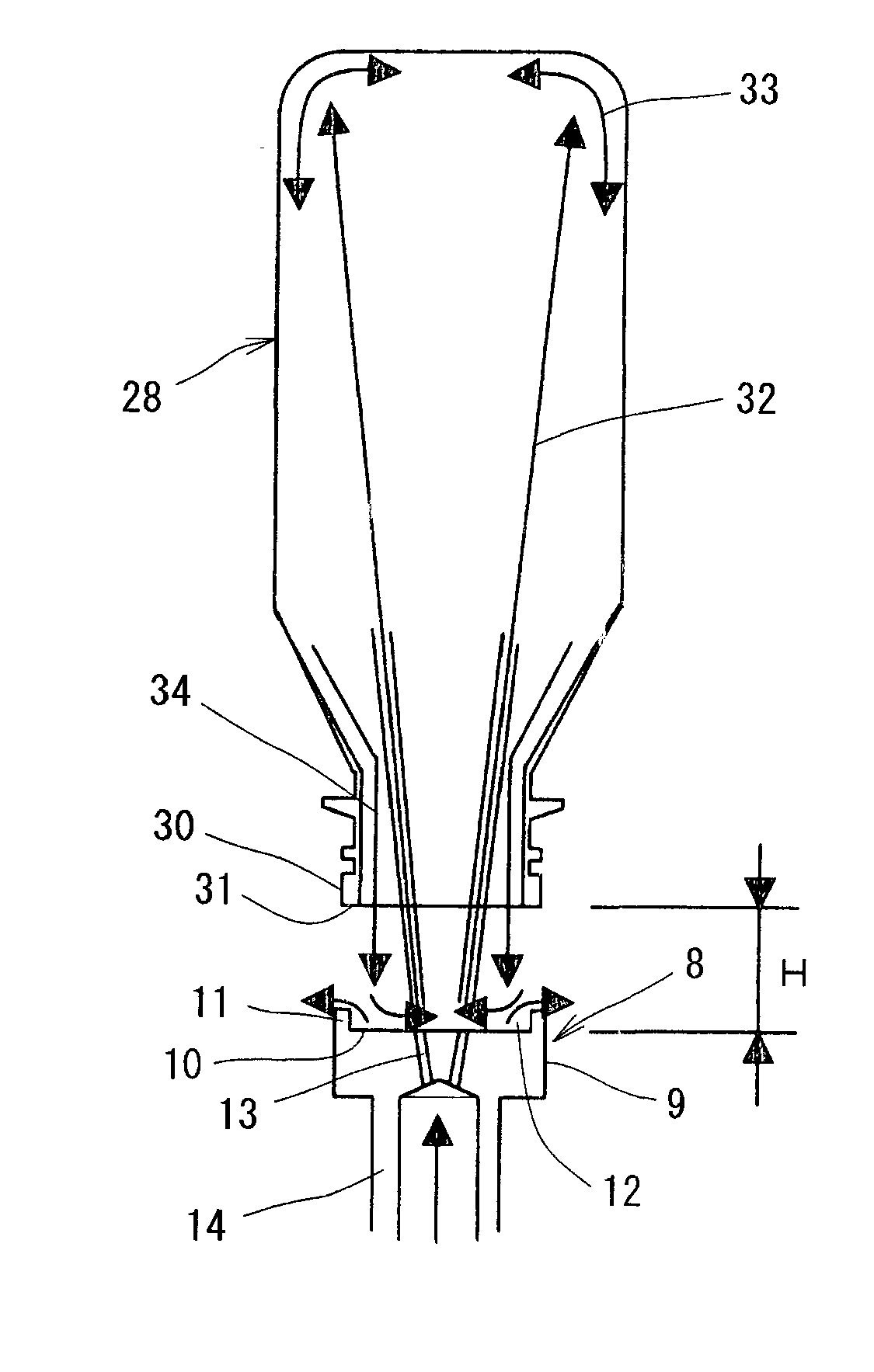

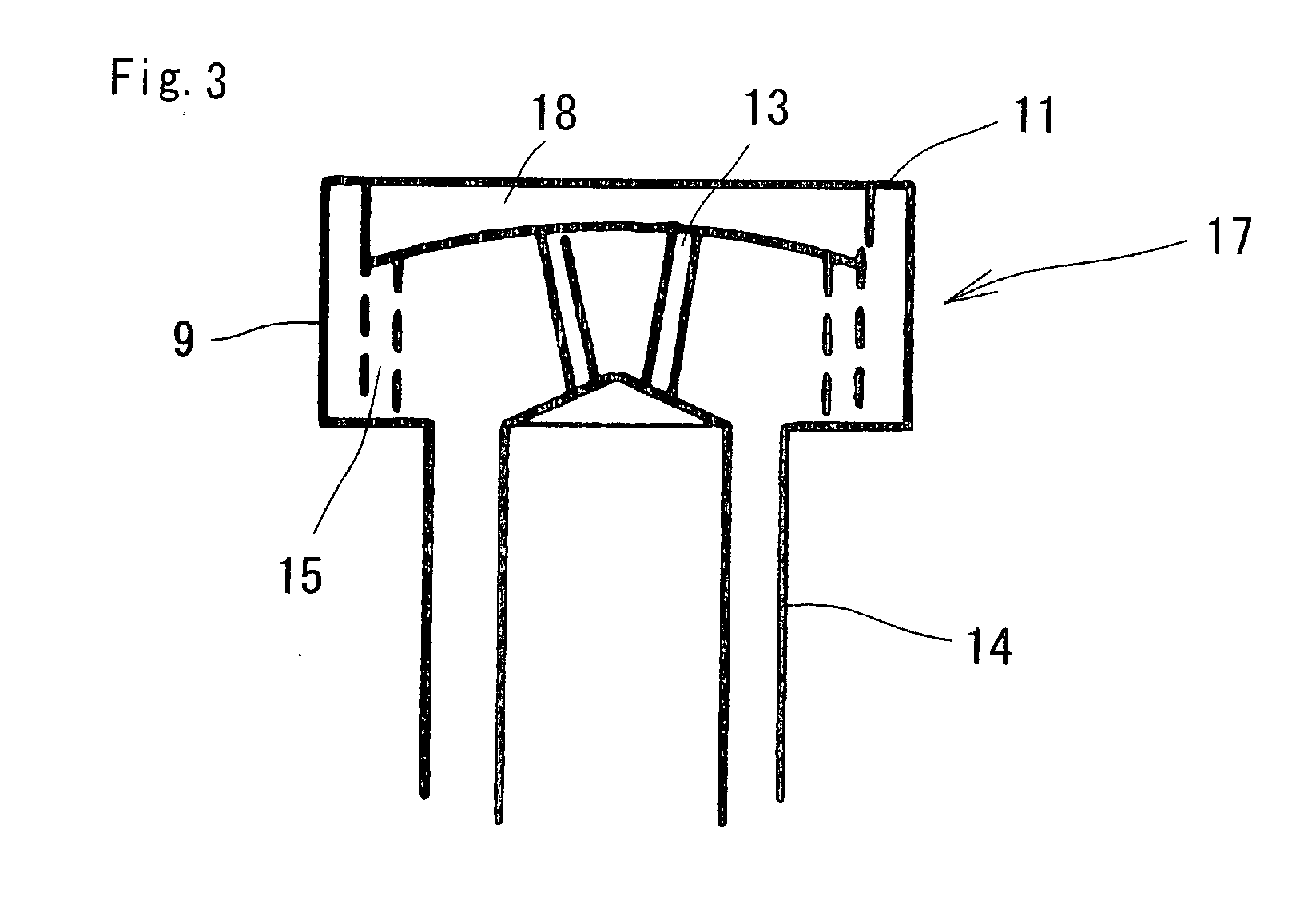

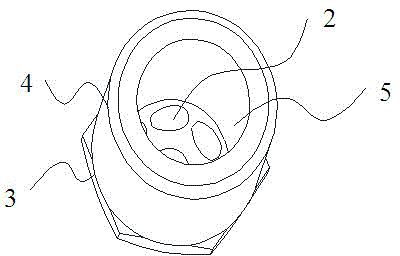

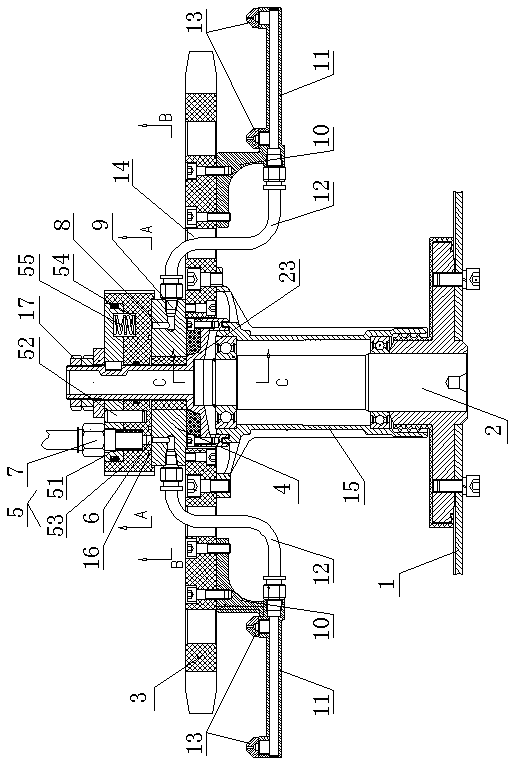

Non-inserted nozzle for sterilizing or washing bottle container and method for sterilizing or washing inner surface of bottle container

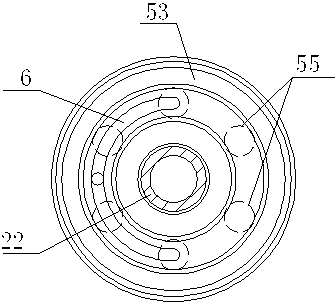

ActiveUS20100229894A1Improve efficiencyFew or no effectsHollow article cleaningPackage sterilisationWash bottleNozzle

A non-inserted nozzle for washing a container that can increase the washing efficiency, decrease the amount of washing fluid used, and shorten the washing time in sterilizing and washing a bottle container. The upper end surface of a non-inserted nozzle 8 serves as a liquid-receiving surface 10, and a retention wall 11 of a predetermined height is formed on the outer periphery of the liquid-receiving surface, thereby producing a retention recess. A plurality of nozzle holes 13 linked to a fluid channel of a nozzle stem 14 are provided obliquely so as to spread outwardly substantially in the central section of the liquid-receiving surface. The non-inserted nozzle 8 is disposed below the mouth of an inverted container 28 at a distance H from it and the sterilizing fluid or washing fluid is sprayed from below the mouth of the container, without inserting the nozzle into the container.

Owner:TOYO SEIKAN KAISHA LTD

Method for rapid detection of hexavalent chromium ions in sewage

InactiveCN102411001AReduce pollutionShorten detection timeMaterial analysis by observing effect on chemical indicatorPhosphoric acidWash bottle

The invention specifically relates to a method for rapid detection of hexavalent chromium ions in sewage, which belongs to the field of detection of metal ions. The method comprises the following steps: adding 100 ml of distilled water or deionized water into a wash bottle; sequentially adding 1 ml of 1+1 sulfuric acid and 1 ml of 1+1 phosphoric acid and shaking up an obtained mixture; adding 4 ml of a prepared diphenylcarbazide solution and shaking up an obtained mixture; adding 100 ml of distilled water or deionized water and shaking up an obtained mixture for usage in subsequent detection; taking 2 to 5 ml of a water sample to be detected, adding 2 to 5 ml of a hexavalent chromium ion detection reagent with a wash bottle, shaking up an obtained mixture, observing the color of mixed liquor and determining the range of the content of chromium ions in detection liquid by observing whether the mixed liquor has a color or by observing the color which the mixed liquor displays. Application of the method provided in the invention for detection of hexavalent chromium ions enables detection time to be saved and on-site detection to be realizable; the method has the advantages of simpleness, easy operation and strong practicality.

Owner:SHANDONG HUIJIN COLOR STEEL

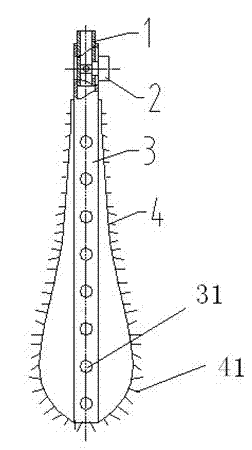

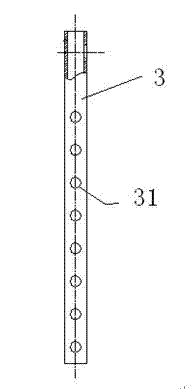

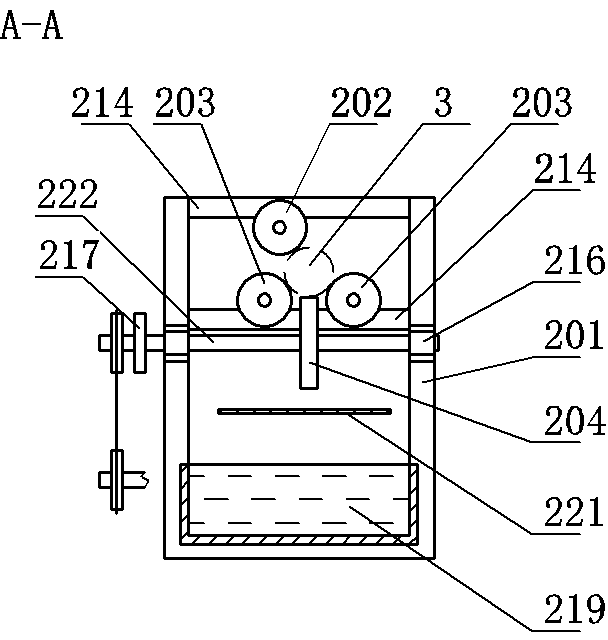

Bottle washing device

InactiveCN102921687ASimple structureEasy to useBrush bodiesHollow article cleaningPulp and paper industryWash bottle

The invention discloses a bottle washing device which comprises an aeration rod, a control ball valve, a washing rod and an air bag. The aeration rod and the washing rod are hollow rods, the upper end of the washing rod is sleeved at the lower end of the aeration rod to form a tight matching, the control ball valve is arranged on the aeration rod, a group of through holes is arranged on the washing rod, the washing rod is sleeved inside the air bag, the upper end of the air bag is tightly connected to the upper end of the washing rod, the lower end of the air bag is bonded to the bottom of the washing rod, and brushing wires are arranged on the surface of the air bag. The bottle washing device stretches into a bottle through aeration, the shape of the aerated air bag after expansion matches with the shape of the inner surface of a bottle body which needs to be washed, the washing rod is rotated to drive the air bag to rotate to wash the bottle clean, and the bottle washing device is suitable for washing bottles in various specifications.

Owner:NANJING VOCATIONAL UNIV OF IND TECH

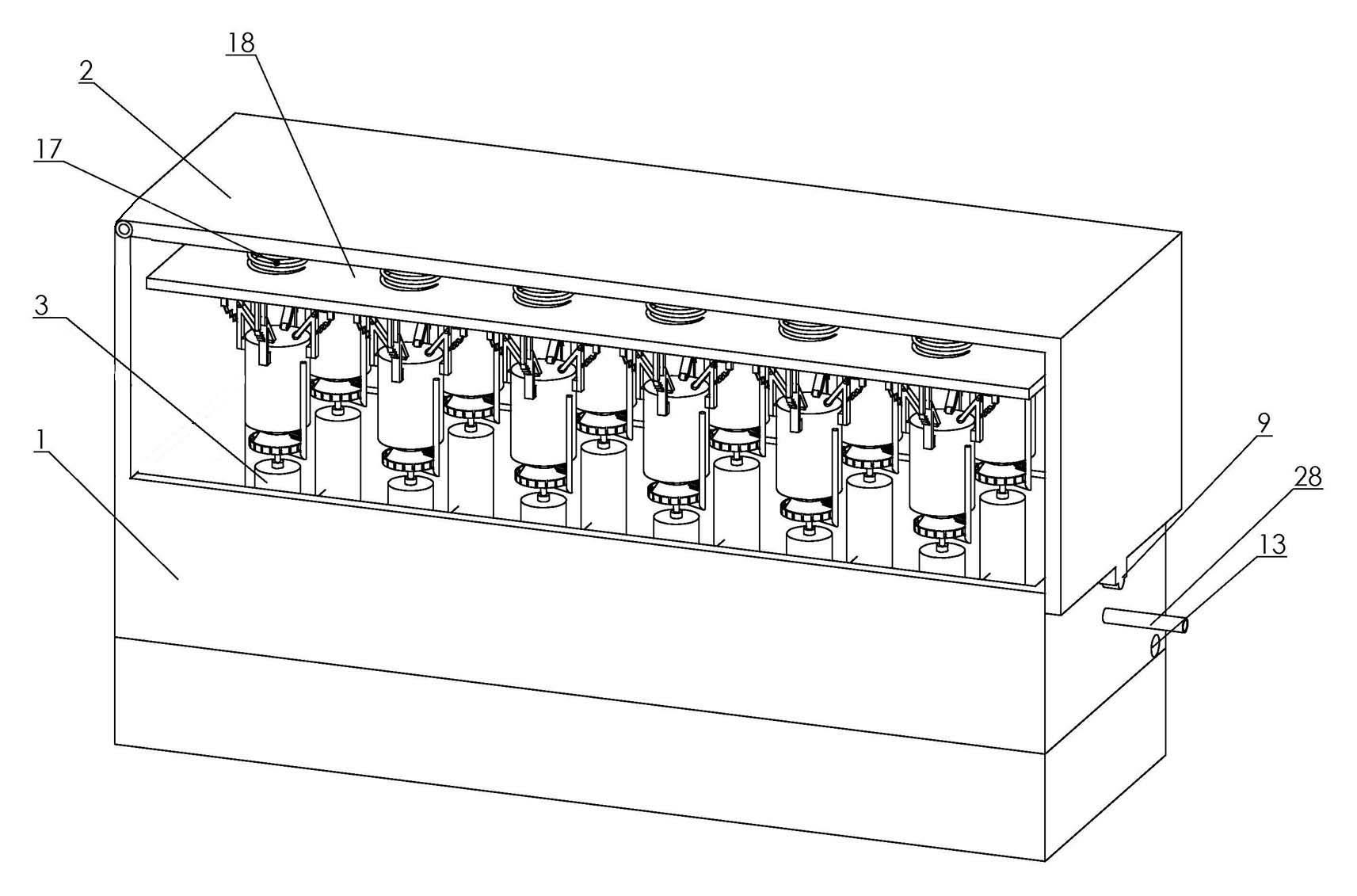

Automatic efficient bottle washer

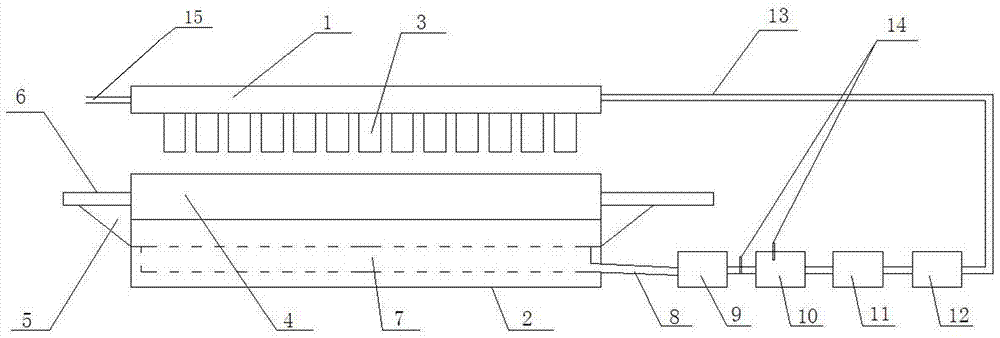

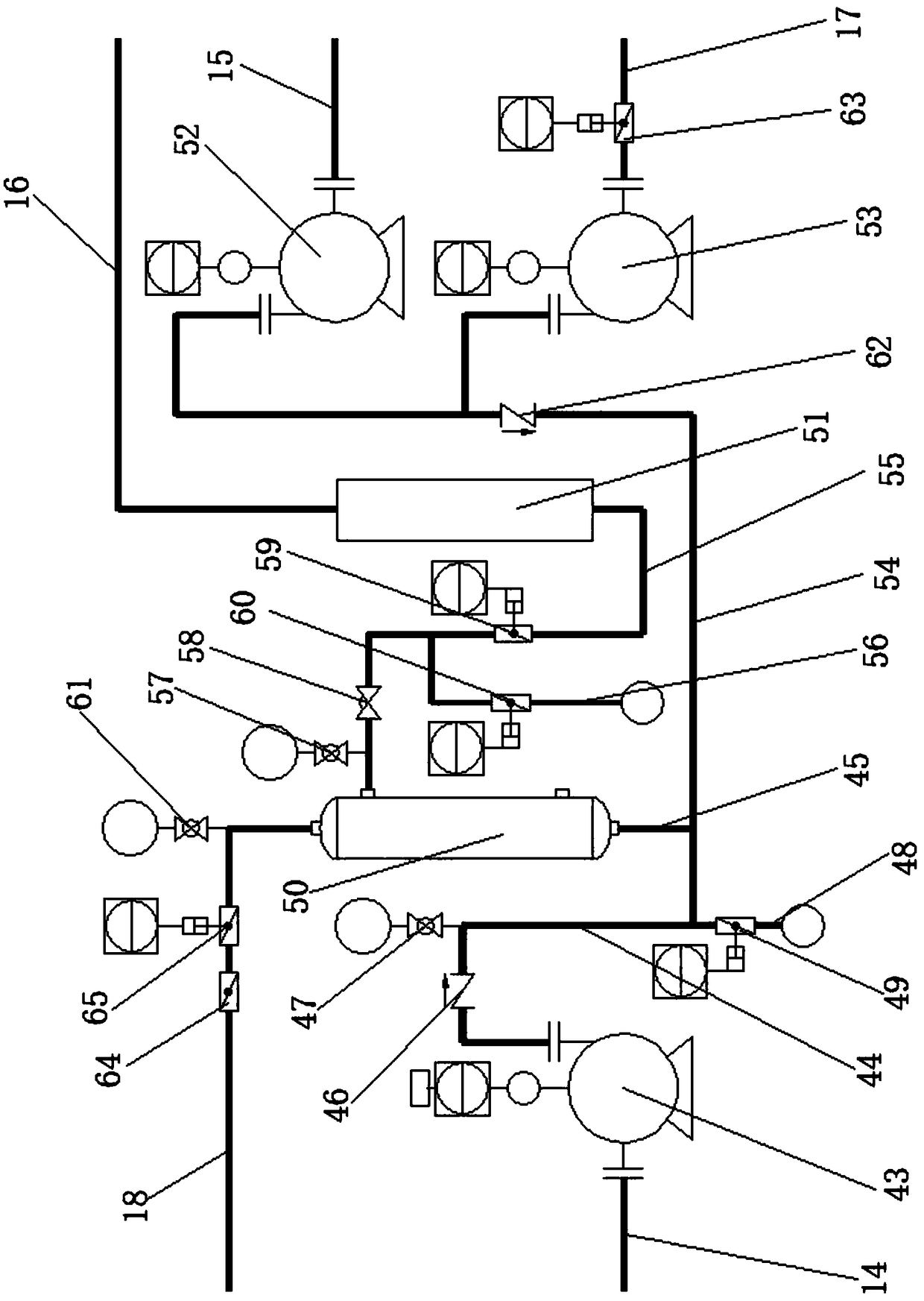

ActiveCN102580969AGuaranteed washing cleanlinessReduce consumptionHollow article cleaningDistilled waterProcess engineering

The invention relates to an automatic efficient bottle washer, which comprises a cleaning device, a pressing device, a transmission device and a waterway control device. The automatic efficient bottle washer can be used for batch washing of bottle-like utensils, and washing effect is guaranteed while operating efficiency is improved by means of standard flow control and automatic mechanical operation during use. The automatic efficient bottle washer is convenient in operation, effective in cleaning and small in occupied area, and normal washing water and distilled water are driven by different water pumps.

Owner:STATE GRID CORP OF CHINA +1

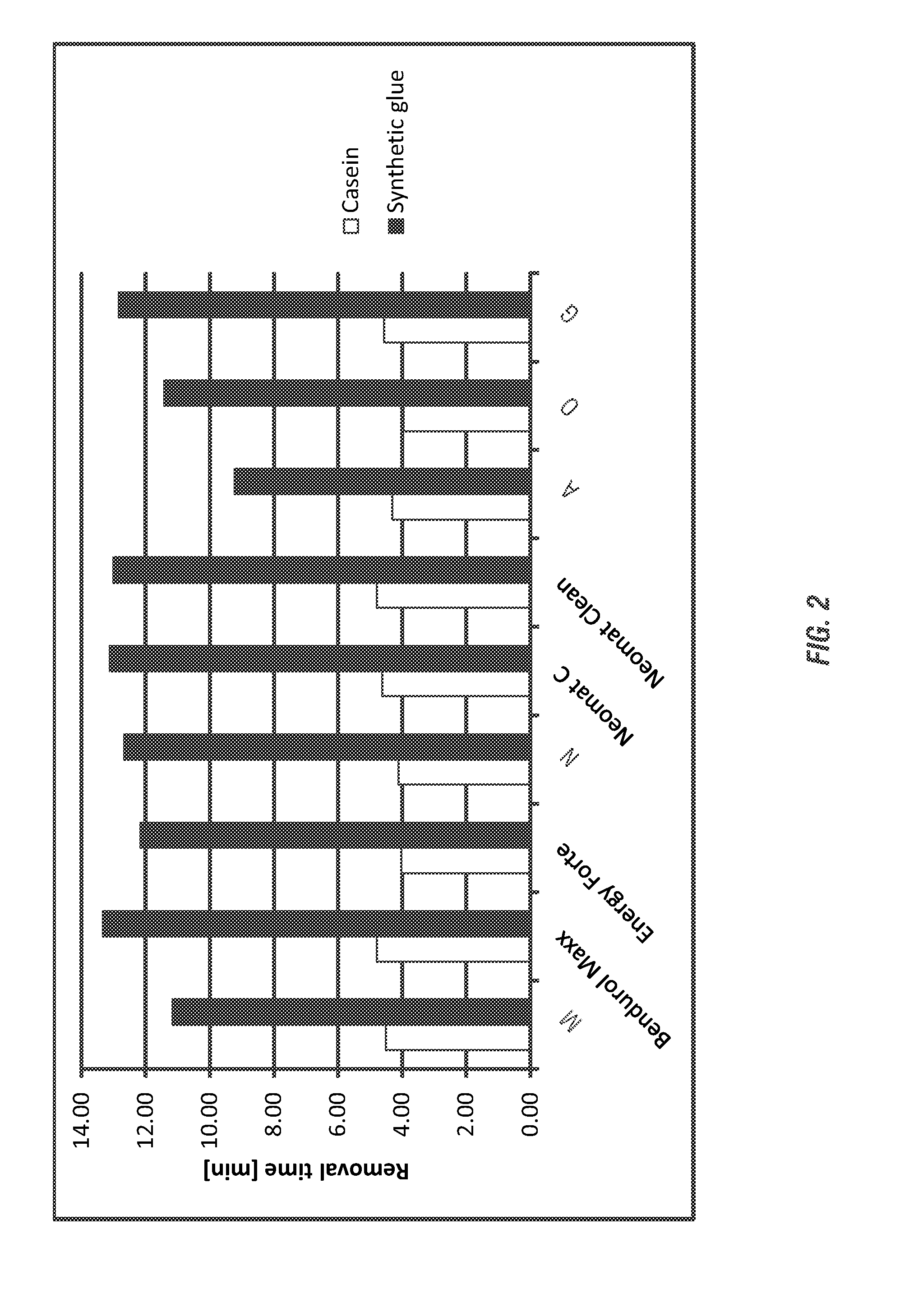

Label removal solution for returnable beverage bottles

ActiveUS20130303422A1Efficient removalInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsOrganic solventAdhesive

Owner:ECOLAB USA INC

Sampling technique with use of vacuum degassing and air blowing method to determine 14C age of ground water as well as sampling system

InactiveCN1415948ASample preparation is convenientSuitable for collectionWithdrawing sample devicesVacuum pumpingEngineering

This invention relates to a sample technology and its sample system for 14C age underground water test with vacuum degas and gas-blast method, composed of air wash bottle, CO2 remover, CO2 collector, buffer bottle, vacuum pump and connection pipes and valve gate and this technology is finished by system vacuum-pumping, water sampling, adjusting PH value, gas boasting and gas removing collecting CO2. The invented sample system has the advantage of good seal performance (without modern carbon pollution) small volume, and light weight.

Owner:INST OF HYDROGEOLOGY & ENVIRONMENTAL GEOLOGY CHINESE ACAD OF GEOLOGICAL SCI

Quick detection method and detection kit for hydrazoate in feed

InactiveCN103776824AFast waySimple methodMaterial analysis by observing effect on chemical indicatorFiltrationField tests

Owner:谱尼测试集团股份有限公司

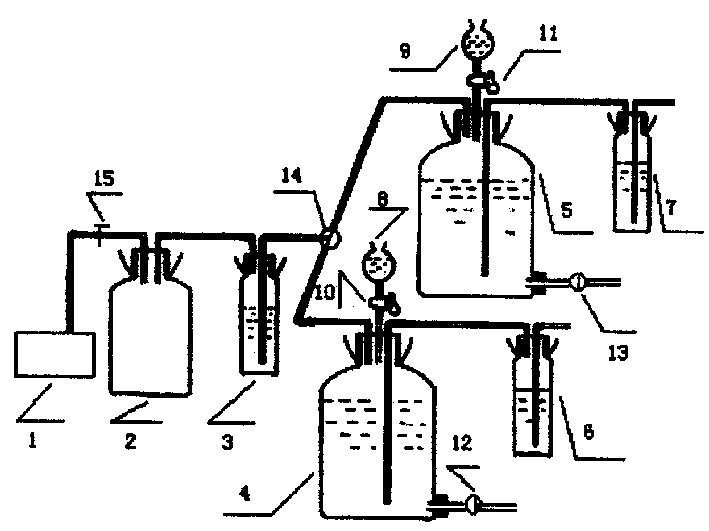

Method and apparatus for rapid determination of water body sediment AVS and SEM

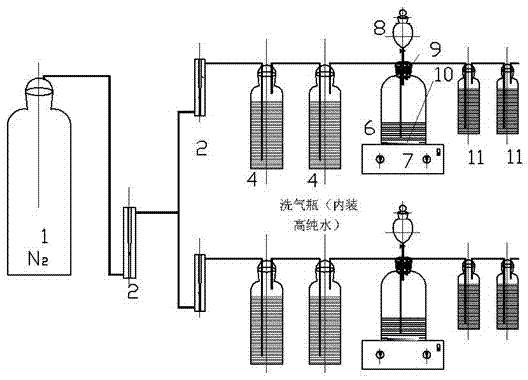

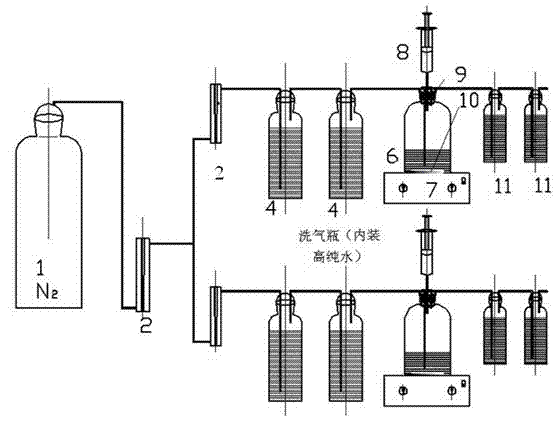

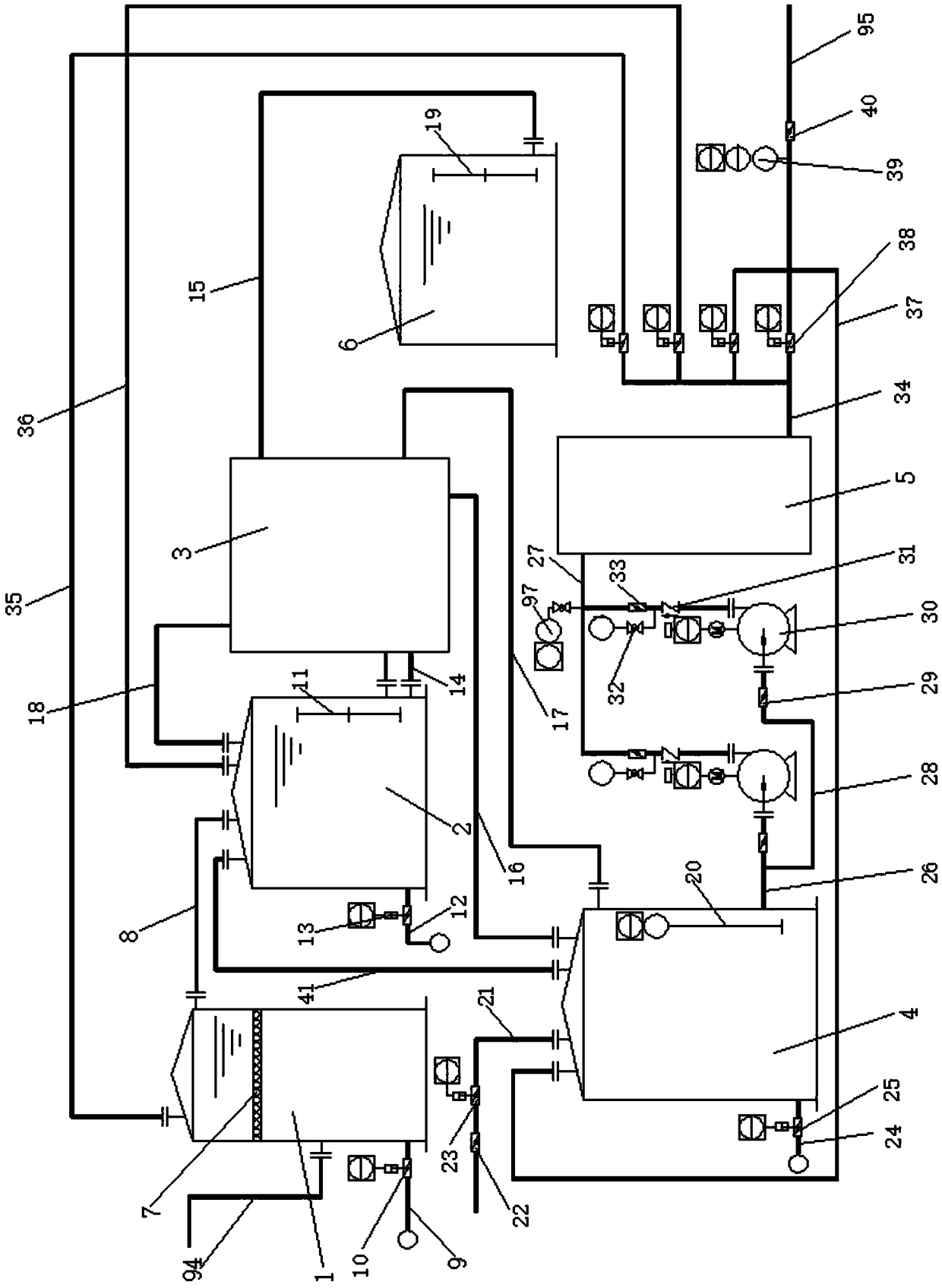

InactiveCN102353638AReduced average measurement timeGuaranteed measurement accuracyAnalysis by material excitationColor/spectral properties measurementsGas cylinderEngineering

The invention discloses a method and an apparatus for rapid determination of water body sediments AVS and SEM. The apparatus comprises a nitrogen cylinder (1), gas-washing bottles (2), reaction bottles (6) and gas absorption bottles (11). A gas-washing bottle (2), a reaction bottle (6) and a gas absorption bottle (11) that are successively installed in series by a pipeline form a branch; a plurality of branches in parallel connection are connected to the nitrogen cylinder; a gas flowmeter (2) is arranged in front of each gas-washing bottle (2) in each branch, and a gas flowmeter (2) is arranged after the nitrogen cylinder in a main road; the reaction bottles are sealed by rubber plug (9) coated with glass cement, and the rubber plug are provided with acid inlet apparatuses. According to the method, hydrogen sulfide gas generated from the reaction is extracted by high purity nitrogen and absorbed by a lye; and the parallel connection accelerates a measure speed; and links of sample introduction, reaction and absorption are reinforced to increase speed and accuracy. On the premise of measure precision guarantee, the AVS determination method of the invention can as shortens time effectively and achieves good effects.

Owner:SOUTH CHINA UNIV OF TECH

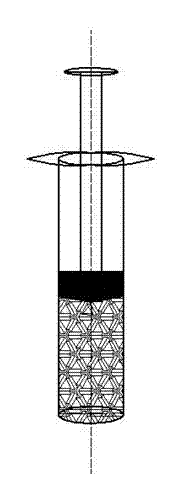

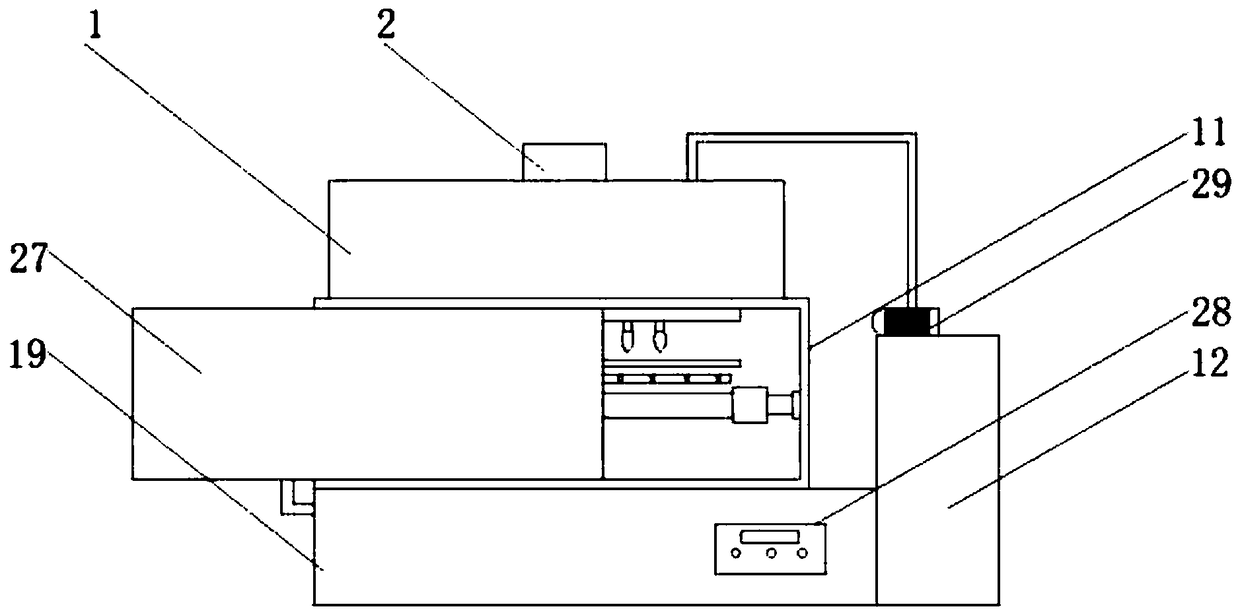

Fully-automatically-controlled efficient ultrasonic bottle washer

InactiveCN104107821AAchieve washingChange the way of manual washingHollow article cleaningCleaning using liquidsAutomatic controlGlass vessel

The invention relates to a fully-automatically-controlled efficient ultrasonic bottle washer. The fully-automatically-controlled efficient ultrasonic bottle washer comprises a washing tank, a bottle-loading rotary washing box, a bottle spraying device, an automatic water supplying device, a distilled water tank, a tap water tank, a detergent solution tank, an ultrasonic washing device, a constant-temperature heating device and an automatic control system. According to the fully-automatically-controlled efficient ultrasonic bottle washer, an ultrasonic oscillation washing technology is adopted, and the former manual hair-brush washing manner is changed; by making full use of the good stain penetrating, crushing and stripping efficacy of ultrasonic waves, brushless washing is fully realized, and meanwhile, the problem that vessels with special appearances cannot be washed is solved; a washing mode can be flexibly set, and the operation of detergent solution impregnated washing, tap water washing and distilled water washing can be automatically completed within an hour while ultrasonic mechanical oscillation is adopted to enhance a stain stripping effect, so that the quick and efficient washing of various types of glassware is realized.

Owner:STATE GRID CORP OF CHINA +1

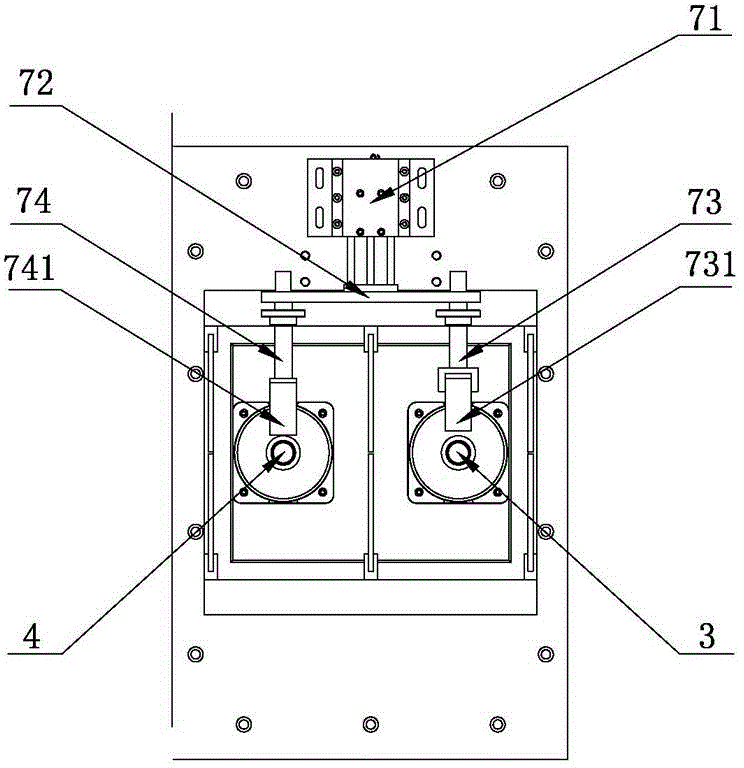

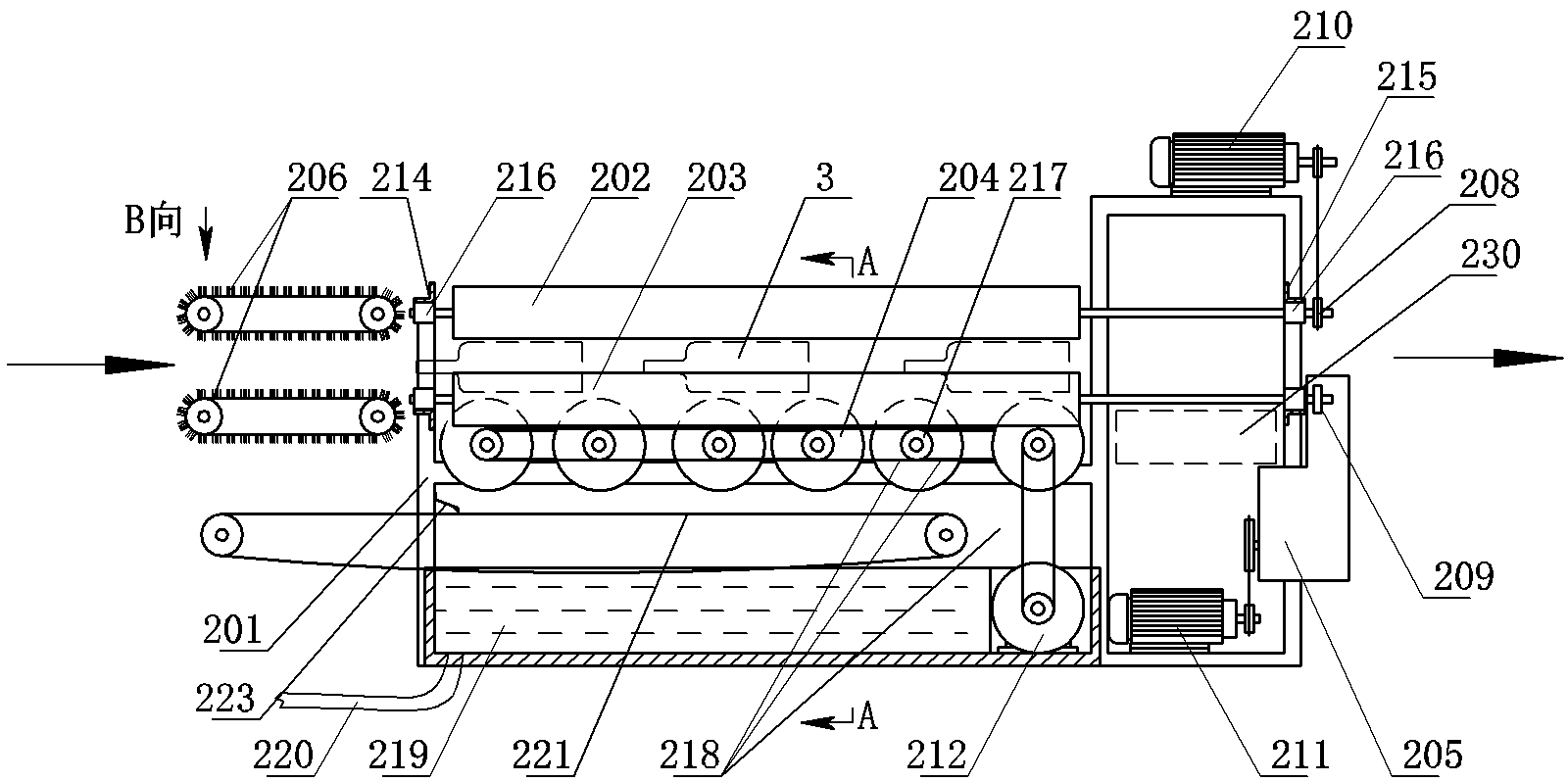

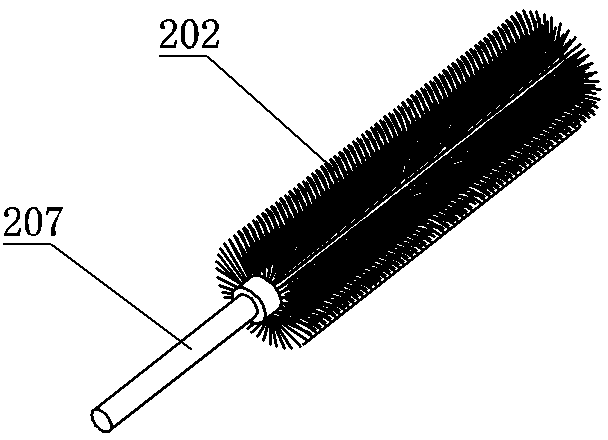

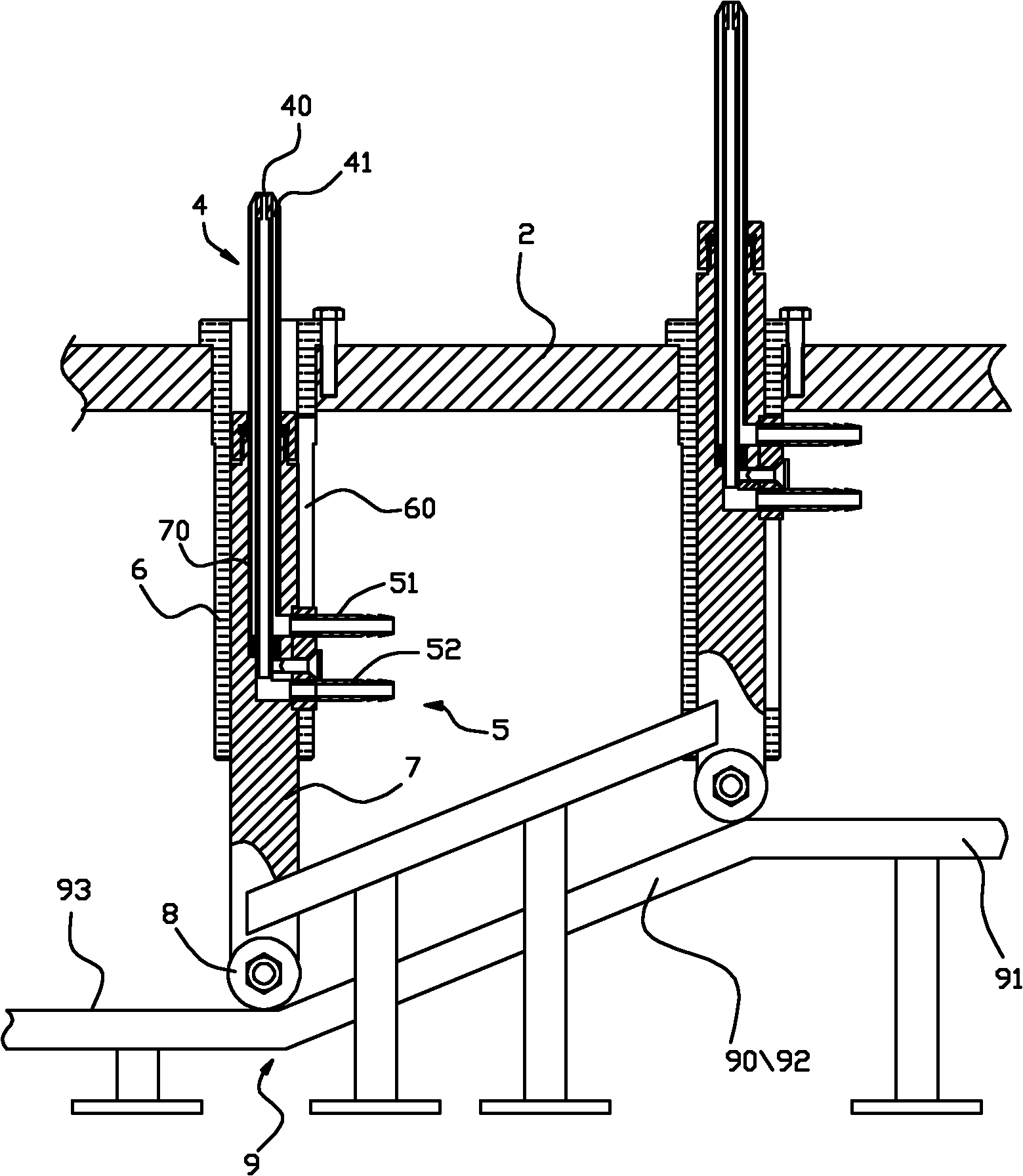

Bottle washing device for bottle washing machine

InactiveCN103537466ASave human resourcesReduce manufacturing costHollow article cleaningFailure rateWash bottle

The invention discloses a bottle washing device for a bottle washing machine. The bottle washing device for the bottle washing machine comprises a support, a power mechanism and a transmission mechanism; at least one upper layer brush roller and at least two lower layer brush rollers are installed on the support in a longitudinally lie mode; the upper layer brush roller and the lower layer brush rollers are formed into triangular washing channels; end portions of the brush rollers are connected with the power mechanism through the transmission mechanism; the brush rollers are maintained rotating in the same direction; a bottle pushing mechanism is arranged between any two lower layer brush rollers. According to the bottle washing device for the bottle washing machine, a function of automatically washing bottles in a whole line is achieved, manpower resource in quantity is saved, and accordingly production costs are reduced; the bottles are washed through the brush rollers during a rapid rotation process due to a single washing channel or a plurality of washing channels which are formed by a plurality of brush rollers, meanwhile in cooperation with a rapidly rotating label removing mechanism, the bottle is partly compressed and scrapped through high speed rotation brush heads, and the labels are completely removed; the structural design is reasonable, coordination of all parts is good, the failure rate is low, and popularization and application is benefited.

Owner:杨运月

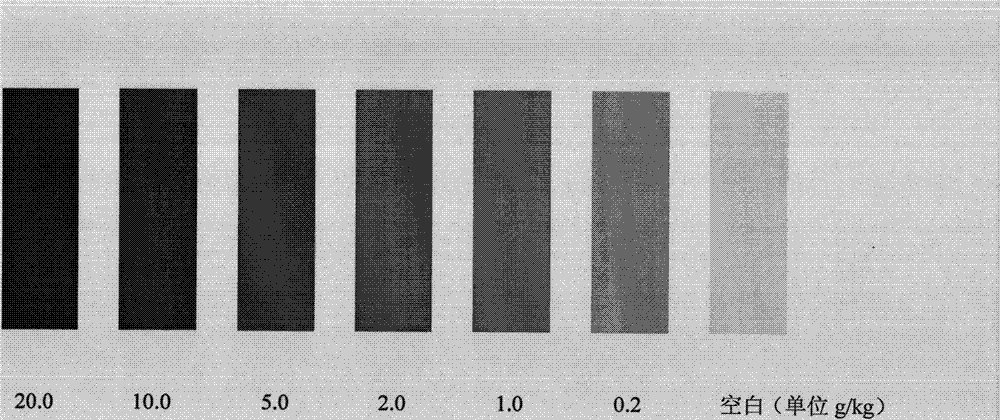

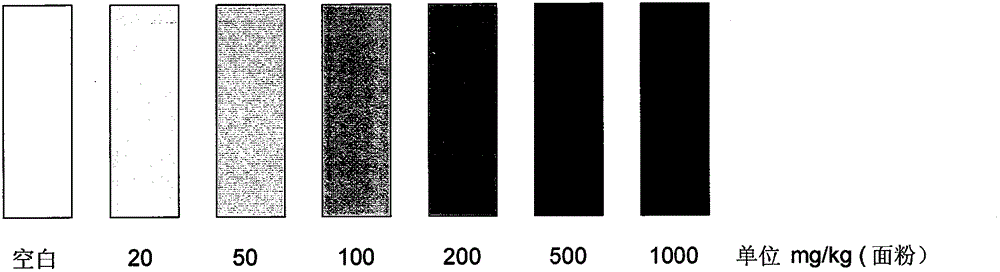

Detection kit for calcium peroxide in flour and detection method for calcium peroxide

ActiveCN102944550AFast waySimple methodMaterial analysis by observing effect on chemical indicatorPeroxidaseWash bottle

The present invention provides a detection kit for calcium peroxide in flour, which is composed ??of plastic sample spoons, plastic droppers, test tubes, a measuring cylinder, a test tube rack, a standard colorimetric card, a chromogenic reagent, pH test strips, reaction reagents, and a wash bottle. Tests are carried out on the samples by observing the different colors being shown and contrasting with the standard colorimetric card to perform qualitative and semi-quantitative detections. The detection method for calcium peroxide in flour includes: adding dilute acid into flour to react, adjusting the pH value to neutral with an alkaline solution, adding a mixed solution including a peroxidase-containing reagent, developing color, comparing with the standard colorimetric card to obtain the qualitative and semi-quantitative result. The detection kit and the detection method of the invention have the advantages of easy usage, fast color developing, relatively loose detection conditions, high sensitivity and low cost, and are suitable for on-site rapid screening assays.

Owner:PONY TESTING INT GRP SHANGHAI CO LTD

Tunnel type ultrasonic bottle cleaning machine

InactiveCN104338708AAvoid dead spotsBottle feeding is stable and reliableHollow article cleaningCleaning using liquidsCrankEngineering

The invention relates to the technical field of cleaning machines, in particular to a tunnel type ultrasonic bottle cleaning machine. The tunnel type ultrasonic bottle cleaning machine comprises a machine case filled with a cleaning fluid, wherein a bottle inlet and a bottle outlet are formed in the machine case; a transmission device capable of circulating rotation is arranged in the machine case; a plurality of bottle carrying boxes are arranged on the transmission device; a bottle feeding mechanism for pushing bottles to be cleaned into the bottle carrying boxes is arranged at the bottle inlet; a bottle discharging mechanism for pushing the cleaned bottles out of the bottle carrying boxes is arranged at the bottle outlet. The bottle feeding device adopts a crank and rocker mechanism, movement dead points of a four-bar mechanism are overcome, the bottles are stably and reliable fed, a bottle discharging device adopts a connecting rod to receive the bottles, and the bottles are firstly discharged by a cushion pad and then fed by a bottle receiving claw, so that the tunnel type ultrasonic bottle cleaning machine works stably. A plurality of cleaning working procedures are set in the machine case, the cleaning requirement of the bottles is met, and the work efficiency is high.

Owner:张家港市贝奇尔机械有限公司

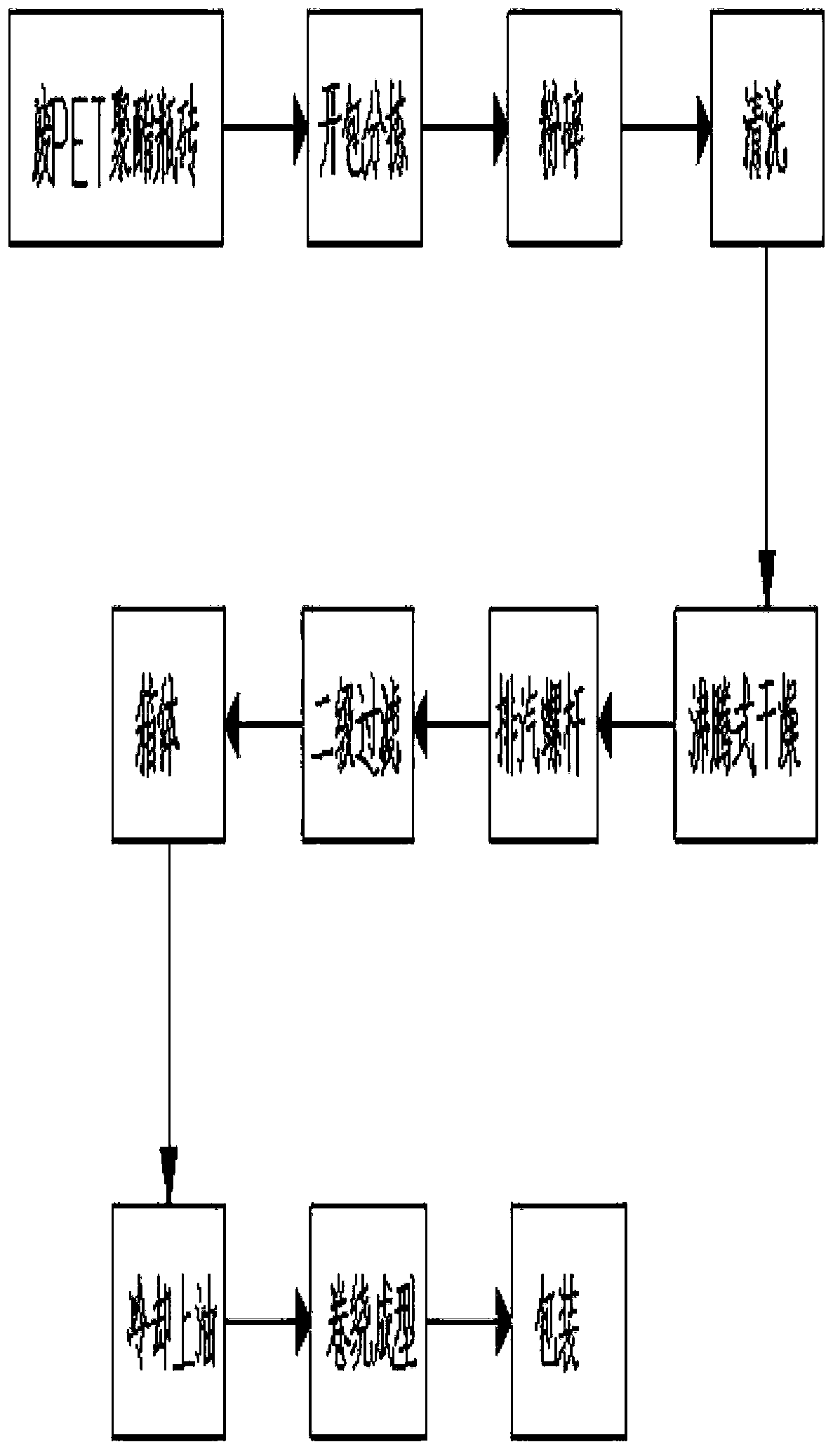

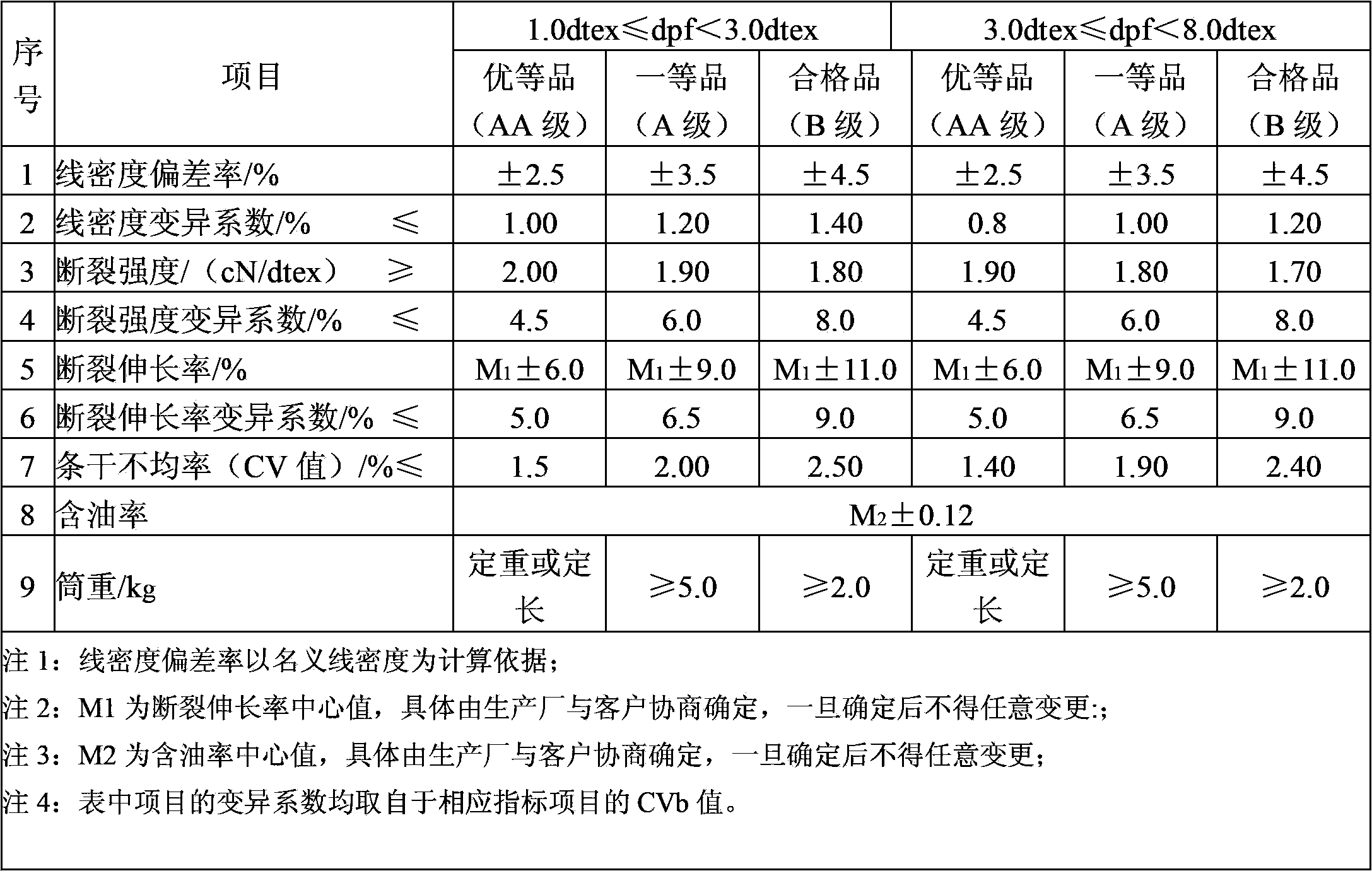

Spun polyester pre-oriented yarn production method using recycled polyester bottle chips

InactiveCN103572391ALess investmentLow running costNew-spun product collectionFilament forming substance formingPolyesterYarn

Disclosed is a spun polyester pre-oriented yarn production method using recycled polyester bottle chips. The method is characterized by including 1, breaking bottles; 2, washing bottle chips; 3, drying the bottle chips; 4, extruding through an exhaust screw and vacuumizing, namely feeding dried bottle chips into an exhaust screw port, controlling the heating temperature between 292 DEG C to 300 DEG C from 7 to 9 regions; allowing the bottle chips to produce vapor and PVC oil gas after being extruded and melted, vacuumizing at an opening in the middle segment of the screw, allowing the degree of vacuum to be smaller than 100 Pa, and performing secondary filtering; spinning; winding to form the spun polyester pre-oriented yarn. Through the application of the exhaust screw adaptable to the polyester pre-oriented yarn spun through bottle chips, on the basis of an original physical spinning method, influences on spinning by impurities such as moisture, PVC and oil can be eliminated; color yarns which have multiple ends and fine denier and which are porous are produced, quality and color are similar to those in native sliced spinning, and investment and operating cost are low; the method is initiative for polyester pre-oriented yarn spun using recycled polyester bottle chips worldwide, economical and applicable prospect is promising, and the entire process is more reasonable and practical.

Owner:ZHONGLANG ENVIRONMENTAL PROTECTION

Sampling system applicable to low-concentration trioxide sampling

PendingCN106813954AAchieve condensationEnsure condensationWithdrawing sample devicesWater/sand/air bathsFlue gasAir pump

The invention relates to a sampling system applicable to low-concentration trioxide sampling. The sampling system comprises a first thermostat water bath, a second thermostat water bath, an ice bath, a gas-washing bottle and an air pump; a first condensing coil is arranged in the first thermostat water bath, a second condensing coil is arranged in the second thermostat water bath, hydrogen peroxide is arranged in the gas-washing bottle, a sulfur trioxide sampling gun is connected to one end of the first condensing coil, an absorption bottle is arranged in the ice bath, isopropanol is arranged in the absorption bottle which is connected with the gas-washing bottle, and the gas-washing bottle is connected with the air pump. The sampling system has the advantages that flue gas is subjected to sampling treatment through the sulfur trioxide sampling gun, the flue gas enters the absorption bottle of the ice bath through condensing treatment of the first thermostat water bath and the second thermostat water bath in sequence, condensation and collection of sulfur trioxide are realized through the isopropanol, the sulfur trioxide in the flue gas can be assuredly condensed and collected as compared with condensation of an existing individual condensing coil, condensing efficiency is improved, and the sulfur trioxide in the flue gas can be completely collected.

Owner:浙江菲达环保科技股份有限公司

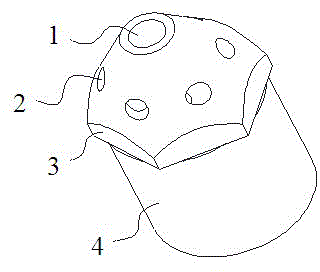

Novel washing bottle shower nozzle

ActiveCN105080740AEasy to cleanGuaranteed cleaning effectHollow article cleaningSpray nozzlesCircular coneWater flow

The invention discloses a novel washing bottle shower nozzle. A shower nozzle body which is convex outside and has a flat spherical surface or circular cone surface is arranged on the front end of the shower nozzle, and a connecting body for connecting the shower nozzle and a gun body of a spray gun together is arranged on the rear end; a straight-through hole is formed in the top part of the center of the shower nozzle body, and the central axis of the straight-through hole is coincided with the rotary axis of the shower nozzle body; a plurality of inclined-through holes are formed in the shower nozzle body around the circumferential direction of the straight-through hole; a through hole is formed in the connecting body, and water or gas flowing out of the gun body is ejected through the through hole from the straight-through hole and the inclined-through holes; airflow or water flows ejected from the inclined-through holes are ejected to the inclined front upper part or the inclined front lower part, and all the water flows or the airflow ejected from the inclined-through holes is ejected to the inclined front upper part and is matched with an infusion bottle wall to form a swirl flow, so that the cleaning effect of the bottle wall is ensured, and a good cleaning effect on depression parts of a bottleneck and a bottle bottom is also achieved.

Owner:HUNAN KELUN PHARMA

Health-care product having liver-protecting function and production process

InactiveCN102138956AEnhance defense functionImprove immunityDigestive systemPill deliverySalidrosideAlcohol

The invention discloses a health-care product having a liver-protecting function and a production process. The health-care product comprises the following components in part by weight: 1.25 to 2 parts of salidroside and 1 to 10 parts of manyprickle acanto-panax root. A production process of tablets, powder, granules and capsules comprises the following steps of: (1) selecting; (2) cleaning raw materials; (3) cutting the raw materials; (4) drying; (5) extracting and concentrating; (6) drying under vacuum; (7) crushing; and (8) making to form finished products. A production process of oral liquid comprises the following steps of: (1) selecting; (2) cleaning raw materials; (3) cutting the raw materials; (4) drying; (5) extracting and concentrating; (6) performing alcohol deposition; (7) blending; (8) washing bottles; (9) filling and rolling covers; (10) detecting leakage and sterilizing; (11) performing lamp inspection; and (12) labeling and packaging. The health-care product has the advantage of preventing and prolonging the development process of liver fibrosis effectively, and particularly has the obvious effect of preventing chemical liver injury.

Owner:吉林延边朝药药业有限公司

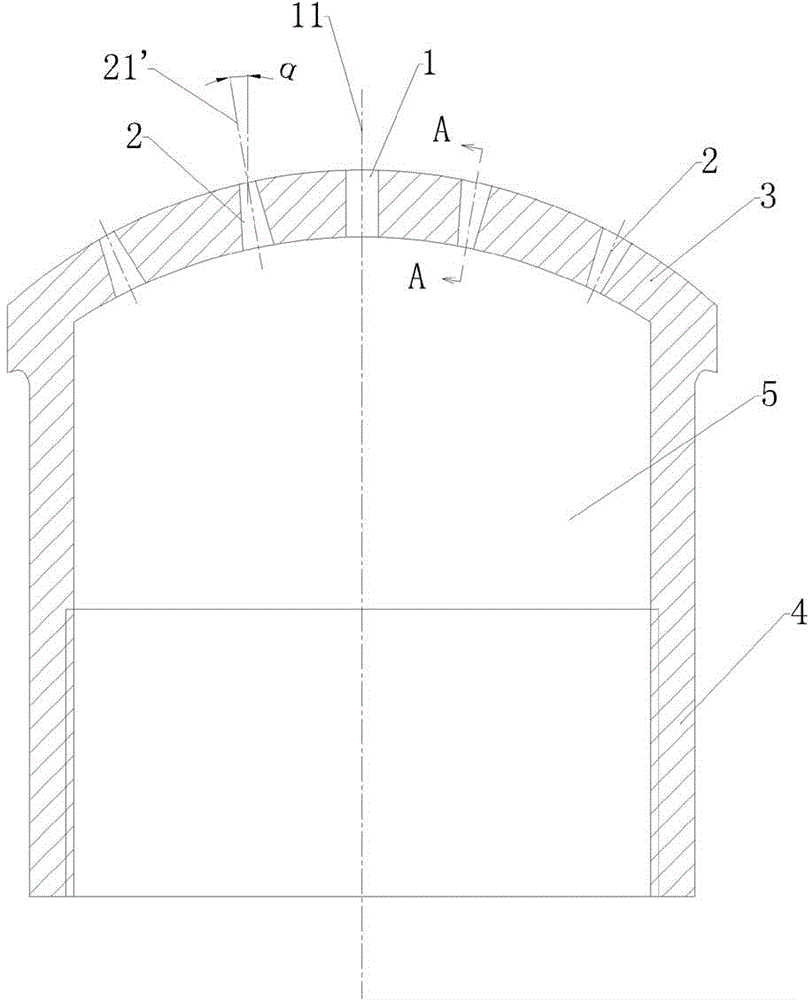

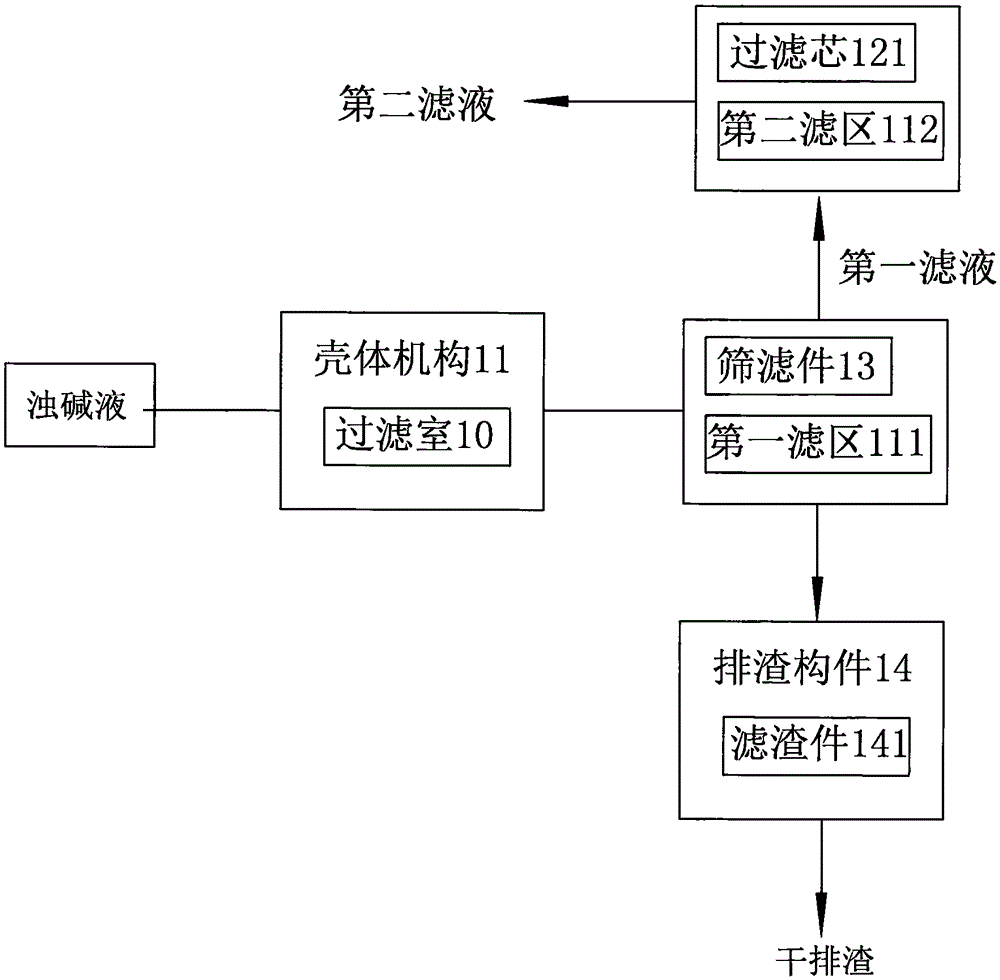

Renewable spent lye filter device and using method thereof

ActiveCN105536330AImprove filtering effectHigh filtration precisionStationary filtering element filtersParticulatesFiltration

The invention provides a renewable spent lye filter device and a using method thereof. The filter device comprises a shell mechanism, a filter element component and a screen filter, wherein the shell mechanism is provided with a filter chamber; the filter element component comprises a filter element; the screen filter is installed in a preset position of the filter chamber and faces the filter element at intervals, so that a first filtering area and a second filtering area are formed in the filter chamber; large-particle impurities are intercepted in the first filtering area by the screen filter; the filter element is arranged in the second filtering area; particulate impurities are filtered by the filter element. The filter device has the beneficial effects that the filter capacity and filter precision of the spent lye are effectively improved and the activity of the lye is restored through multistage filtration of the spent lye, thus achieving the aims of effectively purifying and recycling the spent lye in wash bottles.

Owner:XIANGSHAN JINXIN LIGHT IND MACHINERY PLANT

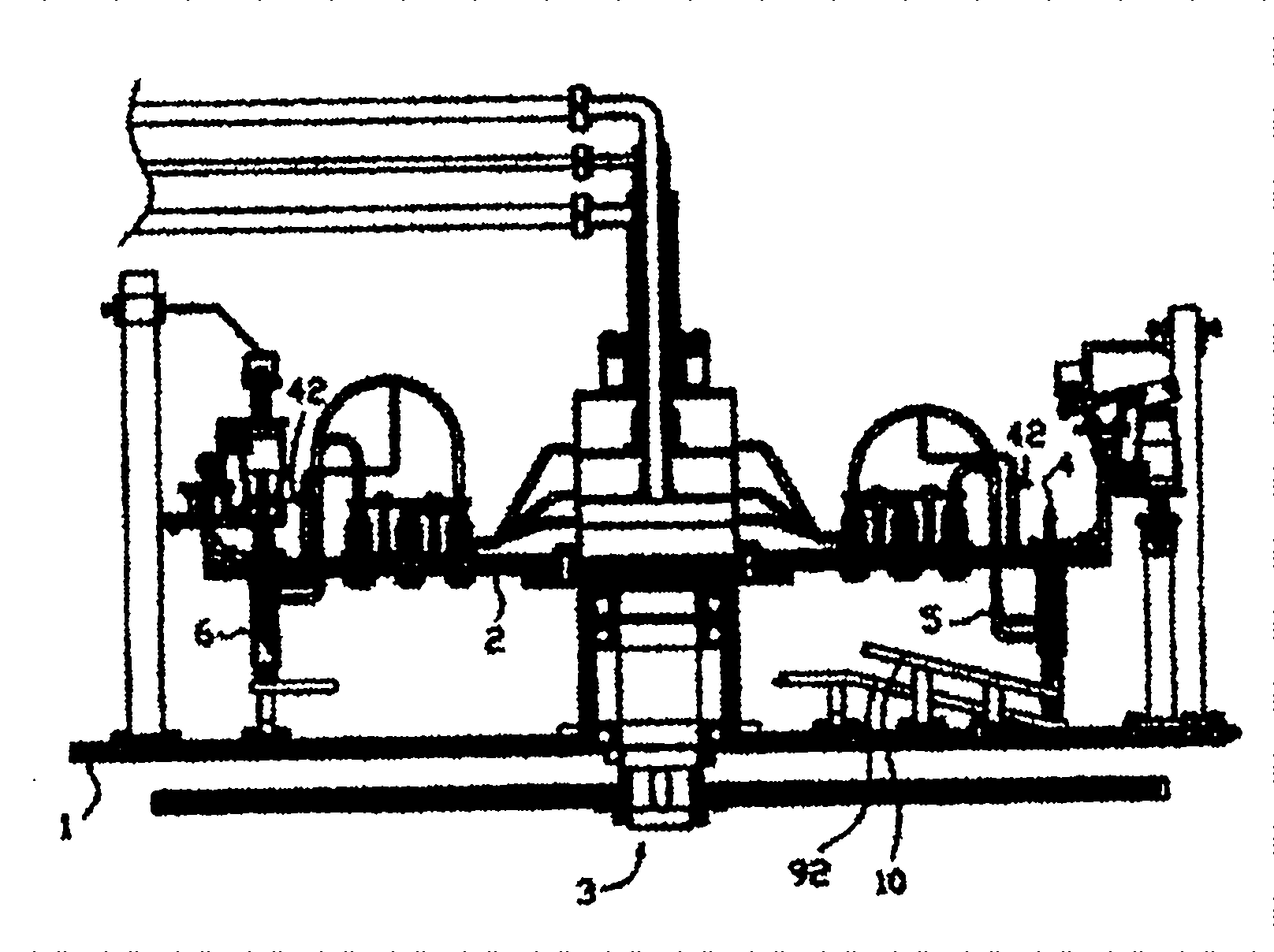

High speed automatic bottle gas washer

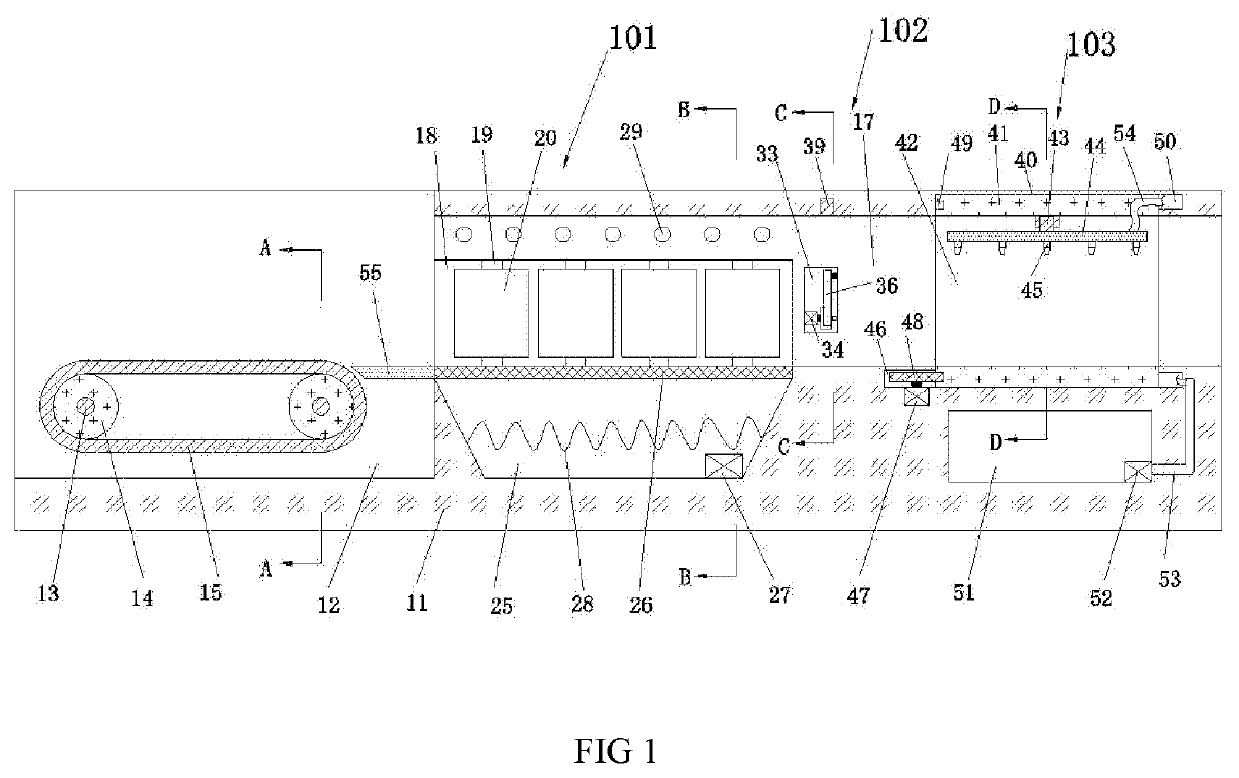

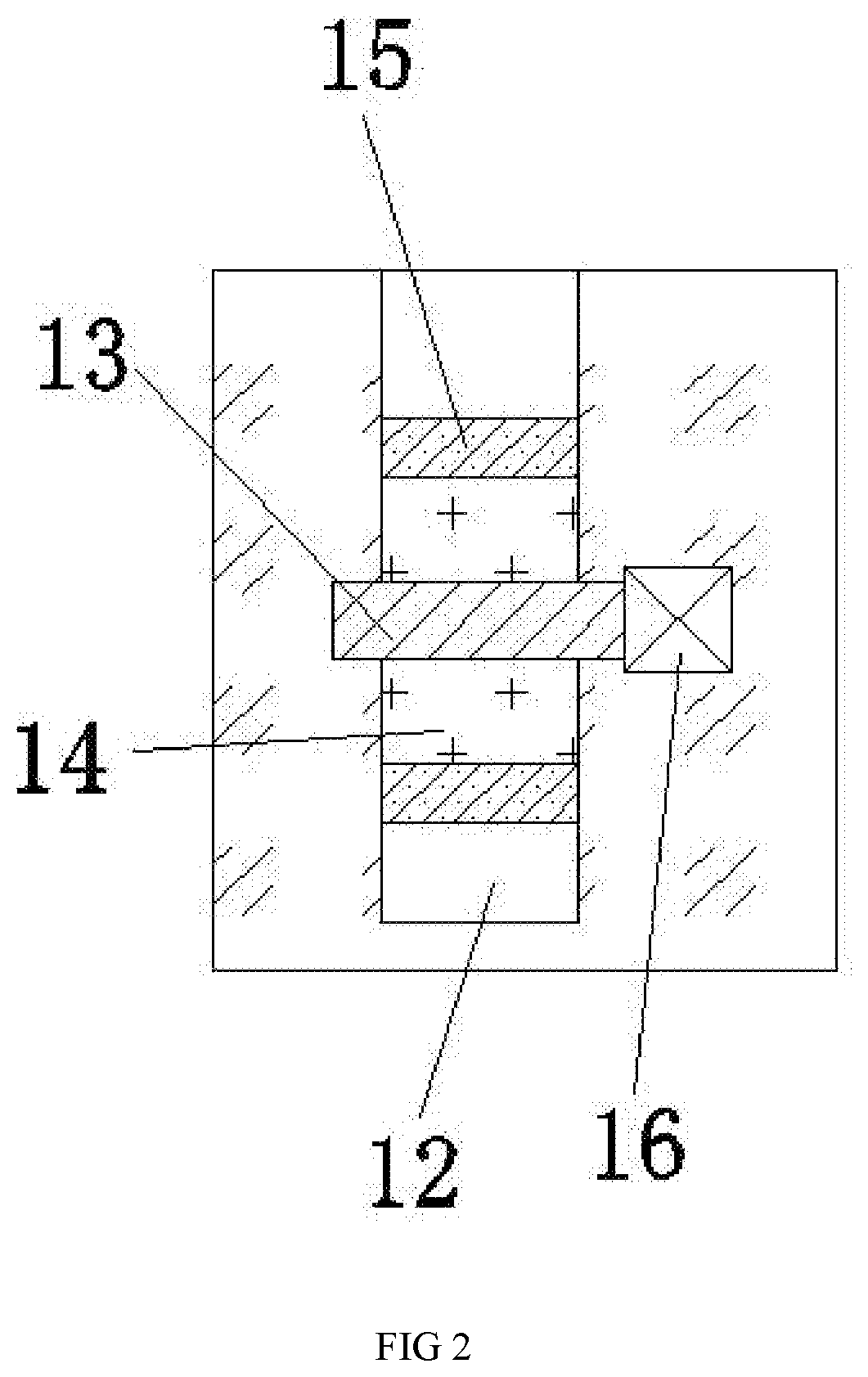

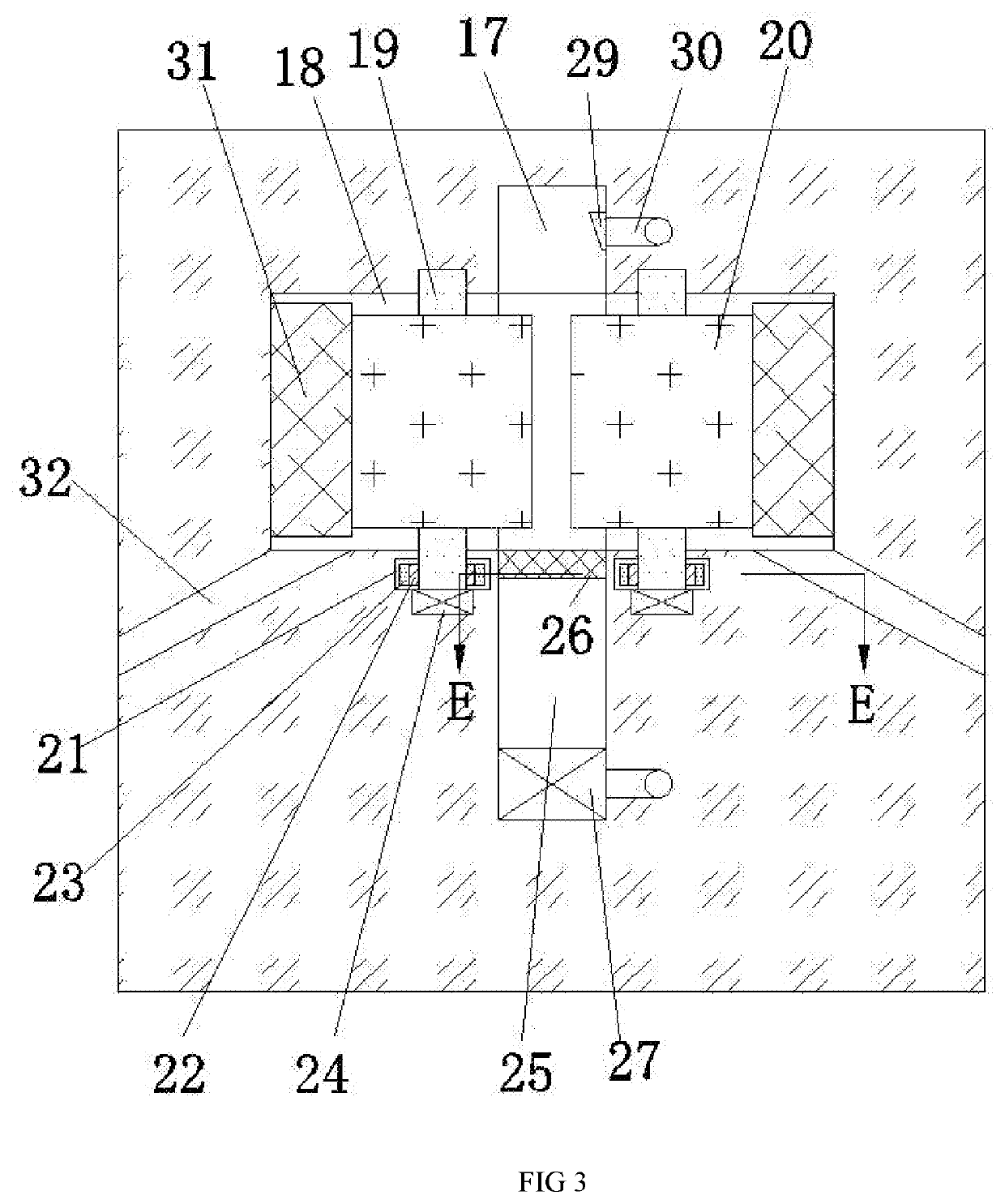

The invention relates to a high-speed automatic air washing bottle device, which comprises a conveyer belt, a bottle turning mechanism consisting of a front cavity body floral disc and a back cavity body floral disc, a controllable positioning and rotating power mechanism, a high-pressure ionic wind-zone dust removing mechanism in a negative pressure area, a bottle pushing mechanism, and the like. The device can be applied to arranged bottles on a bottle packaging production line, that is, when the bottles are led in by the conveyer belt before encapsulation and are turned to keep bottle openings in a downward state, static electricity of dust is eliminated by a high-pressure ionic wind zone, and particles leave bottle cavities under the attraction of negative pressure; and then the washed bottles automatically turn and return to a state that the bottle openings are upward, and the bottles are transported to an encapsulation process by the conveyer belt.

Owner:SHANGHAI HENGYI PHARMA EQUIP

Intelligent drink bottle washing machine

InactiveCN108941111AEasy to cleanQuick disassemblyHollow article cleaningDrying gas arrangementsEngineeringWash bottle

The invention discloses an intelligent drink bottle washing machine which comprises an equipment box, an air cylinder, a spraying plate, a washing box, a water tank, a bottom box, a bottle body storing plate and a controller. The washing box is fixedly installed on the left side of the top of the bottom box. The water tank is fixedly installed on the outer wall of the right side of the bottom box.The equipment box is fixedly installed on the top of the washing box. An opening is formed in the front end of the washing box. A sealing door is installed on the opening of the front end of the washing box in a sliding manner. The controller is fixedly installed at the position, close to the right side, of the outer wall of the front end of the bottom box. A water pump is fixedly installed on the top of the water tank. A motor is fixedly installed on the outer wall of the left side of the washing box. A rectangular opening is formed in the top of the washing box. The intelligent drink bottlewashing machine is novel in design, the bottle body storing plate can be assembled and disassembled fast, the bottle body washing effect is improved, a hot wind pipe is fixedly installed in the washing box, washed bottle bodies are dried through the hot wind pipe, thus integrated operation is achieved, and the working efficiency is improved.

Owner:芜湖盛创新材料科技有限公司

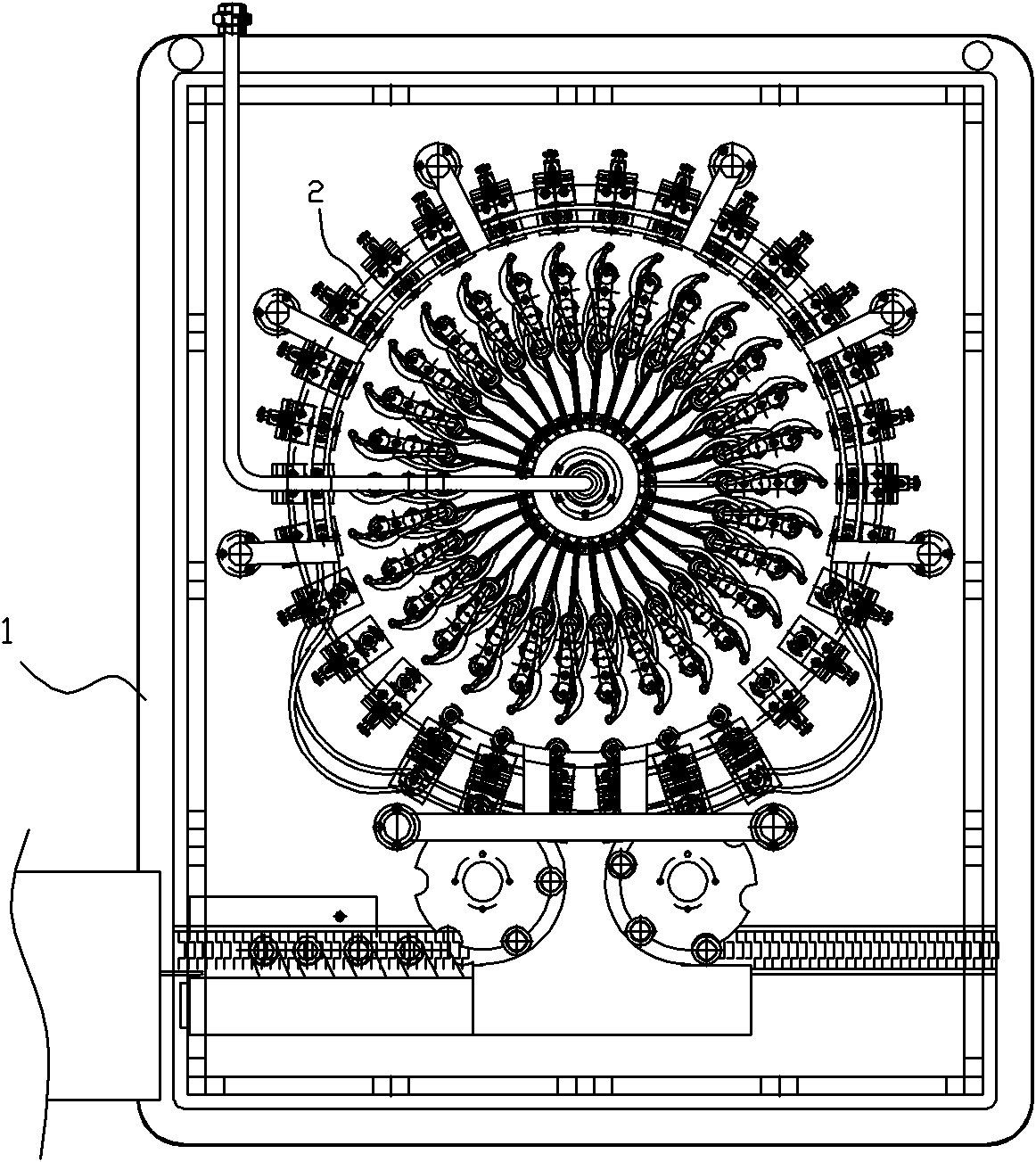

Device capable of washing bottles by spraying

InactiveCN103272809ASave waterImprove bottle washing efficiencyHollow article cleaningWater resourcesSprocket

The invention discloses a device capable of washing bottles by spraying. The device capable of washing bottles by spraying comprises a supporting frame fixedly arranged on a bottle washing machine body. A supporting shaft which extends upwards is installed on the supporting frame. A chain wheel and a distribution tray are connected to the supporting shaft in a rotation mode, wherein the chain wheel is driven by a power device and the distribution tray is arranged on the upper portion of the chain wheel and in power connection with the chain wheel. An upper pressing disc is in key connection with the upper portion of the supporting shaft. An arc groove is formed in the lower surface of the upper pressing disc. A liquid intake pipe communicated with the arc groove is installed on the upper pressing disc. Multiple blind holes and multiple liquid exhaust holes are formed in the distribution disc in an annular mode, wherein the blind holes extend downwards from the upper surfaces of the distribution disc and rotate along with the distribution disc and are communicated with the arc groove; the inner ends of the liquid exhaust holes are communicated with the bottoms of the blind holes, the outwards-extended ends of the liquid exhaust holes are exposed out of the circumferential surface of the distribution disc and the liquid exhaust holes are radially formed. Multiple spraying seats which are annularly arranged along the chain wheel and spraying pipes connected to the spraying seats are fixedly arranged on the lower portion of the chain wheel. Nozzles are installed to the spraying pipes. Connection pipes which penetrate through the chain wheel are installed between the liquid exhaust holes and the spraying pipes. The device capable of washing bottles by spraying has the advantages of being capable of saving water resources, high in efficiency of washing bottles and good in cleaning effect.

Owner:ANQIU YAOFA MACHINE

Waste water circulating and recycling device for medicine bottle cleaning machine

InactiveCN105436173ASave waterLow costHollow article cleaningTreatment involving filtrationWastewaterWater resources

The invention discloses a waste water circulating and recycling device for a medicine bottle cleaning machine. The waste water circulating and recycling device comprises a spraying table and a cleaning table and is characterized in that the spraying table is located above the cleaning table; a plurality of spraying devices are arranged at the bottom of the spraying table; a water inlet pipe is arranged on the side face of the spraying table; a medicine bottle conveying table is arranged on the top face of the cleaning table; water collecting grooves are formed in the positions, below the medicine bottle conveying table, of the two sides of the cleaning table; baffles are arranged in the positions, on the two sides of the medicine bottle conveying table, of the top face of the cleaning table; a waste liquid recycling tank is arranged in the cleaning table and connected with a solid filtering device through a draining pipe; the solid filtering device is connected with a liquid neutralizing and filtering device which is connected with a sterilization tank; and the sterilization tank is connected with a recycling and checking tank which is connected with the spraying table through a recycling pipeline. According to the waste water circulating and recycling device, water resources used in the cleaning process of medicine bottles are effectively saved, waste liquid is recycled after being effectively disposed, and the cost is effectively lowered.

Owner:HEILONGJIANG ZHICHENG MEDICAL TECH

Bottle washing water circulation system

InactiveCN109110993AEffective filteringPurify waterWater/sewage treatment by irradiationTreatment involving filtrationWater filterWater quality

The invention discloses a bottle washing water circulation system. The bottle washing water circulation system comprises a coarse water filtering tank, a sewage tank, a filtering group, a water purification tank, a heating set and a chemical dosing box, and is characterized in that a bottle washing machine water returning pipe is connected with the middle of the left side of the water purificationtank; the water purification tank is internally provided with a filtering screen; the position of the filtering screen is higher than a connection part of the coarse water filtering tank and the bottle washing machine water returning pipe; a first blowdown pipe is connected with the lower part of the left side of the coarse water filtering tank, and a first blowdown valve is arranged on the firstblowdown pipe; a first overflowing pipe is connected between the coarse water filtering tank and the sewage tank; a first liquid level meter is arranged at the front side of the sewage tank. The bottle washing water circulation system disclosed by the invention is simple in structure and can be used for effectively filtering high-temperature bottle washing water and purifying the water quality ofthe bottle washing water, so that the bottle washing water is cyclically utilized and the treatment efficiency of the bottle washing water is ensured.

Owner:KUAIJISHAN SHAOXING WINE

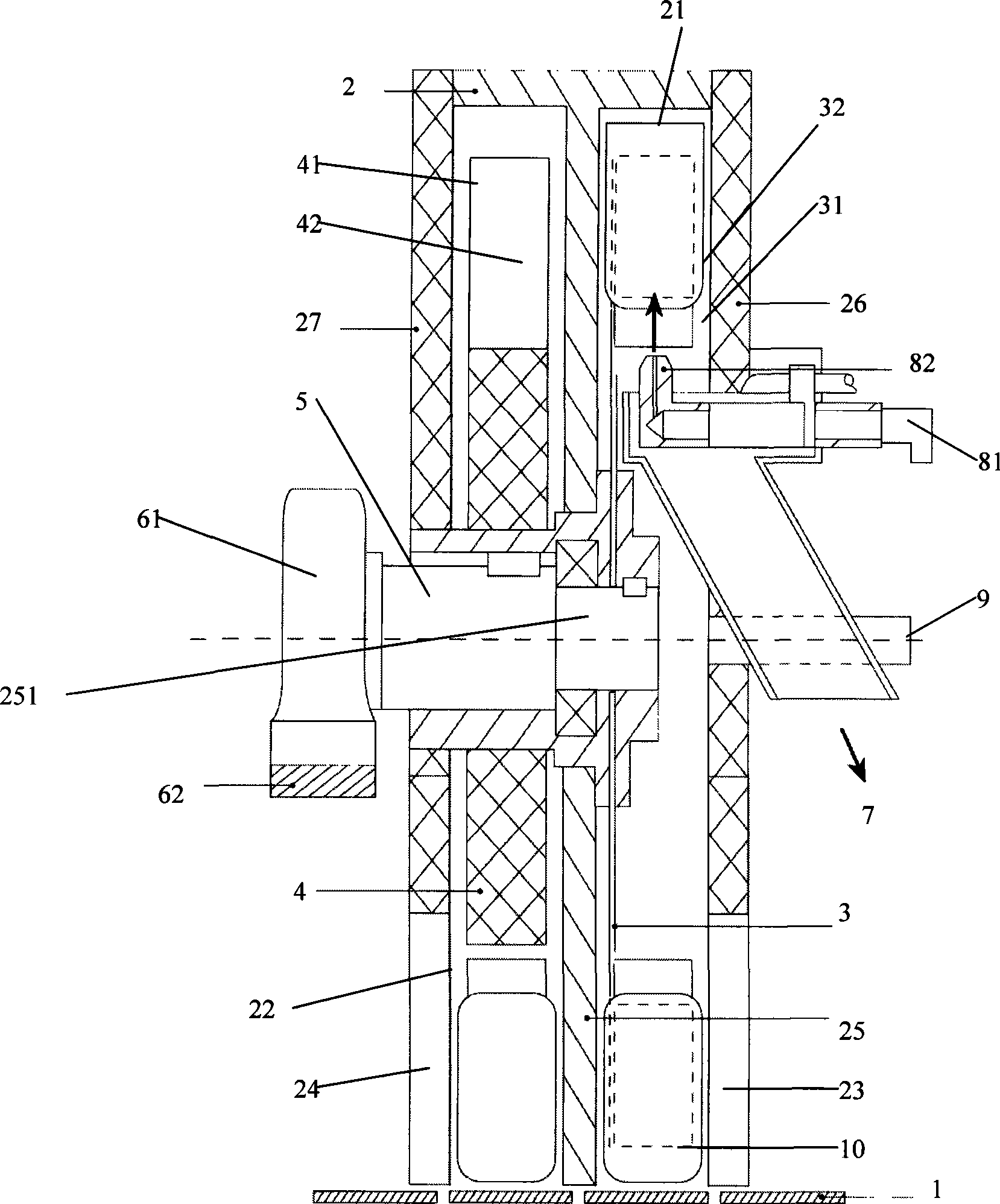

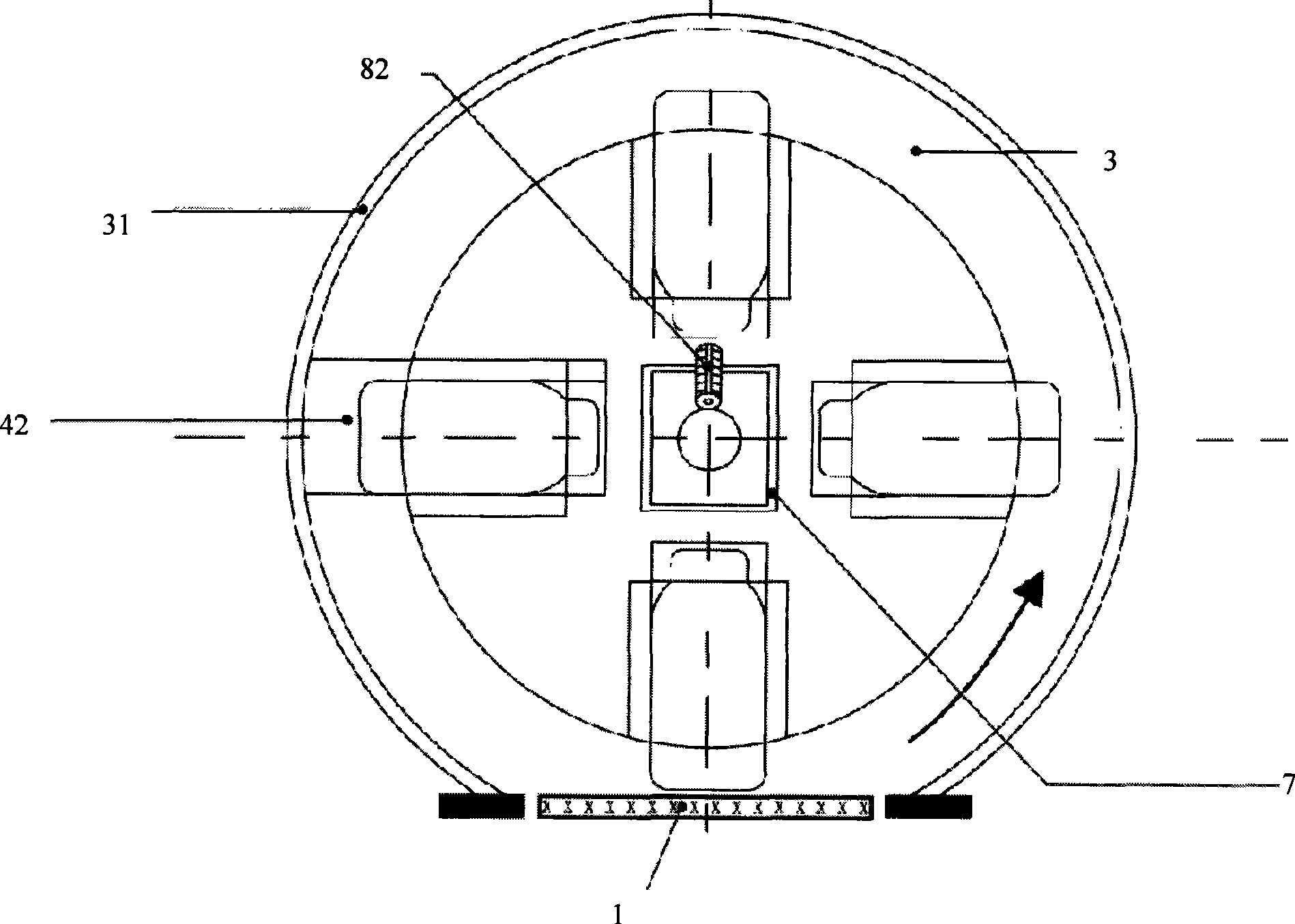

Three-wash bottle washing machine for wild-mouth bottles

InactiveCN102151677AStable clampingNot easy to get stuckHollow article cleaningDrying gas arrangementsSpray nozzleWide mouth

The invention relates to a fully-automatic bottle washing machine, in particular to a three-wash bottle washing machine for wild-mouth bottles, which comprises a machine frame platform, a turntable arranged above the machine frame platform and driven by a spindle to rotate, and a plurality of valve banks, wherein a plurality of spray pipes capable of moving up and down is arranged along a circumferential direction between the turntable and the machine frame platform; one end of each spray pipe extends into a wide-mouth bottle which is placed above the spray pipe with top side down, and the other end of the spray pipe is communicated with a water inlet and / or air duct; a plurality of positioning guide sleeves are arranged correspondingly along a circumferential direction between the turntable and the machine frame platform; and the upper end of each positioning guide sleeve is fixed on the turntable, and a guide post capable of sliding along the inner cavity of each positioning sleeve is arranged in each positioning sleeve. In the invention, the spray nozzle is driven by a single guide post to move, the structure allows the spray pipes to enter the bottle bodies to follow bottle washing, the processing and assembly are simple, time-saving and labor-saving, the spray pipes are insusceptible to dead clamping, and the structure is simple.

Owner:GUANGDONG JINOU MACHINERY MFG CO LTD

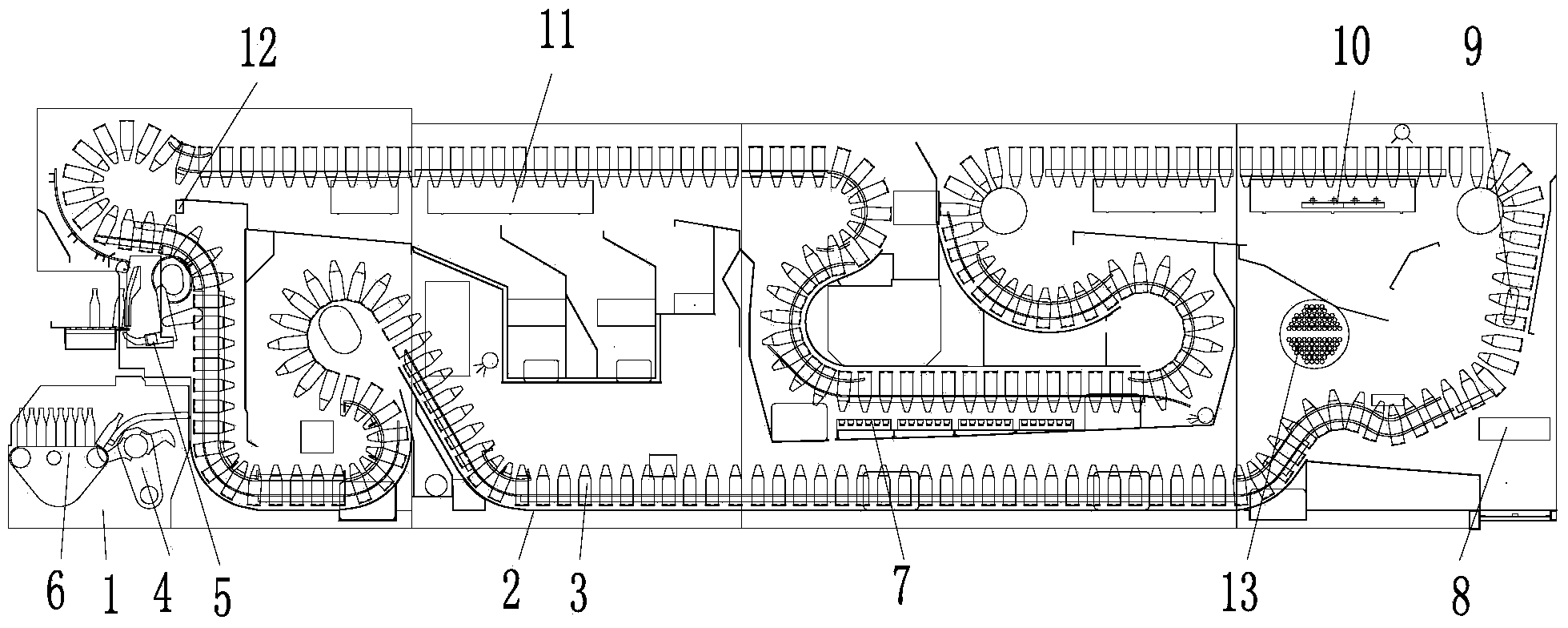

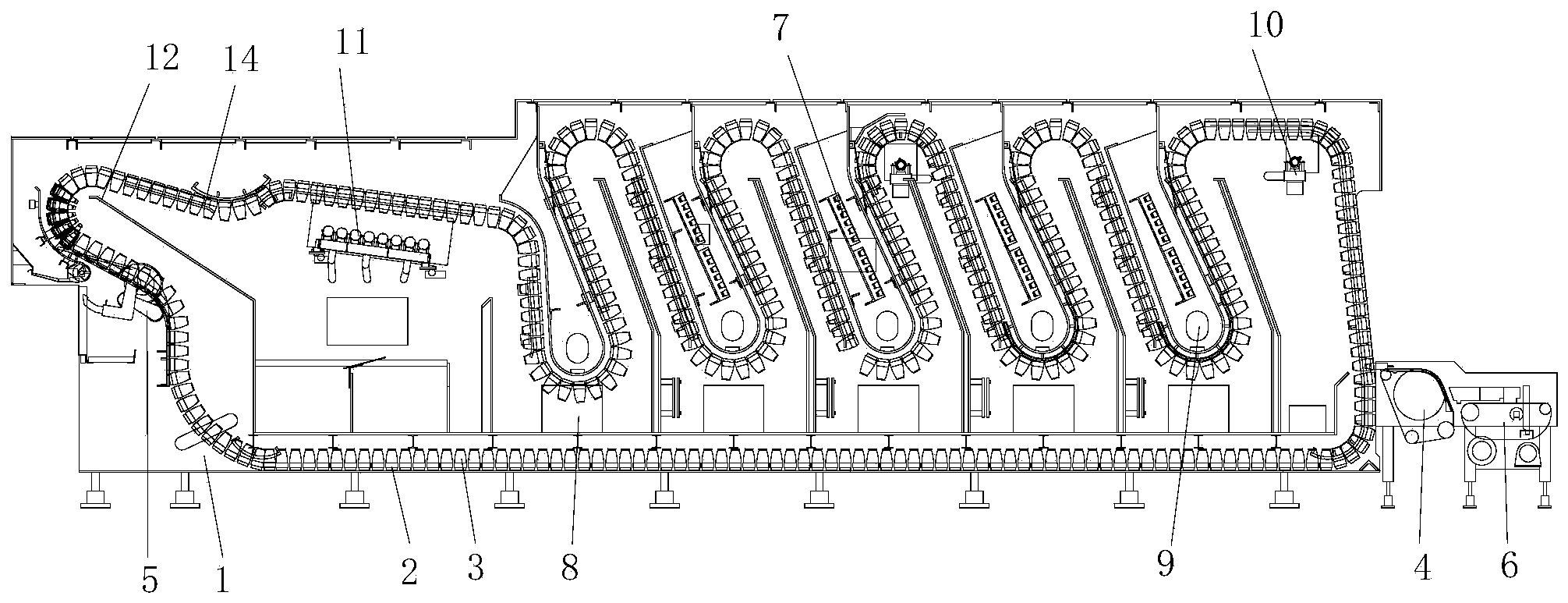

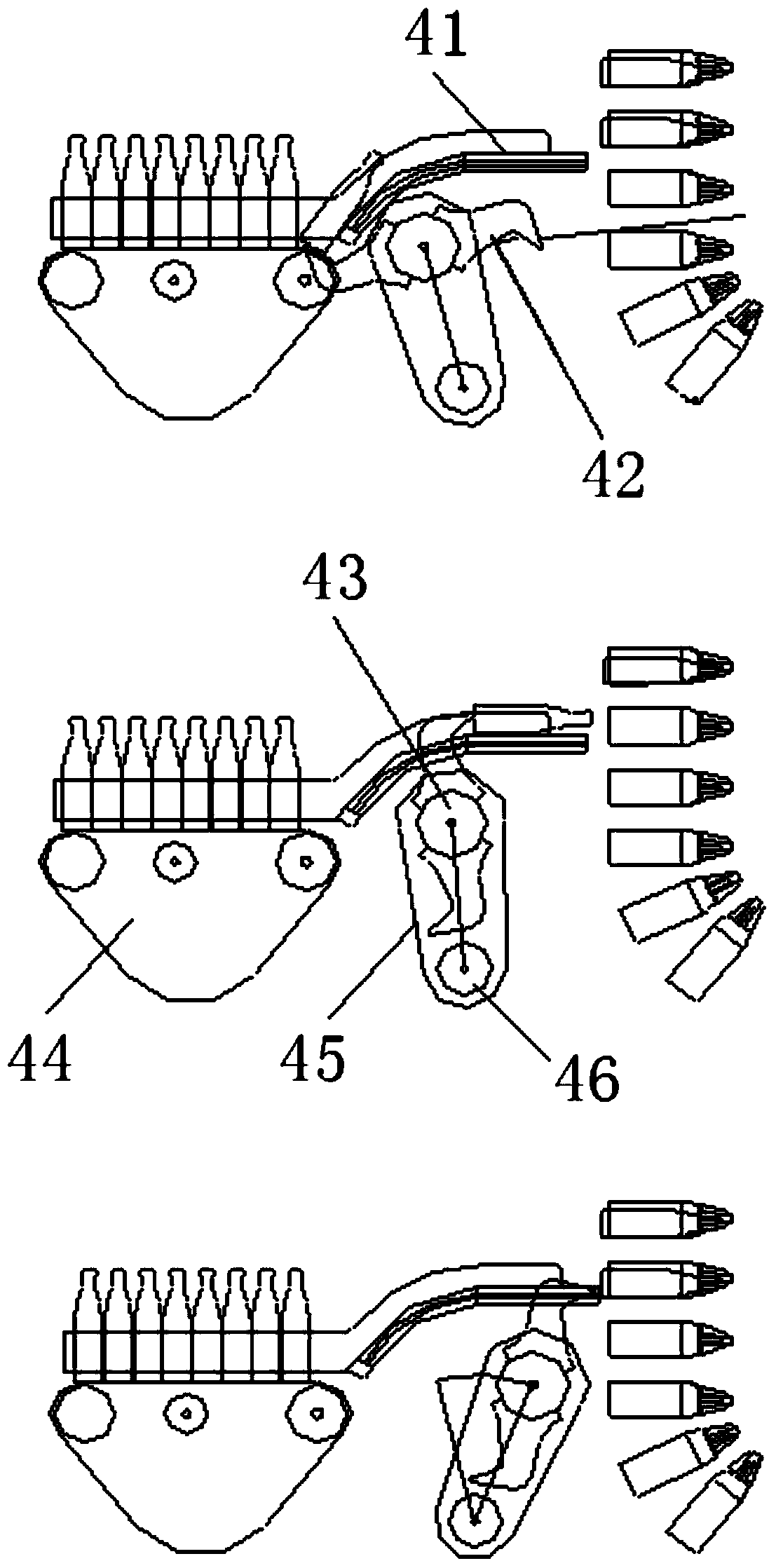

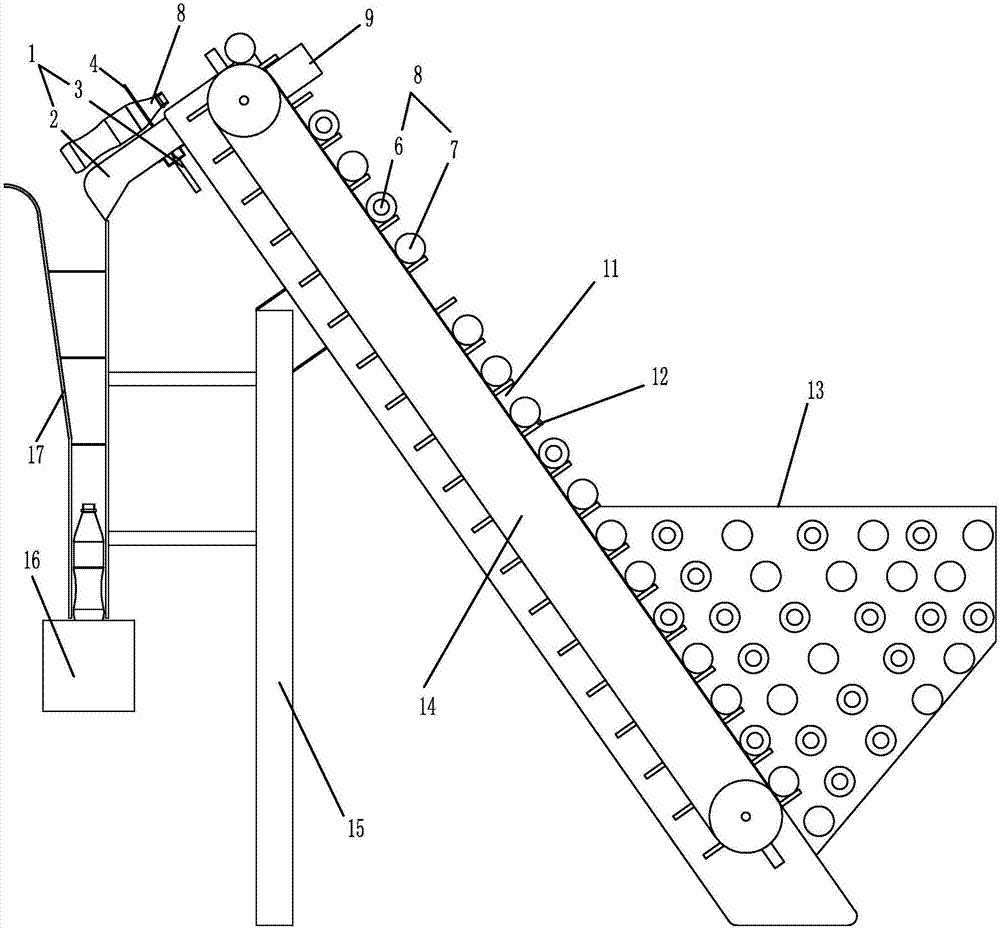

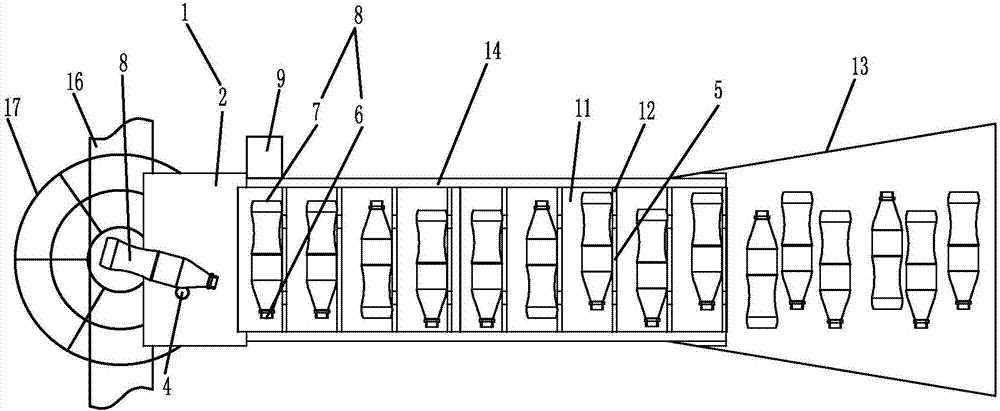

Beer bottle arranging practical training device and control method thereof

ActiveCN107265045AHigh degree of intelligenceImprove reliabilityConveyorsMeasurement devicesProduction lineMicrocontroller

The invention discloses a beer bottle arranging practical training device and a control method thereof, and belongs to the technical field of bottle arranging on a beer production line. The beer bottle arranging practical training device can conduct the bottle discharge operation with bottle openings facing upwards and bottle bottoms facing downwards after automatically judging the bottle opening directions of beer bottles on a bottle arranging conveyor belt. The beer bottle arranging practical training device comprises a support, a storage device and a microcontroller. The bottle arranging conveyor belt obliquely conducting conveying upwards is arranged on the support. A hopper is arranged on the portion, at the input end of the bottle arranging conveyor belt, on the support. A bottle discharge fence is arranged on the portion, below the output end of the bottle arranging conveyor belt, on the support. A bottle washing conveyor belt is arranged on the portion, below the bottle discharge fence, on the support. A bottle thumbing mechanism and a bottle opening direction detection mechanism capable of detecting the bottle opening directions of the beer bottles conveyed on the bottle arranging conveyor belt are arranged on the portion, at the output end of the bottle arranging conveyor belt, on the support. The bottle thumbing mechanism is arranged in front of the bottle opening direction detection mechanism. The control site of the bottle arranging conveyor belt, the storage device, the control site of the bottle opening direction detection mechanism and the control site of the bottle thumbing mechanism are all connected with the microcontroller.

Owner:JINHUA VOCATIONAL TECH COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com