Fully-automatically-controlled efficient ultrasonic bottle washer

An ultrasonic, fully automatic technology, applied in the direction of cleaning methods using liquids, cleaning methods and utensils, cleaning hollow objects, etc., can solve the problems of potential safety hazards, low cleaning efficiency, chemical burns, etc. Elimination effect, the effect of reducing the cost of washing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

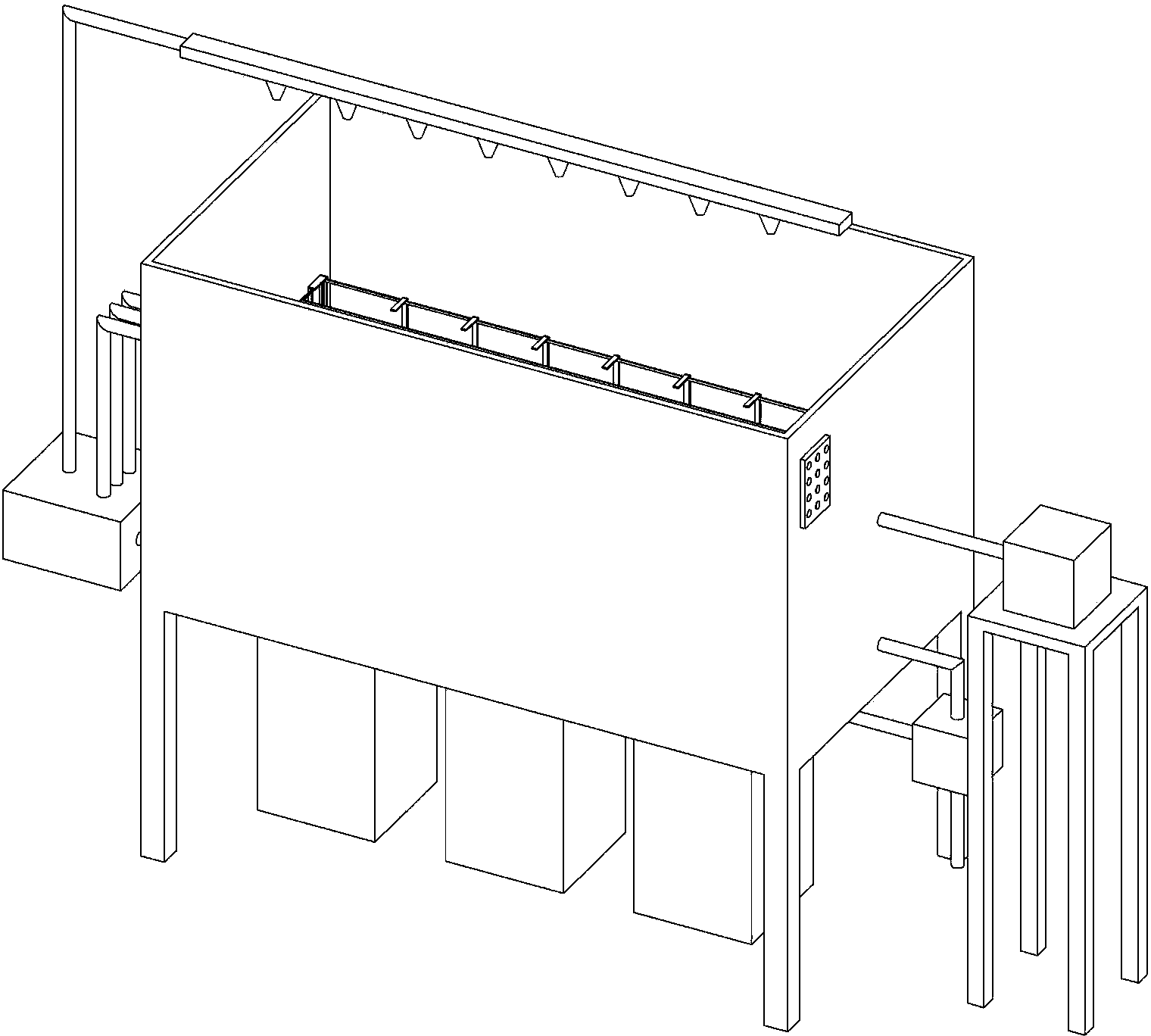

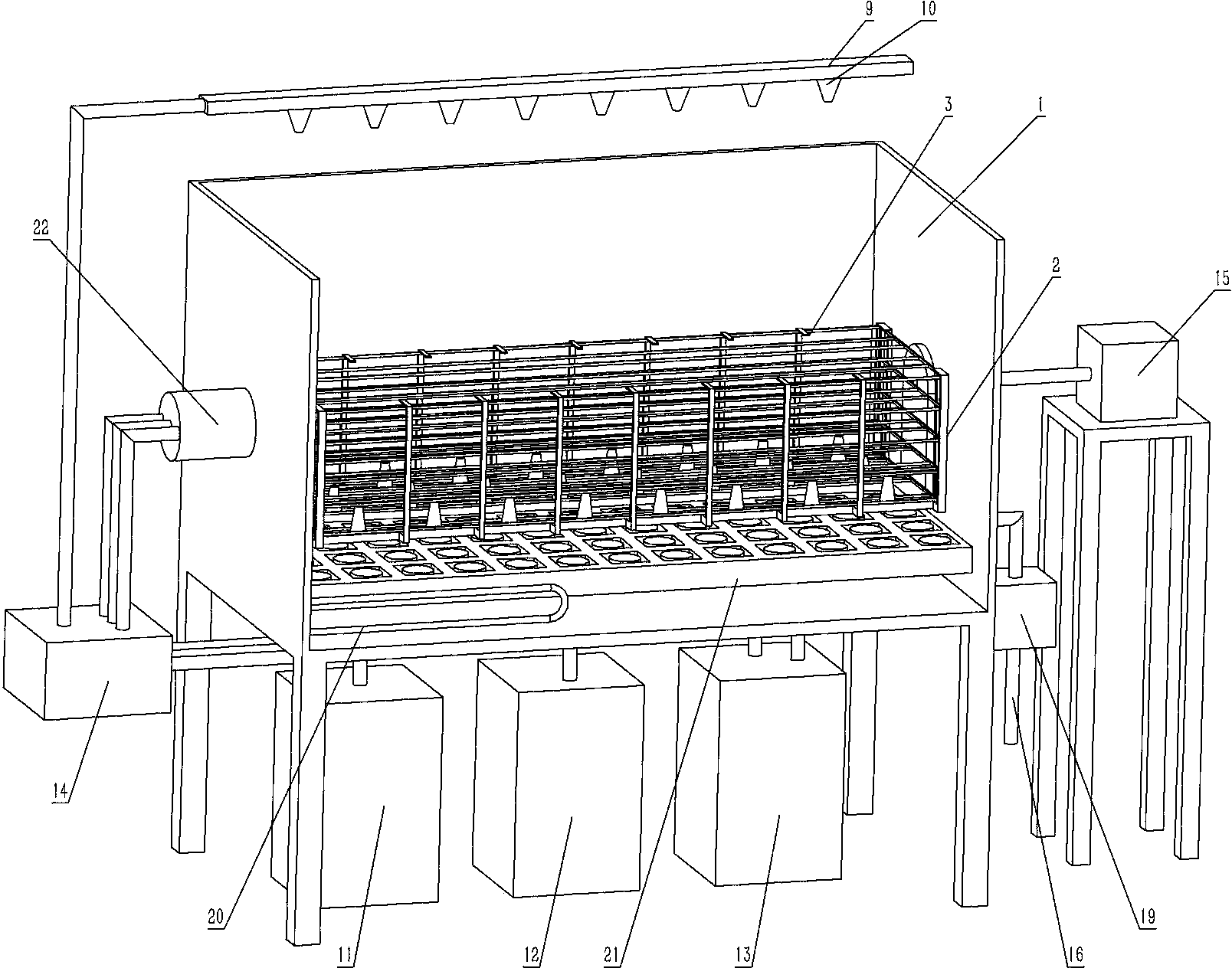

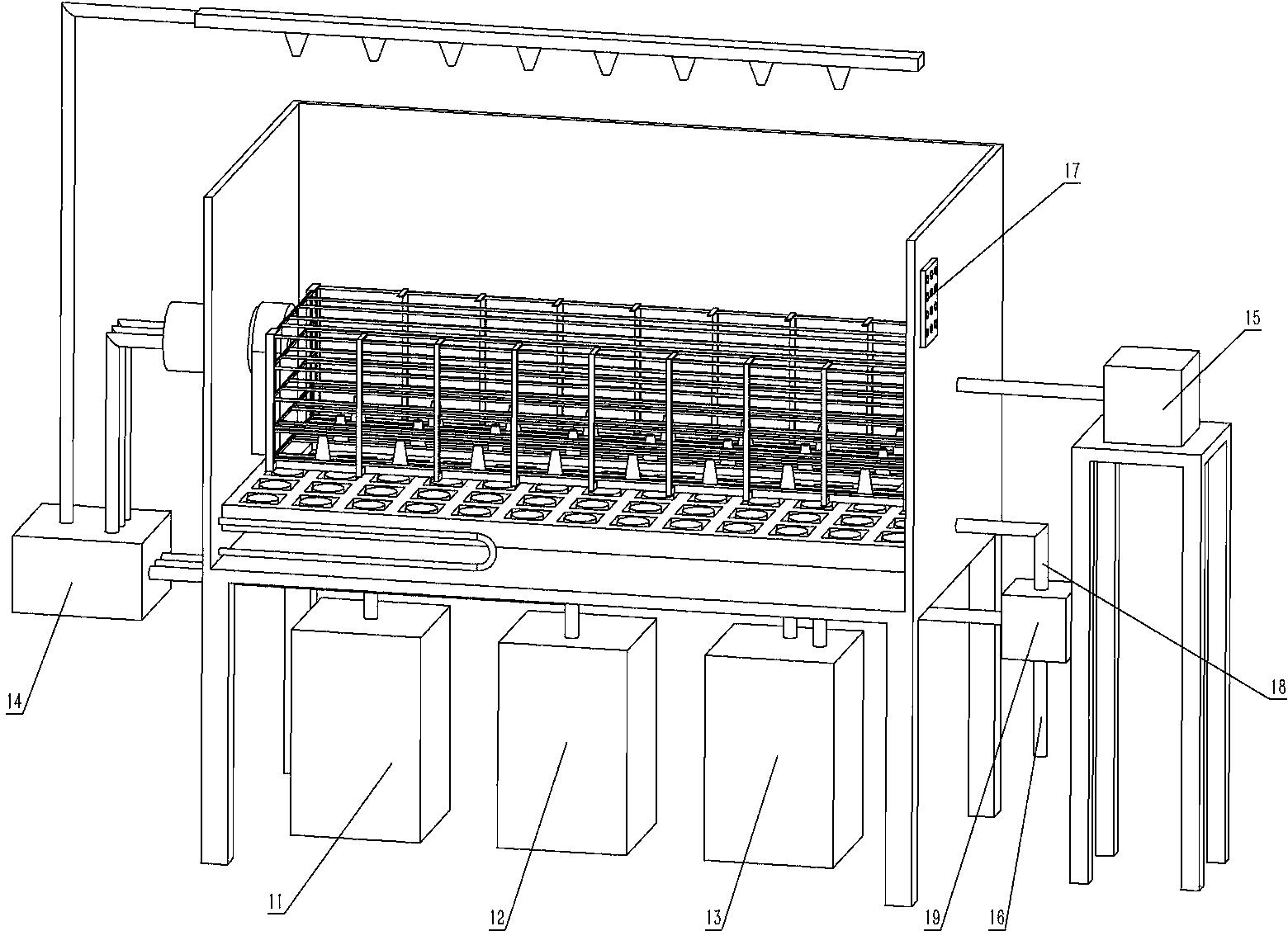

[0057] as attached Figure 1-9 As shown, the present invention includes a cleaning tank 1, a bottle-carrying rotary rinsing frame, a driving motor 15, a bottle spray device, an automatic water supply device 14, a distilled water tank 11, a tap water tank 12, a detergent solution tank 13, an ultrasonic cleaning device, and a sewage tank. Recovery device 19, constant temperature heating device and automatic control system,

[0058] The bottle-carrying rotary flushing frame is composed of a cleaning basket rotary frame 2 with a built-in water channel, a carrier cage 3 embedded in the cleaning basket rotary frame 2, and a water seal 22 arranged at the water inlet end of the cleaning basket rotary frame 2. The cleaning basket swivel frame 2 is composed of the inner nozzle carrier plate 4, the carrier cage limit rod 5 symmetrically arranged on the lateral side of the inner nozzle carrier plate 4, and the drive motor rotation positioning connecting plate 6 symmetrically arranged on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com