Combined washing and drying integrated machine and control method

A control method and the technology of an all-in-one machine, which are applied to the control device of washing machines, other washing machines, household clothes dryers, etc., can solve the problems of high energy consumption, waste of resources, and non-environmental protection of washing machines, and achieve high heat utilization and energy saving Space and cost, good washing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

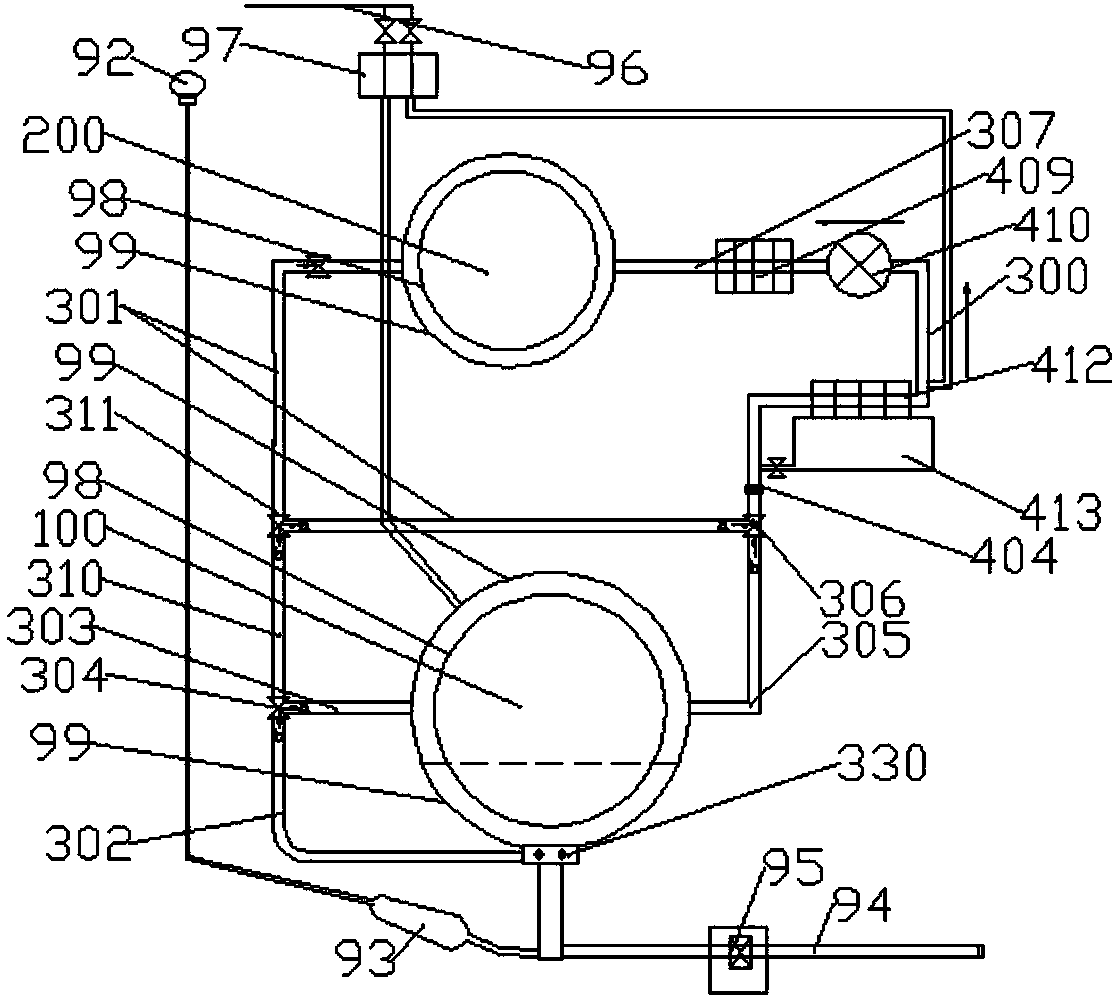

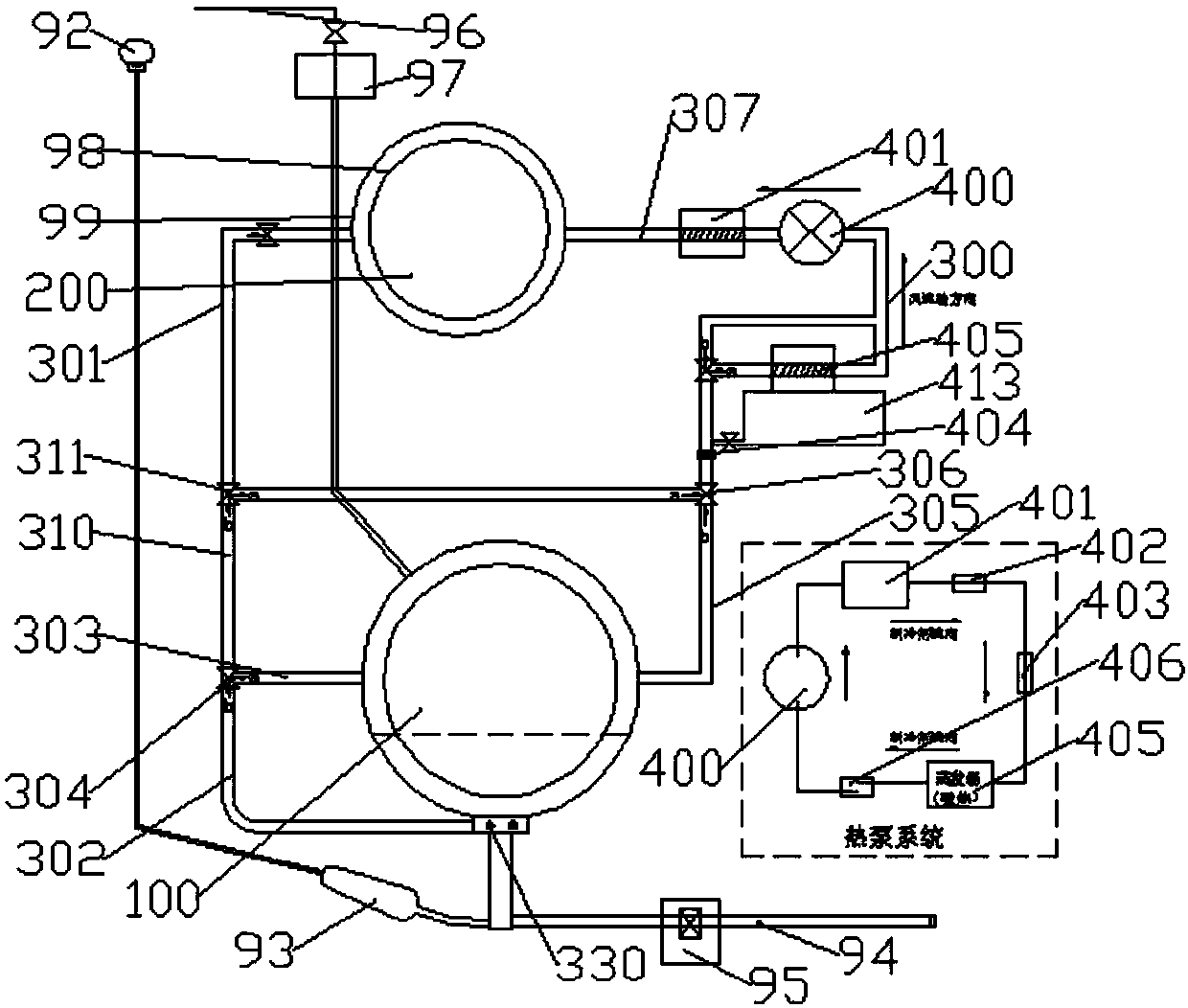

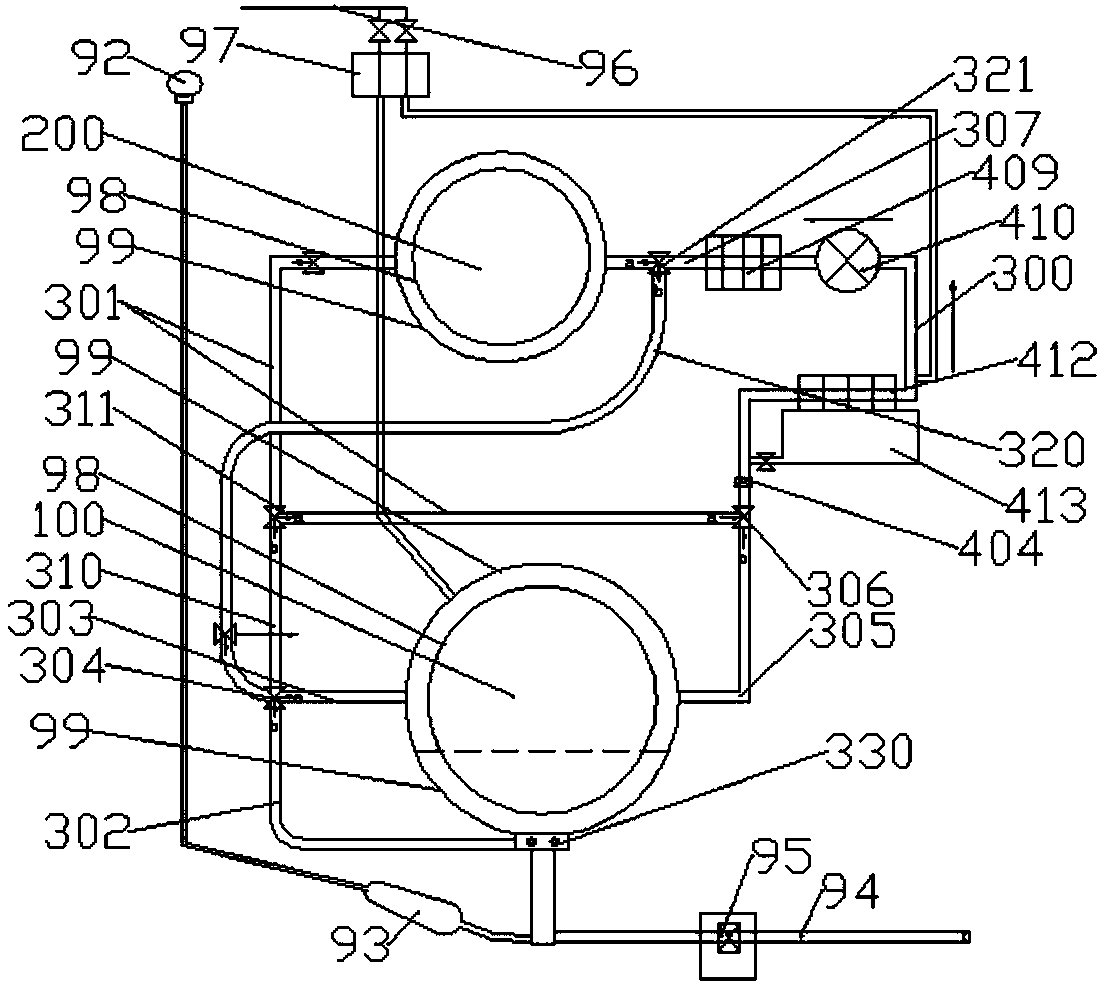

[0043] Such as Figure 1-2As shown, a combined washing and drying machine includes a drying system, at least one first laundry processing cylinder and at least one second laundry processing cylinder, and the drying system includes a circulation pipeline communicated with the first laundry processing cylinder 300, the circulation pipeline 300 is provided with an air supply branch 310, which is used to introduce drying air into the second laundry processing cylinder, and the circulation pipeline 300 and / or the air supply branch 310 is provided with an air supply branch The control unit 311 and the air supply control unit 311 control the conduction of the air supply branch 310 to guide the drying air into the second laundry processing cylinder. Utilize the air supply branch to introduce the drying air in the first clothes processing drum into the second clothes processing drum, realize the same supply of the same drying system to the first clothes processing drum and the second c...

Embodiment 2

[0060] Such as Figure 1-2 As shown, this embodiment is a further limitation of Embodiment 1. The combined washing and drying machine is a washing machine, and the washing machine includes two drums, a drying drum and a washing drum, and the drying drum is arranged on the upper part of the washing drum.

[0061] The circulation pipeline 300 includes a derivation pipeline 301 for deriving the drying air that has completed the heat exchange in the drying drum 200. The air supply branch 310 is arranged on the derivation pipeline 301. The air supply branch 310 The air outlet end communicates with the washing tub 100 , and guides the drying air from the drying tub 200 into the washing tub 100 .

[0062] Since the temperature required for heating the washing water in the washing tub 100 or heating the air / items to be washed in the washing tub 100 is relatively low, the cost of setting the heating device 330 separately is high. The heat-exchanged drying air is introduced into the wa...

Embodiment 3

[0075] Such as Figure 1-2 As shown, this embodiment is a further limitation of Embodiment 2. The washing tub 100 is provided with a washing water heating branch pipe 302 for introducing the drying air into the washing water in the washing tub 100 and / or for introducing the drying air into the washing water. Introduce the air heating branch pipe 303 above the washing water level.

[0076]The connection port on the washing tub 100 connected with the washing water heating branch pipe 302 is set below the minimum liquid level in the washing tub 100, so that the drying wind can heat the washing water in the washing tub 100, so as to speed up the washing speed and improve the washing effect. Form bubbling agitation to speed up washing speed and efficiency. The communication port communicating with the air heating branch pipe 303 is set above the highest liquid level in the washing tub 100 to heat the load in the washing tub 100 (such as items to be washed or air).

[0077] Prefer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com