Clip for washing bottle

A bottle clip and clip technology, which is applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of unfavorable transportation, increase the production cost of the bottle washer, and the shape of the bottle washer is huge, and saves money. Installation space, the effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

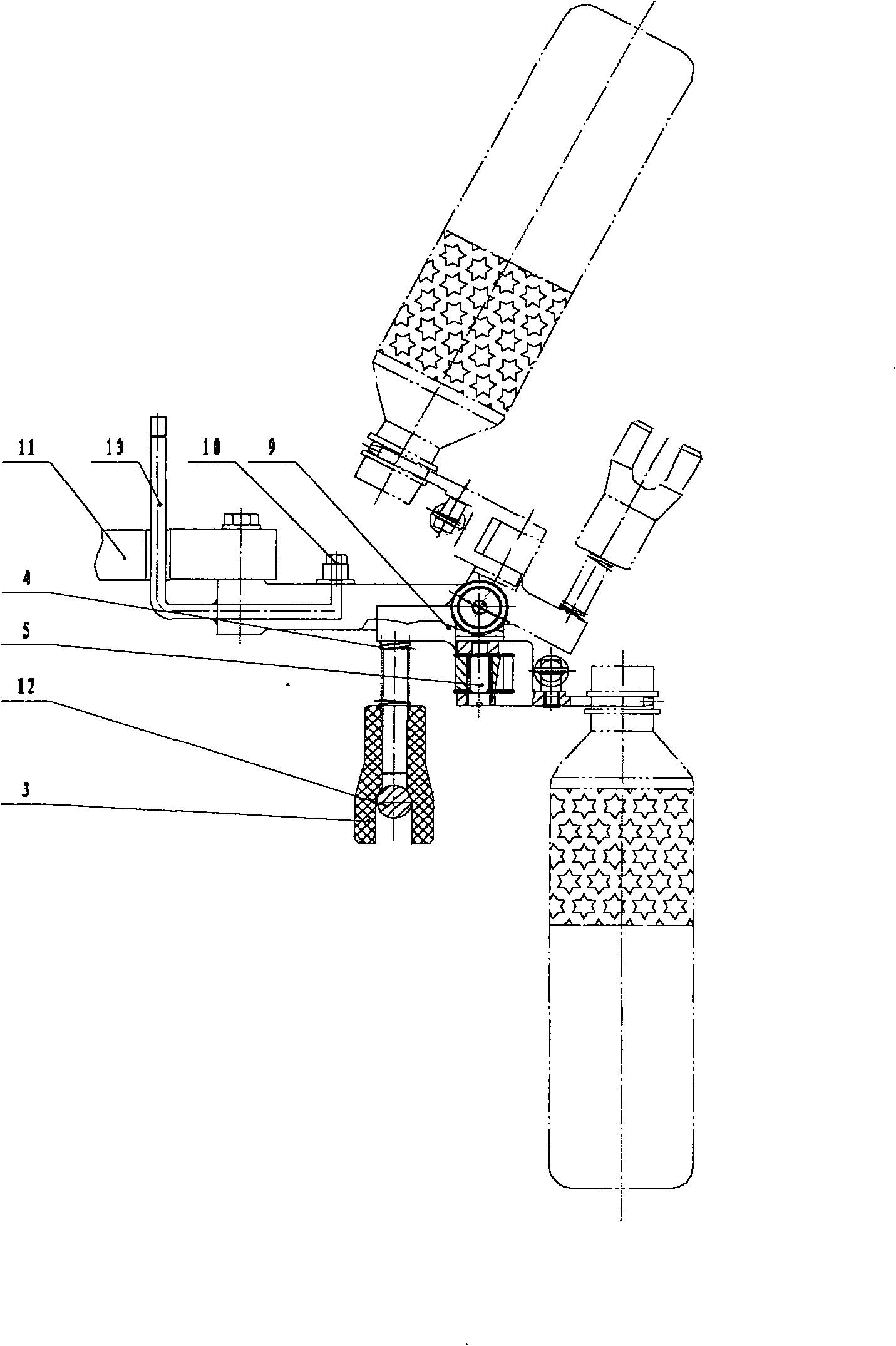

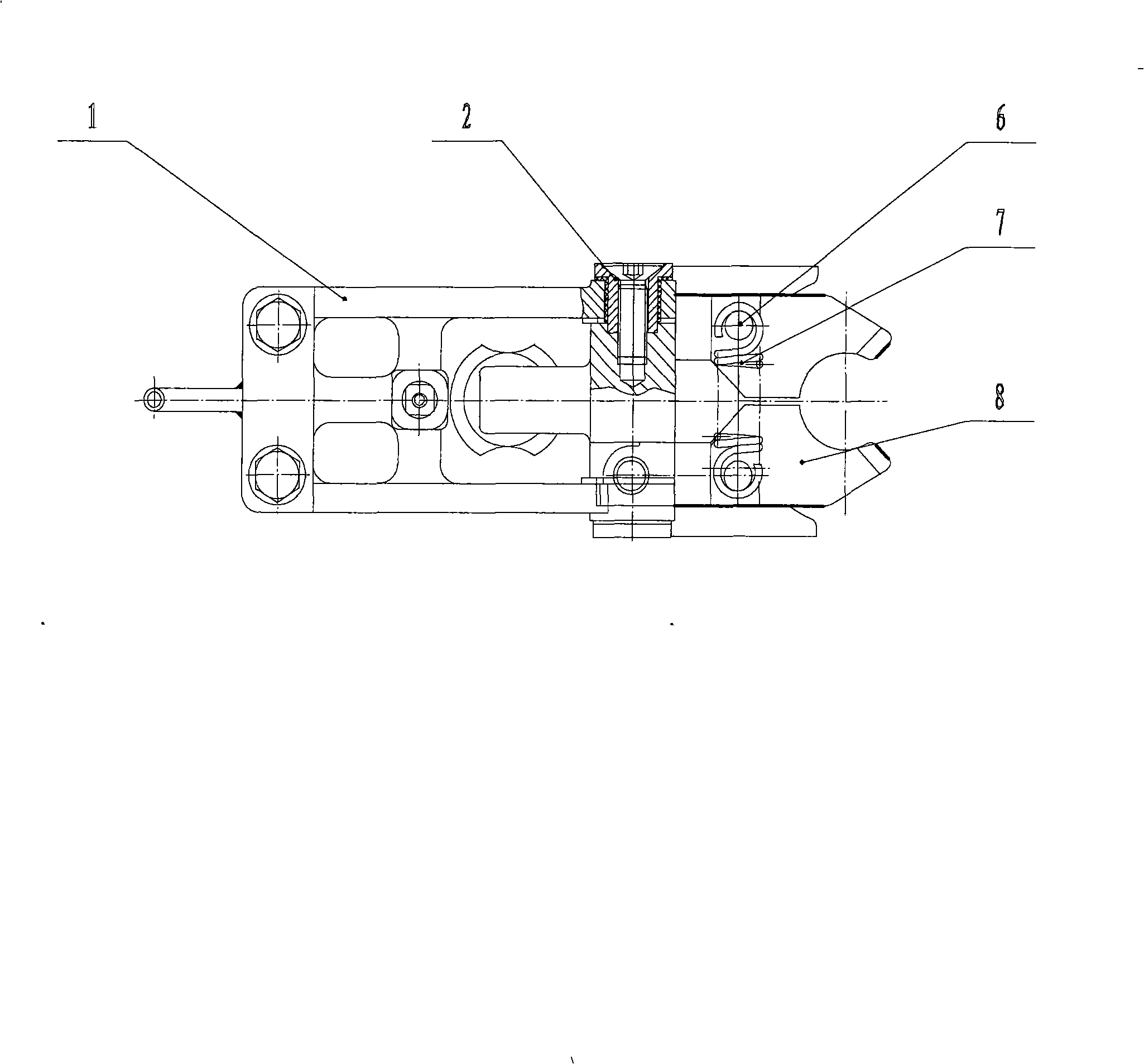

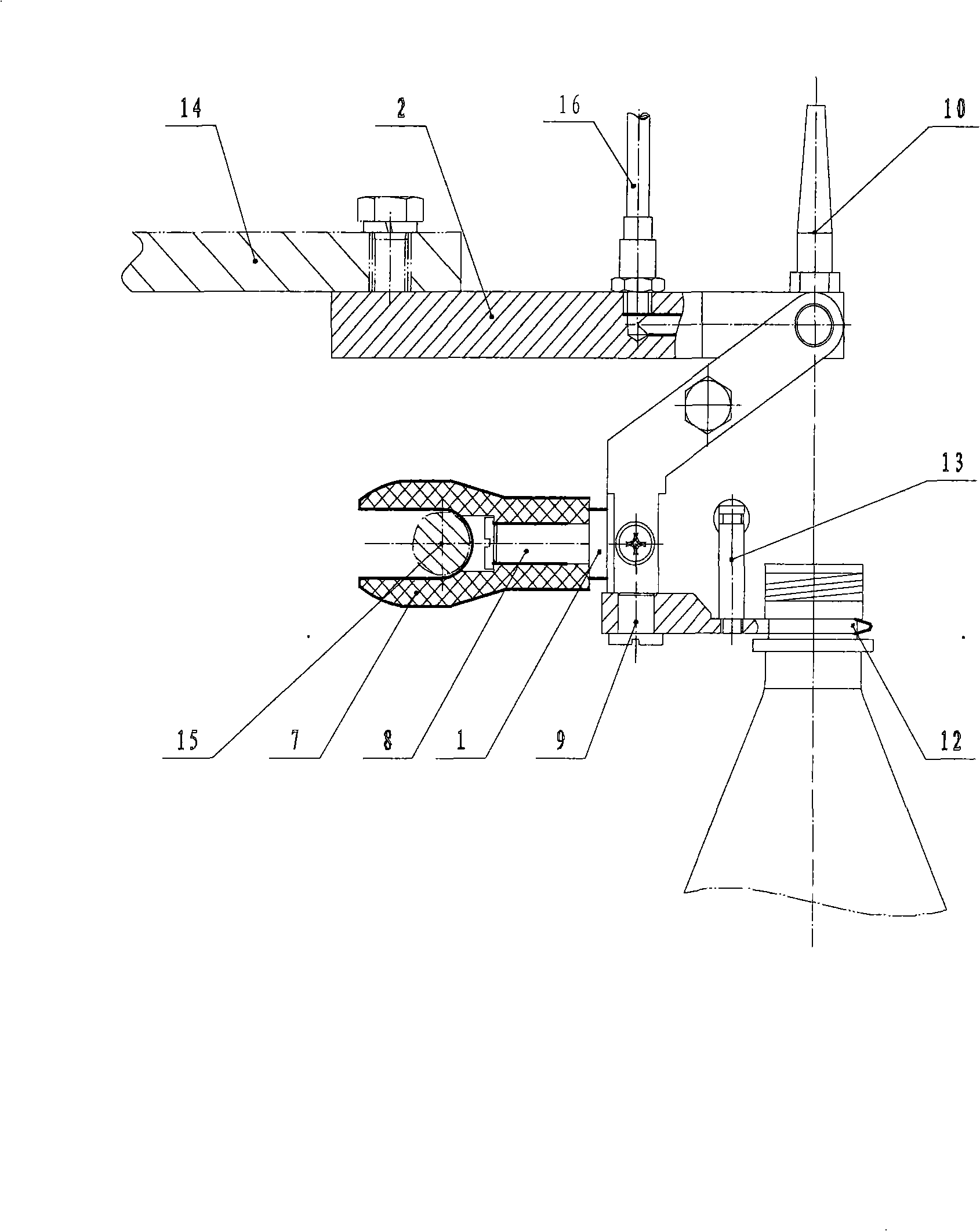

[0012] Such as figure 2 As shown, the bottle rinsing device of the present invention includes: the support block 2 is fixed on the rotary disk 14, and the left toggle lever 4 and the right toggle lever 5 are respectively installed on both sides of the support block 2 with a small shaft 11 and can be rotated around the small shaft 11 turn. There is distance body 6 to connect between two toggle levers. The left and right clips 12 are installed on the left toggle 4 and the right toggle 5 with screws 9 respectively, and column pins 13 are installed on the left and right clips 12 for fixing the extension spring 3 to control the closing of the left and right clips 12. The center of rotation of the left toggle lever 4 and the right toggle lever 5 is on the center line of the left and right clips 12 clamping bottles. The support body 1 is fixed on the side of the left toggle lever 4 and the right toggle lever 5. The retaining ring screw 8 connects the sliding fork 7 to the support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com