Bottle washing device for bottle washing machine

A bottle washing machine and bottle washing technology, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of poor quality and low efficiency of manual bottle washing, reduce production costs, and facilitate popularization and implementation , good coordination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

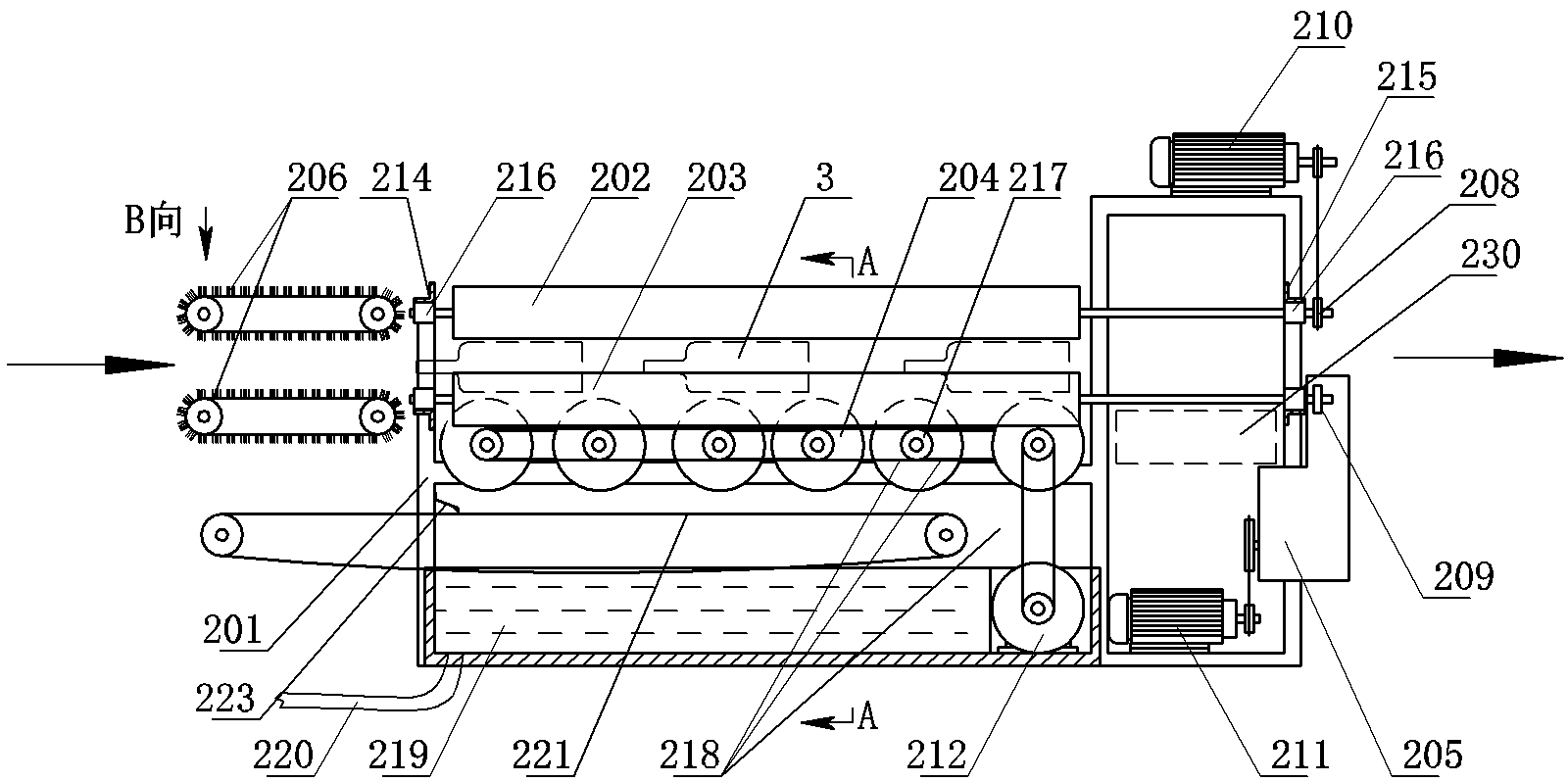

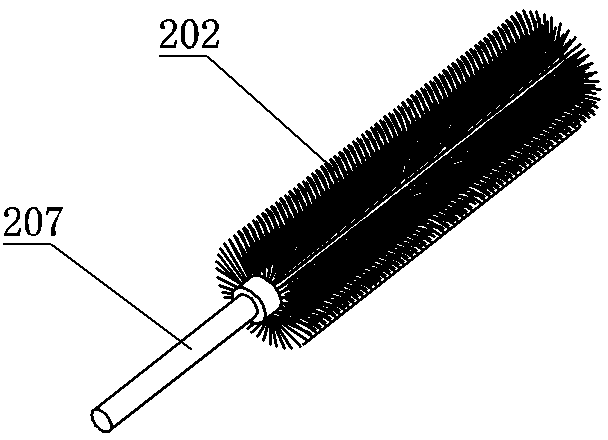

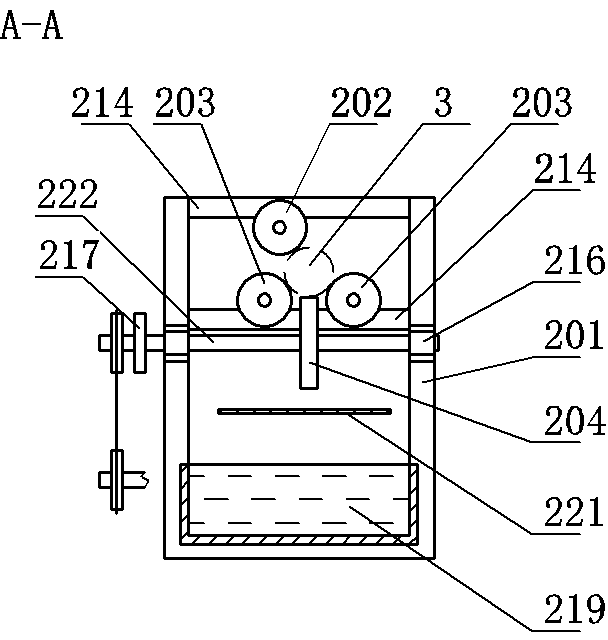

[0020] Embodiment 1: a kind of bottle washing device of bottle washing machine, see figure 1 , figure 2 with image 3 , The bottle washing device includes a bracket 201, a power mechanism, a transmission mechanism and the like. Three brush rollers are horizontally installed on the support 201, wherein one brush roller is arranged on the upper layer, two brush rollers are arranged on the lower layer, and the upper and lower layer brush rollers form a triangular scrubbing channel. The rotating shaft of each brush roller is connected with the power mechanism through the transmission mechanism after the output end extends outwards. Each brush roller keeps rotating in the same direction, so that the bottle body can be driven to rotate continuously. A bottle body pushing mechanism is arranged between any two brush rollers on the lower layer, and the pushing mechanism can drive the bottle body to move forward. An output mechanism is installed at the outlet of the triangular scru...

Embodiment 2

[0025] Embodiment 2: The content is basically the same as that of Embodiment 1, and the similarities will not be repeated. The difference is that this embodiment provides more than three brush rollers. The quantity of upper and lower floor brush rollers can be 5 or 7. see Figure 5 with Image 6 , 3 brush rollers in the upper layer and 4 brush rollers in the lower layer form 7 composite structures, forming three triangular scrubbing channels in total. The delabeling mechanism can be located in the gap between the corresponding brush rollers, and the brush rollers are different to form an equilateral triangle channel, and the upper brush rollers can be biased to one side.

Embodiment 3

[0026] Embodiment 3: The content is basically the same as in Embodiment 1, and the similarities will not be repeated. The difference is that the pushing mechanism positioned at the bottom of the triangular scrubbing channel is different. The pushing mechanism adopts a conveyor belt, and a support wheel is arranged below the conveyor belt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com