Novel washing bottle shower nozzle

A bottle washing nozzle, a new type of technology, applied in the direction of spraying device, spraying device, cleaning hollow objects, etc., can solve the problems of poor cleaning effect, cleaning dead angle, large consumption of cleaning gas and liquid, etc., and achieve better cleaning effect Good, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

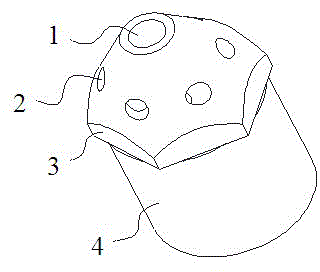

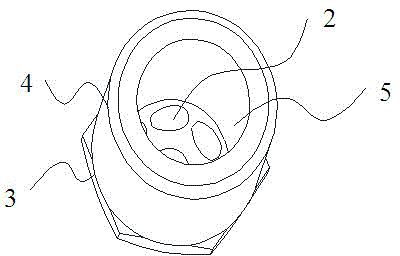

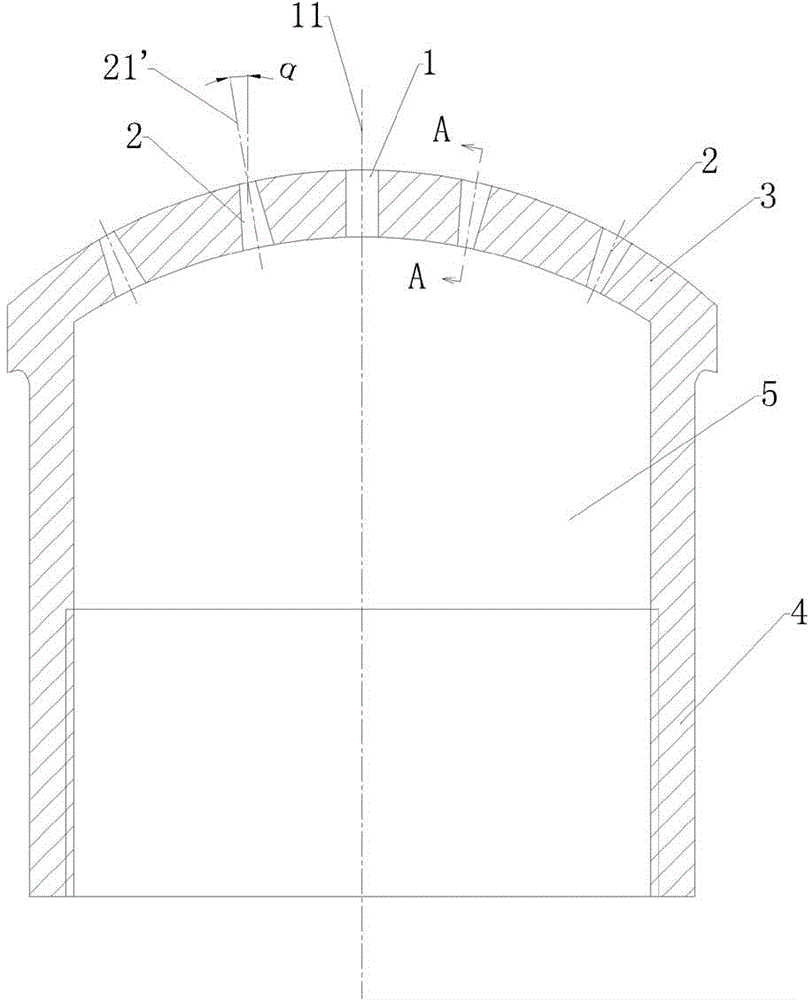

[0019] As shown in 1 and 2, the front end of a new type of bottle washing nozzle is a convex and flat spherical or conical nozzle body 3, and the rear end is a connecting body 4 for connecting the nozzle and the gun body of the spray gun; The central top of the nozzle body 3 is provided with a straight through hole 1, and the central axis of the straight through hole 1 coincides with the rotation axis of the rotating nozzle body 3; several oblique through holes 2 are arranged on the nozzle body around the straight through hole; the connecting body 4 A through hole 5 is arranged inside, and the water or gas flowing out from the gun body is sprayed from the straight through hole 1 and the oblique through hole 2 through the through hole; , the water flow or air flow ejected from all the oblique through holes converges to form a vortex.

[0020] In order t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com