Renewable spent lye filter device and using method thereof

A filtration device and technology for waste lye, which are applied in the fields of filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of high speed of consumables, high cost of membrane filtration system and high investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

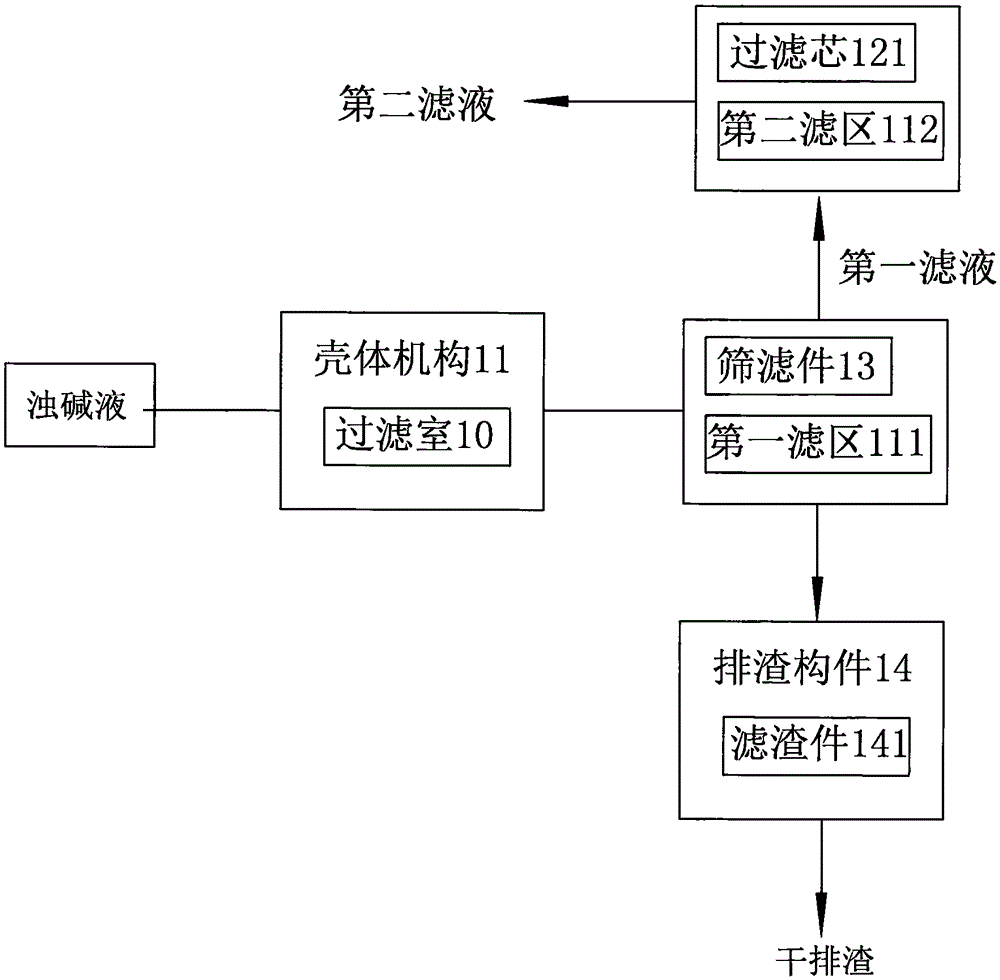

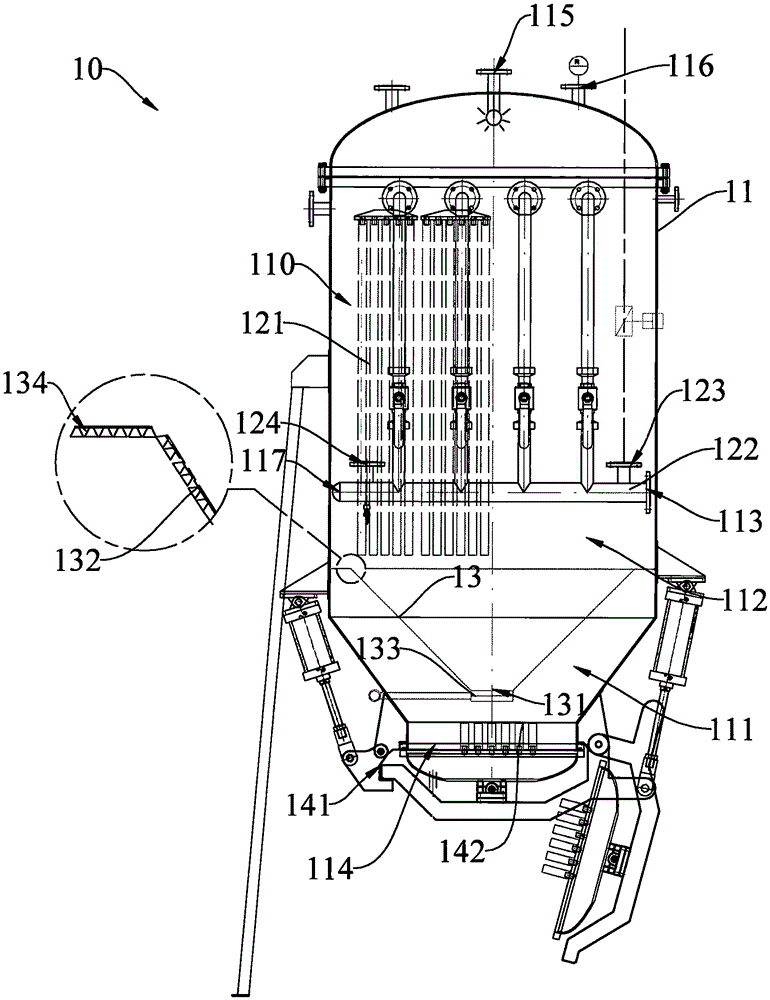

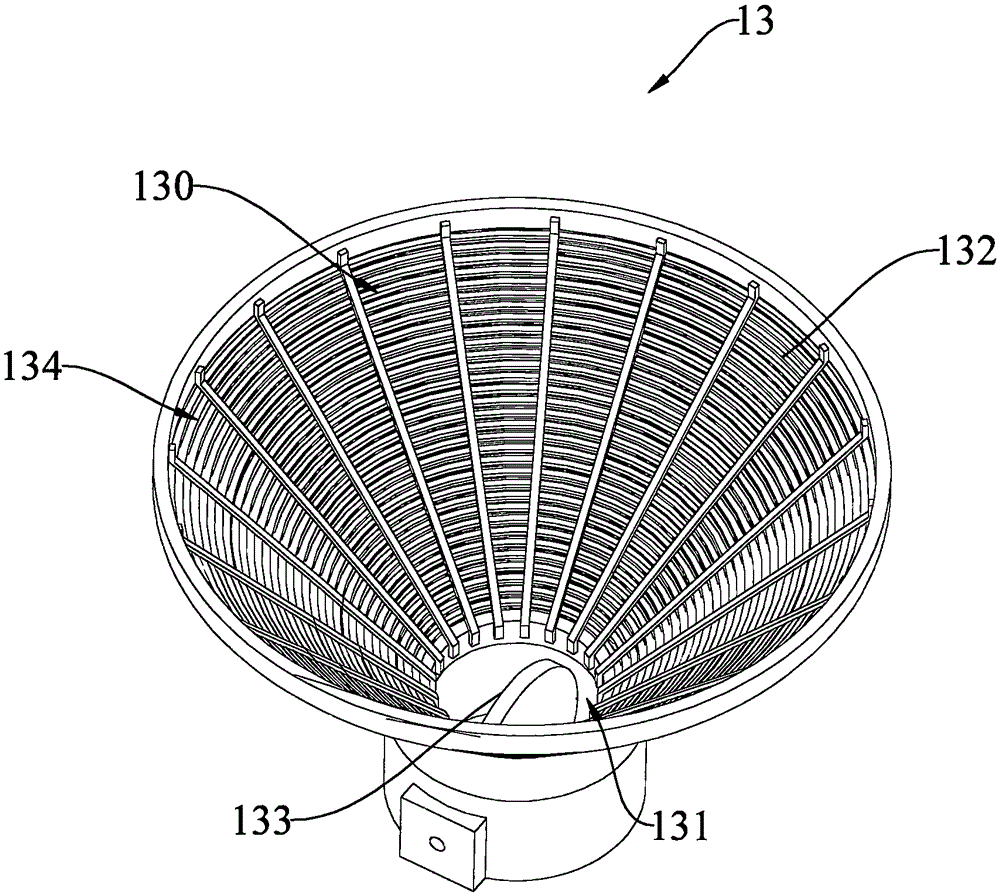

Method used

Image

Examples

Embodiment 1 to Embodiment 10

[0084] The operating steps of Examples 1 to 10 are the same, the difference is the aperture of the filter core 121, the working pressure of the filter device 10 is set to 0.3MPa, the working temperature is 80°C, the design temperature is 105°C, and the normal flow rate is 10T / h, the initial turbidity of spent lye was determined to be 40.25EBC, wherein, the determination of turbidity was detected by the Huffman desktop turbidimeter VosRota90 / 25, and the measured value of each implementation was determined by measuring the measured value at an angle of 25 degrees. Example of lye turbidity value. Table 1 shows the pore size of the filter element 121 in Examples 1-10, the turbidity and filtration flow rate of the filtrate filtered through the filter device 10 .

[0085] The filter element 121 of the different pore size of table 1 embodiment 1~10

[0086]

[0087] As can be seen from Table 1, in order to take into account the filtration flow rate and filtration accuracy, as we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com