Method for extracting uranium by using ion exchange fixed tower under alternate Ph condition

A technology of ion exchange and pH, which is applied in the direction of improving process efficiency, can solve problems such as pipeline and equipment damage, safety hazards, and impact on ion exchange resin adsorption, so as to shorten the leaching volume, improve leaching efficiency, improve efficiency and effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] A method for extracting uranium in an ion-exchange fixed tower of the present invention under alternating conditions of pH is introduced below in conjunction with the accompanying drawings and examples:

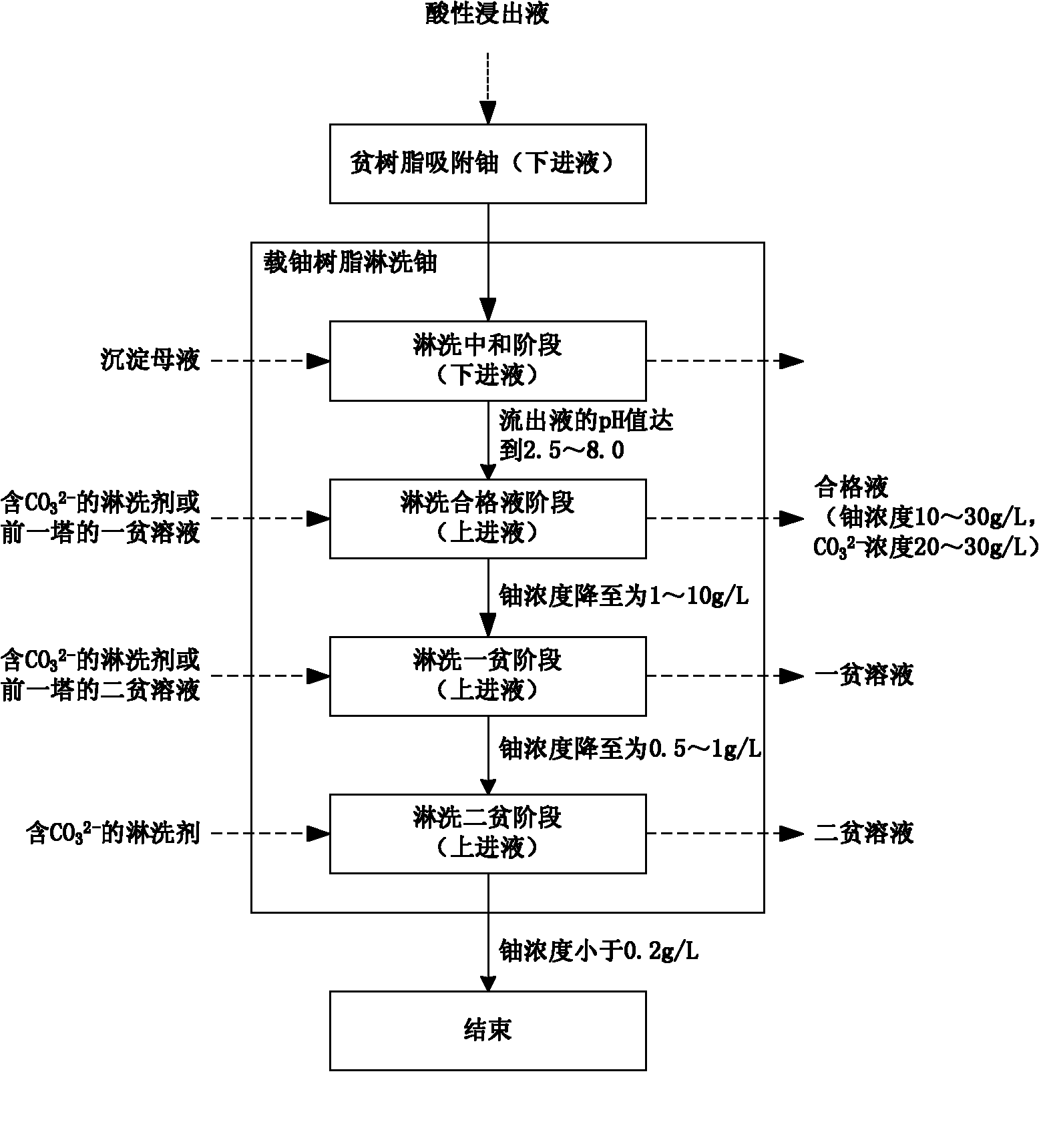

[0031] Such as figure 1 As shown, a method for extracting uranium in an ion-exchange fixed column under the condition of alternating pH is divided into the following steps:

[0032] (1) Poor resin adsorption uranium step: use ion exchange fixed tower to recover uranium from the acid leach solution, the acid leach solution is fed from the bottom, and the resin adsorbs the uranium in the acid leach solution. During this process, the outflow after the adsorption When the concentration of liquid uranium is basically the same as that of the original solution before adsorption (that is, when the concentration difference between the two is 0-20 mg / L), the ion resin can be considered saturated, and the solution in the ion exchange tower is emptied for leaching.

[0033] In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com