Low-power-consumption miniaturized kitchen waste intelligent treatment device

A technology for intelligent processing of food waste, applied in chemical instruments and methods, filtration separation, separation methods, etc., can solve the problems of inability to realize resource utilization of food waste, heavy burden on environmental protection departments, and unsuitable for family use, etc., to achieve Ease of post-processing, compact structure, and reduced procurement costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

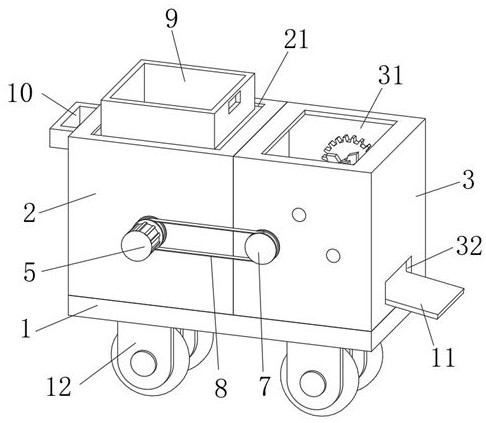

[0032] A low-power miniaturized intelligent processing device for food waste, such as Figure 1-2As shown, including the base 1, a filter box 2 and a crushing box 3 are fixedly installed on the upper left part and the upper right part of the base 1 respectively, and a fixed plate 4 is fixedly welded on the upper part of the front and rear box walls in the filter box 2, two The lower part of the fixed plate 4 is movably connected with a driving mechanism 5, and the upper part of the fixed plate 4 is slidably connected with a lifting mechanism 6, and the lifting mechanism 6 is connected with the driving mechanism 5 in transmission, and a crushing mechanism 7 is interspersed and connected in the crushing box 3. The crushing mechanism 7 and the driving mechanism 5 are jointly connected with a conveyor belt 8, the left end of the filter box 2 is fixedly welded with a push rod 10, a material guide plate 11 is interspersed and connected in the crushing box 3, and a garbage collector i...

Embodiment 2

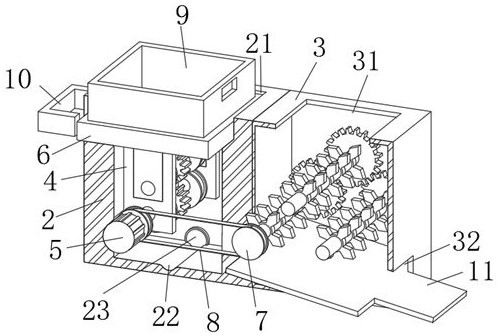

[0035] On the basis of Example 1, as Figure 3-6 As shown, a low-power miniaturized intelligent processing device for food waste includes a base 1, and a filter box 2 and a crushing box 3 are fixedly installed on the upper left part and the upper right part of the base 1 respectively. A fixed plate 4 is fixedly welded on the upper part of the front and rear box walls, and a drive mechanism 5 is movably connected to the lower part of the two fixed plates 4, and a lifting mechanism 6 is slidingly connected to the upper part of the fixed plate 4, and the lifting mechanism 6 and the driving mechanism 5 Transmission connection, crushing box 3 is interspersed with a crushing mechanism 7, crushing mechanism 7 and driving mechanism 5 are jointly connected with a conveyor belt 8, the left end of the filter box 2 is fixedly welded with a push rod 10, and the crushing box 3 is interspersed and connected with a A material guide plate 11, the upper end of the lifting mechanism 6 is provide...

Embodiment 3

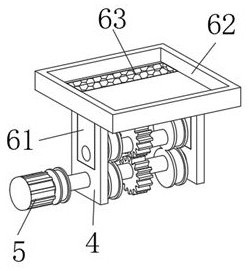

[0037] On the basis of Example 2, such as Figure 7-8 As shown, a low-power miniaturized intelligent processing device for food waste includes a base 1, and a filter box 2 and a crushing box 3 are fixedly installed on the upper left part and the upper right part of the base 1 respectively. A fixed plate 4 is fixedly welded on the upper part of the front and rear box walls, and a drive mechanism 5 is movably connected to the lower part of the two fixed plates 4, and a lifting mechanism 6 is slidingly connected to the upper part of the fixed plate 4, and the lifting mechanism 6 and the driving mechanism 5 Transmission connection, crushing box 3 is interspersed with a crushing mechanism 7, crushing mechanism 7 and driving mechanism 5 are jointly connected with a conveyor belt 8, the left end of the filter box 2 is fixedly welded with a push rod 10, and the crushing box 3 is interspersed and connected with a A material guide plate 11, the upper end of the lifting mechanism 6 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com