Patents

Literature

35results about How to "Reduce the solidification rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

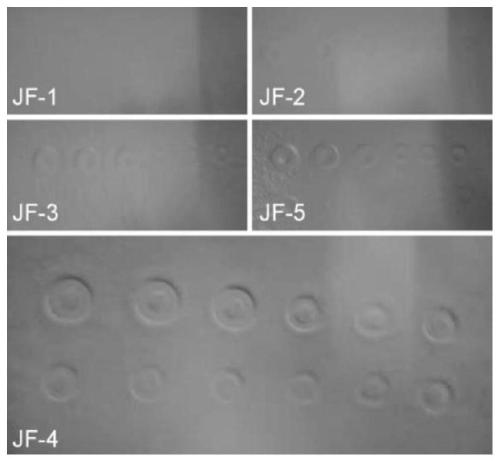

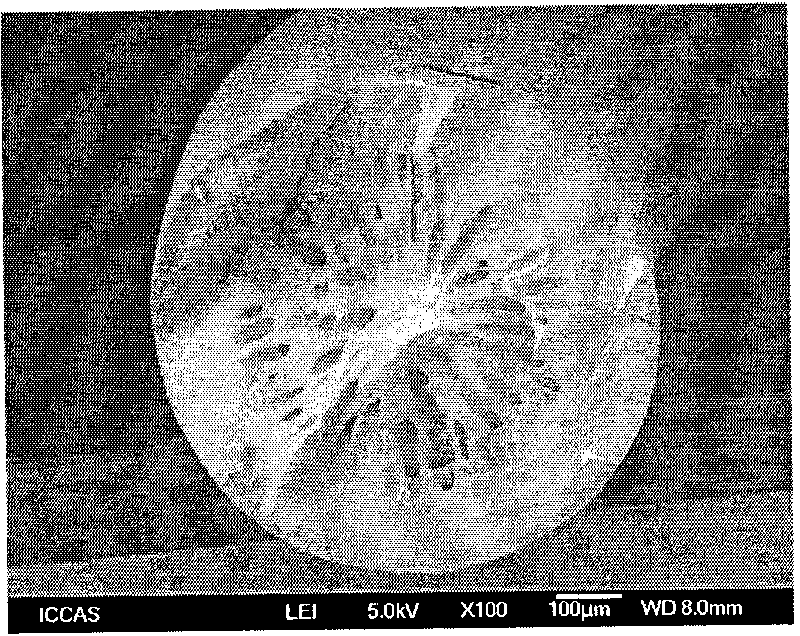

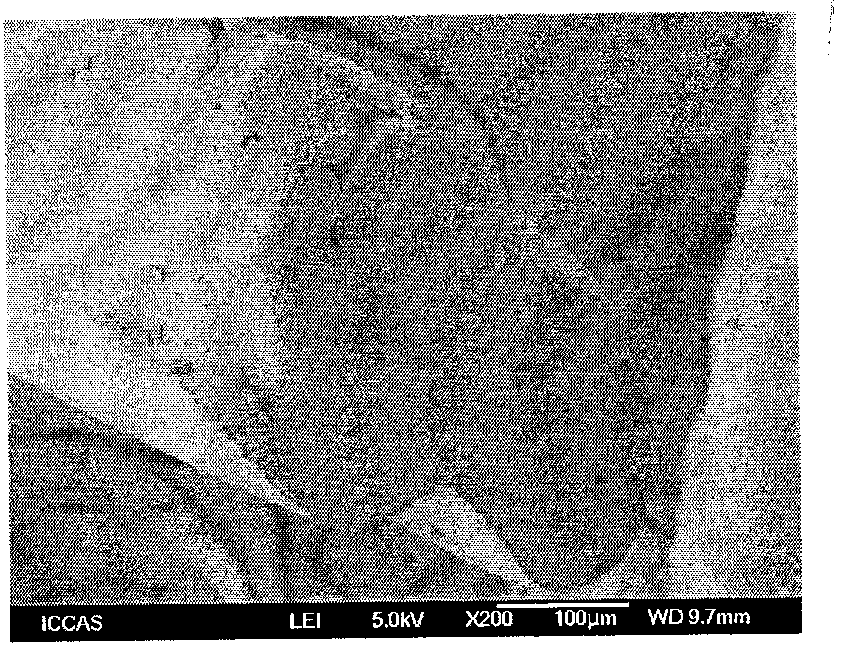

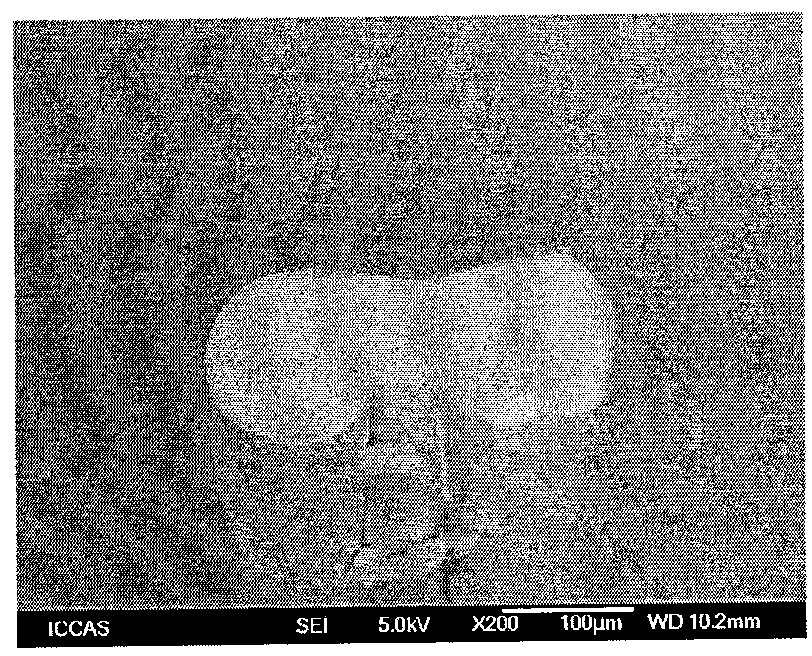

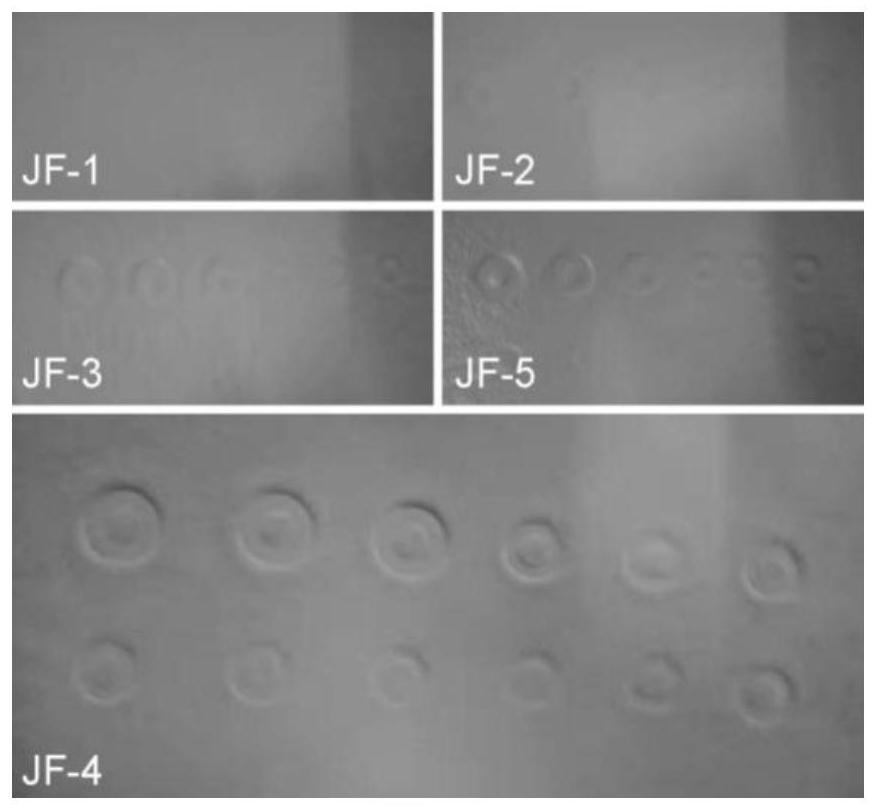

Medical Mg-Gd-Zn (-Ca) magnesium alloy with LPSO structure and preparation method thereof

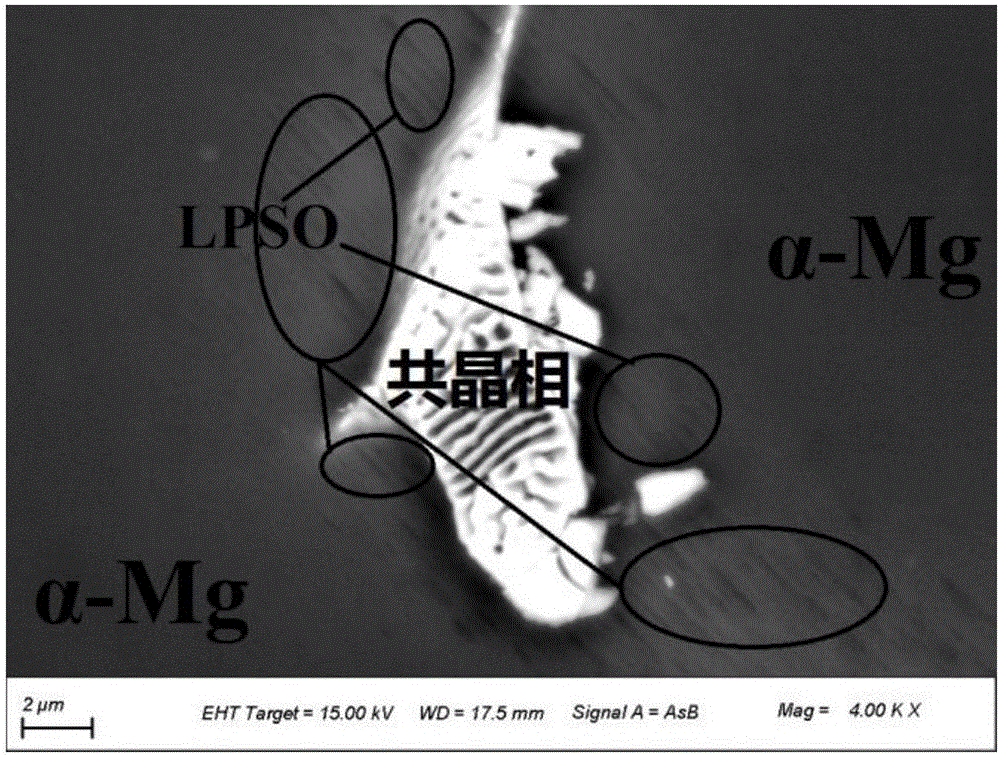

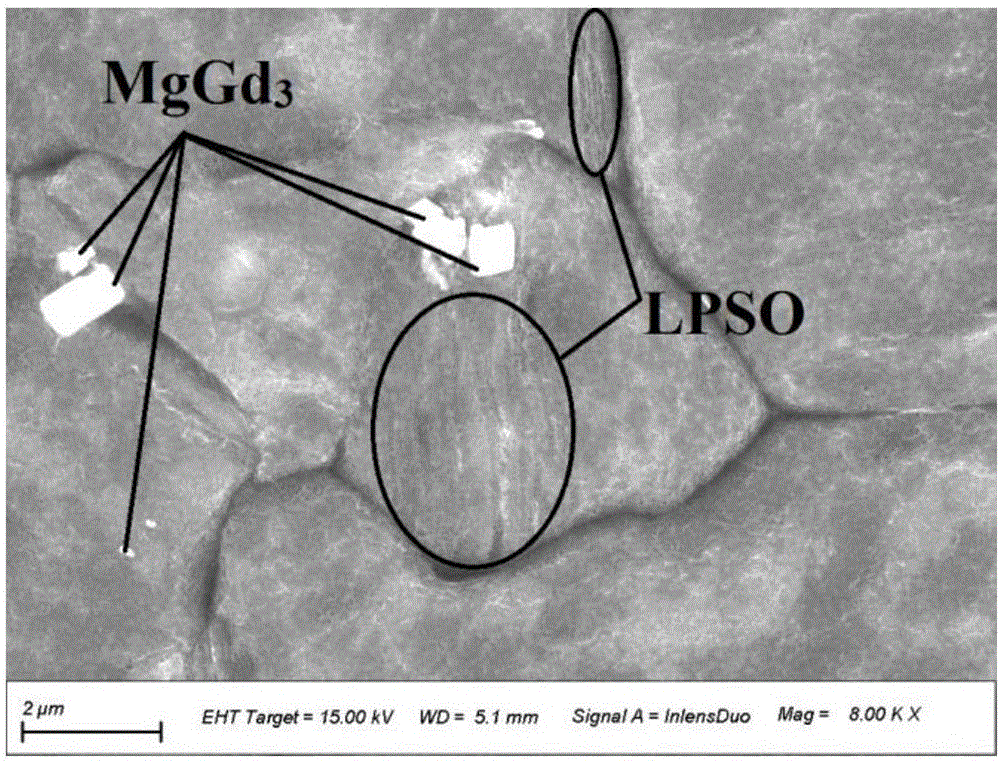

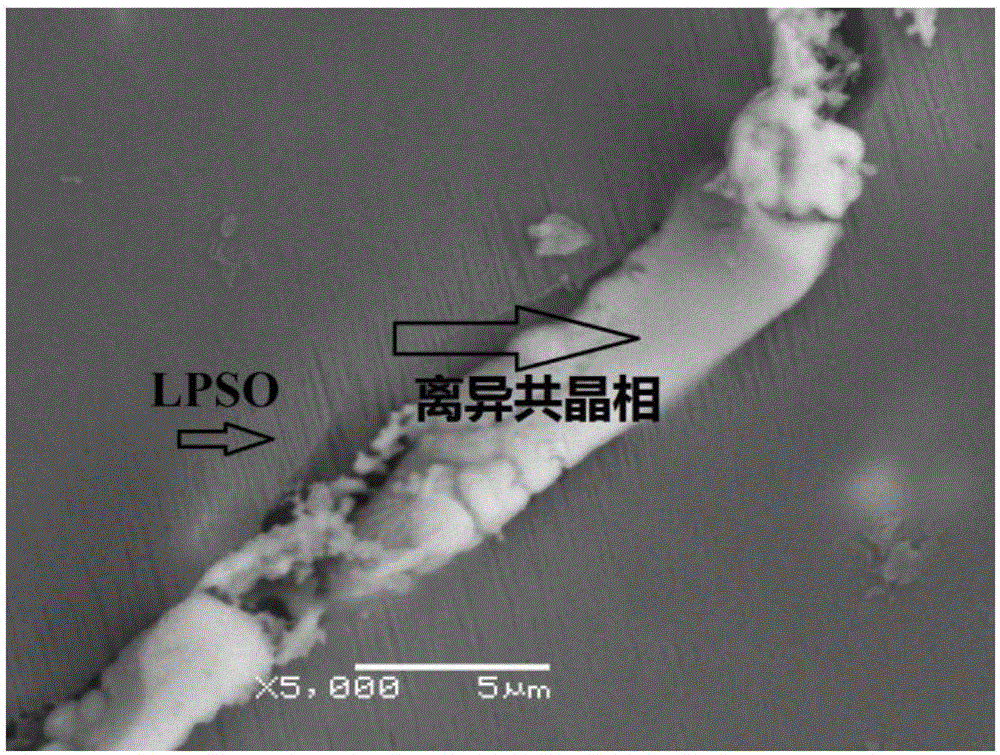

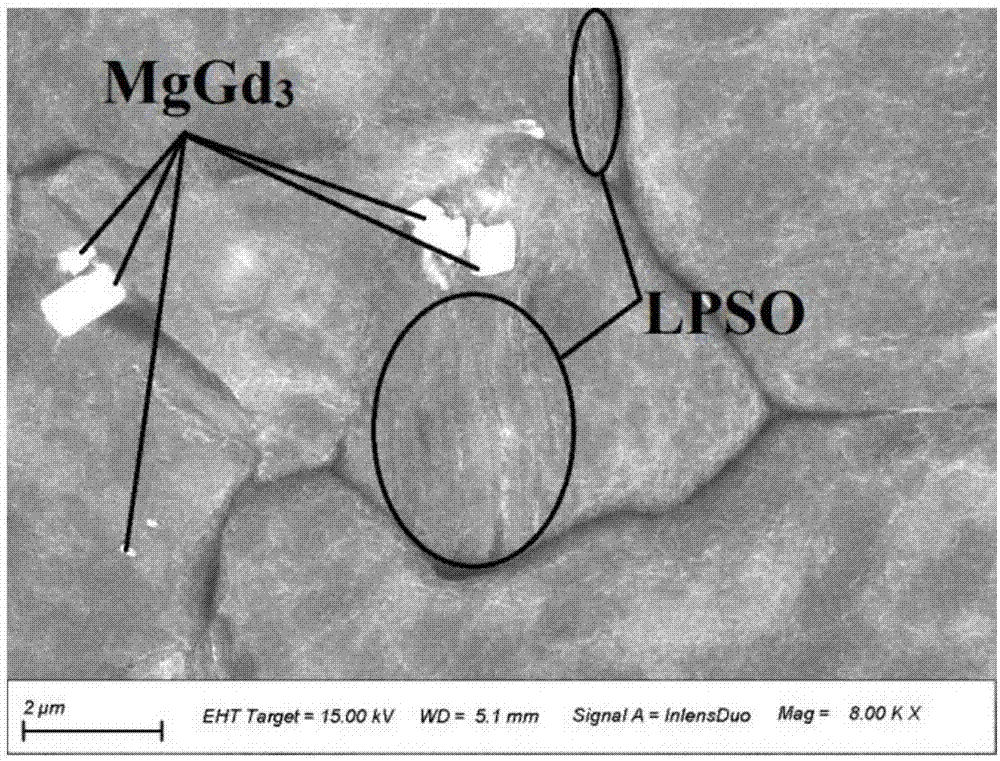

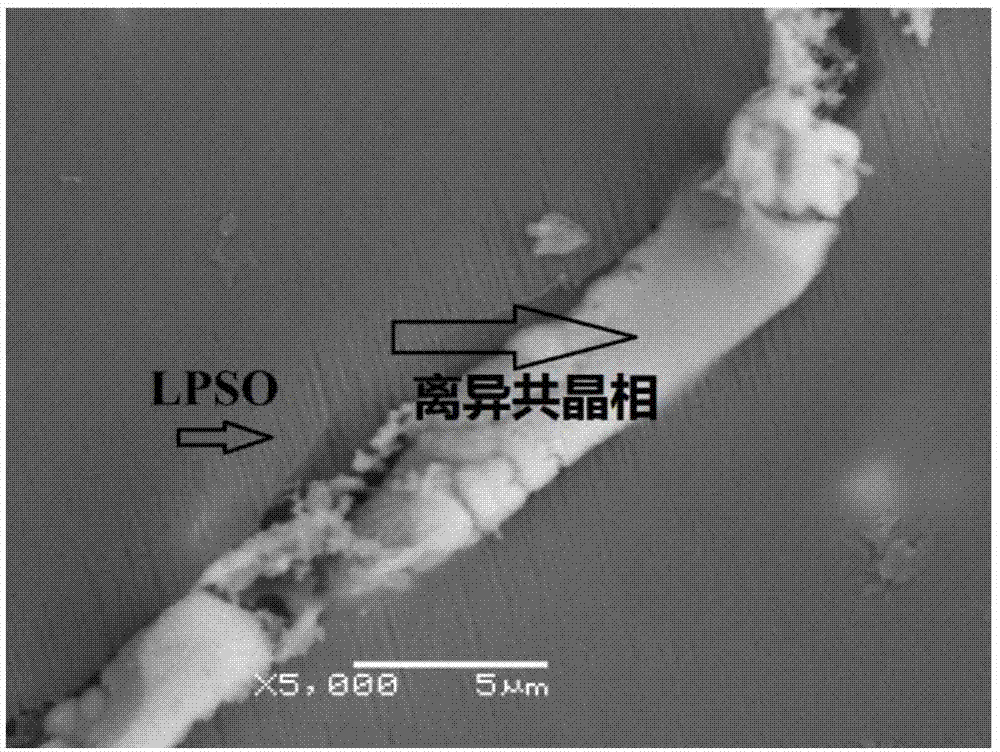

The invention relates to a medical Mg-Gd-Zn (-Ca) magnesium alloy with an LPSO structure and a preparation method of the medical Mg-Gd-Zn (-Ca) magnesium alloy with the LPSO structure and belongs to the field of medical magnesium alloy preparation. The medical Mg-Gd-Zn (-Ca) magnesium alloy with the LPSO structure comprises, by mass, 1.0%-3.5% of Gd, 0.3%-1.2% of Zn and 0-1.0% of Ca. The preparation method of the medical Mg-Gd-Zn (-Ca) magnesium alloy with the LPSO structure comprises the steps that raw materials which are in an appropriate ratio are placed in a crucible containing mixed protective gases of CO2 and SF6 in sequence for melting, stirring, standing and casting, wherein during casting, the solidification rate is controlled; and a cast ingot is placed in a resistance furnace with a protective atmosphere for heat treatment, and then rod materials are formed through extrusion. The medical Mg-Gd-Zn (-Ca) magnesium alloy with the LPSO structure has the advantages that the contents of the Gd element and the Zn element are low, the biological safety is high, the cost is low, and the technology is simple. Cast alloy tissue and extrusion alloy tissue both have the LPSO structure. Besides, after Ca is added, a divorced eutectic (Mg, Zn, Ca) 3Gd phase is formed in the cast alloy and is beneficial for the abrasion resistance performance of the alloy, the microstructure is adjustable, and the corrosion resistance of a material can be effectively improved. The medical Mg-Gd-Zn (-Ca) magnesium alloy with the LPSO structure has broad application prospect in the biomedical fields of orthopedics and cardiovascular stent implantation.

Owner:NANJING INST OF TECH

High-strength and high-temperature alloy for thermal power generating unit and processing technology of high-strength and high-temperature alloy

ActiveCN111394638AHigh Fe contentLimit raw material costsFurnace typesHeat treatment furnacesElectric arc furnaceSuperalloy

The invention provides a high-strength and high-temperature alloy for a thermal power generating unit and a processing technology of the high-strength and high-temperature alloy. The high-strength andhigh-temperature alloy is prepared from the components in percentage by mass: 0.05-0.08% of C, 14-17% of Cr, less than or equal to 0.5% of Mn, less than or equal to 0.5% of Si, 1.0-2.5% of W, 0.3-2.0% of Mo, 2.0-2.5% of Ti, 1.0-1.5% of Al, less than or equal to 0.003% of B, less than or equal to 0.03% of Zr, 37-48% of Fe, and the balance of Ni. The processing technology comprises the steps that an electric-arc furnace is adopted at the vacuum degree not exceeding 0.5Pa to smelt pre-matched alloy furnace charge; the alloy is subjected to cogging forging with the deformation amount reaching 70%within the temperature range of 200-250 DEG C above Ni3Al (gamma') precipitation temperature; and high-temperature rolling with the deformation amount reaching 80% above the precipitation temperatureof 150-200 DEG C. The alloy has excellent high-temperature mechanical properties above 650 DEG C.

Owner:HUANENG POWER INT INC +1

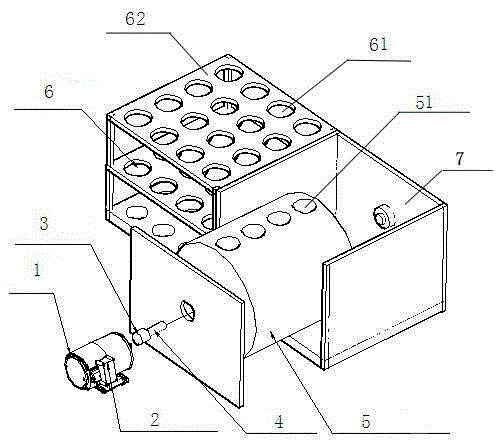

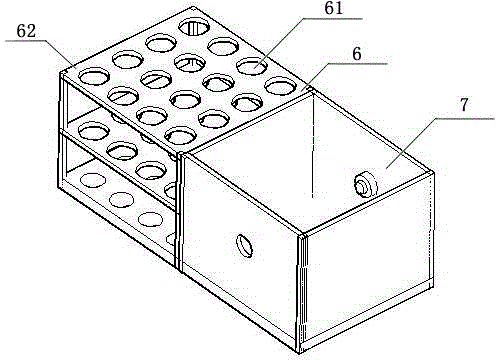

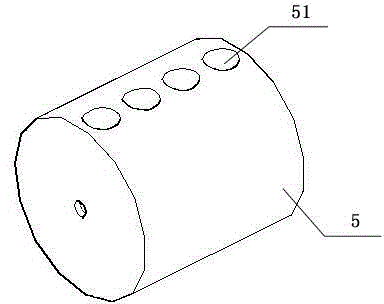

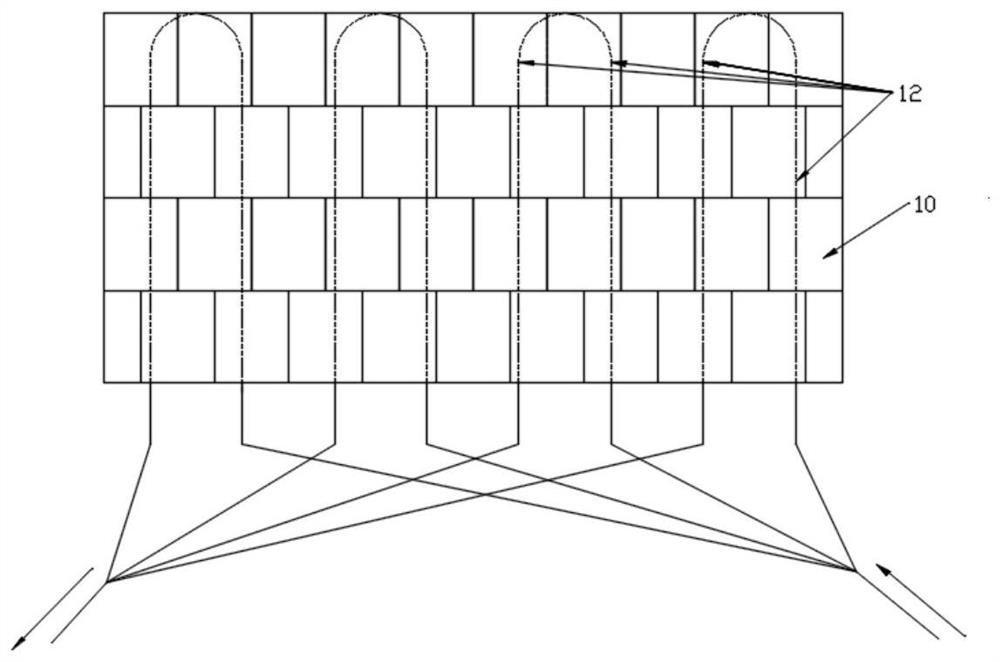

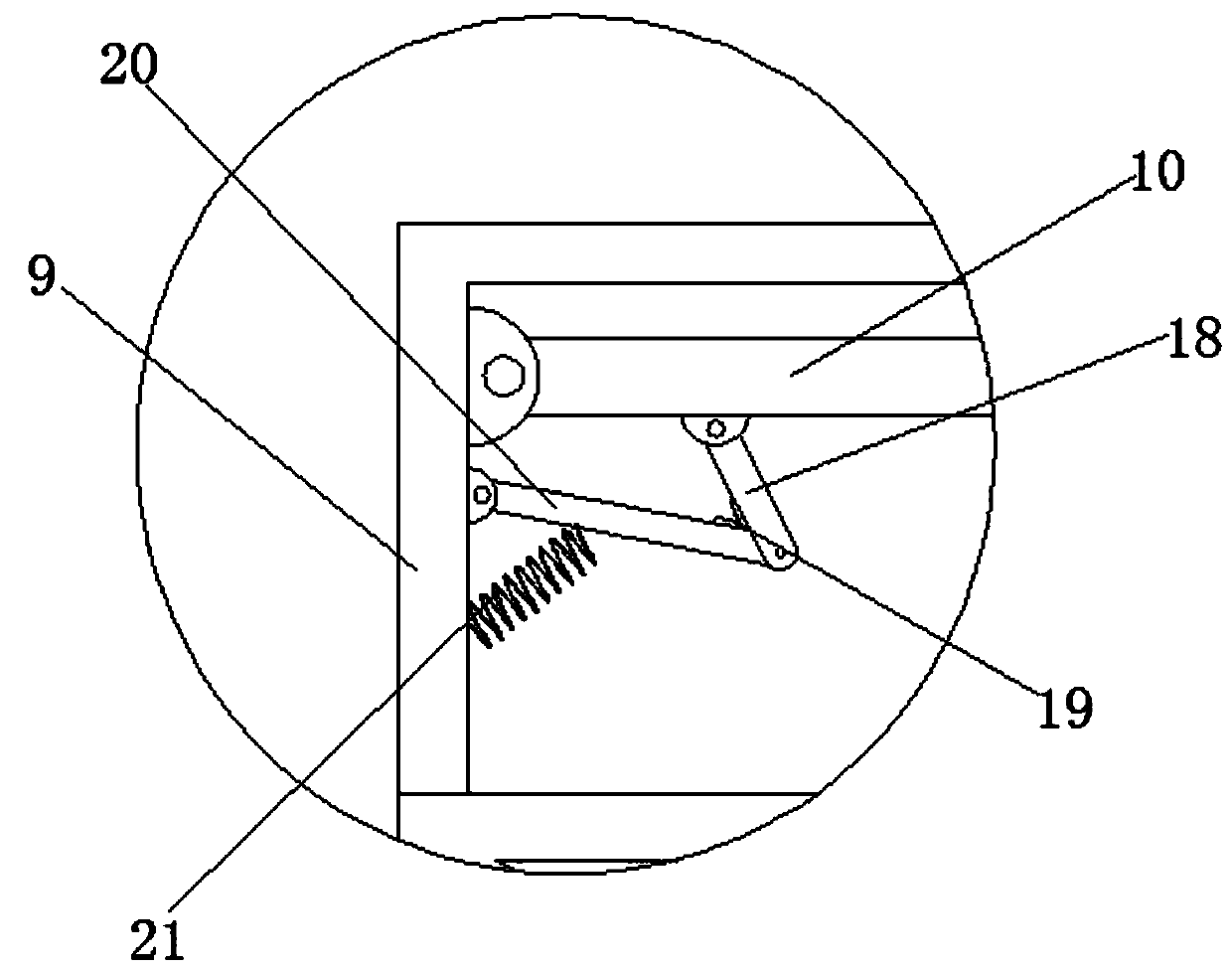

Vibration type test tube shaking device

InactiveCN104857881AReduce the solidification rateAchieve the purpose of shakingShaking/oscillating/vibrating mixersBlood specimenDrive shaft

The invention discloses a vibration type test tube shaking device which comprises a test tube rack, wherein a chamber is arranged at the side part of the test tube rack in an extending manner. The vibration type test tube shaking device is characterized in that a test tube rolling box is arranged inside the chamber; one end of the test tube rolling box is connected with the inner wall of the chamber; the other end of the test tube rolling box is connected with a motor through a fixing device. The motor is rotated to drive a coupling and a transmission shaft to make regular reciprocation movement leftwards and rightwards under the control of a PLC, so that the test tube rolling box can make regular shaking movement for limited times leftwards and rightwards, and the purpose of uniformly shaking test tubes can be achieved. The vibration type test tube shaking device is small and exquisite, and nursing operators can carry the device conveniently. Specimen without anticoagulant can be put on the test tube rack on the left side, blood specimen uniformly vibrated and shaken can be also put on the test tube rack on the left side, and as a heat supply rotation device is arranged on the test tube rack, the blood cannot be invalid within a relatively long time.

Owner:THE AFFILIATED SIR RUN RUN SHAW HOSPITAL OF SCHOOL OF MEDICINE ZHEJIANG UNIV

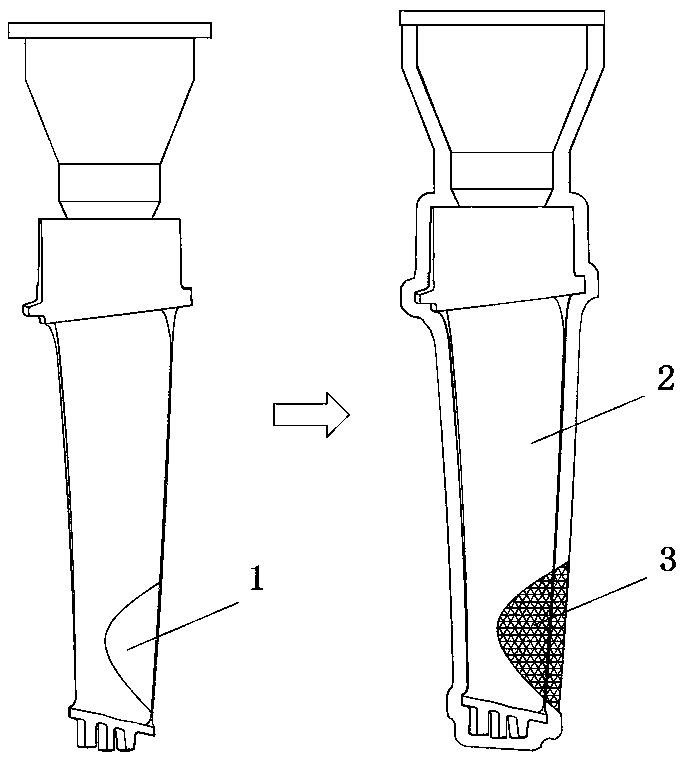

Method capable of rapidly solving problem of gas turbine blade casting deformation

InactiveCN107755636AImprove deformationReduce the solidification rateFoundry mouldsFoundry coresWaxDimensional modeling

The invention discloses a method capable of rapidly solving the problem of gas turbine blade casting deformation. The method is characterized by comprising the following steps: (1) designing a gas turbine blade pouring system by utilizing three-dimensional modeling software, guiding into finite element software, simulating the temperature distribution of the gas turbine blade pouring system, accurately positioning an area, which is cooled and solidified earlier than the periphery, of the gas turbine blade; (2) taking a wax mold module corresponding to the gas turbine blade, coating the surfaceof the wax mold module with coating, and sequentially performing dewaxing, roasting and cooling treatment to obtain a mold shell; (3) wrapping the mold shell, corresponding to the area, which is cooled and solidified earlier than the periphery, of the gas turbine blade with ceramic heat-insulating cotton with certain thickness; and (4) roasting the wrapped mold shell, taking out the roasted moldshell and pouring. By the method, the deformation area of the gas turbine blade is accurately positioned, the qualification rate of the gas turbine blade casting is increased, operation is facilitated, and the method is an effective method capable of solve the problem of deformation generated by shrinkage stress of the gas turbine blade.

Owner:DONGFANG TURBINE CO LTD

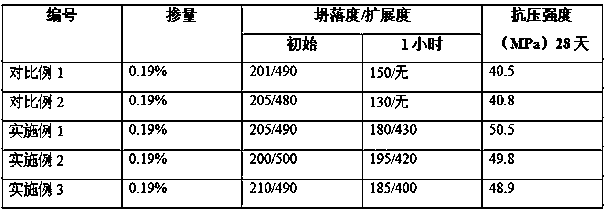

Polycarboxylate water reduction agent having high heat stability modification and preparation method of polycarboxylate water reduction agent

The invention discloses a polycarboxylate water reduction agent having high heat stability modification and a preparation method of the polycarboxylate water reduction agent. The raw materials of thepolycarboxylate water reduction agent mainly comprise methylpropenoic acid, unsaturated polyether, aqueous polyurethane emulsion, hexafluorobutyl methacrylate, polymer colloid of which the concentration is 10-15%, and sodium dodecyl sulfate. According to the polycarboxylate water reduction agent and the preparation method thereof disclosed by the invention, the hexafluorobutyl methacrylate is usedfor performing lyophobic modification treatment on aqueous polyurethane, and is combined with polymer colloid forming sol state to be self-assembled on the surfaces of molecule chains of polycarboxylate, and membrane layers having high dispersion and high heat resistance are formed, can enable cement to have long-time dispersion maintaining capacity, can retard concrete solidification rate of theconcrete in the transportation course, and is high in heat stability, long in action time, environmentally friendly, nonhazardous, convenient to store and transport, extensive in raw material sourcesand suitable for industrial production.

Owner:山西康力建材有限公司

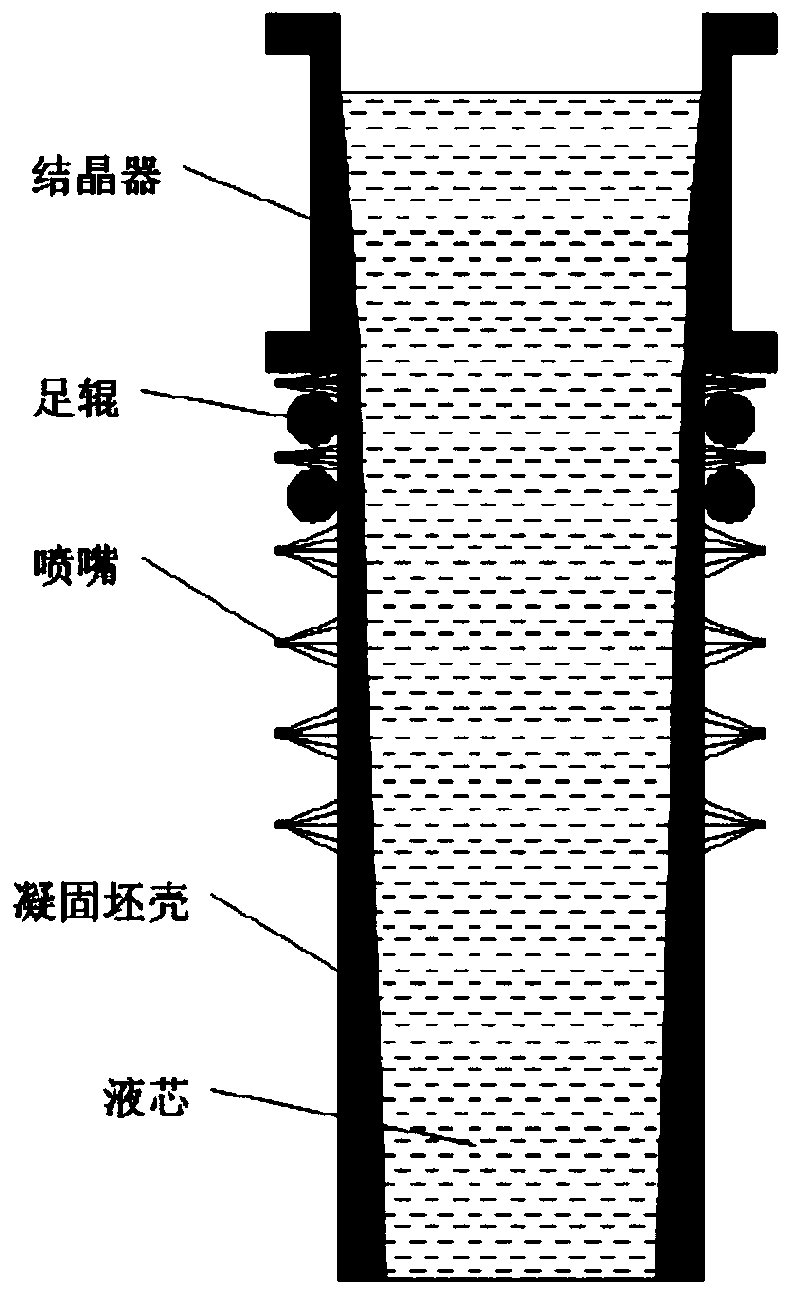

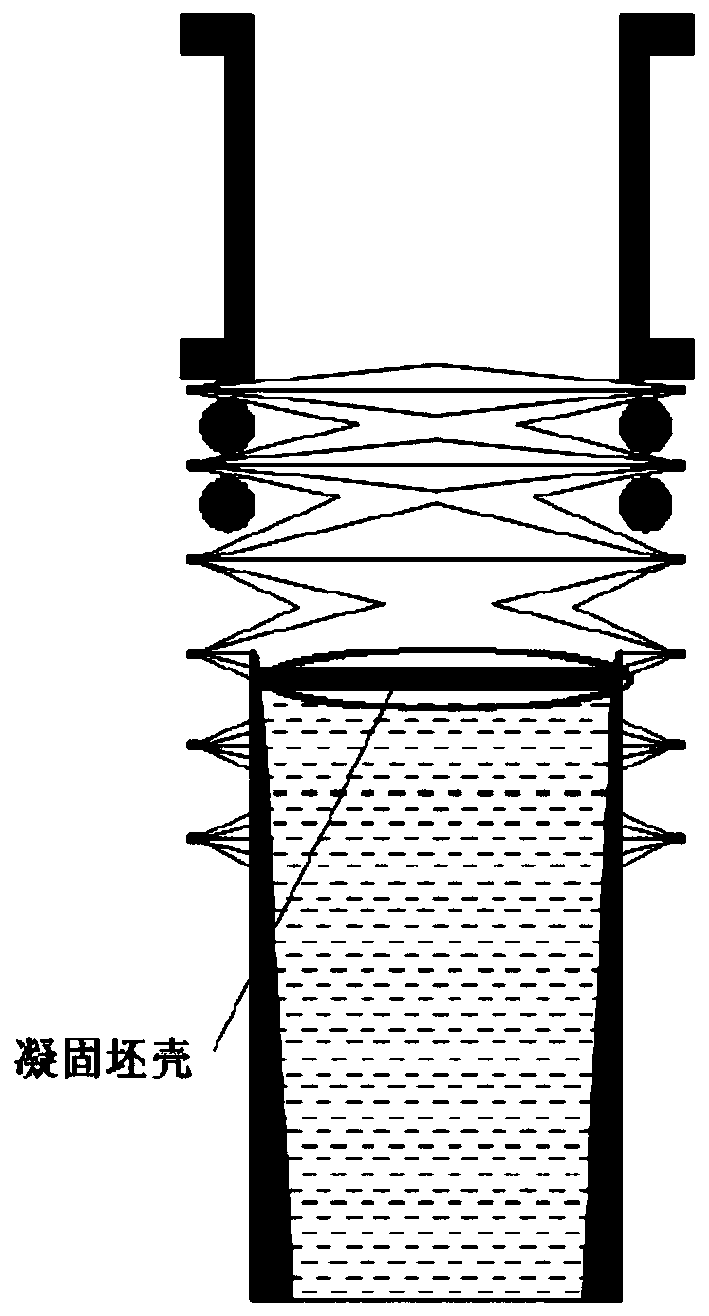

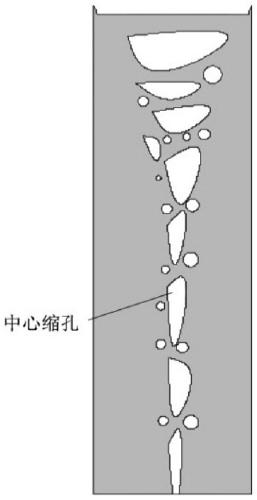

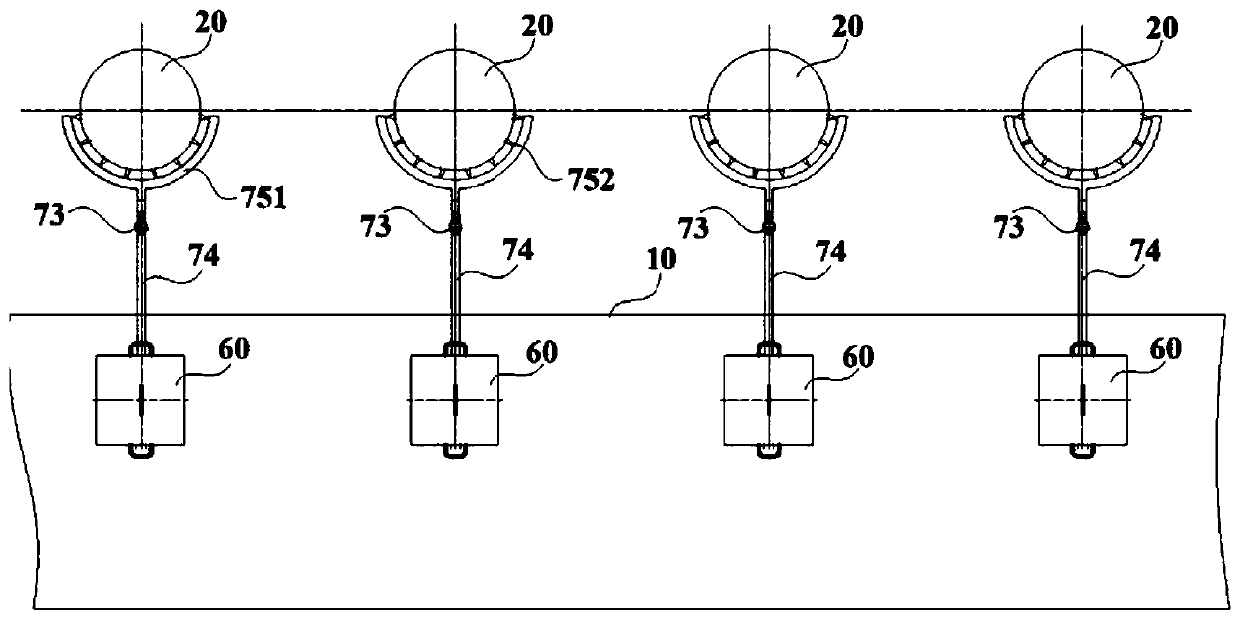

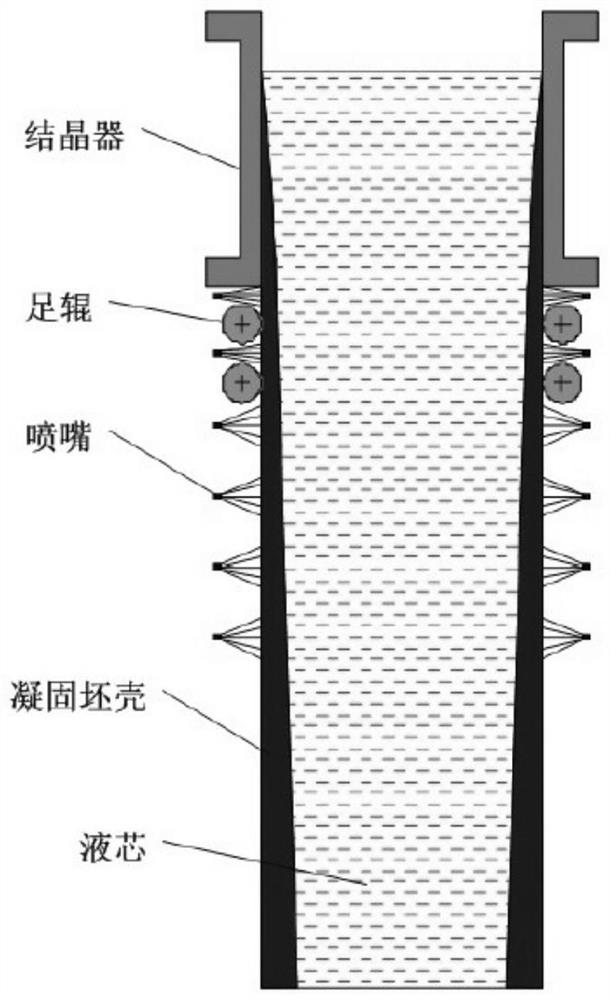

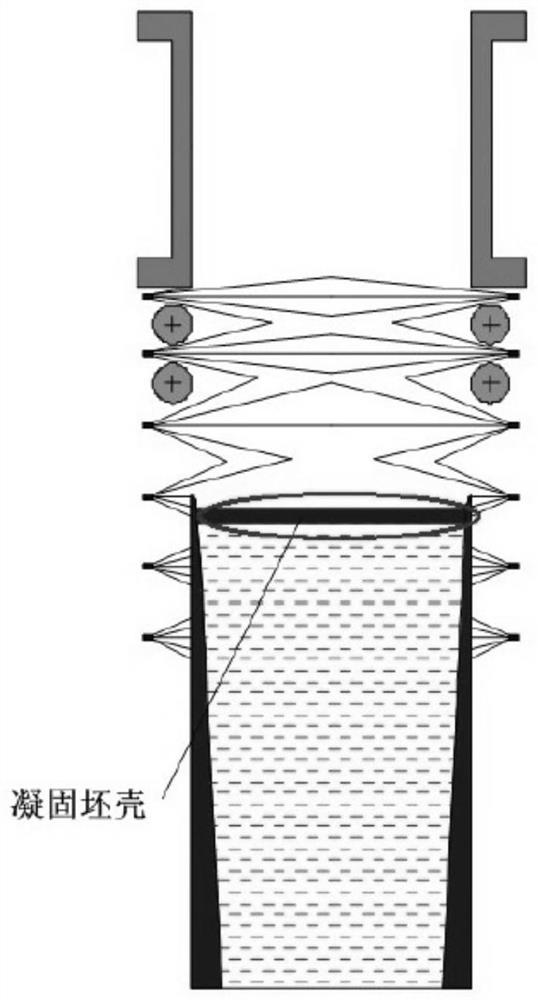

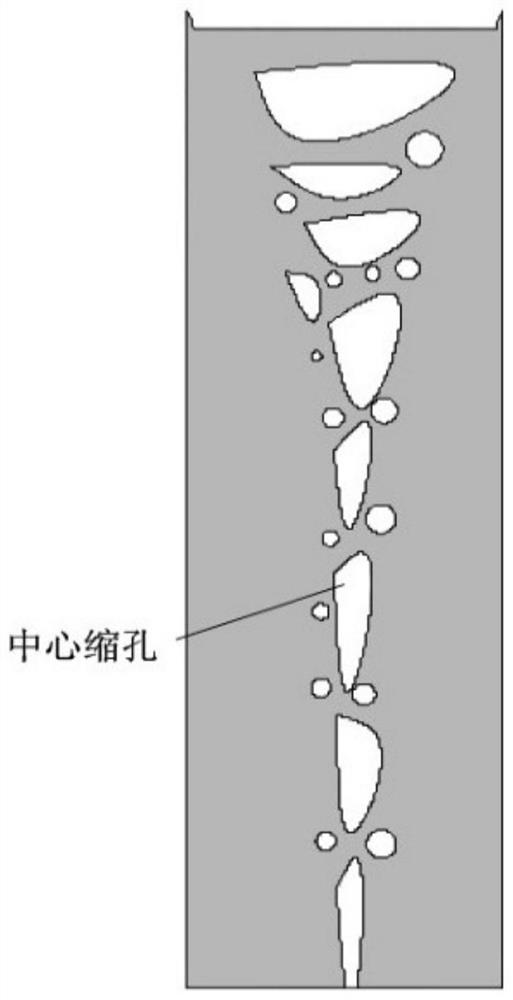

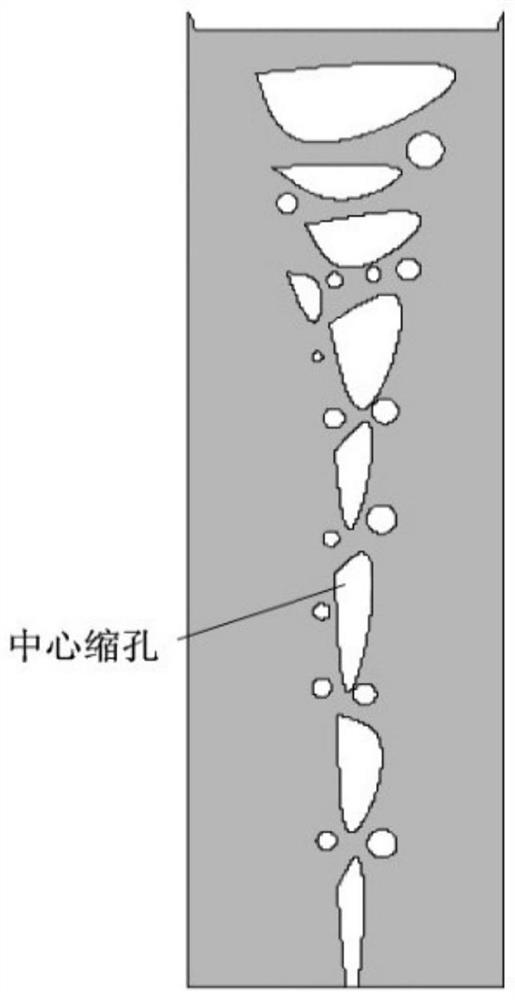

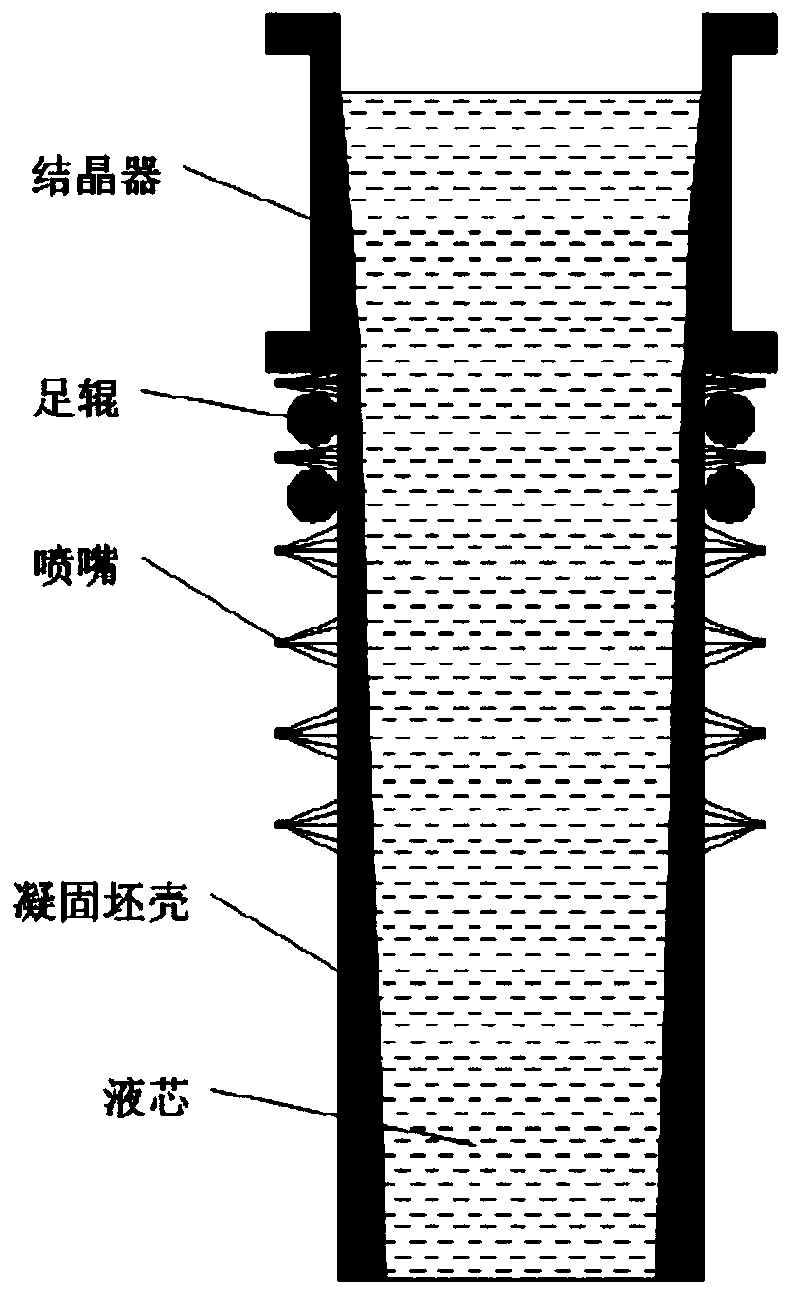

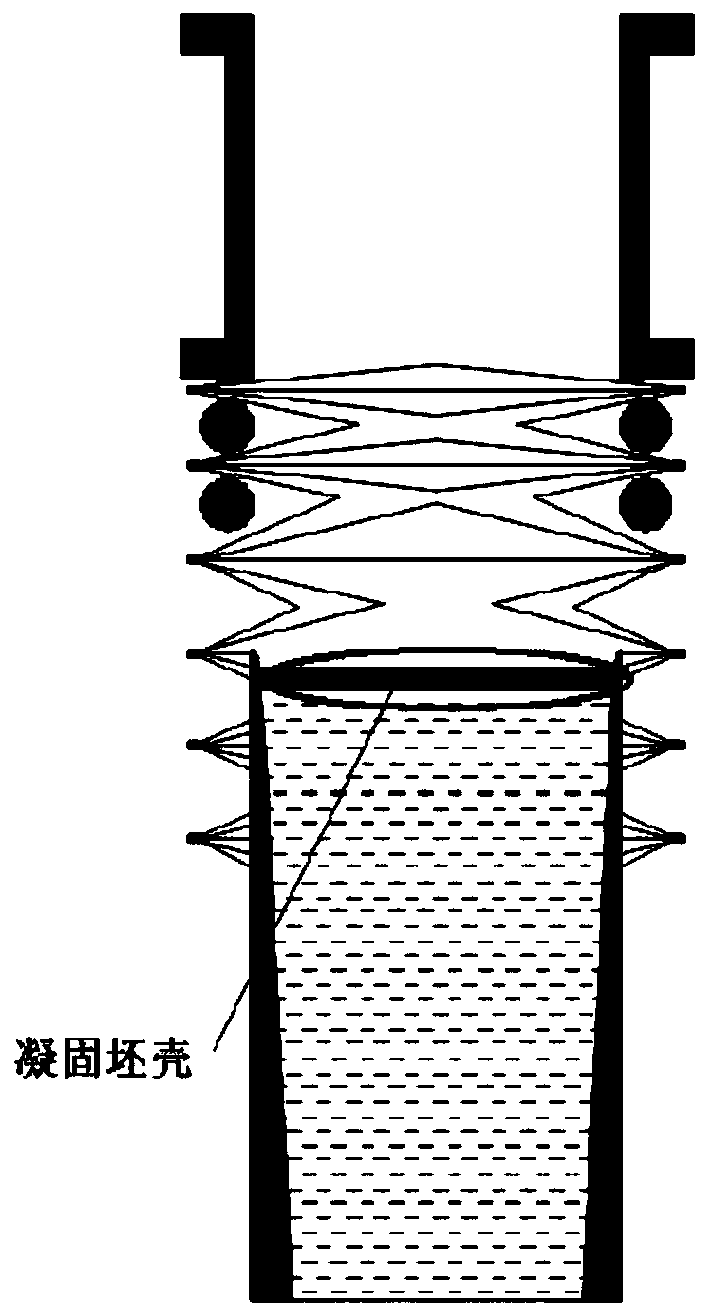

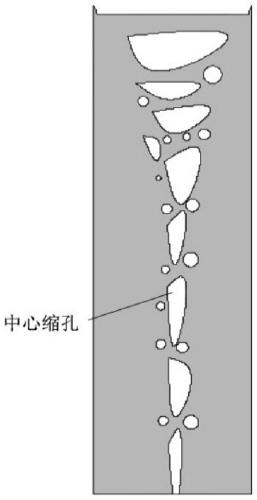

Process method for improving quality and yield of continuous casting tail billet

The invention discloses a process method for improving the quality and yield of continuous casting tail billet, and belongs to the technical field of metallurgical continuous casting. The process method includes the steps that when the tail billet is obtained after continuous casting, a special metallurgical heating agent is evenly sprinkled into a mold liquid level, and when the tail billet is about to be pulled out of a mold, the secondary cooling water is closed sequentially from top to bottom. The metallurgical heating agent can be in chemical reaction with liquid steel of the tail billet,heat is continuously released, and in the absence of the cooling effect of the secondary cooling water, the top of the tail billet remains in a high temperature liquid state, so that the solidification time of the tail billet is prolonged, the volume shrinkage of a liquid core is supplemented by metal iron generated by exothermic reaction and iron of the heating agent, and the purposes of improving the solidification structure quality of the tail billet and the yield rate of the molten steel of the tail billet are achieved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

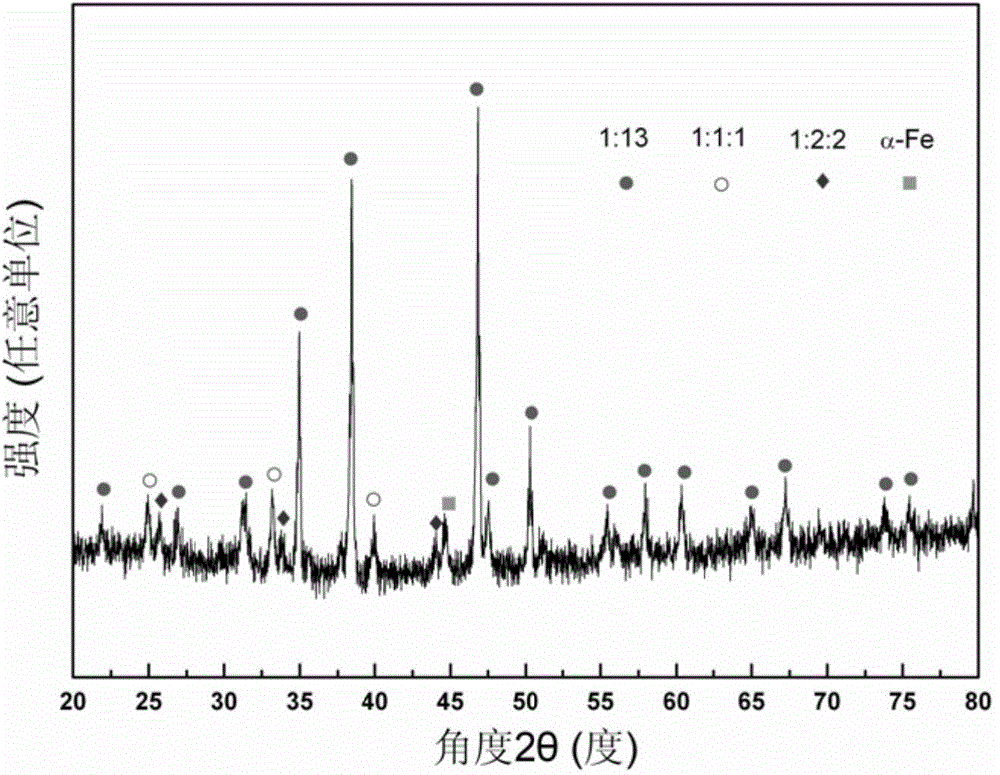

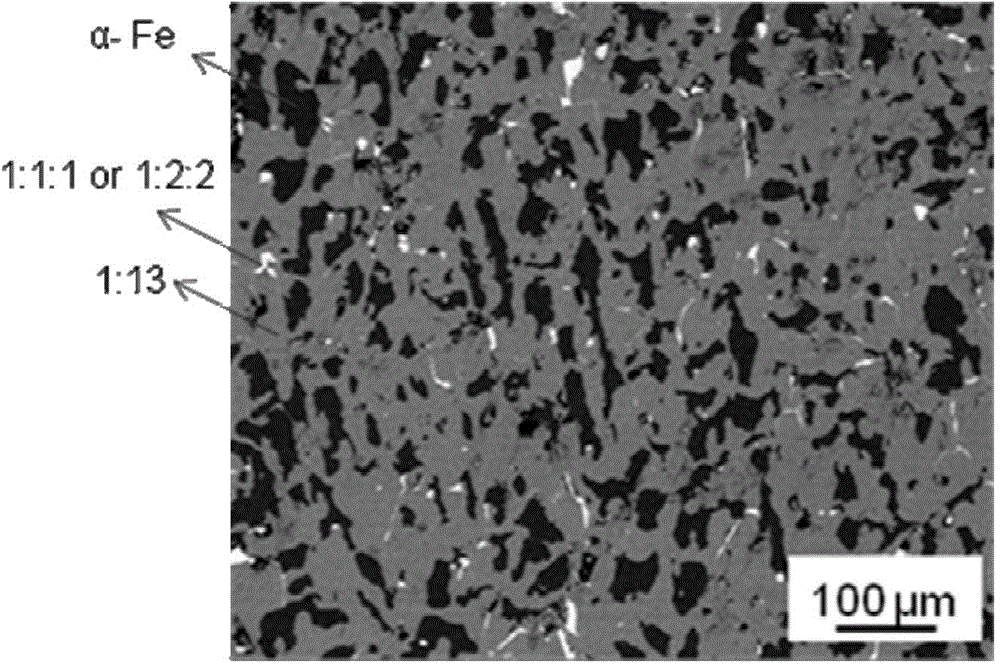

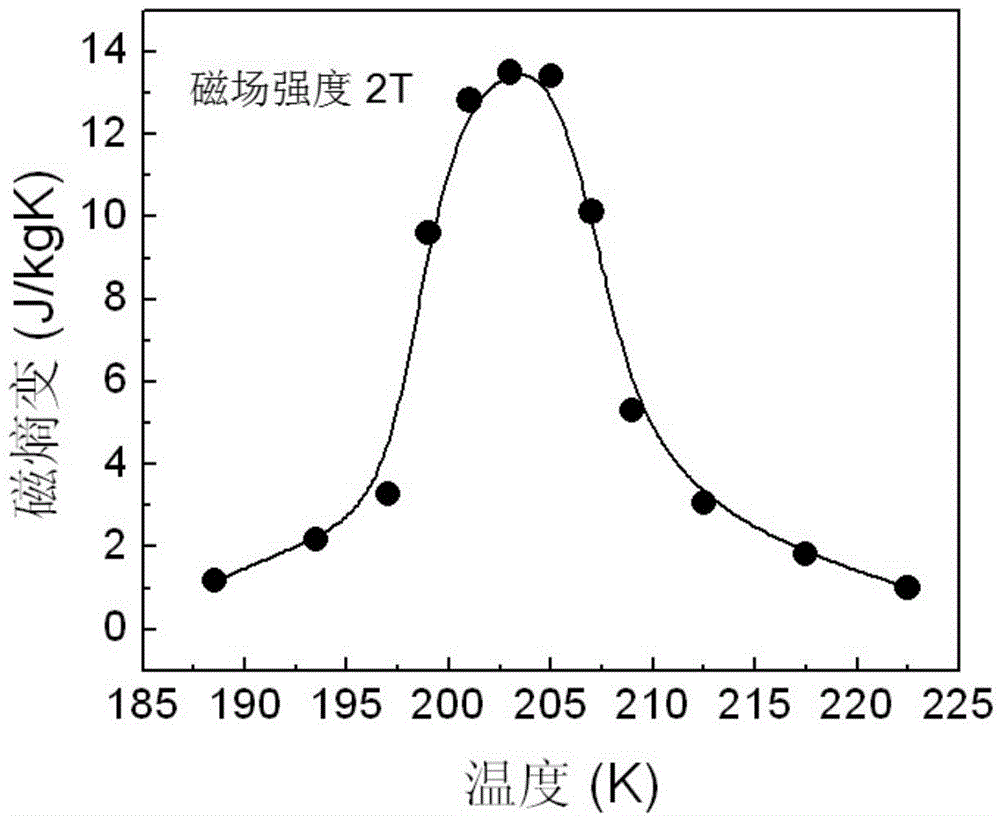

Preparation method for rare earth ferrous alloy compound with NaZn13 type structure

The invention provides a preparation method for a rare earth ferrous alloy compound with a NaZn13 type structure. The method comprises: using high frequency induction to heat a rare earth ferrous alloy ingot, to make the rare earth ferrous alloy ingot induced and molten to a rare earth ferrous alloy melt, the rare earth ferrous alloy melt entering a cooling medium for slow directional solidification, to prolong the stay duration in the temperature interval of the peritectic reaction thereof, so that [alpha]-Fe and liquid phase which is rich in rare earth phase are fully reacted, and a magnetic-thermo functional phase with the NaZn13 type structure is directly formed in one step, showing a good magnetic refrigeration characteristic. The method greatly simplifies a preparation process, and is advantaged by short production process, high effect, and energy conservation, and the method has good application prospect in the field of magnetic refrigeration materials.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

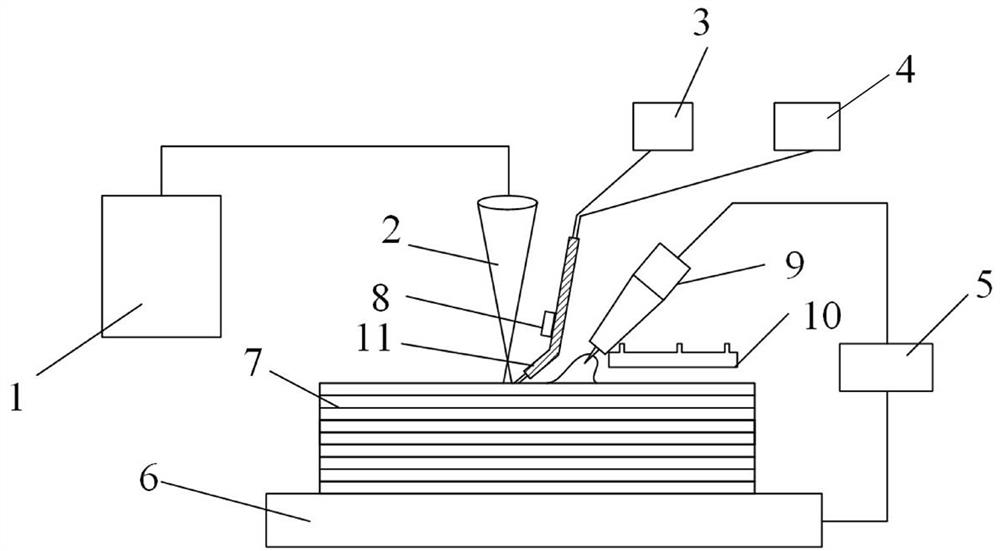

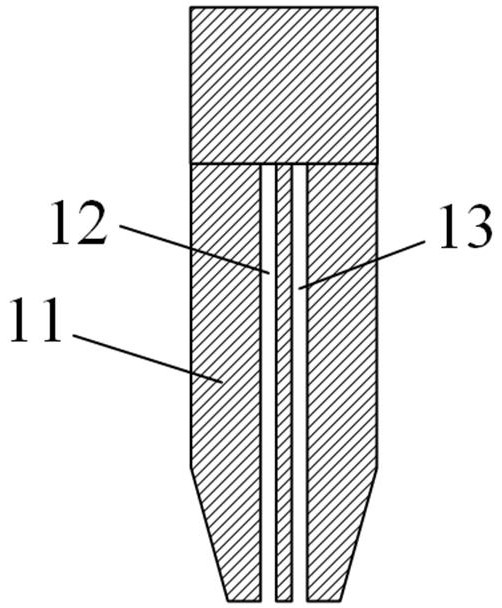

Substrate-wire cooperative preheating device for arc additive manufacturing and method thereof

InactiveCN111730172AAchieving synergistic heatingGood macroscopic appearanceAdditive manufacturing apparatusWelding accessoriesMaterials scienceResistance wire

The invention belongs to the field of additive manufacturing, and particularly relates to a substrate-wire cooperative preheating device for arc additive manufacturing and a method thereof. The substrate-wire cooperative preheating device comprises a ceramic sheet heater, a thermocouple temperature sensor, high-heat resistance wires, spiral resistance wires, an infrared temperature sensor and a preheating controller, wherein the ceramic sheet heater is arranged below a substrate; the thermocouple temperature sensor is arranged on one side of the substrate; the high-heat resistance wires are laid in the ceramic sheet heater; the spiral resistance wires are arranged at the periphery of a wire; and the infrared temperature sensor is used for measuring the temperature of the wire heated by thespiral resistance wires. According to the substrate-wire cooperative preheating device for arc additive manufacturing and the method thereof, the substrate is preheated, the macroscopic morphology ofthe first layer of an additive is improved, the metallurgical combination of deposited metal and base metal of the substrate is enhanced, and the solidification rate of molten metal is reduced, so that the escaping of gas in a molten pool is facilitated; and in addition, preheating is synchronously carried out in the wire feeding process of the wire, so that under the condition that a current ofa welding machine is not increased, the metal deposition amount is increased, the oxidation is reduced, and the uniformity of a microstructure is improved.

Owner:NANJING UNIV OF SCI & TECH

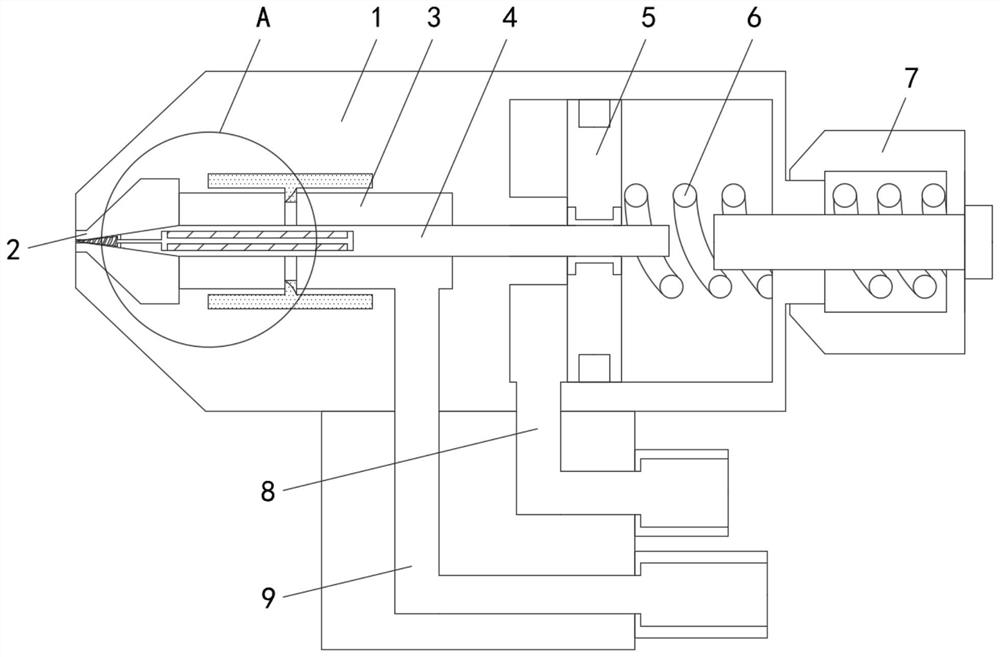

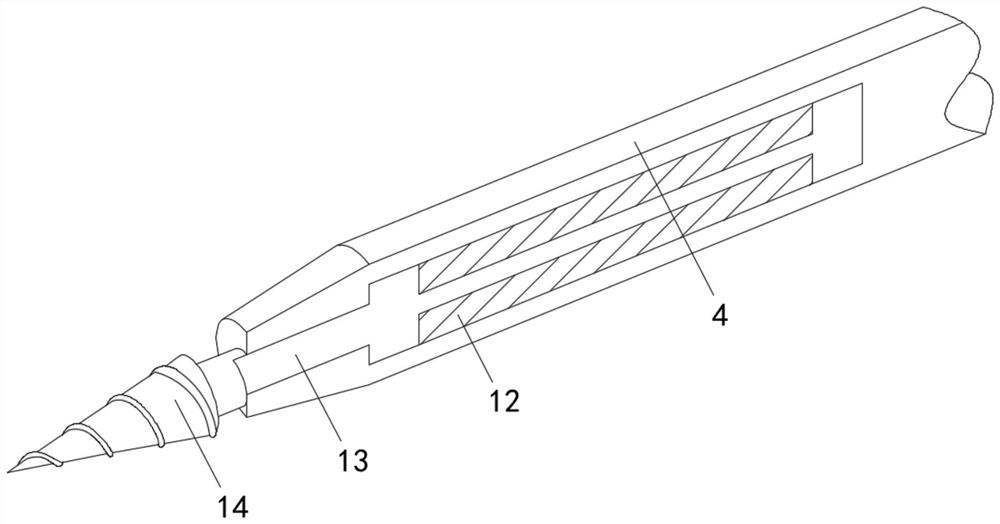

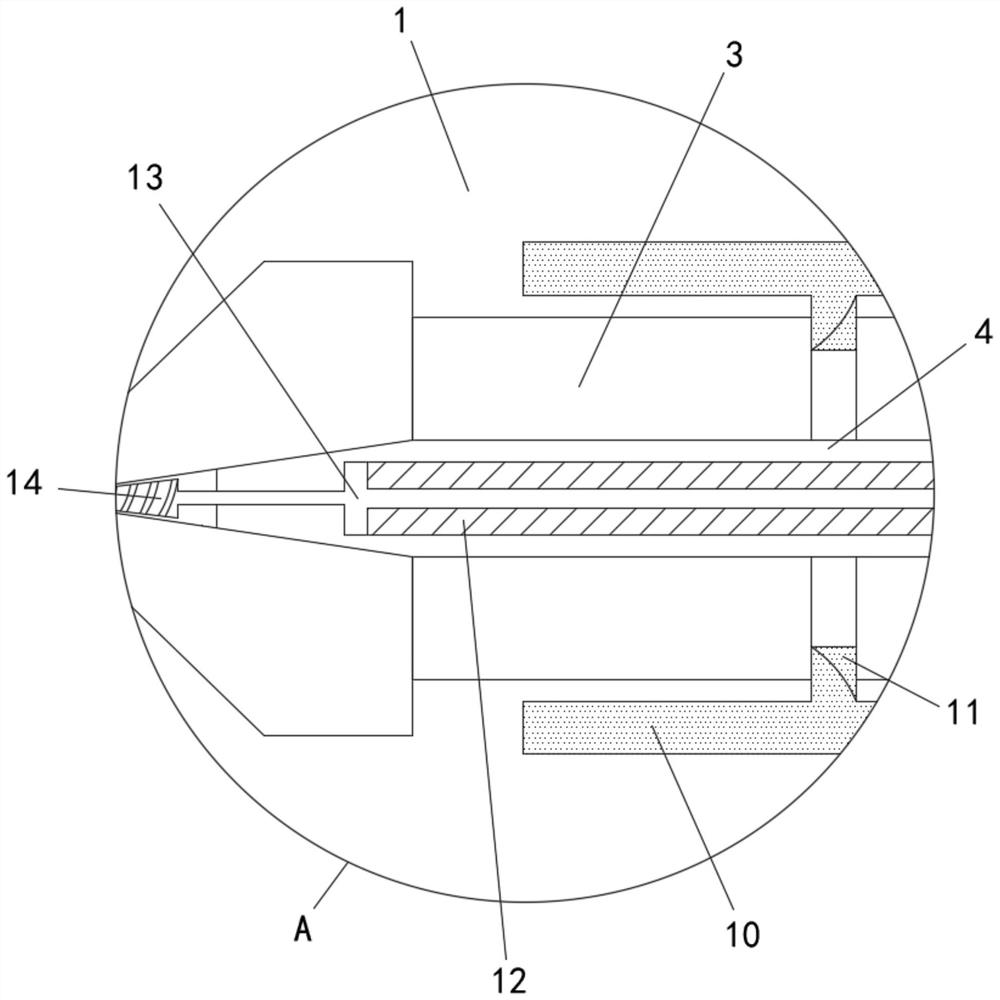

Mechanical-electrical integrated paint spraying equipment for automobile parts

InactiveCN112619920AReduce the solidification rateAvoid situations of increased resistanceLiquid spraying apparatusSuction forceEngineering

The invention relates to the technical field of machining, and discloses mechanical-electrical integrated paint spraying equipment for automobile parts. The mechanical-electrical integrated paint spraying equipment comprises a gun body, a nozzle is arranged at the left end of the gun body, a spraying cavity is formed in the middle of an inner cavity in the left side of the gun body, a needle rod is movably connected to the middle of the inner cavity of the gun body in a sleeving mode, and a piston plate is movably connected to the middle of an inner cavity in the right side of the gun body in a sleeving mode. By arranging a heating anti-condensation mechanism, when paint flows into the spraying cavity from a paint spraying pipe and is sprayed outwards through the nozzle, a driving plate is impacted, the driving plate drives a rotary drum to vertically rotate, and the rotary drum made of a magnetic material overcomes the magnetic attraction force or magnetic repulsion force of magnetic blocks to do work and does friction work with the gun body, so that heat is generated, the temperature in the spraying cavity is gradually increased, the solidification rate of the paint remained in the spraying cavity is reduced under the action of a certain temperature, and the situation that the resistance is increased when the needle rod opens and closes the spraying gun due to the fact that the paint is dried in the spraying cavity is avoided.

Owner:刘伟

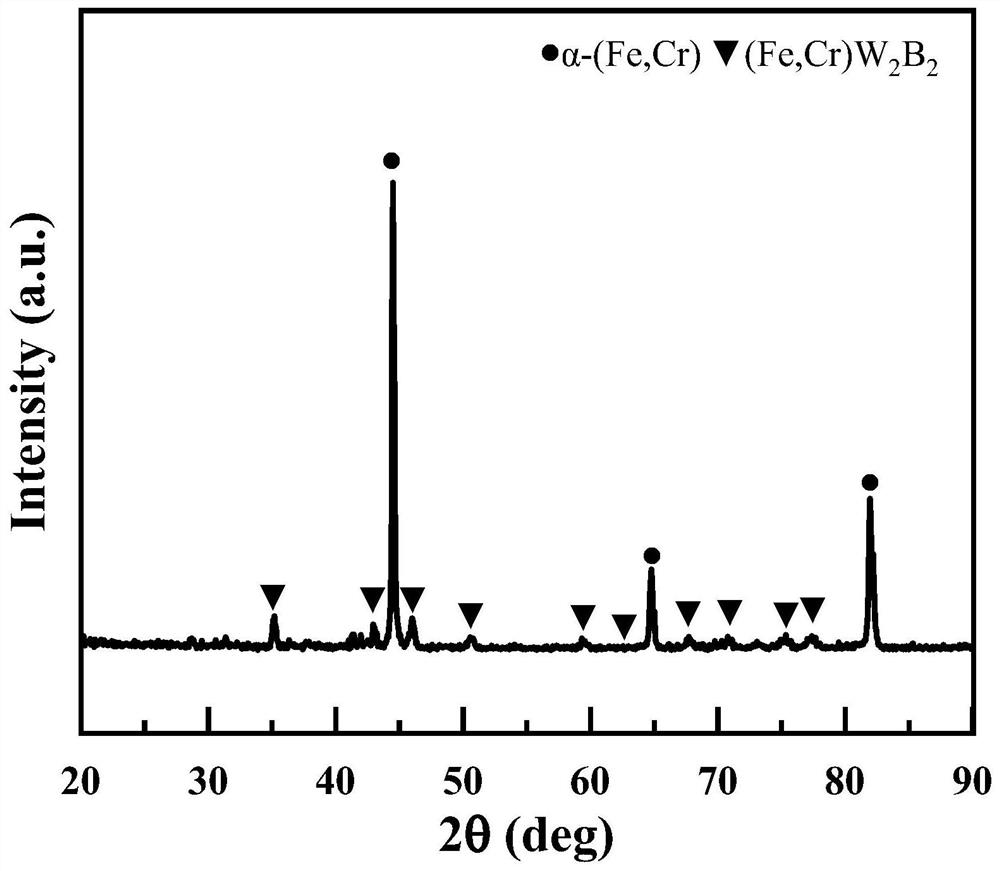

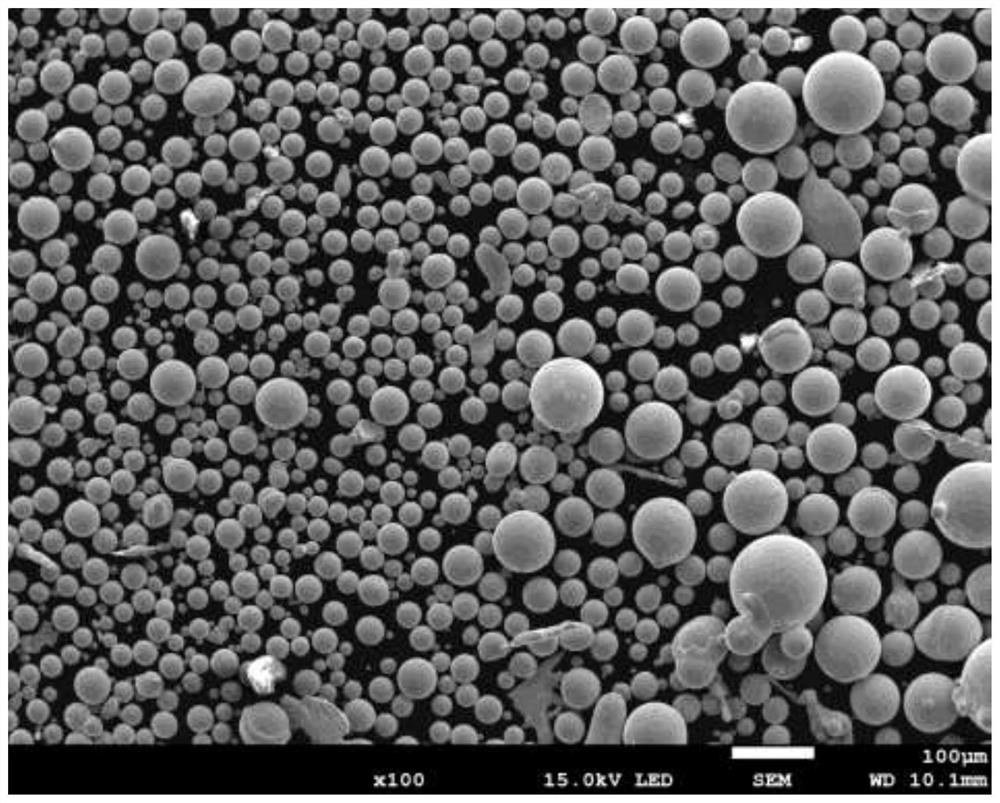

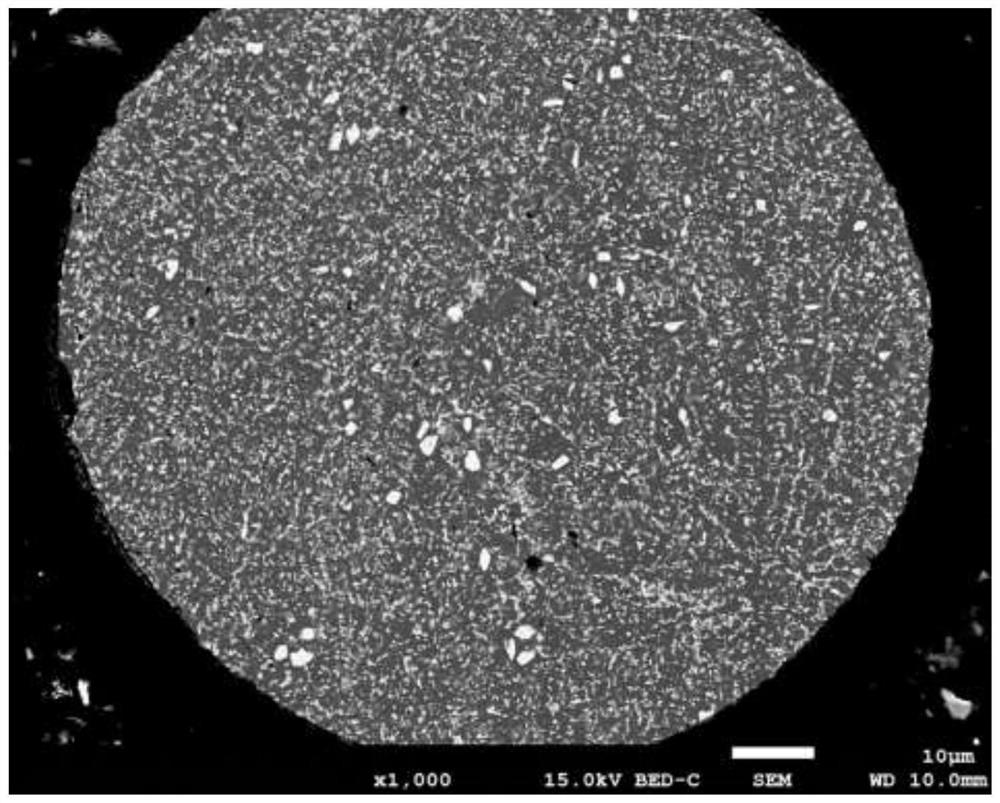

Novel Fe-based spherical shielding alloy powder and preparation method thereof

ActiveCN113798487AGuaranteed shielding effectImprove corrosion resistanceNuclear energy generationShieldingNuclear radiationBoride

The invention relates to the field of nuclear radiation shielding materials, and particularly discloses novel Fe-based spherical shielding alloy powder and a preparation method thereof. The novel Fe-based spherical shielding alloy powder has excellent gamma ray and thermal neutron shielding performance. Components of the Fe-based alloy powder comprise, by weight percent, 13.6-28.9% of W, 0.8-1.7% of B, 0-15.0% of Cr and the balance Fe. Raw materials are weighed according to the components of the alloy powder and the component proportion, smelting and atomization are carried out under argon protection to obtain the alloy powder, then heat treatment and ball milling dispersion are carried out on the alloy powder, and finally the alloy powder which is high in sphericity degree and fluidity, uniform in boride phase distribution and good in comprehensive shielding performance is obtained. The Fe-based shielding alloy powder can be widely applied to the field of filling of special-shaped structures for nuclear radiation shielding and the field of repairing of Fe-based shielding body materials.

Owner:SICHUAN UNIV

Graphite fiber of lamination cross section structure and melting spinning method for graphite fiber

ActiveCN110578187AHigh surface finishGood orientationFibre chemical featuresMelt spinning methodsMetal coatingCarbonization

The invention provides a graphite fiber of a lamination cross section structure and a melting spinning method for the graphite fiber. The method comprises the following steps that 1, intermediate-phase asphalt is adopted for melting spinning to obtain a fiber protofilament; the cross section of a spinneret orifice used for melting spinning is rectangular, the long edge of a spinneret orifice outlet is provided with an outlet chamfer, and the inner surface of the spinneret orifice is plated with a layer of metal coating with nickel or silver or platinum; 2, the fiber protofilament is subjectedto non-melting carbonization and graphitization in sequence to obtain the graphite fiber of the lamination cross section structure. After the prepared fiber protofilament with an oval cross section issubjected to non-melting carbonization and graphitization, a graphite flake layer of the fiber protofilament is approximately parallel to the direction of the long edge of the cross section of the fiber, La and Lc of graphite microcrystals can sufficiently develop, the graphite flake layer has few and compact wrinkles, and the heat conductivity of the finally-obtained graphite fiber can reach 800-1,100 W / (m.K).

Owner:SHAANXI TIANCE NEW MATERIAL TECH

High-strength gray cast iron and low Si-Al inoculation process thereof

InactiveCN107460398AReduce the solidification rateReduced wall thickness sensitivityLiquid stateGraphite

The invention discloses high-strength gray cast iron and a low Si-Al inoculation process thereof, and relates to the technical field of gray cast iron. The high-strength gray cast iron comprises the following components, in percentage by weight, 3.5-3.8% of C, 1.5-1.9% of Si, 0.01-0.09% of Ti, 1.1-1.33% of Mn, 0.4-0.6% of Cu, 0.63-0.92% of Cr, 0.63-0.92% of Zr, 0.63-0.92% of Ba, 0.17-0.73% of Ni, 1.12-2.21% of Zn, 0.012-0.021% of As, 70-120 ppm of N, 0.03-0.05% of Re, less than 0.12% of P, less than 0.03 of S, less than 20 ppm of Pb, and the balance Fe. Two grades of inoculation agents are added in liquid-state cast iron to form a lot of sub-microscopic cores to accelerate growth of eutectic cells in a liquid phase; when an eutectic solidification temperature is approached, fine graphite flakes are firstly formed in the core growth places, and the eutectic cells are grown; less heat can be released to the surrounding liquid phase due to formation of each eutectic cell; and more eutectic cells are formed, and the solidification speed of the cast iron is lower.

Owner:MAANSHAN WANXIN CASTING

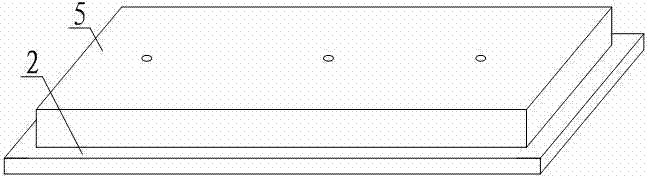

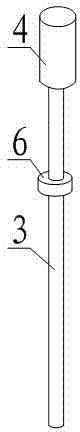

Stirring and mixing mechanism applied to industrial construction

InactiveCN104117306AReduce the solidification rateSimple structureRotary stirring mixersIndustrial constructionBLENDER/MIXER

The invention discloses a stirring and mixing mechanism applied to industrial construction. The stirring and mixing mechanism applied to industrial construction comprises a storage container (1), a seal cover (2) and a stirring mechanism, wherein the upper end surface of the storage container (1) indents to form a rectangular groove; the lower end surface of the seal cover (2) bulges downward to form a rectangular bulged block (5) matched with the rectangular groove in length and width; the rectangular bulged block (5) is embedded into the rectangular groove and seals the upper end opening of the rectangular groove; the stirring mechanism comprises stirring rods (3); round through holes running through the upper end surface and the lower end surface of the seal cover (2) are formed in the seal cover(2); the lower ends of the stirring rods (3) pass through the round through holes and are positioned in the rectangular groove. By adopting the structure, the stirring and mixing mechanism applied to industrial construction provided by the invention is simple in integral structure, is easy to realize, and is low in cost; when the stirring and mixing mechanism applied to industrial construction is applied, a mixed material after mixing is stored in the rectangular groove, and the condensation velocity of the mixed material is slowed down by the stirring mechanism, so that the resource waste is reduced.

Owner:成都派莱克科技有限公司

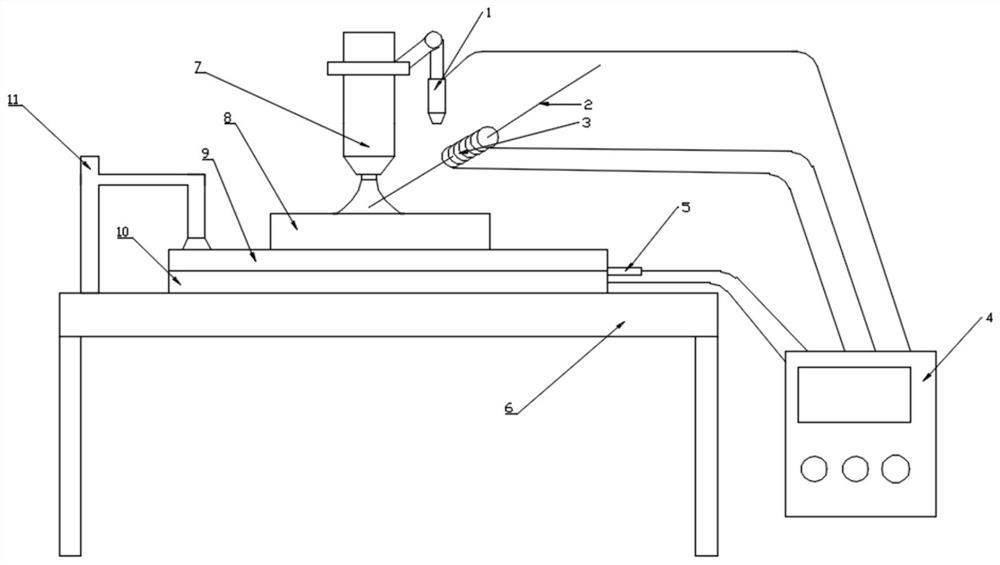

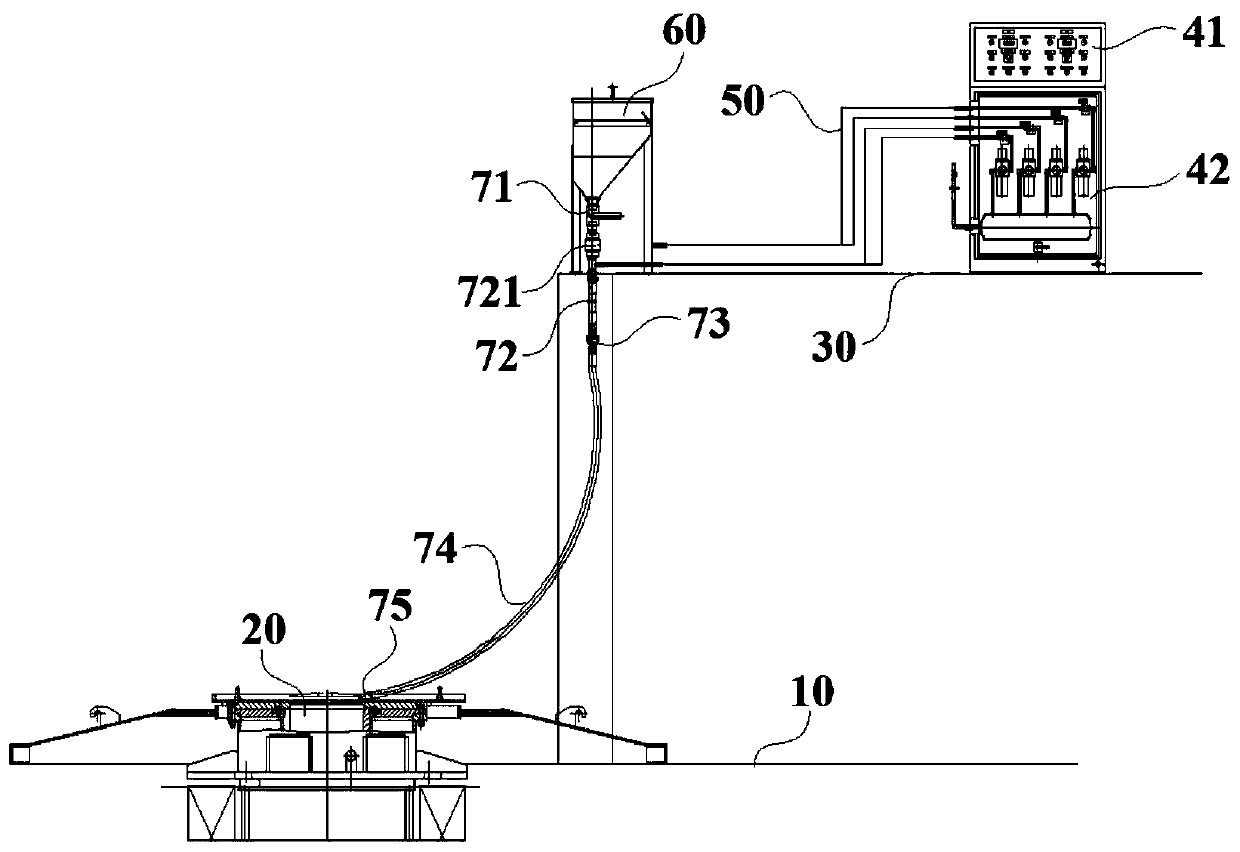

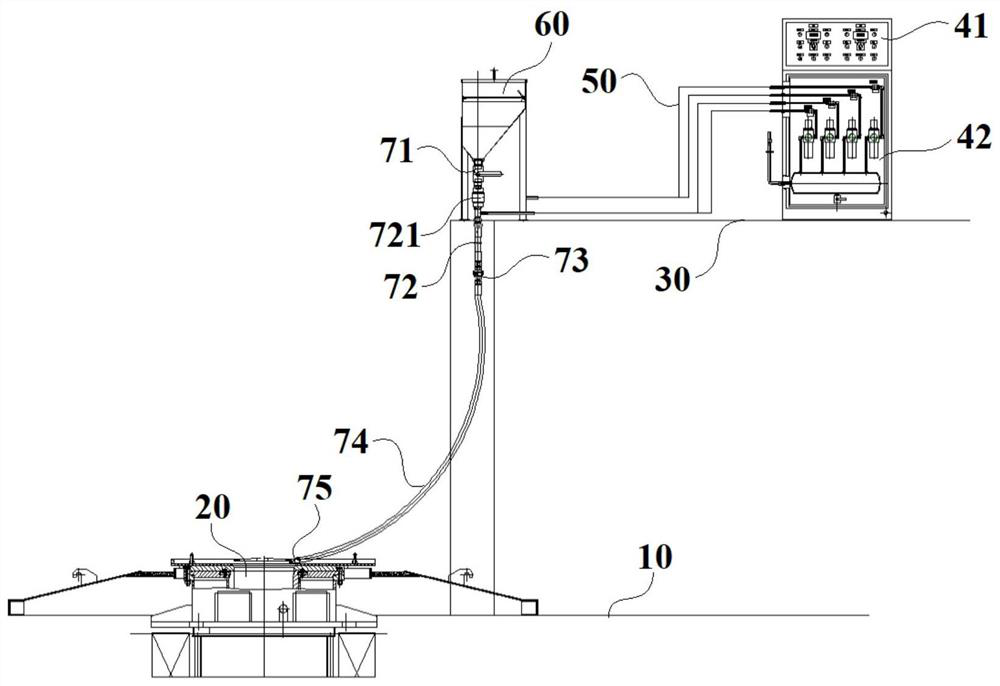

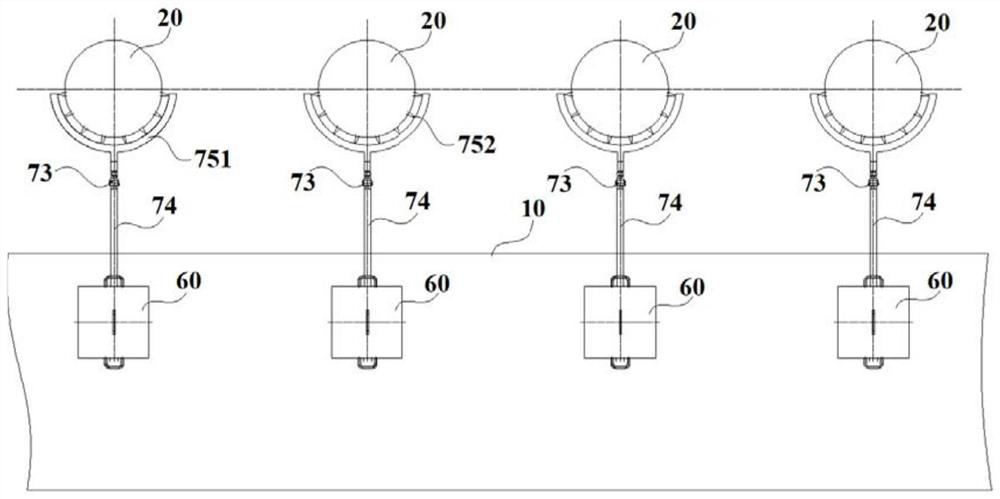

Automatic metallurgical heating agent adding device for continuous casting and collecting tailing billet

The invention discloses an automatic metallurgical heating agent adding device for a continuous casting and collecting tailing billet, and belongs to the technical field of metallurgical continuous casting equipment. The device comprises a control cabinet, a heating agent bin, a metallurgical heating agent feeding pipe and a nozzle, the lower end of the heating agent bin is in communication with one end of the metallurgical heating agent feeding pipe, the nozzle is in communication with the other end of the metallurgical heating agent feeding pipe, and the nozzle is located on the edge of a crystallizer; and the control cabinet is used for controlling the metallurgical heating agent in the heating agent bin to be added into the crystallizer. According to the automatic adding device, the metallurgical heating agent is added into the crystallizer, the whole process is controlled by the control cabinet, the metallurgical heating agent is sprayed into the crystallizer from the nozzle alongthe metallurgical heating agent feeding pipe, the adding time of the whole metallurgical heating agent is controlled to be not longer than 3 min, the manual participation amount in the whole processis small, and the degree of the mechanization and automation is high; and meanwhile, the using performance of the metallurgical heating agent can be effectively guaranteed, and the quality of a casting blank and the yield of molten steel are improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

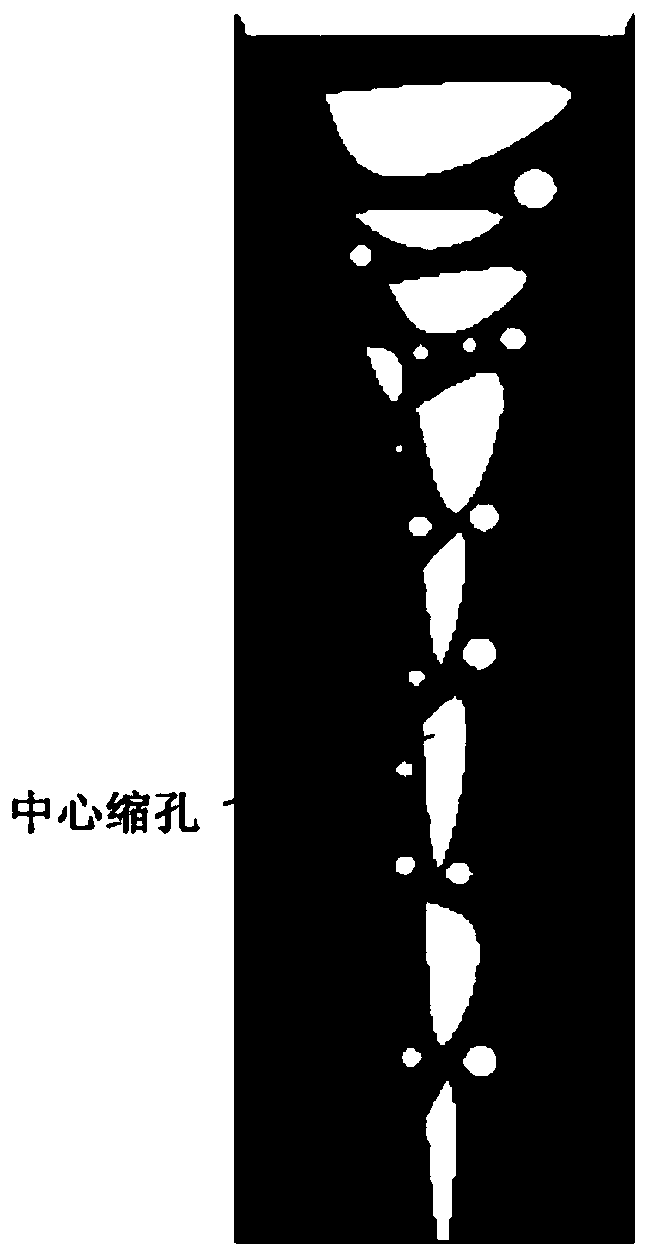

A kind of preparation method of metallurgical exothermic agent for continuous casting end billet

ActiveCN111331092BStable physical and chemical propertiesImprove convenienceIron powderMolding machine

The invention discloses a preparation method of a metallurgical exothermic agent for continuous casting end billets, belonging to the technical field of metallurgical continuous casting. In the present invention, aluminum powder, carbon powder, iron powder, silicon powder, FeO and CaO are configured according to weight percentage, and are stirred and mixed by a mixer; a binder is added therein, and then the mixer is continued to be stirred. Mix well; send the stirred raw materials to a molding machine to be pressed into agglomerates; finally, the agglomerates are dried and cooled naturally to obtain a metallurgical exothermic agent. In the present invention, the metallurgical exothermic agent prepared by the method is added to the crystallizer, and the carbon and aluminum in the metallurgical exothermic agent undergo an exothermic reaction with FeO, so as to provide higher heat for the tail billet when the continuous casting tail billet is solidified, and reduce the energy consumption. The solidification rate of the tail billet shell, and the metal Fe generated at the same time will feed the solidification shrinkage hole in the center of the tail billet, increase the density of the tail billet, improve the quality of the tail billet, and greatly improve the quality of the tail end of the billet, thereby reducing the The cutting amount of the tail end of the continuous casting billet.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Die-casting magnesium alloy containing rare earth and forming process of die-casting magnesium alloy

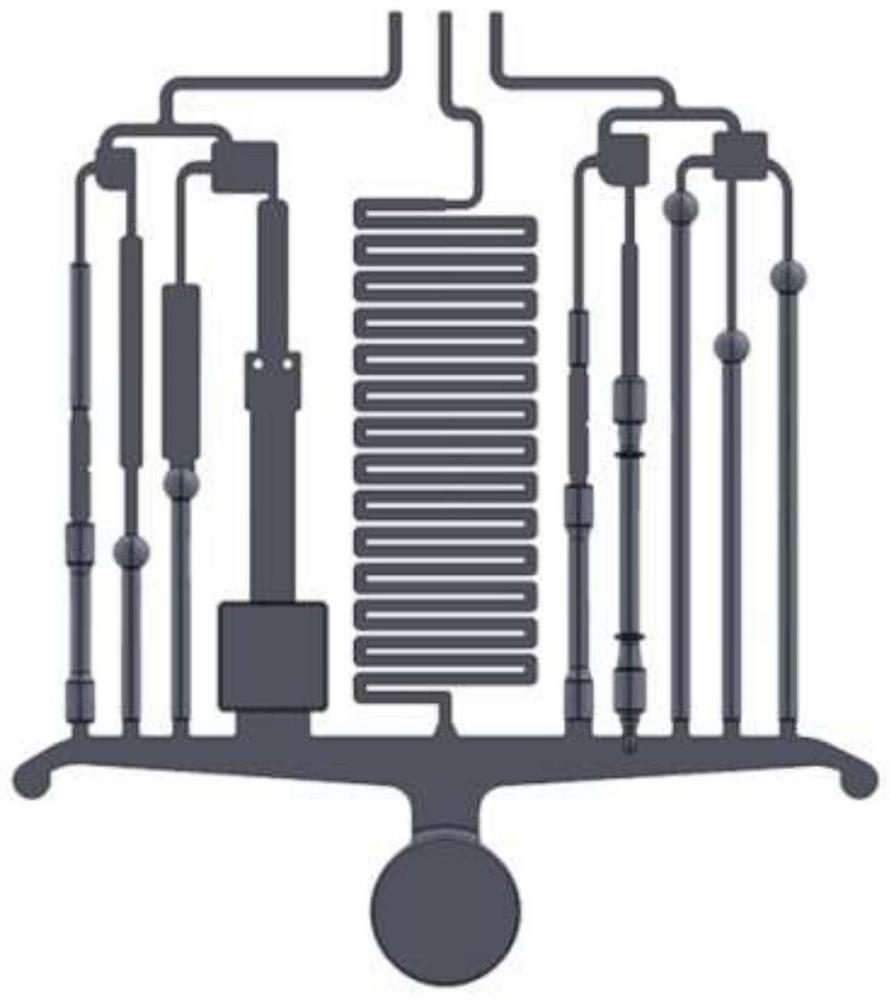

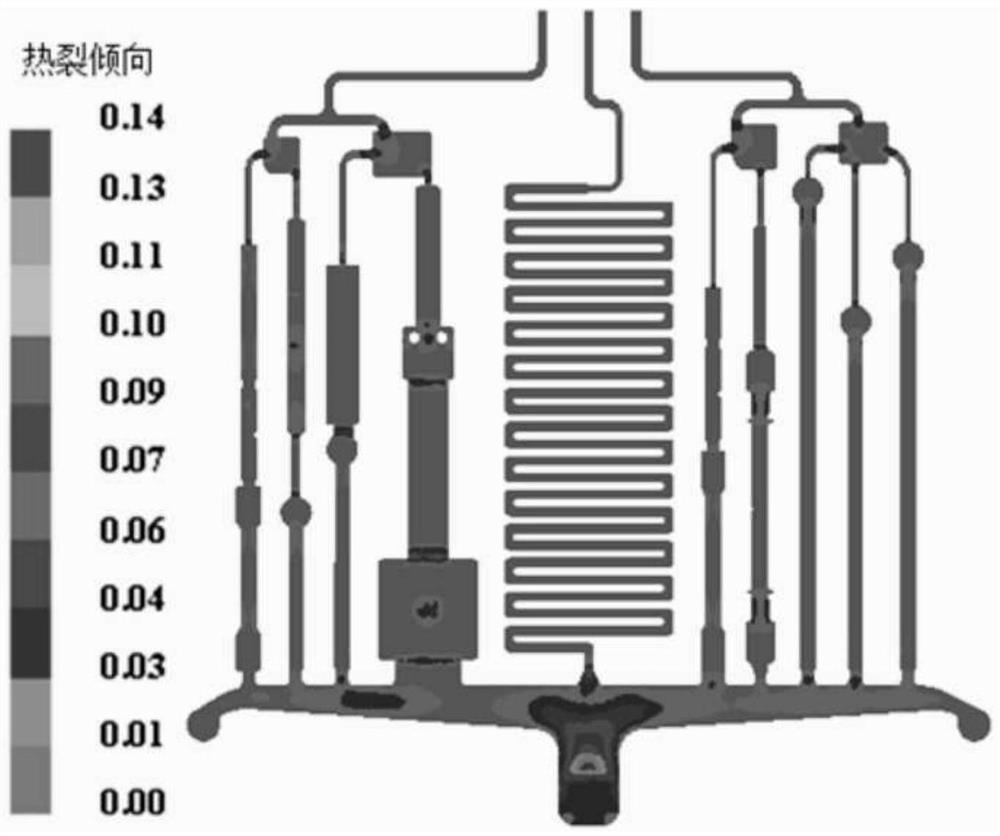

PendingCN114855041AImprove mechanical propertiesImprove heat resistanceDesign optimisation/simulationSpecial data processing applicationsShrinkage rateDie casting

The invention relates to the technical field of die-casting processes, in particular to a die-casting magnesium alloy containing rare earth and a forming process thereof.The die-casting magnesium alloy comprises 0.4-0.8 wt.% of zinc, 0.4-0.8 wt.% of lanthanum, 0.4-0.8 wt.% of cerium, 0.4-0.8 wt.% of zirconium and the balance magnesium. According to the die-casting magnesium alloy containing the rare earth and the forming process of the die-casting magnesium alloy containing the rare earth and the forming process of the die-casting magnesium alloy containing the rare earth, simulation software is adopted for conducting simulation analysis on a magnesium alloy die casting; model establishment, grid division, boundary condition setting, process parameter setting and result analysis are sequentially carried out, and based on orthogonal test design, the optimal die-casting forming process is obtained by comparing the influences of the process parameters such as pouring temperature, mold temperature, injection speed and dwell time on the shrinkage rate and the hot crack tendency index. According to the die-casting magnesium alloy containing the rare earth, the result of casting defects is analyzed through software, the limitation that the mechanical performance is optimized through repeated production tests is improved, the production period is shortened, the test casting cost is reduced, and the casting quality is improved.

Owner:SHANGHAI UNIV

An automatic adding device for metallurgical exothermic agent for continuous casting final billet

The invention discloses a device for automatically adding a metallurgical exothermic agent for continuous casting finishing billets, belonging to the technical field of metallurgical continuous casting equipment. The invention includes a control cabinet, a heating agent silo, a metallurgical heating agent feeding pipe and a nozzle. connected, and the nozzle is located at the edge of the crystallizer; the control cabinet is used to control the addition of the metallurgical heating agent in the heating agent silo to the crystallizer. The present invention adds the metallurgical heating agent into the crystallizer through the automatic adding device, and the whole process is controlled by the control cabinet, so that the metallurgical heating agent is sprayed into the crystallizer from the nozzle along the metallurgical heating agent feeding pipe, and the entire metallurgical heating is controlled The addition time of the agent does not exceed 3 minutes, the whole process requires less human participation, and the degree of mechanization and automation is high. At the same time, it can effectively ensure the performance of the metallurgical heating agent and improve the quality of the casting slab and the yield of molten steel.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Anti-curling low-solidification-rate PU resin and preparation method thereof

ActiveCN111269382AIncrease elasticityWith anti curlCoatingsTextiles and paperPolyesterPolymer science

The invention relates to an anti-curling low-solidification-rate PU resin and a preparation method thereof. The preparation method comprises the steps: 1, adding polyester polyol into a reaction kettle, adding phosphoric acid, an antioxidant, a dihydric alcohol chain extender and N, N-dimethylformamide, and stirring and mixing the mixture uniformly; 2) adding isocyanate, heating the mixture to 75-80 DEG C, and carrying out a tackifying reaction until the viscosity of the system reaches 200,000-240,000 cps / DEG C; and 3) after the tackifying reaction, adding methanol to terminate the tackifyingreaction, then adding malic acid, stirring the mixture for 1h, and discharging the product. The preparation method provided by the invention adopts a one-step method, the synthesis process is simple and convenient, the prepared PU resin has good resilience, and the PU wet base prepared from the PU resin has the functions of edge curling prevention and low solidification rate.

Owner:YANGZHOU POLYTECHNIC INST

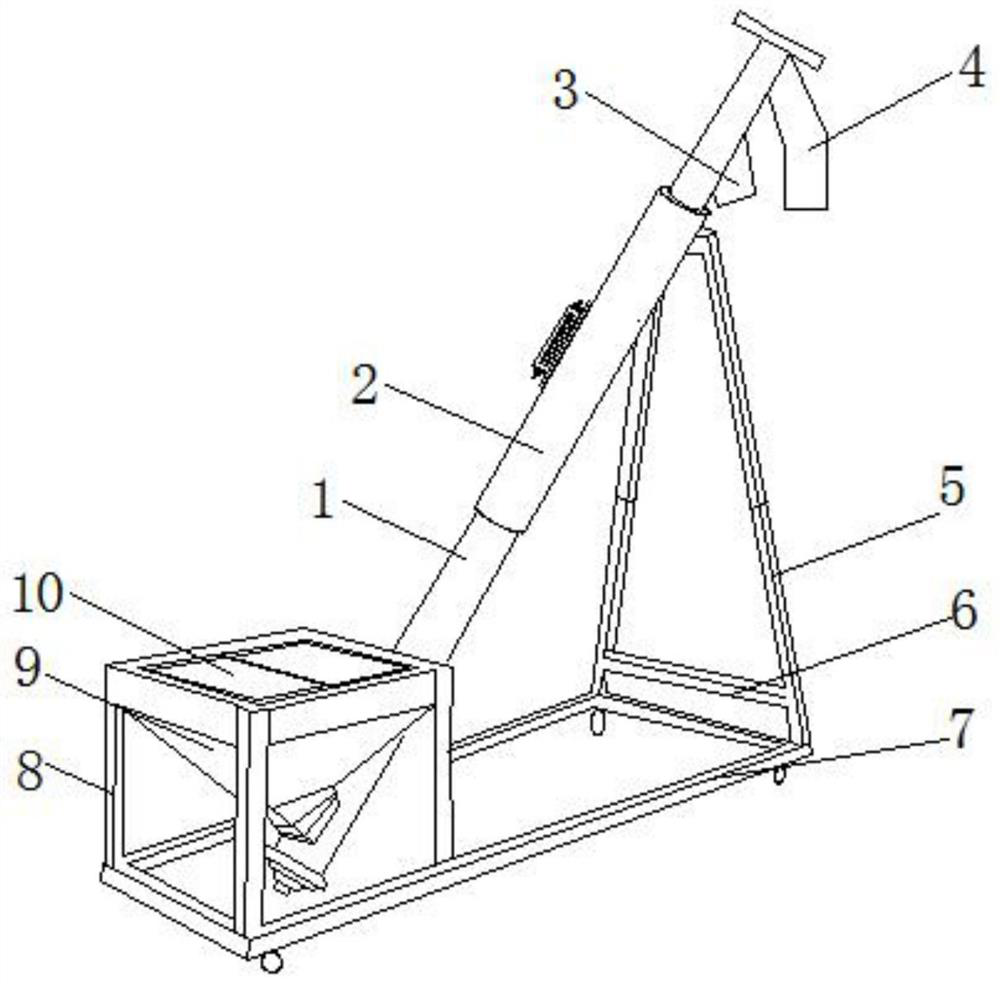

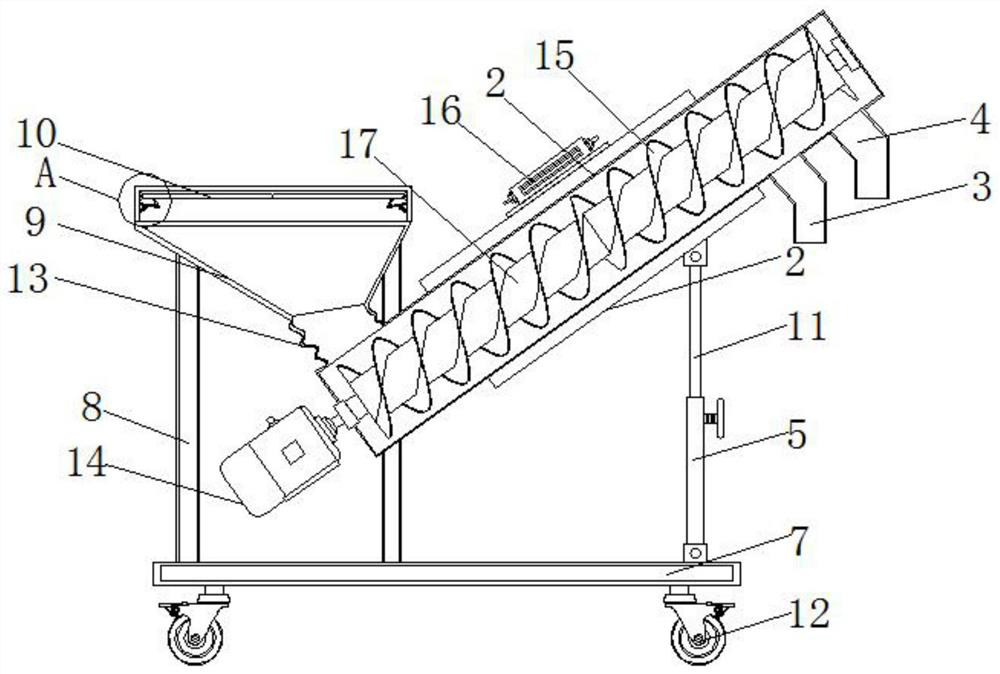

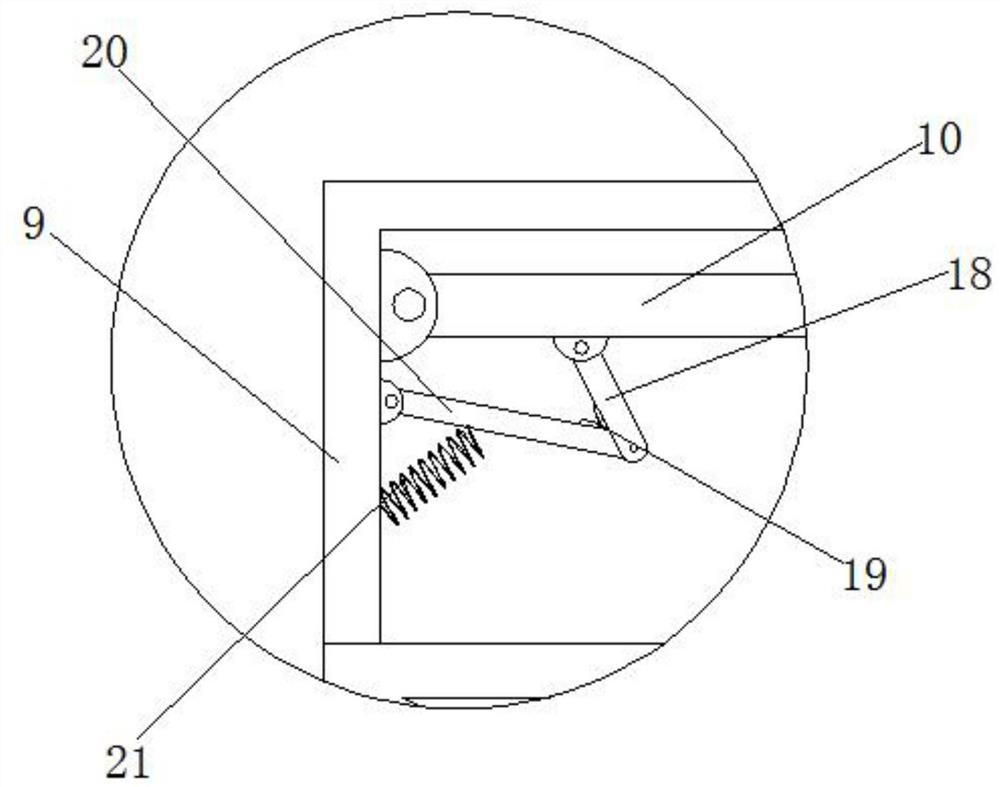

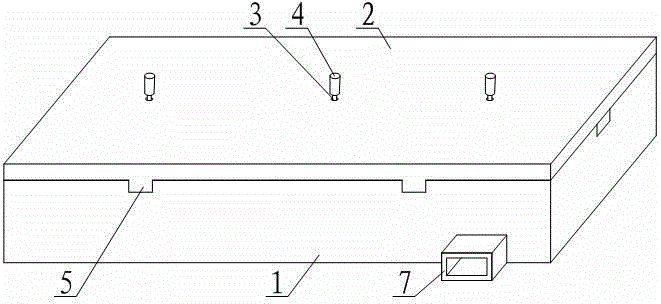

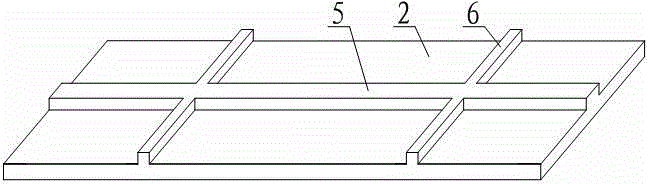

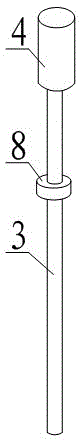

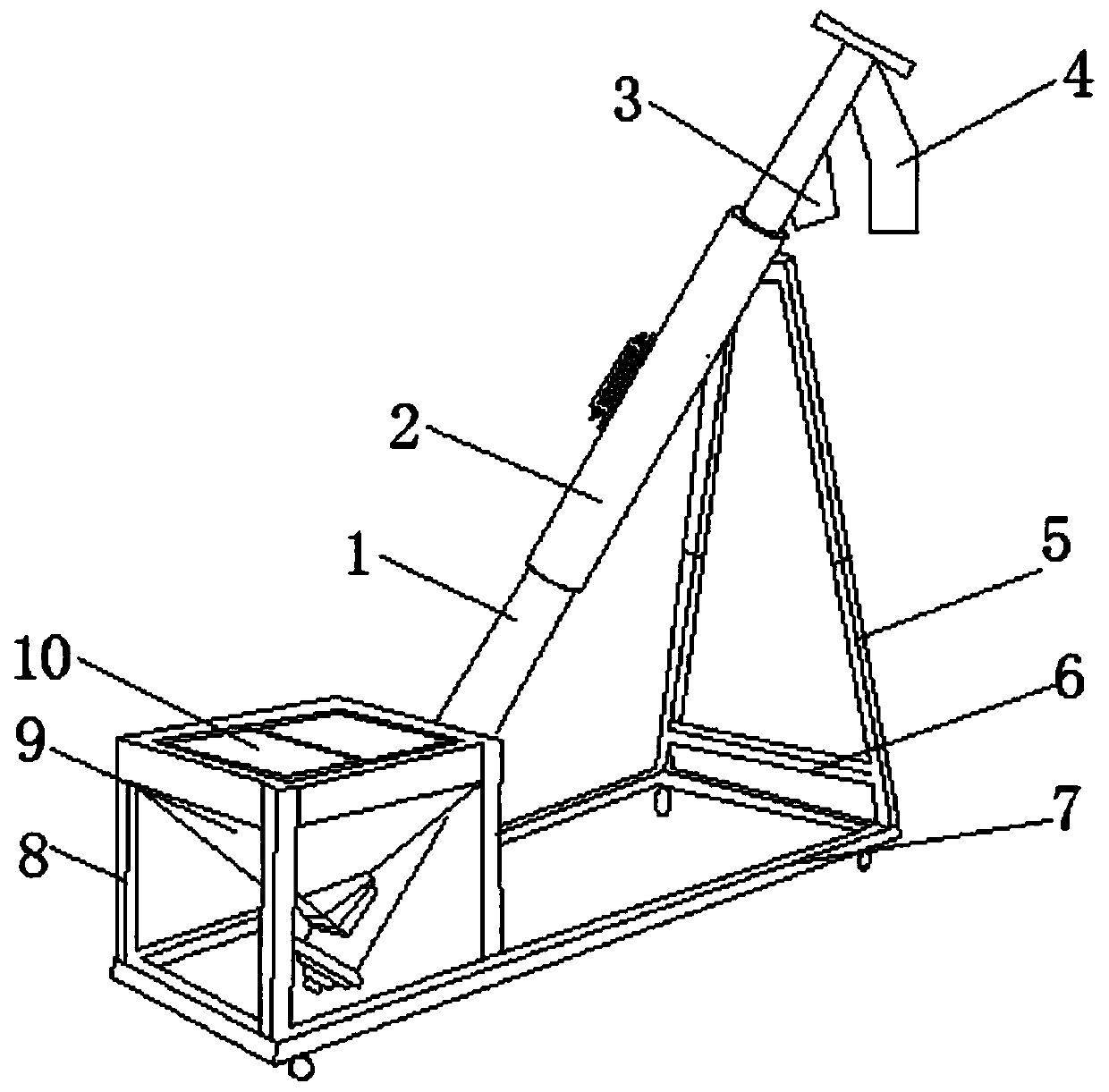

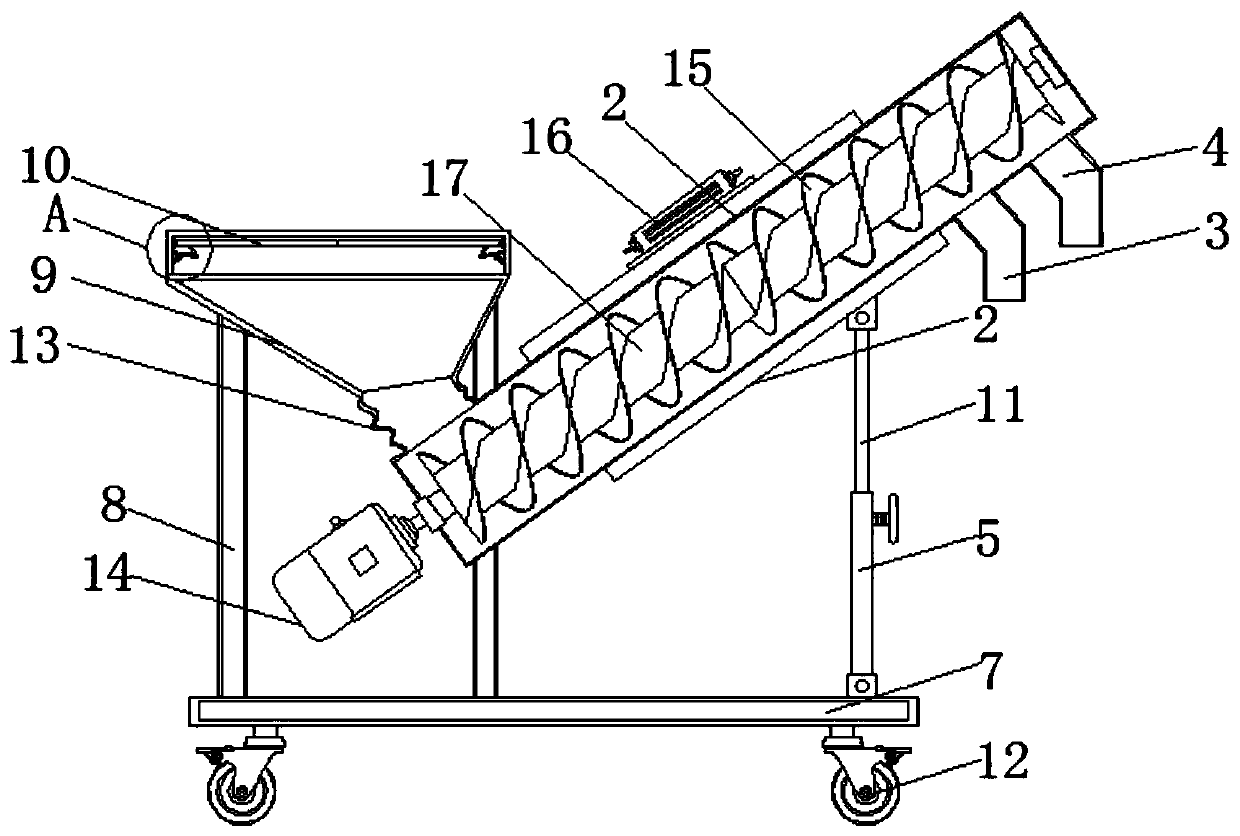

A construction concrete feeding device

ActiveCN110094061BReduce the solidification rateReduce exposureBuilding material handlingArchitectural engineeringStructural engineering

The invention discloses a feeding device of building concrete, and belongs to the technical field of raw material transporting. The feeding device of the building concrete includes a material inlet bin and a material conveying pipe body communicating with the material inlet bin. The feeding device is characterized in that a baffle is hinged to the top of the inner side of the material inlet bin, afirst connecting rod is hinged to the bottom of the baffle, a second connecting rod is hinged to the first connecting rod, an elastic hinging sheet is fixed to an included angle between the second connecting rod and the first connecting rod, one part of the elastic hinging sheet is fixed to the second connecting rod, the other part of the elastic hinging sheet is fixed to the first connecting sheet to form an elastic buffering assembly, a spring is mounted on the second connecting rod, and the other end of the spring is fixed to the inner wall of the material inlet bin. According to the feeding device of the building concrete, the material inlet bin is sealed, contact between the concrete and air is reduced, the solidified rate of the concrete is lowered, and waste of resources is reduced.

Owner:济南临港建设集团有限公司

Mixing and stirring mechanism in industrial construction

InactiveCN104147955AReduce the solidification rateAvoid wastingRotary stirring mixersIndustrial constructionBLENDER/MIXER

The invention discloses a material mixing and stirring mechanism in industrial construction. The material mixing and stirring mechanism in industrial construction comprises a storage container, a sealing cover and a stirring mechanism, wherein the storage container is rectangular; the upper end side of the storage container sinks inwards to form a rectangular groove; an upper opening of the rectangular groove is sealed by the sealing cover; the upper ends of four side plates of the rectangular groove in the storage container sink inwards to form location notches; the lower end side of the sealing cover protrudes downwards to form a vertical location strip with two ends which are respectively embedded in the location notches in the front side plate and the rear side plate of the rectangular groove and a transverse location strip with two ends which are respectively embedded in the location notches of the left side plate and the right side plate of the rectangular groove; the stirring mechanism comprises a stirring rod; a circular through hole penetrating through the upper end side and the lower end side of the sealing cover is formed in the sealing cover; the lower end of the stirring rod penetrates through the circular through hole and is located in the rectangular groove. Due to the adoption of the structure, the material mixing and stirring mechanism in industrial construction is simple in overall structure, convenient to implement and low in cost; when the material mixing and stirring mechanism is used, materials are stored in the rectangular groove and subsequently mixed; through the stirring mechanism, the coagulation rate of the mixed material is reduced; the waste of resources is reduced.

Owner:成都派莱克科技有限公司

Heterogeneous intermetallic compound additive processing equipment and processing method thereof

ActiveCN114850632ASolving Melting InstabilitySolve for uniformityAdditive manufacturing apparatusArc welding apparatusWelding power supplyIntermetallic

The invention discloses dissimilar intermetallic compound additive processing equipment and a processing method thereof. The dissimilar intermetallic compound additive machining equipment comprises a heating plate, a first welding power source, a double-hole wire feeding contact tube, a first wire feeder, a second wire feeder and a second welding power source, the heating plate is used for containing a substrate, and the first welding power source is used for heating and melting an additive deposition layer on the substrate; the first wire feeder and the second wire feeder are both connected with the double-hole wire feeding contact tube and communicate with a first wire feeding hole and a second wire feeding hole of the double-hole wire feeding contact tube correspondingly, and the second welding power source can move and is used for heating and melting an additive deposition layer. The double-hole wire feeding contact tube, the first welding power source and the second welding power source are all arranged opposite to the heating plate. By means of the dissimilar intermetallic compound additive machining equipment, the structure property uniformity of a complex special-shaped component can be improved.

Owner:湖南湘投金天科技集团有限责任公司

Feeding device of building concrete

ActiveCN110094061AReduce the solidification rateReduce exposureBuilding material handlingEngineeringRaw material

The invention discloses a feeding device of building concrete, and belongs to the technical field of raw material transporting. The feeding device of the building concrete includes a material inlet bin and a material conveying pipe body communicating with the material inlet bin. The feeding device is characterized in that a baffle is hinged to the top of the inner side of the material inlet bin, afirst connecting rod is hinged to the bottom of the baffle, a second connecting rod is hinged to the first connecting rod, an elastic hinging sheet is fixed to an included angle between the second connecting rod and the first connecting rod, one part of the elastic hinging sheet is fixed to the second connecting rod, the other part of the elastic hinging sheet is fixed to the first connecting sheet to form an elastic buffering assembly, a spring is mounted on the second connecting rod, and the other end of the spring is fixed to the inner wall of the material inlet bin. According to the feeding device of the building concrete, the material inlet bin is sealed, contact between the concrete and air is reduced, the solidified rate of the concrete is lowered, and waste of resources is reduced.

Owner:济南临港建设集团有限公司

A kind of preparation method of polycarboxylate high performance water reducing agent

The invention discloses a preparation method of a polycarboxylic acid high-performance water reducer. The raw materials mainly include methacrylic acid, unsaturated polyether, water-based polyurethane emulsion, hexafluorobutyl methacrylate, polymer colloid, dodecyl Sodium sulfonate; the present invention utilizes hexafluorobutyl methacrylate to carry out hydrophobic modification treatment on water-based polyurethane, and polymer colloid is bonded by chemical bonds through esterification grafting to form polysaccharide graft copolymers at the same time. The surface self-assembly of molecular chains of carboxylic acid forms a film layer with high dispersion and high heat resistance. It has the ability to disperse and maintain cement for a long time, slows down the concrete solidification rate during transportation, and has high thermal stability. Long time, environmental protection and non-toxic, convenient storage and transportation, wide source of raw materials, suitable for industrial production.

Owner:山西桑穆斯建材化工有限公司

Preparation method of polyacrylonitrile precursor

ActiveCN102453972BReduce the solidification rateCompact structureMonocomponent synthetic polymer artificial filamentWet spinning methodsInorganic saltsAqueous solution

The invention discloses a preparation method of a polyacrylonitrile precursor. The method comprises the following steps: (1) spinning a polyacrylonitrile spinning stock solution, injecting the stock solution into a fatty alcohol coagulation bath and solidifying to obtain a primary gel fibre filament; (2) adding the primary gel fibre filament into at least one stage of inorganic salt aqueous coagulation bath and solidifying to obtain a polyacrylonitrile solidified filament; (3) washing the polyacrylonitrile solidified filament and drying to obtain the polyacrylonitrile precursor. Without changing a prior art, the method merely adds a segment of the coagulation bath consisting of fatty alcohol and inorganic salt to obtain the polyacrylonitrile precursor with more compact structure and more excellent performances.

Owner:WEIHAI TUOZHAN FIBER +1

A kind of graphite fiber with laminated cross-section structure and its melt spinning method

ActiveCN110578187BHigh surface finishGood orientationFibre chemical featuresMelt spinning methodsMetal coatingGraphite

The invention provides a graphite fiber with a laminated cross-section structure and a melt spinning method thereof, comprising the following steps: step 1, using mesophase pitch for melt spinning to obtain fiber precursors; the spinneret hole cross section used for melt spinning It is rectangular, and the outlet chamfer is provided on the long side of the spinneret outlet, and the inner surface of the spinneret is coated with a layer of nickel, silver or platinum metal coating; step 2, the fiber precursors are sequentially subjected to non-melting carbonization and graphitization After processing, graphite fibers with a laminated cross-sectional structure are obtained. The present invention prepares fiber precursors with elliptical cross-sections. After non-melting carbonization and graphitization, the graphite sheets are approximately parallel to the direction of the long side of the fiber cross-section, so that La and Lc of graphite microcrystals can be fully developed. The graphite flakes are less wrinkled and dense, and the thermal conductivity of the final graphite fiber can reach 800-1100W / (m·K).

Owner:SHAANXI TIANCE NEW MATERIAL TECH

Preparation method for metallurgical exothermic agent for continuous casting tail billet collection

ActiveCN111331092AStable physical and chemical propertiesReduce the solidification rateSilica fumeExothermic reaction

The invention discloses a preparation method for a metallurgical exothermic agent for continuous casting tail billet collection, and belongs to the technical field of metallurgical continuous casting.The preparation method comprises the following steps of preparing aluminum powder, carbon powder, iron powder, silicon powder, FeO and CaO in percentage by weight, and uniformly stirring and mixing the aluminum powder, the carbon powder, the iron powder, the silicon powder, the FeO and the CaO by using a stirrer; then adding a binder into the mixture, and then continuously and uniformly stirringand mixing the mixture by using the stirrer; conveying the stirred raw materials to a forming machine to make the stirred raw materials be pressed into agglomerates; and finally, drying the prepared agglomerates and naturally cooling the agglomerates to obtain the metallurgical exothermic agent. According to the preparation method, the metallurgy exothermic agent prepared through the method is added into a mould, carbon and aluminum in the metallurgy exothermic agent and FeO generate an exothermic reaction, then the relatively high heat can be provided for a tail billet when the continuous cast tail billet is solidified, the solidification rate of a tail billet shell is reduced, meanwhile, the generated metal Fe can feed a solidification shrinkage cavity in the center of the tail billet, the density of the tail billet is increased, the quality of the tail billet is improved, the quality of the tail end of a cast billet is greatly improved, and therefore the cutting amount of the tail end of the continuous cast billet is reduced.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

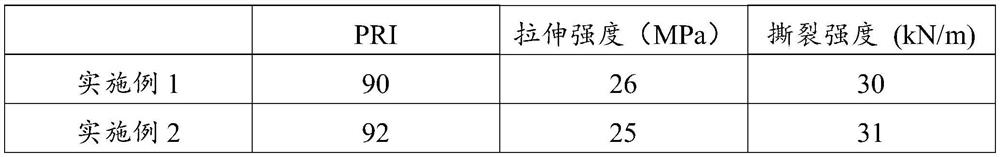

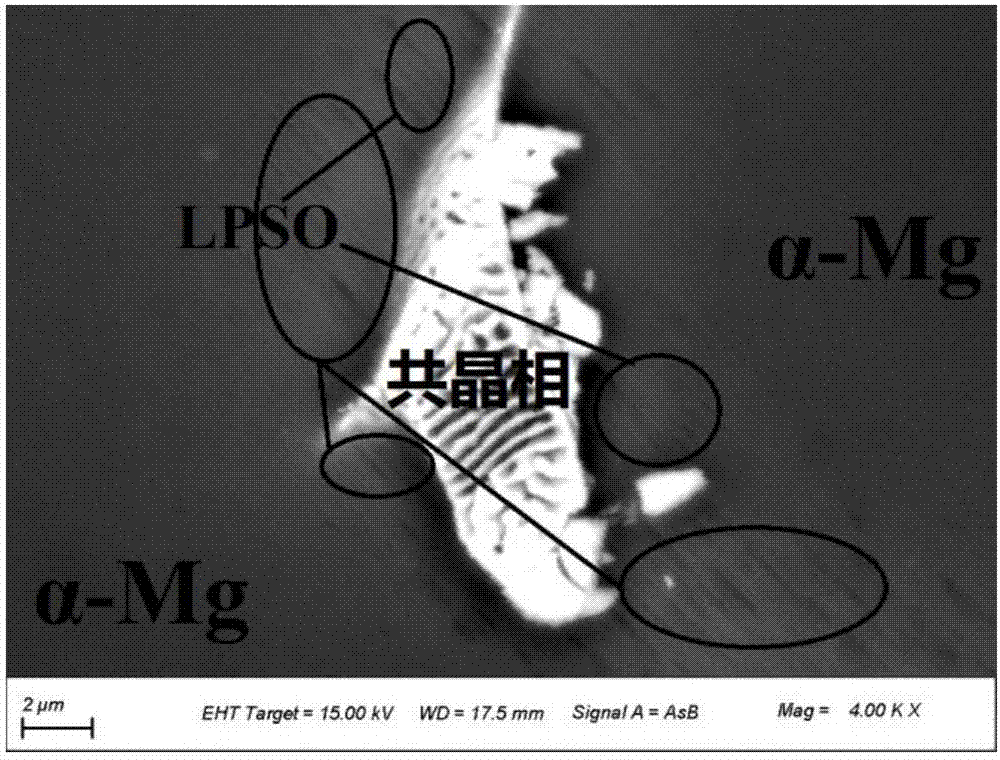

Anti-aging high-strength natural rubber and preparation method thereof

ActiveCN113929977ALong storage timeLow impurity contentRolling resistance optimizationGlycinePolymer science

The invention discloses a preparation method of anti-aging high-strength natural rubber. The preparation method comprises the steps of (1) obtaining natural latex; (2) adding ammonia water and hydrogen peroxide; (3) adding soluble phosphate or amino acid; (4) conducting centrifugal sedimentation; (5) mixing with a reinforcing agent to obtain a mixed solution; (6) solidifying the mixed solution to obtain a gel block; (7) curing the gel block; (8) pressing the cured gel block into creases, washing with water, firstly drying at 150-170 DEG C for 5-15 minutes, and then drying at 70-90 DEG C to obtain a natural rubber finished product, wherein the soluble phosphate is selected from trisodium phosphate and / or dipotassium phosphate; and amino acid is selected from glycine and / or alanine. The natural rubber prepared by the invention is good in aging resistance, and the tensile strength and tearing strength of vulcanized rubber are high.

Owner:RUBBER RES INST CHINESE ACADEMY OF TROPICAL AGRI SCI

Anti curling low solidification rate pu resin and preparation method thereof

ActiveCN111269382BIncrease elasticityWith anti curlCoatingsTextiles and paperPolyesterO-Phosphoric Acid

This case involves an anti-curling low solidification rate PU resin and its preparation method. The preparation method includes: 1) adding polyester polyol to the reaction kettle, adding phosphoric acid, antioxidant, glycol chain extender and N, N-dimethylformamide, stirring and mixing; 2) adding isocyanate, heating up to 75-80°C for viscosity-increasing reaction until the viscosity of the system reaches 20-240,000 cps; 3) adding methanol to terminate the viscosity-increasing reaction, Then add malic acid, and discharge after stirring for 1h. The preparation method of this case adopts a one-step method, and the synthesis process is simple and convenient; the prepared PU resin has good resilience performance, and the PU wet-process bass made of it has the functions of anti-curling and low solidification rate.

Owner:YANGZHOU POLYTECHNIC INST

Preparation process of a high-aluminum, titanium-deformed superalloy

ActiveCN111534718BExcellent high temperature strength propertiesReduce manufacturing costAlloyTitanium

Owner:HUANENG POWER INT INC +1

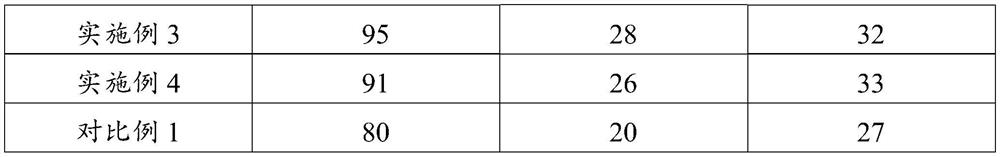

mg-gd-zn(-ca) medical magnesium alloy with lpso structure and preparation method thereof

ActiveCN106244882BImprove corrosion resistanceReduces propensity for corrosion to occurCardiovascular stentShielding gas

The invention relates to a medical Mg-Gd-Zn (-Ca) magnesium alloy with an LPSO structure and a preparation method of the medical Mg-Gd-Zn (-Ca) magnesium alloy with the LPSO structure and belongs to the field of medical magnesium alloy preparation. The medical Mg-Gd-Zn (-Ca) magnesium alloy with the LPSO structure comprises, by mass, 1.0%-3.5% of Gd, 0.3%-1.2% of Zn and 0-1.0% of Ca. The preparation method of the medical Mg-Gd-Zn (-Ca) magnesium alloy with the LPSO structure comprises the steps that raw materials which are in an appropriate ratio are placed in a crucible containing mixed protective gases of CO2 and SF6 in sequence for melting, stirring, standing and casting, wherein during casting, the solidification rate is controlled; and a cast ingot is placed in a resistance furnace with a protective atmosphere for heat treatment, and then rod materials are formed through extrusion. The medical Mg-Gd-Zn (-Ca) magnesium alloy with the LPSO structure has the advantages that the contents of the Gd element and the Zn element are low, the biological safety is high, the cost is low, and the technology is simple. Cast alloy tissue and extrusion alloy tissue both have the LPSO structure. Besides, after Ca is added, a divorced eutectic (Mg, Zn, Ca) 3Gd phase is formed in the cast alloy and is beneficial for the abrasion resistance performance of the alloy, the microstructure is adjustable, and the corrosion resistance of a material can be effectively improved. The medical Mg-Gd-Zn (-Ca) magnesium alloy with the LPSO structure has broad application prospect in the biomedical fields of orthopedics and cardiovascular stent implantation.

Owner:NANJING INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com