Mixing and stirring mechanism in industrial construction

A stirring mechanism and technology in construction, applied to mixers with rotating stirring devices, mixers, dissolving, etc., can solve the problems that the mixed materials cannot be reused, the mixed materials are easy to condense, and waste resources, etc., and achieve low cost and slow down The rate of solidification and the effect of avoiding waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

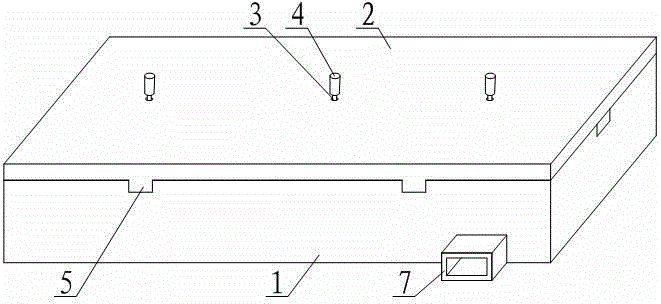

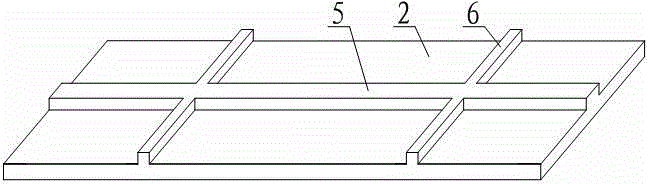

[0016] like figure 1 and figure 2 As shown, the ingredient mixing mechanism in industrial construction includes a storage container 1, a cover 2 and a mixing mechanism, wherein the storage container 1 is formed in a rectangular shape, the upper end surface of the storage container 1 is concaved to form a rectangular groove, and the cover 2 closes a rectangular shape. The upper end of the groove is open, and the upper ends of the four side panels of the rectangular groove of the storage container 1 are all recessed to form a positioning gap, and the lower end surface of the cover 2 is convex to form a horizontal positioning bar 5 and a vertical positioning bar 6, and the horizontal positioning bar 5 The two ends are respectively embedded in the positioning gaps on the left and right side panels of the rectangular groove, and the two ends of the longitudinal positioning strip 6 are respectively embedded in the positioning gaps on the front and rear two side panels of the rectan...

Embodiment 2

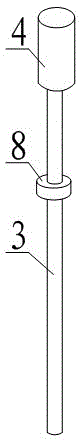

[0019] like image 3 As shown, in order to make the operation of this embodiment convenient and convenient, this embodiment makes the following further limitations on the basis of Embodiment 1: the stirring mechanism of this embodiment also includes a handle 4 and a sleeve connected to the upper end of the stirring rod 3 The limit ring 8 provided on the stirring rod 3, wherein the limit ring 8 is located in the rectangular groove, and the diameter of the outer ring of the limit ring 8 is larger than the diameter of the circular through hole.

Embodiment 3

[0021] In order to make the mixing of the mixed materials in the rectangular groove more uniform when this embodiment is applied, this embodiment makes the following further limitations on the basis of Embodiment 1 or Embodiment 2: the stirring mechanism and the cover 2 of this embodiment The number of circular through-holes is three, and the three circular through-holes are equally spaced in the lateral direction of the cover 2, and the stirring rods 3 of the three stirring mechanisms pass through the three circular through-holes in one-to-one correspondence. When this embodiment is applied, the uniformity of the mixed material can be improved by stirring at three places.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com