Anti-aging high-strength natural rubber and preparation method thereof

A natural rubber and high-strength technology, applied in the field of rubber, can solve the problems of natural rubber physical and mechanical properties, poor aging resistance, difficulty in meeting the requirements of high-end products, and affecting the safe supply of national strategic materials, so as to slow down the solidification rate, Effect of prolonging storage time and improving tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

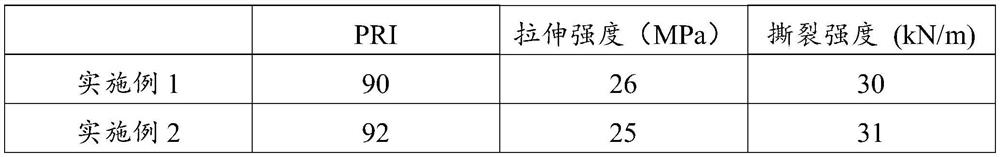

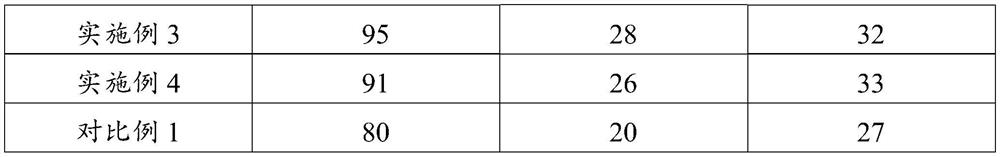

Embodiment 1

[0034] The present embodiment provides a kind of preparation method of aging-resistant high-strength natural rubber, which comprises:

[0035] Adding 15g concentration in 3000g fresh latex is 10wt% ammoniacal liquor, adding 24g concentration is 10wt% hydrogen peroxide, adding 30g concentration is the compound solution of 10wt% trisodium phosphate and dipotassium hydrogen phosphate (trisodium phosphate: dihydrogen phosphate The ratio of potassium is 1: 1), after described latex is processed by centrifuge settler, then add 300g concentration and be the compound solution of 0.1wt% cellulose and nano silicon dioxide (the ratio of cellulose: nano silicon dioxide is 1:1), fresh latex and compound solution were mixed and stirred for 1 hour, then 240g of microbial coagulation solution (yeast: molasses: water ratio of 1:5:100) was added to coagulate, and the curd was matured for 3 days after the coagulation was complete, and then Crepe, wash with water, dry at 160°C for 5 minutes, and ...

Embodiment 2

[0037] Adding 18g concentration is 10wt% ammoniacal liquor at 3000g fresh latex, adding 24g concentration is 10wt% hydrogen peroxide, adding 30g concentration is the compound solution of 10wt% aminoacetic acid and alanine (aminoacetic acid: the ratio of alanine is 1 : 1), after the latex is processed by a centrifugal sedimentation machine, adding 120g concentration is a compound solution of 0.2% cellulose and starch (the ratio of cellulose: starch is 1:1), fresh latex and compound After the solution is mixed and stirred for 2 hours, add 300g of microbial coagulation solution (yeast: molasses: water ratio is 1:5:100) to solidify. After the solidification is complete, the curd is matured for 5 days, then crepeed, washed with water, and dried at 155°C for 10 minutes. Then dry at 80°C to obtain natural rubber samples.

Embodiment 3

[0039] Adding 18g concentration is 10wt% ammoniacal liquor at 3000g fresh latex, adding 15g concentration is 10wt% hydrogen peroxide, adding 24g concentration is the compound solution of 10wt% trisodium phosphate and dipotassium hydrogen phosphate (trisodium phosphate: dipotassium hydrogen phosphate The ratio of cardanol and cashew nut shell oil is 1:1), and after the latex is processed by a centrifugal sedimentation machine, 10 g of a compound solution of 0.3% cardanol and cashew nut shell oil is added (the ratio of cardanol: cashew nut shell oil is 3:1) After mixing the fresh latex and the compound solution and stirring for 3 hours, add 240g of microbial coagulation liquid (yeast: molasses: water ratio of 1:5:100) to solidify. Wash with water, dry at 155°C for 5 minutes, and then dry at 70°C to obtain natural rubber samples.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com