A kind of preparation method of metallurgical exothermic agent for continuous casting end billet

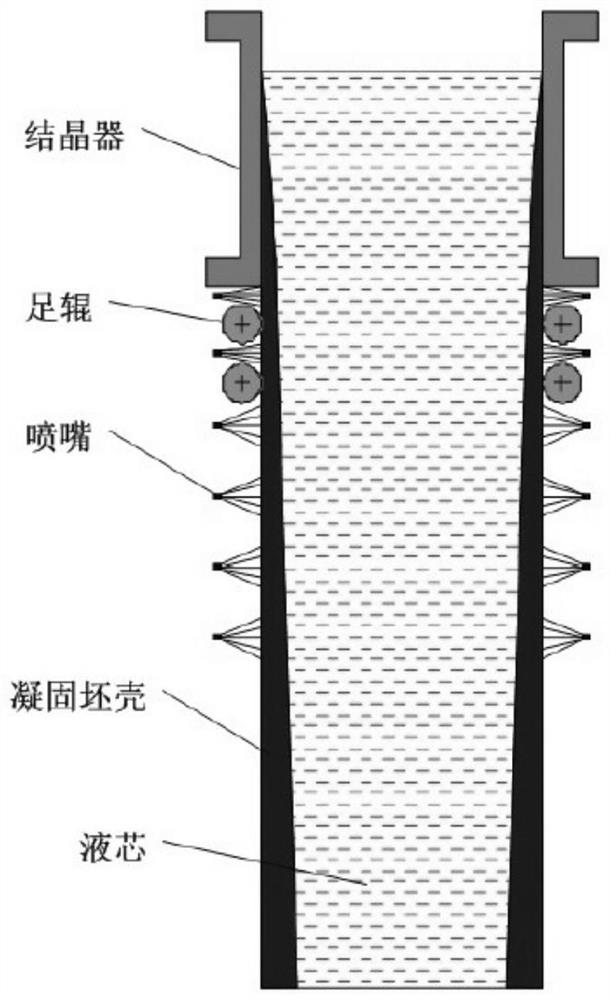

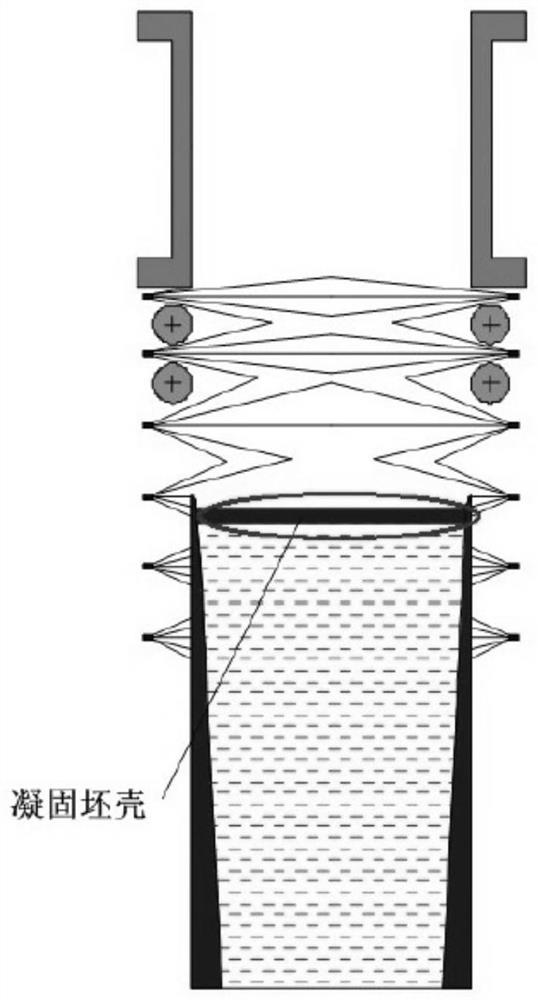

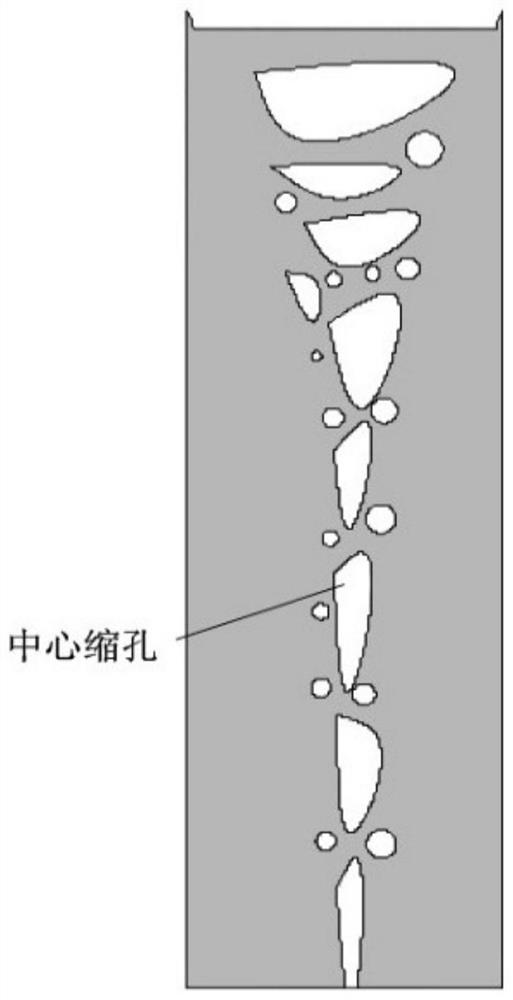

A heat-generating agent and continuous casting technology, applied in the field of metallurgical continuous casting, can solve problems such as quality defects of the casting billet, reduce the amount of cut off the tail end of the continuous casting billet, and reduce the solidification rate of the billet shell of the tail billet, so as to improve the metallurgical effect and reduce the Solidification rate, the effect of reducing central shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039]The preparation method of a metallurgical exothermic agent for continuous casting end billets in this embodiment adopts a metallurgical exothermic agent for continuous casting end billets, and the exothermic agent includes aluminum powder, carbon powder, iron powder, silicon powder, FeO, CaO and The binder, the aluminum powder and carbon powder in the metallurgical exothermic agent are used as the heat supply source in the continuous casting tail billet. The aluminum powder and carbon powder have an exothermic reaction with FeO in the tail billet, and also with FeO undergoes an exothermic reaction, which provides sufficient heat for the continuous casting tail billet, thereby effectively delaying the solidification time of the continuous casting tail billet, which is beneficial for the metallurgical exothermic agent to feed the center of the tail billet.

[0040] The carbon powder and aluminum powder in the metallurgical exothermic agent will form the following exothermic...

Embodiment 2

[0085]The preparation method of a metallurgical exothermic agent for continuous casting end billets in this embodiment is basically the same as that in Example 1, except that the weight percentage of aluminum powder in the metallurgical exothermic agent used in this embodiment is 40%; The weight percentage of powder is 34%; the weight percentage of iron powder is 10%; the weight percentage of silicon powder is 2%; the weight percentage of FeO is 8%; the weight percentage of CaO is 6%; The agent adopts two-component epoxy resin, and the amount of binder is 2ml per 50g of metallurgical exothermic agent.

[0086] In addition, the basicity of the metallurgical exothermic agent in this example is 7.2, and the calcium-aluminum ratio is 1.6.

Embodiment 3

[0088] The preparation method of a metallurgical exothermic agent for continuous casting end billets in this embodiment is basically the same as that in Example 1, except that the weight percentage of aluminum powder in the metallurgical exothermic agent used in this embodiment is 41%; The weight percentage of powder is 35%; the weight percentage of iron powder is 8%; the weight percentage of silicon powder is 2%; the weight percentage of FeO is 9%; the weight percentage of CaO is 5%; The agent is polyurethane, and the amount of the binder is 2ml per 50g of metallurgical exothermic agent.

[0089] In addition, the basicity of the metallurgical exothermic agent of this example is 6.5, and the calcium-aluminum ratio is 1.6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com