Novel Fe-based spherical shielding alloy powder and preparation method thereof

A technology of alloy powder and base alloy, which is applied in the field of new Fe-based spherical shielding alloy powder and its preparation, can solve the problems such as the need to optimize the microscopic uniformity of alloy elements, the limited effect of γ-ray shielding, and the small relative atomic mass, so as to ensure comprehensive Shielding performance, improving corrosion resistance, improving the effect of balanced electrode potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The present invention provides a preparation method of Fe-based shielding alloy powder with high sphericity, high fluidity and excellent comprehensive shielding performance described in the above technical solution, comprising the following steps:

[0050] Under the protection condition of argon, the alloy raw material is smelted and atomized in the atomization equipment, and the sieved atomized powder is subjected to vacuum heat treatment and ball milling to obtain Fe-based alloy shielding powder. The melting temperature is 1600-1700° C.; the atomization pressure of the alloy is 3.5-5.5 MPa; the intermediate heat temperature of the alloy powder is 900-1200° C., and the heat treatment time is 0.5-3 hours. The rotational speed of the ball mill is 50-300r / min, and the milling time is 0.5-3h. The chemical composition of the alloy powder is consistent with the composition of the Fe-based shielding alloy powder described in the above technical solution.

[0051] In the pres...

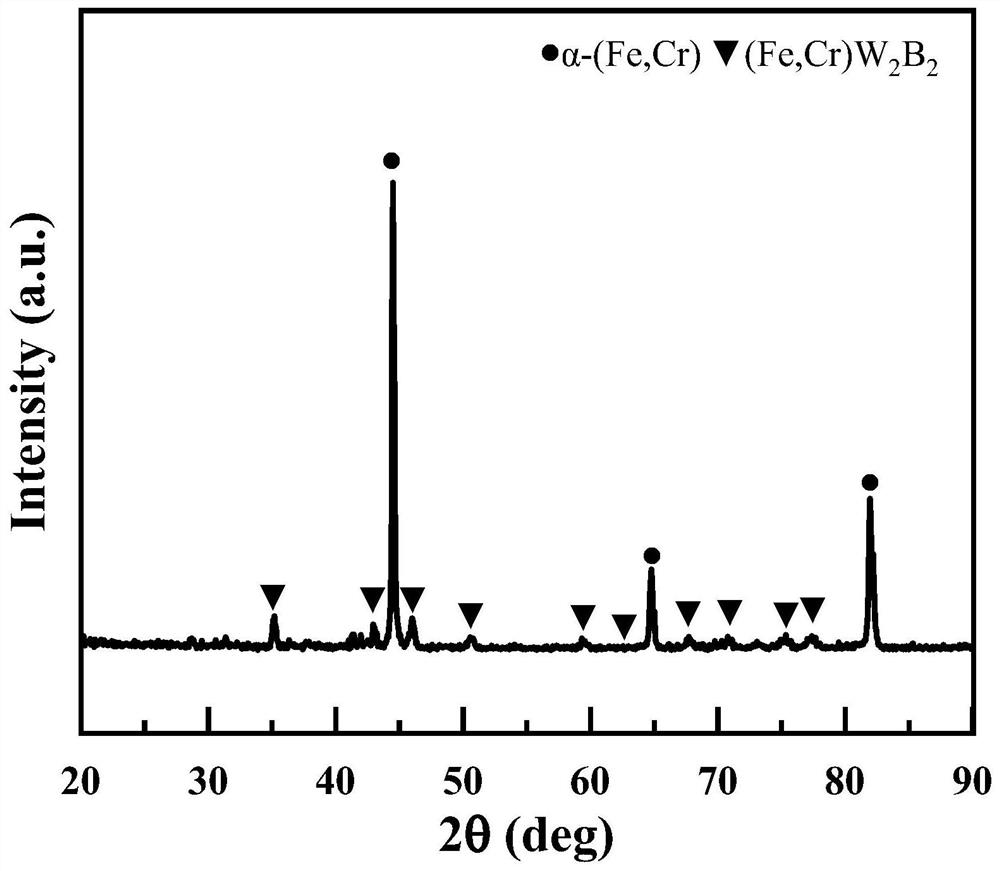

Embodiment 1

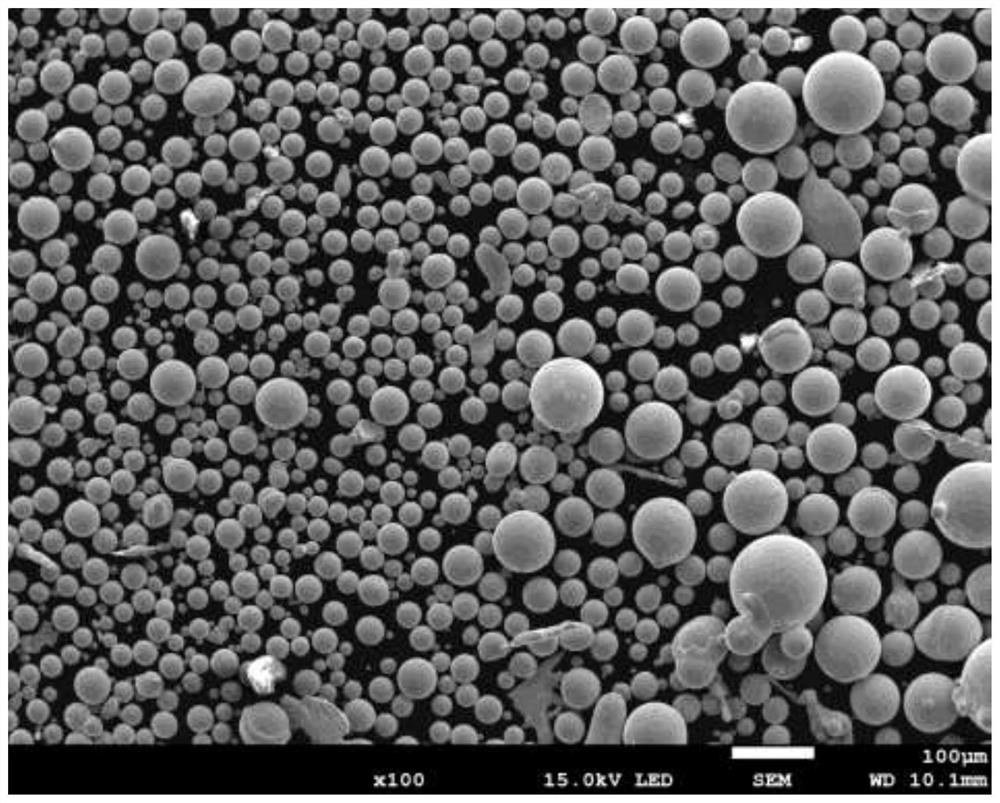

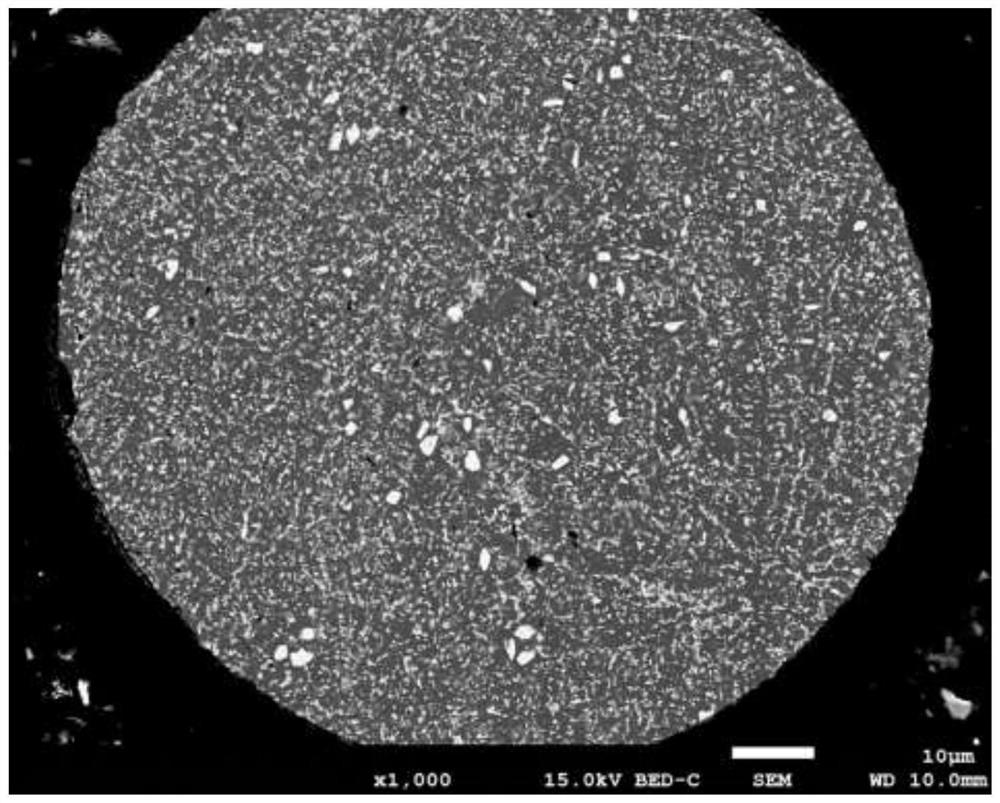

[0066] An Fe-based shielding alloy powder with high sphericity, high fluidity and good comprehensive shielding performance: 67.2% Fe, 13% Cr, 18.7% W, 1.1% B. The preparation method of the alloy is as follows: add industrial pure iron, ferrotungsten, and ferrochrome into the magnesia crucible according to the ratio of ingredients, add ferroboron into the secondary feeding hopper, charge the material tightly, vacuumize until the vacuum degree is 4Pa, and fill Enter argon gas to 0.1MPa (micro positive pressure), smelt at 1650°C until industrial pure iron, ferrotungsten, and ferrochrome are completely melted to form an alloy liquid, add ferroboron in the secondary feeding hopper, and refine for 3 minutes; wait for the alloy liquid After the temperature reaches 1700°C, it is poured into the tundish, and the alloy melt is atomized and powdered with an argon atomization pressure of 4 MPa, and the powder is collected. Subsequently, the collected powder was heat-treated in a vacuum tu...

Embodiment 2

[0070] An Fe-based shielding alloy powder with high sphericity, high fluidity and good comprehensive shielding performance: 65.2% Fe, 15% Cr, 18.7% W, 1.1% B. The preparation method of the alloy is as follows: add industrial pure iron, ferrotungsten, and ferrochrome into the magnesia crucible according to the ratio of ingredients, add ferroboron into the secondary feeding hopper, charge the material tightly, vacuumize until the vacuum degree is 4Pa, and fill Enter argon gas to 0.1MPa (slightly positive pressure), smelt at 1680°C until industrial pure iron, ferrotungsten, and ferrochrome are completely melted to form alloy liquid, add ferroboron in the secondary feeding hopper, and refine for 3 minutes; wait for the alloy liquid After the temperature reaches 1730°C, it is poured into the tundish, and the alloy melt is atomized and powdered with an argon atomization pressure of 4 MPa, and the powder is collected. Subsequently, the collected powder was heat-treated in a vacuum tu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fluidity | aaaaa | aaaaa |

| D50 | aaaaa | aaaaa |

| Fluidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com