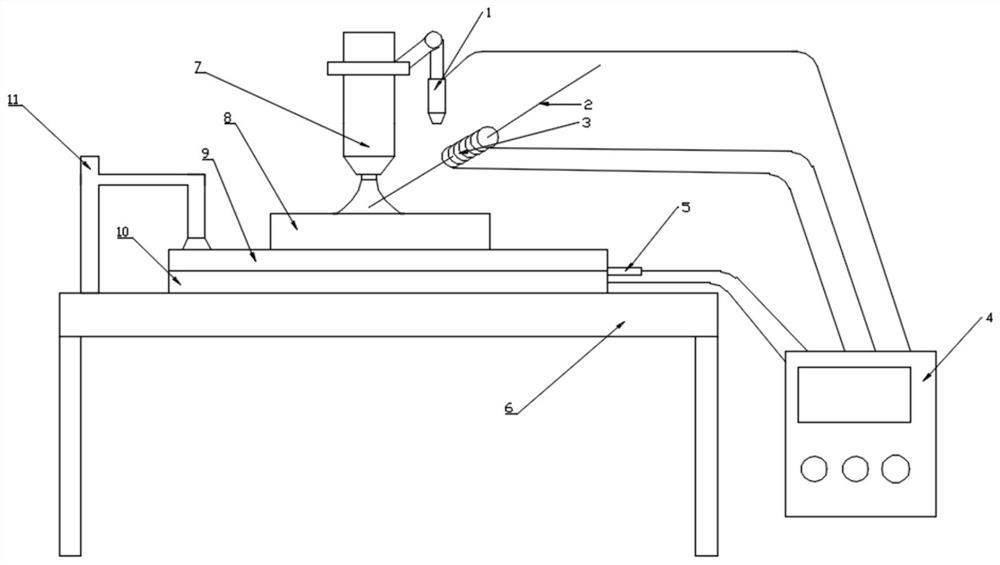

Substrate-wire cooperative preheating device for arc additive manufacturing and method thereof

An additive manufacturing and substrate technology, which is applied in the field of substrate-wire synergistic preheating devices for arc additive manufacturing, can solve the problems of the final quality of the additive components, the inability to spread the deposited metal, and the scrapping of components. Reduce solidification rate, improve heat dissipation, reduce oxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

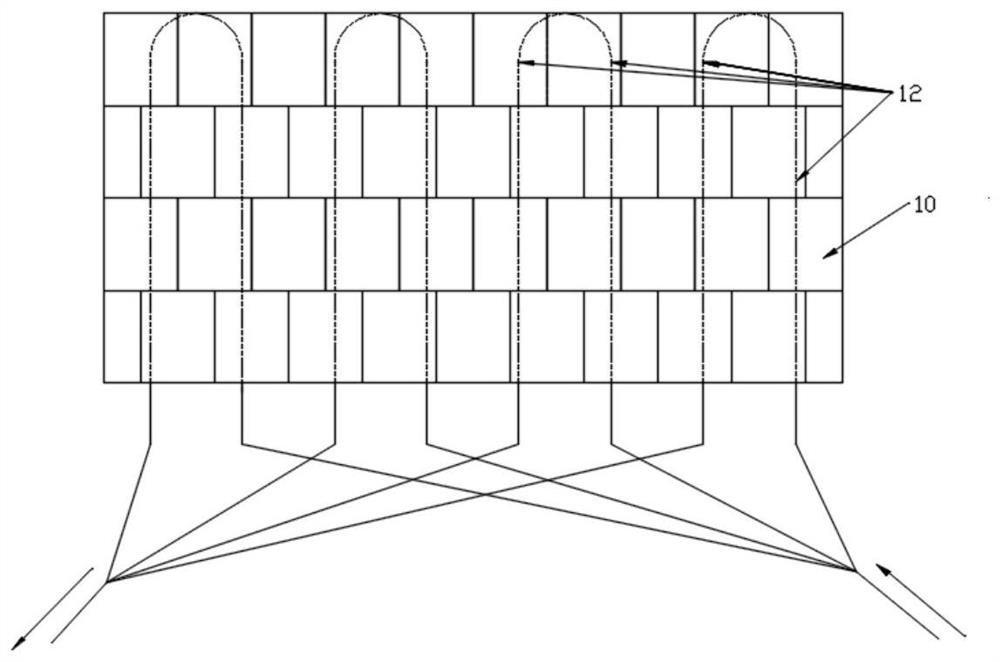

[0035] Select AZ91 magnesium alloy welding wire with a diameter of 1.2mm; 5mm thick AZ91D magnesium alloy substrate additive straight wall as an example. The specific steps are:

[0036] (1) Establish the solid geometric model of the part, import the part model into the computer for slicing and path planning, and set the required additive process parameters;

[0037] (2) Before starting the additive process, let the substrate preheating controller be powered on, and after the power indicator light is on, set the substrate preheating temperature to 150°C through the digital display regulator, and turn on the preheating switch;

[0038] (3) After the preheating indicator light is on, the high thermal resistance wire in the ceramic chip preheater starts to heat up, and the heat is transferred to the substrate. The thermocouple temperature sensor placed between the substrate and the ceramic chip transmits the temperature data to the substrate preheating controller. When the therm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com