Self-healing coating for improving surface quality and preparation method thereof

A surface quality, self-healing technology, applied in the coating, metal material coating process, fusion spraying, etc., can solve the problems of reducing the mechanical properties of the base material, poor corrosion resistance of the coating, and damage to the coating surface, etc., to achieve Realize the crack gradient healing effect, enhance the bonding strength, and improve the overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

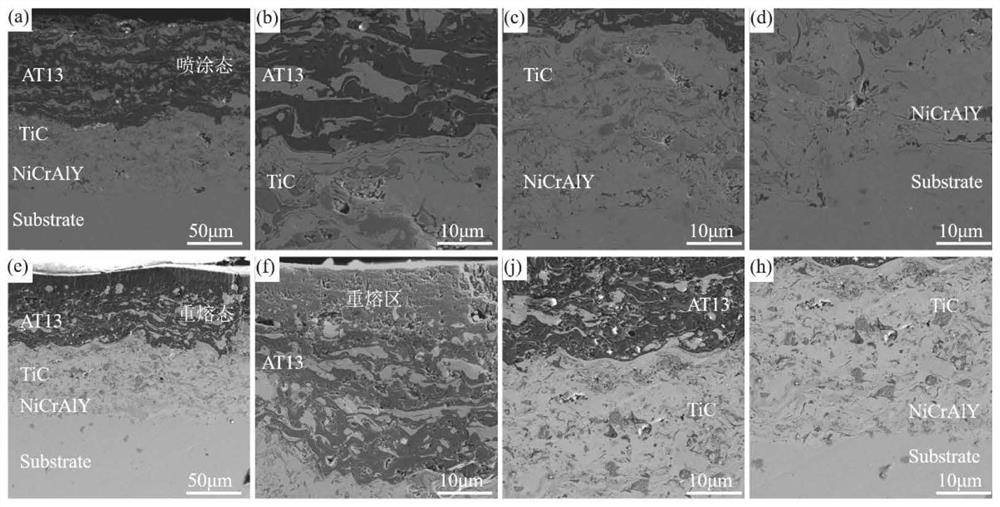

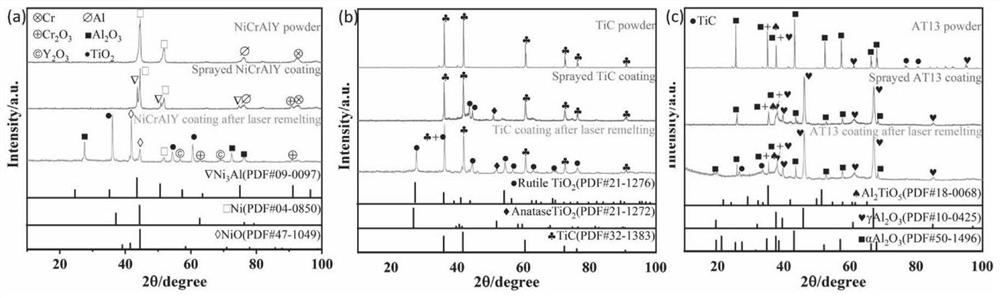

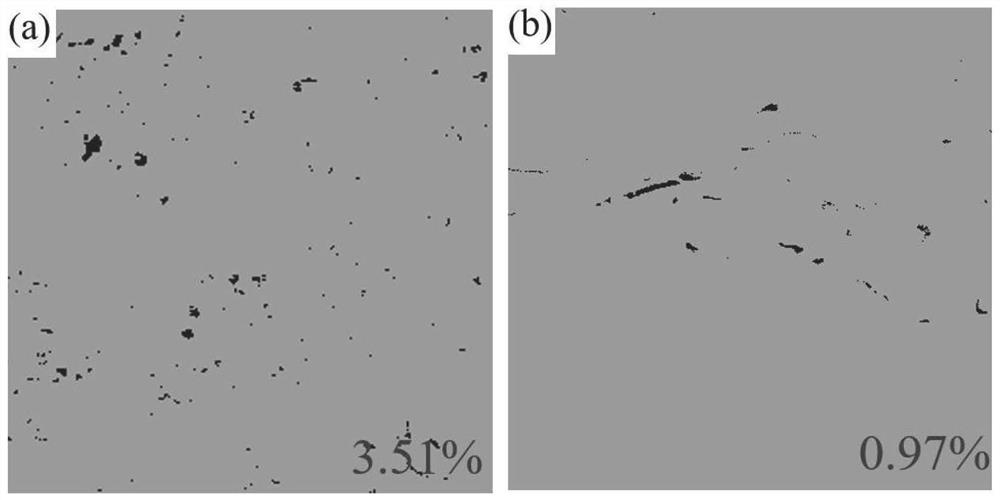

Embodiment 1

[0047] (1) Surface mechanical polishing: The hot-rolled austenitic stainless steel samples are polished with sandpapers of different particle sizes (80#~1200#) until there are no obvious scratches visible to the naked eye, and then cleaned with acetone for 5~20min in ultrasonic waves to remove oil , ultrasonic cleaning with absolute ethanol for 5 to 20 minutes, remove stains, and finally put it in a drying oven at 80 ° C for drying for 20 to 40 minutes; (among which 321 austenitic stainless steel is a rolled sheet, and the mass fraction of its chemical composition is C 0.04%, Si 0.38 %, Mn 1.08%, Cr 17.02%, Ni9.06%, N 0.05%, P 0.03%, Ti 0.22%, the rest is Fe. The mechanical properties of 321 stainless steel at room temperature are: tensile strength (σb) 667MPa, yield strength (σ0.2) 245MPa, elongation 56.5%, hardness 175HV.) The chromium hardness of the base metal should be less than 40, and if the hardness is too high, it is not conducive to the bonding between the coating and...

Embodiment 2

[0055] (1) Surface mechanical polishing: The hot-rolled austenitic stainless steel samples are polished with sandpapers of different particle sizes (80#~1200#) until there are no obvious scratches visible to the naked eye, and then cleaned with acetone for 5~20min in ultrasonic waves to remove oil , ultrasonic cleaning with absolute ethanol for 5 to 20 minutes, remove stains, and finally put it in a drying oven at 80 ° C for drying for 20 to 40 minutes; (among which 321 austenitic stainless steel is a rolled sheet, and the mass fraction of its chemical composition is C 0.04%, Si 0.38 %, Mn 1.08%, Cr17.02%, Ni9.06%, N 0.05%, P 0.03%, Ti 0.22%, the rest is Fe. The mechanical properties of 321 stainless steel at room temperature are: tensile strength (σb) 667MPa, yield Strength (σ0.2) 245MPa, elongation 56.5%, hardness 175HV.) The chromium hardness of the base metal should be less than 40, and if the hardness is too high, it is not conducive to the bonding between the coating and ...

Embodiment 3

[0063] (1) Surface mechanical polishing: The hot-rolled austenitic stainless steel samples are polished with sandpapers of different particle sizes (80#~1200#) until there are no obvious scratches visible to the naked eye, and then cleaned with acetone for 5~20min in ultrasonic waves to remove oil , ultrasonic cleaning with absolute ethanol for 5 to 20 minutes, remove stains, and finally put it in a drying oven at 80 ° C for drying for 20 to 40 minutes; (among which 321 austenitic stainless steel is a rolled sheet, and the mass fraction of its chemical composition is C 0.04%, Si 0.38 %, Mn 1.08%, Cr17.02%, Ni9.06%, N 0.05%, P 0.03%, Ti 0.22%, the rest is Fe. The mechanical properties of 321 stainless steel at room temperature are: tensile strength (σb) 667MPa, yield Strength (σ0.2) 245MPa, elongation 56.5%, hardness 175HV.) The chromium hardness of the base metal should be less than 40, and if the hardness is too high, it is not conducive to the bonding between the coating and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com