Polycarboxylate water reduction agent having high heat stability modification and preparation method of polycarboxylate water reduction agent

A high thermal stability, polycarboxylic acid technology, applied in the field of water reducing agent, can solve the problems of far-flung concrete slump retention, insufficient slump retention, strong temperature sensitivity, etc., to slow down the concrete solidification rate and long acting time , The effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

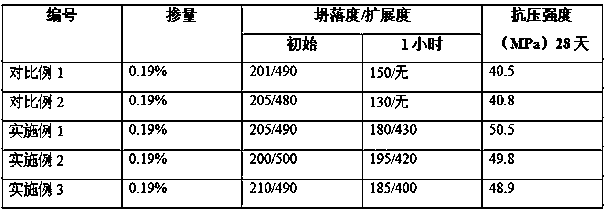

Examples

Embodiment 1

[0019] Weighing: methacrylic acid 25kg, allyl polyoxyethylene ether 32kg, water-based polyurethane emulsion 40kg, hexafluorobutyl methacrylate 8kg, potassium permanganate 0.2kg, citric acid 0.5kg, aluminum isopropoxide 0.4kg , 40 kg of deionized water, 2 kg of guar gum solution with a concentration of 15%, and 1 kg of nitric acid solution with a concentration of 2%.

[0020] A preparation method of polycarboxylate water reducer with high thermal stability modification, comprising the following steps:

[0021] a) First put aluminum isopropoxide into 5kg of deionized water, after it is completely dissolved, add nitric acid solution, stir and mix for 40 minutes, then add guar gum solution, continue to stir and mix for 30 minutes, the obtained first mixture is ready for use.

[0022] b) Put the water-based polyurethane emulsion into a four-neck flask, add hexafluorobutyl methacrylate dropwise, stir and mix at high speed for 1 hour, then heat the reaction system to 55°C, react for ...

Embodiment 2

[0027] Weighing: methacrylic acid 35kg, isopentenol polyoxyethylene ether 46kg, water-based polyurethane emulsion 50kg, hexafluorobutyl methacrylate 10kg, potassium permanganate 0.5kg, H 2 o 2 -V C 1kg, 0.5kg of aluminum isopropoxide, 65kg of deionized water, 5kg of locust bean gum with a concentration of 15%, and 1kg of nitric acid solution with a concentration of 5%.

[0028] A preparation method of polycarboxylate water reducer with high thermal stability modification, comprising the following steps:

[0029] a) First put aluminum isopropoxide into 10kg of deionized water, after it is completely dissolved, add nitric acid solution, stir and mix for 50 minutes, then add locust bean gum solution, continue to stir and mix for 40 minutes, the obtained first mixture is ready for use.

[0030] b) Put the water-based polyurethane emulsion into a four-necked flask, add hexafluorobutyl methacrylate dropwise, stir and mix at high speed for 2 hours, then heat the reaction system to...

Embodiment 3

[0035] 30kg of methacrylic acid, 40kg of allyl alcohol polyoxyethylene ether, 45kg of water-based polyurethane emulsion, 9kg of hexafluorobutyl methacrylate, 0.3kg of potassium permanganate, 0.7kg of citric acid, 0.45kg of aluminum isopropoxide, deionized 60kg of water, 3kg of guar gum with a concentration of 13%, and 1kg of nitric acid solution with a concentration of 1%.

[0036] A preparation method of polycarboxylate water reducer with high thermal stability modification, comprising the following steps:

[0037] a) First put aluminum isopropoxide into 8kg of deionized water, after it is completely dissolved, add nitric acid solution, stir and mix for 45 minutes, then add guar gum with a concentration of 13%, and continue to stir and mix for 35 minutes to obtain the first mixed material spare.

[0038] b) Put the water-based polyurethane emulsion into a four-necked flask, add hexafluorobutyl methacrylate dropwise, stir and mix at high speed for 1.5h, then heat the reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com