High-strength and high-temperature alloy for thermal power generating unit and processing technology of high-strength and high-temperature alloy

A technology for thermal power units and high-temperature alloys, applied in the field of materials and material preparation, can solve the problems of poor structure stability and corrosion resistance, high performance, low thermal strength, etc., and achieve the effect of excellent high-temperature strength performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

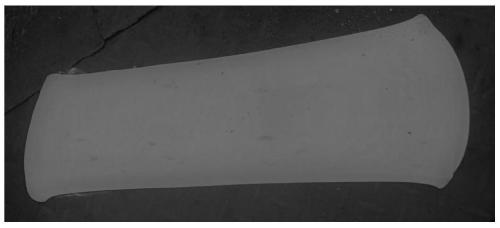

Image

Examples

preparation example Construction

[0028] The above-mentioned alloy preparation process mainly includes three steps of alloy melting, deformation and heat treatment, as follows:

[0029] (1) Smelting and homogenization treatment: the above-mentioned alloys are smelted in an induction electric arc furnace, the induction electric arc furnace is made of magnesium oxide basic furnace lining, the furnace is washed with pure nickel before smelting, and the alloy raw materials are subjected to shot blasting treatment before adding the alloy raw materials; the vacuum degree is controlled at Within the range of 0.3-0.5Pa, after Cr, Ni, W, Si, Mn, Mo and Fe in the alloy are completely melted, refine for 0.5-1h, and then add Al, Ti, B, Zr and C, and casting; after solidification, the ingot is homogenized in the range of 1050-1120 °C for 24-72 hours and then air-cooled to room temperature;

[0030] (2) Forging blanking: The alloy smelted and homogenized in step (1) is subjected to blank forging at 200-250°C above the γ' pr...

Embodiment 1

[0037] The high-strength high-temperature alloy for thermal power units of this embodiment comprises: C: 0.06%, Cr: 16%, Mn: 0.2%, Si: 0.15%, W: 1.6%, Mo: 1.2%, Ti: 2.2% by mass percentage %, Al: 1.4%, B: 0.002%, Zr: 0.02%, Fe: 37%, and the balance is Ni.

[0038] Alloy smelting adopts magnesium oxide basic furnace lining, and pure nickel is used to wash the furnace before smelting, and shot blasting is carried out before alloy raw materials are added. The alloy is smelted in an induction arc furnace, and the vacuum degree is controlled at 0.35Pa. After Cr, Ni, W and other elements are completely melted, it is refined for 40 minutes, and high-purity argon is introduced before adding Al, Ti, B, Zr, and C for protection. Add coke for deoxidation after Cr, Ni, W and other alloy raw materials are completely melted. , Zr, C and other elements that are easy to burn out, after stirring for 5 minutes, they are released from the furnace, and the casting temperature is 1630°C. Alloy c...

Embodiment 2

[0042] The high-strength superalloy of this embodiment includes: C: 0.07%, Cr: 15%, Mn: 0.2%, Si: 0.15%, W: 2.2%, Mo: 0.4%, Ti: 2.2%, Al: 1.4%, B: 0.002%, Zr: 0.02%, Fe: 47%, and the balance is Ni. Alloy smelting adopts magnesium oxide basic furnace lining, and pure nickel is used to wash the furnace before smelting, and shot blasting is carried out before alloy raw materials are added. The alloy is smelted in an induction arc furnace, and the vacuum degree is controlled at 0.35Pa. After Cr, Ni, W and other elements are completely melted, it is refined for 40 minutes, and high-purity argon is introduced before adding Al, Ti, B, Zr, and C for protection. Add coke for deoxidation after Cr, Ni, W and other alloy raw materials are completely melted, and the added mass should not exceed 40% of the mass of C element in the alloy raw material. After completion, add Ni-Mg alloy for secondary deoxidation, and finally add Al, Ti, B , Zr, C and other easily burnt elements, after stirrin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com