Stirring and mixing mechanism applied to industrial construction

A stirring mechanism and technology in construction, applied in mixers, mixers, dissolving and other directions with a rotating stirring device, can solve the problems that the mixed materials cannot be reused, the mixed materials are easy to coagulate, and are not easy to separate, etc. The rate of solidification, the effect of avoiding waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

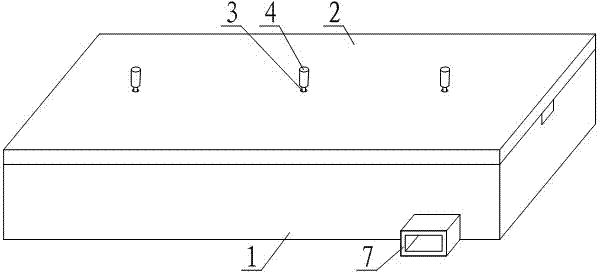

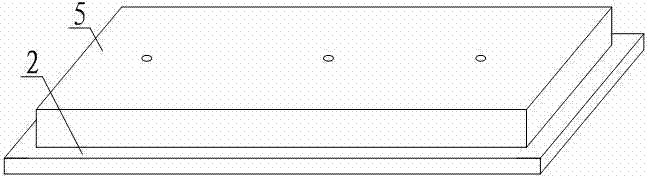

[0016] like figure 1 and figure 2 As shown, the mechanism used for mixing ingredients in industrial construction includes a storage container 1, a cover 2 and a stirring mechanism, wherein the storage container 1 is formed in a rectangular shape, and the upper end surface of the storage container 1 is concave to form a rectangular groove, and the cover 2 The lower end surface is downwardly convex to form a rectangular protrusion 5 , the rectangular protrusion 5 matches the length and width of the rectangular groove, and the rectangular protrusion 5 is embedded in the rectangular groove and closes the upper opening of the rectangular groove. The stirring mechanism of this embodiment includes a stirring rod 3, the cover 2 is formed with a circular through hole passing through its upper and lower end surfaces, and the lower end of the stirring rod 3 passes through the circular through hole and is located in a rectangular groove. In order to facilitate the discharge of the mixed...

Embodiment 2

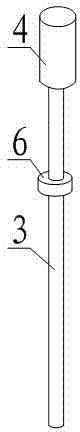

[0019] like image 3 As shown, in order to make the operation of this embodiment convenient and convenient, this embodiment makes the following further limitations on the basis of Embodiment 1: the stirring mechanism of this embodiment also includes a handle 4 and a sleeve connected to the upper end of the stirring rod 3 The limit ring 6 provided on the stirring rod 3, wherein the limit ring 6 is located in the rectangular groove, and the diameter of the outer ring of the limit ring 6 is larger than the diameter of the circular through hole.

Embodiment 3

[0021] In order to make the mixing of the mixed materials in the rectangular groove more uniform when this embodiment is applied, this embodiment makes the following further limitations on the basis of Embodiment 1 or Embodiment 2: the stirring mechanism and the cover 2 of this embodiment The number of circular through holes is three, and the three circular through holes are equally spaced in the lateral direction of the cover 2, and the stirring rods 3 of the three stirring mechanisms pass through the three circular through holes in one-to-one correspondence. When this embodiment is applied, the uniformity of the mixed material can be improved by stirring at three places.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com