Anti-curling low-solidification-rate PU resin and preparation method thereof

A PU resin, low solidification technology, applied in coatings, textiles and papermaking, etc., can solve the problems of wasting manpower and material resources of synthetic leather factories, soft synthetic leather, darkened surface gloss, etc., and achieve good resilience performance , excellent physical properties and high economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

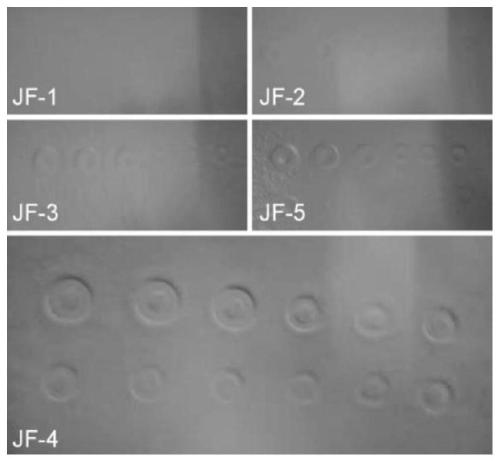

Image

Examples

Embodiment 1

[0022] Example 1: Take 250g of 4000 molecular weight polyester polyol (PEBA-4000) and put it into a 2000mL glass reactor, then add 0.001g of phosphoric acid, 0.2g of antioxidant BHT, 44g of BDO and 500g of solvent DMF into it, and stir thoroughly for 30min Then put in MDI (R value is set to 1), and then raise the temperature to 75-80°C to make it react to increase viscosity. During the reaction process, a small amount of MDI can be added in an appropriate amount. During the thickening process, DMF is continuously added to the reactor for dilution. After the thickening reaction is completed, methanol is used to terminate the reaction. Half an hour after the methanol is terminated, 0.5g of malic acid is added to prevent it from reducing viscosity. After continuing to stir for 1 hour, pack the resin in the glass reactor. The final viscosity of the resin is 200,000-240,000 (cps / °C), and the solid content is 29.5-30.5%. The resin is named JF-1.

Embodiment 2

[0023] Embodiment 2: Get 250g 4000 molecular weight polyester polyol (PBHA-4000) and drop in the 2000mL glass reactor, then add 0.001g phosphoric acid, 0.2g antioxidant BHT, 30.3g EG and 500g solvent DMF to it respectively, fully After stirring for 30 minutes, add MDI (set the R value to 1), and then raise the temperature to 75-80°C to make it react to increase viscosity. During the reaction process, a small amount of MDI can be added in an appropriate amount. During the thickening process, DMF is continuously added to the reactor for dilution. After the thickening reaction is completed, methanol is used to terminate the reaction. Half an hour after the methanol is terminated, 0.5g of malic acid is added to prevent it from reducing viscosity. After continuing to stir for 1 hour, pack the resin in the glass reactor. The final viscosity of the resin is guaranteed to be 200,000-240,000 (cps / °C), and the solid content is 29.5-30.5%. The resin is named JF-2.

Embodiment 3

[0024] Example 3: Put 250g of 4000 molecular weight polyester polyol (125g PEBA-4000+125g PBHA-4000) into a 2000mL glass reactor, and then add 0.001g of phosphoric acid, 0.2g of antioxidant BHT, and 20.2g of EG , 14.6g BDO and 500g solvent DMF, stir well for 30min and then put into MDI (R value is set to 1), then raise the temperature to 75-80°C to make it react to increase viscosity. During the reaction process, a small amount of MDI can be added in an appropriate amount. During the thickening process, DMF is continuously added to the reactor for dilution. After the thickening reaction is completed, methanol is used to terminate the reaction. Half an hour after the methanol is terminated, 0.5g of malic acid is added to prevent it from reducing viscosity. After continuing to stir for 1 hour, pack the resin in the glass reactor. The final viscosity of the resin is guaranteed to be 200,000-240,000 (cps / °C), and the solid content is 29.5-30.5%. The resin is named JF-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com