Preparation method for rare earth ferrous alloy compound with NaZn13 type structure

An iron-based alloy and compound technology, which is applied in the field of preparation of rare earth iron-based alloy compounds, can solve the problems of high temperature and long-term annealing, expensive preparation equipment, reduced practicability, etc., and achieves improved composition uniformity, simplified preparation process, and prolonged residence time. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

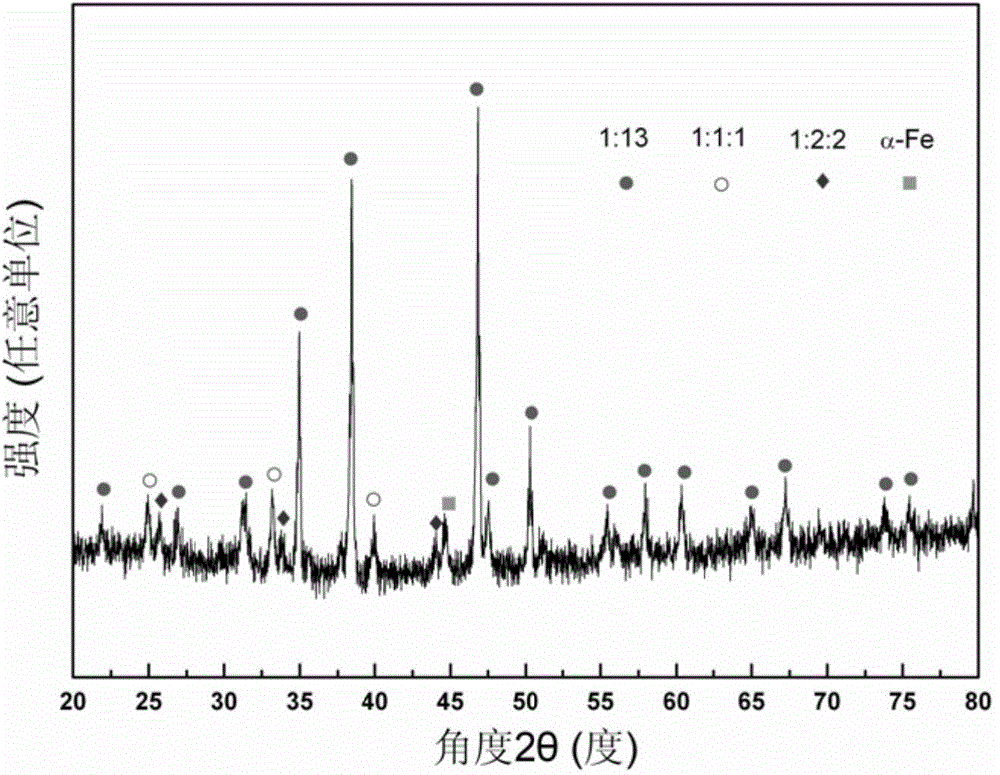

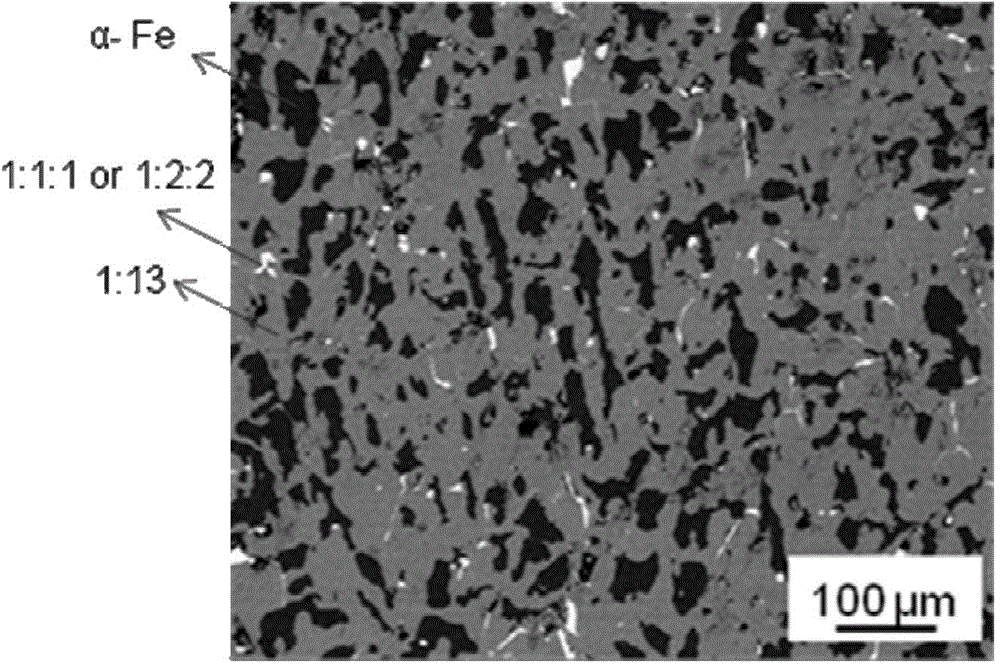

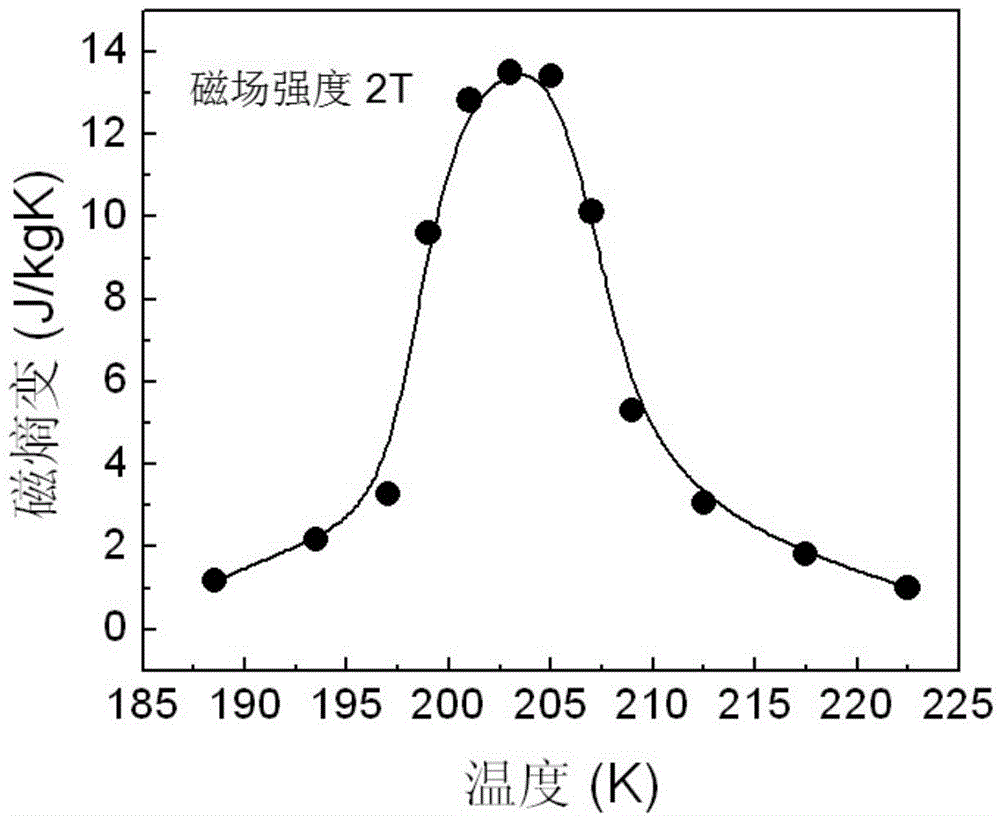

[0030] In this embodiment, the rare earth iron-based alloy compound is LaFe 11.6 Si 1.4 , the preparation process of the rare earth iron-based alloy compound is as follows:

[0031] (1) According to the chemical formula LaFe 11.6 Si 1.4 The elements and their content are weighed, and the metal La, Fe and Si raw materials with a purity higher than 99.9wt% are uniformly mixed;

[0032] (2) Place the mixture obtained in step (1) in a vacuum induction furnace and evacuate until the vacuum degree is less than 1×10 -2 Pa, cleaning the furnace chamber with high-purity argon gas with a purity greater than 99wt% for 1 to 2 times, then filling the furnace chamber with the argon gas to a pressure of 0.5 atmospheres, and then energizing induction melting to obtain alloy ingots;

[0033] (3) The alloy ingot obtained in step (2) is placed in a directional solidification device, the bottom end of the alloy ingot contacts the Ga-In alloy cooling liquid surface, and the alloy ingot on the ...

Embodiment 2

[0037] In this embodiment, the rare earth iron-based alloy compound is La 0.8 (CePrNd) 0.2 Fe 11.4 Si 1.6 B 0.3 , the preparation process of the rare earth iron-based alloy compound is as follows:

[0038] (1) According to the chemical formula La 0.8 (CePrNd) 0.2 Fe 11.4 Si 1.6 B 0.3 The elements and their content are weighed, and the metal La, Ce, Pr, Nd with a purity higher than 99.9wt% and Fe, Si and FeB alloy raw materials are mixed, wherein the FeB alloy is used to provide B;

[0039] (2) Place the mixture obtained in step (1) in a vacuum induction furnace and evacuate until the vacuum degree is less than 1×10 -2 Pa, cleaning the furnace chamber with high-purity argon gas with a purity greater than 99wt% for 1 to 2 times, then filling the furnace chamber with the argon gas to a pressure of 1.5 atmospheres, and then energizing induction melting to obtain alloy ingots;

[0040] (3) The alloy ingot obtained in step (2) is placed in a directional solidification devi...

Embodiment 3

[0043] In this embodiment, the rare earth iron-based alloy compound is La 0.99 Ce 0.01 Fe 11.5 al 1.5 C 0.01 , the preparation process of the rare earth iron-based alloy compound is as follows:

[0044] (1) According to the chemical formula La 0.99 Ce 0.01 Fe 11.5 al 1.5 C 0.01 The elements and content of the material are weighed, and the metal La, Ce, Fe, Al and FeC alloy raw materials with a purity higher than 99.9wt% are mixed, and the FeC alloy is used to provide C;

[0045] (2) Place the mixture obtained in step (1) in a vacuum induction furnace and evacuate until the vacuum degree is less than 1×10 -2 Pa, cleaning the furnace chamber with high-purity argon gas with a purity greater than 99wt% for 1 to 2 times, then filling the furnace chamber with the argon gas to 1 atmospheric pressure, and then electrifying and induction melting to obtain alloy ingots;

[0046] (3) The alloy ingot obtained in step (2) is placed in a directional solidification device, the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com