Preparation method of polyacrylonitrile precursor

A technology of polyacrylonitrile spinning and polyacrylonitrile, which is applied in the direction of spinning solution preparation and wet spinning, which can solve the problems of poor performance of raw silk and achieve the effects of excellent performance, easy operation and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1, the preparation of polyacrylonitrile precursor

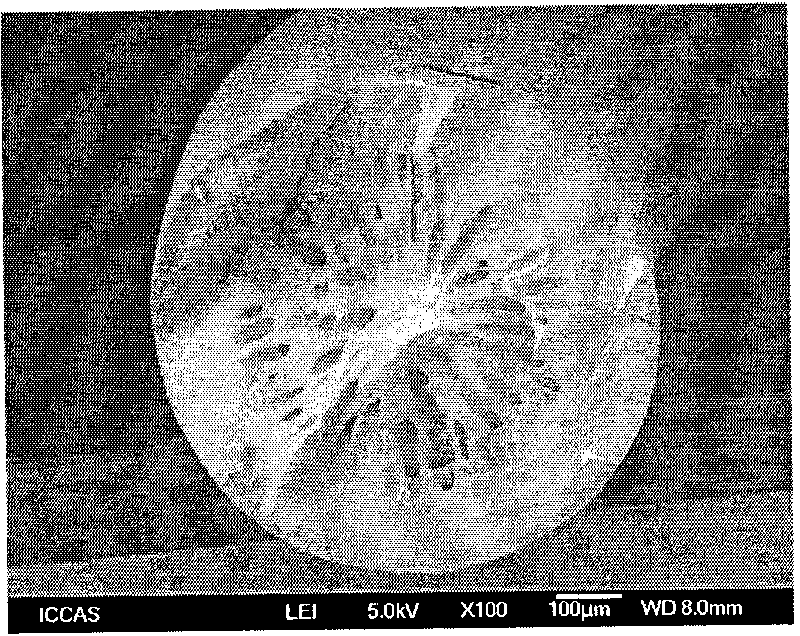

[0038] With the 45wt% sodium thiocyanate solution that contains 17wt% acrylonitrile-itaconic acid-methyl acrylate terpolymer (wherein, the molar percentage composition of each monomer is respectively 95%, 1% and 4%), adopt Dry-jet wet spinning, after the spinning solution leaves the spinneret hole, it is coagulated in a n-butanol coagulation bath at 2°C for about 1.0 min to obtain primary gel filaments. The obtained primary gel filaments are further coagulated through a 30 wt % sodium thiocyanate aqueous solution coagulation bath at 50° C. to obtain coagulated filaments. After the coagulated filaments are taken out of the sodium thiocyanate aqueous solution coagulation bath, they are washed with water at a temperature of 60°C. After washing with water, the washed silk is dried in a blast drying oven at 80°C for 1 hour to obtain a polyacrylonitrile raw silk. The SEM photograph of gained polyacrylonitrile pr...

Embodiment 2

[0039] Embodiment 2, the preparation of polyacrylonitrile precursor

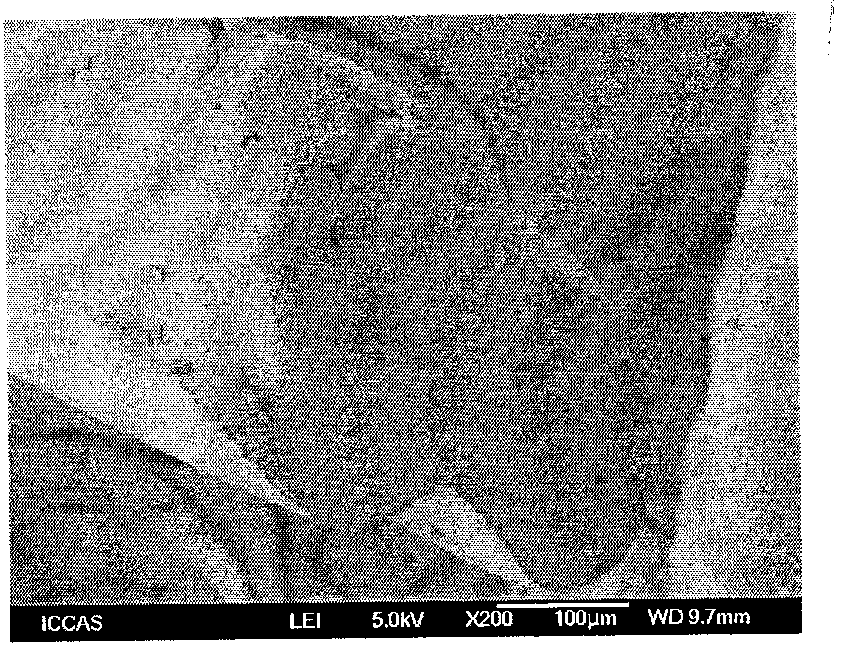

[0040]With the 50wt% sodium thiocyanate solution that contains 17wt% acrylonitrile-itaconic acid-methyl acrylate terpolymer (wherein, the molar percentage composition of each monomer is respectively 96%, 2% and 2%), adopt Dry-jet wet spinning, after the spinning solution leaves the spinneret hole, the aliphatic alcohol coagulation bath composed of n-butanol and 30wt% sodium thiocyanate aqueous solution (wherein, n-butanol and 30wt% sodium thiocyanate The mass fraction ratio of the aqueous solution is 4:1), and the primary gel filaments are obtained after coagulating for about 10.0 min. The obtained primary gel strands are then passed through the first-stage coagulation bath of 25wt% sodium thiocyanate aqueous solution at 30°C and the second-stage coagulation bath of 15wt% sodium thiocyanate aqueous solution at 20°C, and are further coagulated to obtain Solidified strands. After the solidified filaments are...

Embodiment 3

[0041] Embodiment 3, the preparation of polyacrylonitrile precursor

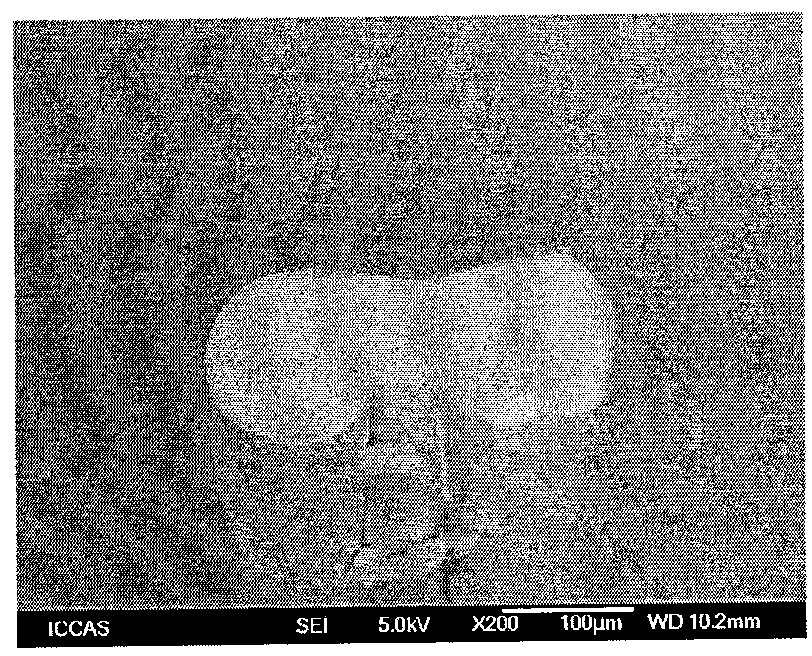

[0042] With the 65wt% nitric acid aqueous solution that contains 30wt% acrylonitrile-itaconic acid binary copolymer (wherein, the molar percentage composition of each monomer is 98% and 2% and respectively), adopt dry-jet wet spinning method to spin, spin The silk liquid leaves the spinneret hole, and first coagulates in a coagulation bath composed of isobutanol and 60% nitric acid aqueous solution (wherein, the mass fraction ratio of isobutanol and 60% nitric acid aqueous solution is 97:3) at 25 ° C for about 6 minutes to obtain primary Gel strands. The resulting primary gel strands are then passed through the first stage coagulation bath of 50wt% nitric acid aqueous solution at 50°C, the second stage coagulation bath of 30wt% nitric acid aqueous solution at 30°C and the 15wt% nitric acid aqueous solution at 20°C The third coagulation bath is further coagulated to obtain coagulated filaments. After the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com