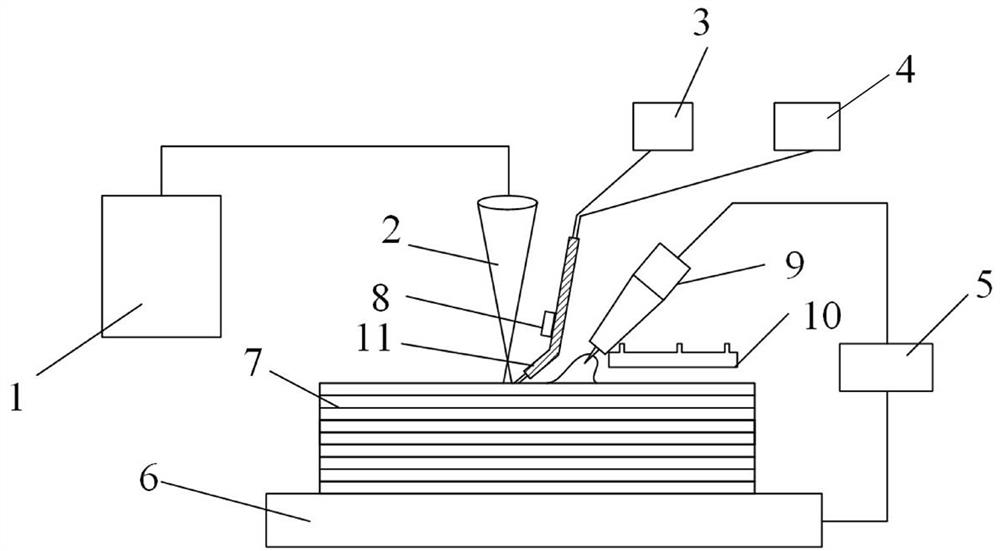

Heterogeneous intermetallic compound additive processing equipment and processing method thereof

A technology of dissimilar metals and processing equipment, applied in metal processing equipment, additive processing, welding equipment and other directions, can solve the problems of component segregation of complex special-shaped components, hindered stability of molten pool, affecting the performance of complex special-shaped components, etc. It is conducive to the uniform mixing of elements, slowing down the solidification rate and prolonging the existence time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] This embodiment provides a heterogeneous intermetallic compound additive processing method.

[0073] In this example, a TiAl intermetallic compound member having a length of 150 mm, a width of 3 mm and a height of 50 mm was fabricated.

[0074] A heterogeneous intermetallic compound additive processing method, comprising the following steps:

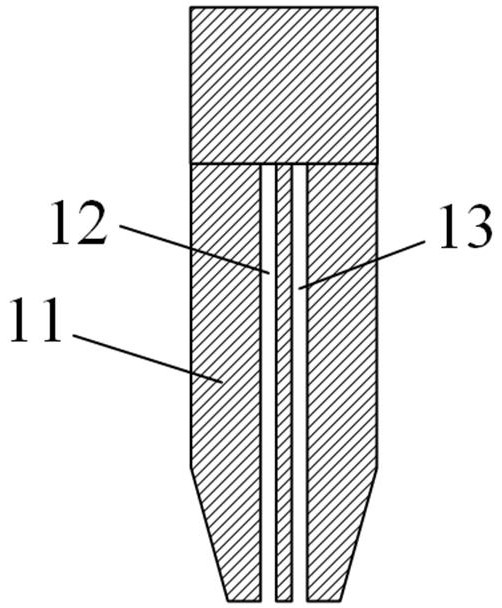

[0075]The first welding power source 1 is selected as a laser, and the second welding power source is selected as a TIG arc heat source.

[0076] Step 1: Select a pure titanium plate with a thickness of 10 mm for the substrate, install and fix the substrate on the heating plate 6, and the heating plate 6 works and heats the pure titanium plate to 450° C. and then starts to keep warm.

[0077] Step 2: Load the trajectory of the additive sample into the control system, and determine the starting and ending positions. The control system can control the movement of the multi-directional motion mechanism according to the trajectory of...

Embodiment 2

[0088] This embodiment provides a heterogeneous intermetallic compound additive processing method.

[0089] In this example, a TiAl intermetallic compound member having a length of 150 mm, a width of 3 mm and a height of 50 mm was fabricated. A heterogeneous intermetallic compound additive processing method in this embodiment is basically the same as that in Embodiment 1, except that in Embodiment 2, the first welding power source 1 is selected as a TIG arc heat source, and the second welding power source is a TIG arc heat source. Among them, in the first welding power source 1, the peak current of the pulsed TIG arc is 250A, the base value current is 70A, the duty ratio is 60%, and the pulse frequency is 150Hz. Other steps and parameter settings in Example 2 are the same as those in Example 1. The TiAl intermetallic compound component of this embodiment has a uniform structure and no cracks.

Embodiment 3

[0091] This embodiment provides a heterogeneous intermetallic compound additive processing method.

[0092] The purpose of this example is to carry out surface cladding and deposition on the surface of the substrate (titanium plate).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com