Feeding device of building concrete

A technology for concrete and construction, applied in the processing of building materials, construction, building structure, etc., can solve the problems of easy solidification of concrete, inflexible adjustment of concrete heating force, waste of concrete, etc., to prevent solidification, fast and convenient cleaning, reduce wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

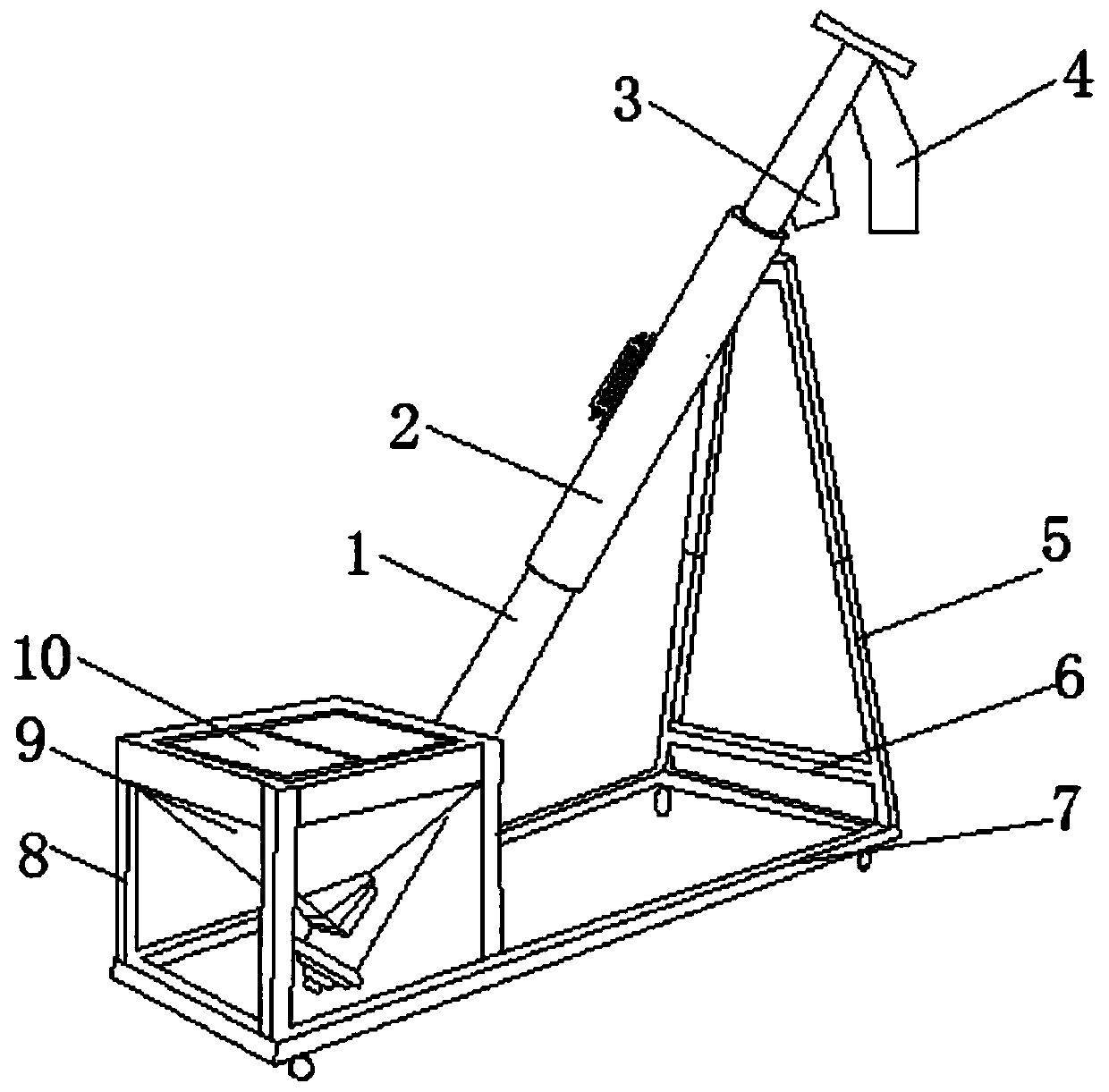

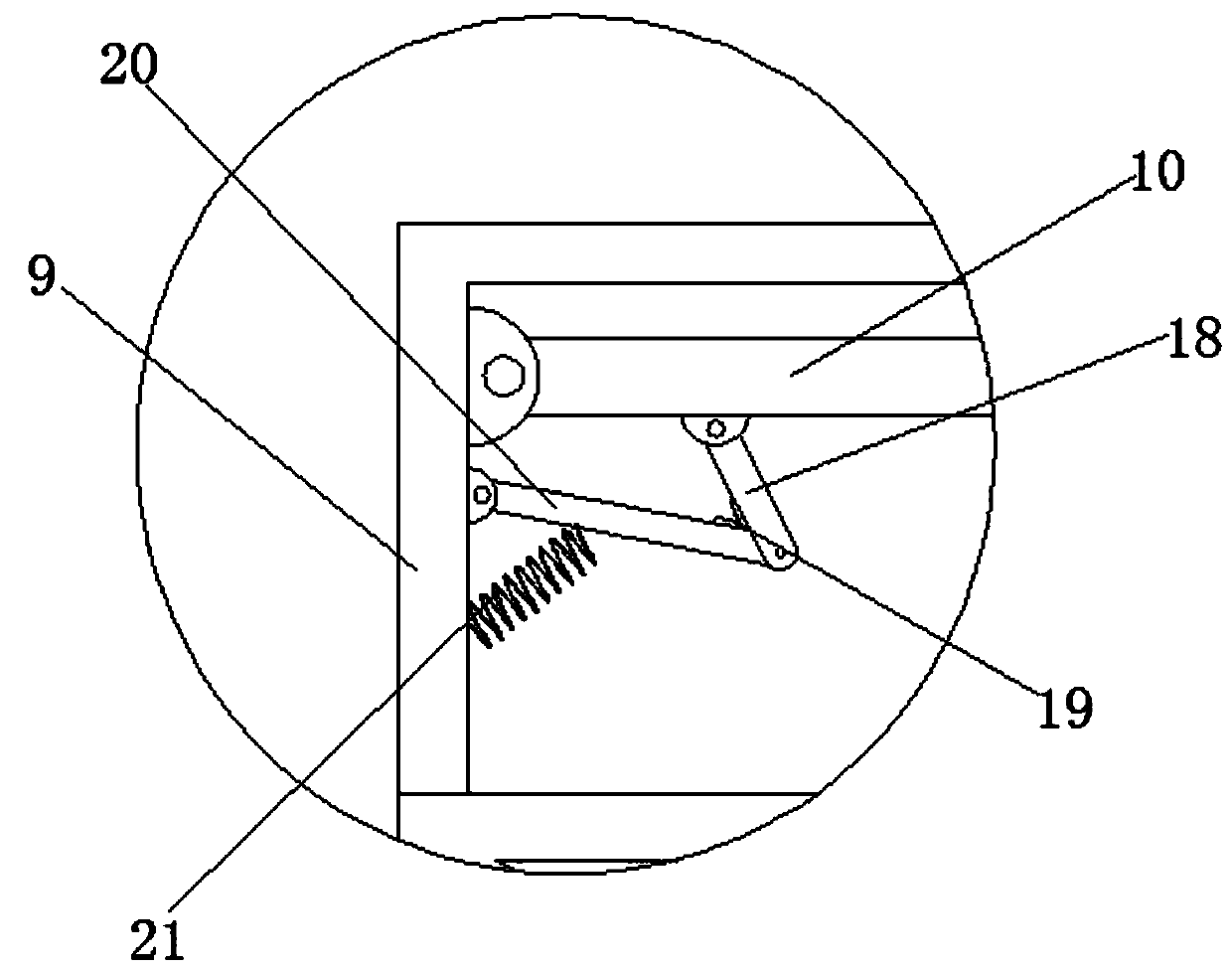

[0024] The first embodiment: as Figure 1-Figure 3 As shown, a construction concrete feeding device provided in this embodiment includes a feeding bin 9 and a feeding pipe body 1 communicating with the feeding bin 9, and is characterized in that a baffle 10 is hinged on the inside top of the feeding bin 9 , the bottom of the baffle plate 10 is hinged with a first connecting rod 18, the first connecting rod 18 is hinged with a second connecting rod 20, and the angle between the second connecting rod 20 and the first connecting rod 18 is fixed with an elastic hinge piece 19 A part of the elastic hinge piece 19 is fixed on the second connecting rod 20, and a part is fixed on the first connecting rod 18 to form an elastic buffer assembly. A spring 21 is installed on the second connecting rod 20, and the other end of the spring 21 is fixed on the feed On the inner wall of the warehouse 9.

[0025] By adding concrete to the feeding bin 9, under the action of gravity, the concrete p...

no. 2 approach

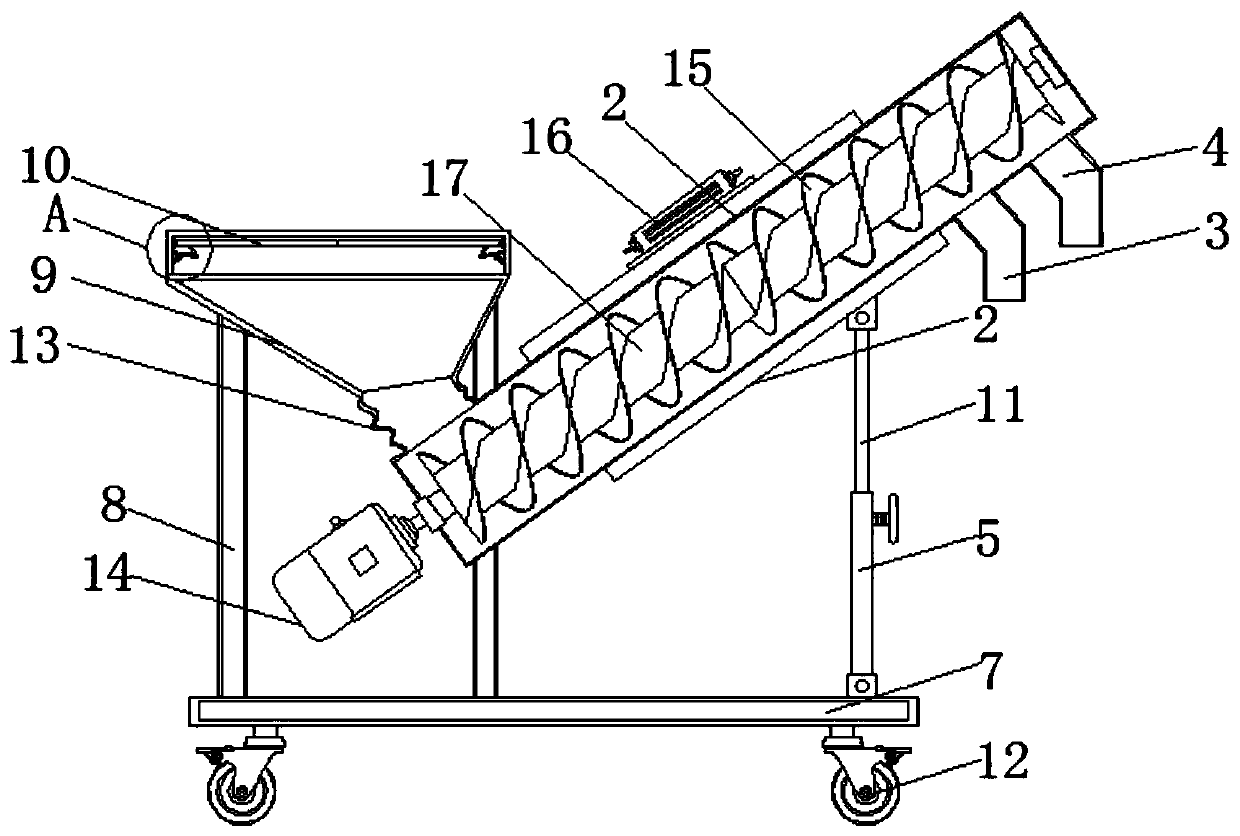

[0043] The second embodiment: a feeding device for building concrete, including a support frame 7, a feeding bin 9 and a feeding pipe body 1 communicated with the feeding bin 9, and the feeding bin 9 and the feeding pipe body 1 are all arranged on On the support frame 7 at the bottom, a baffle plate 10 is hinged on the inside top of the feed bin 9, and a first connecting rod 18 is hinged on the bottom of the baffle plate 10, and a second connecting rod 18 is hinged on the first connecting rod 18. rod 20, and an elastic hinge piece 19 is fixed between the angle between the second connecting rod 20 and the first connecting rod 18, a part of the elastic hinge piece 19 is fixed on the second connecting rod 20, and a part is fixed An elastic buffer assembly is formed on the first connecting rod 18, a spring 21 is installed on the second connecting rod 20, and the other end of the spring 21 is fixed on the inner wall of the feed bin 9;

[0044] The feeding bin 9 communicates with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com