Kitchen garbage treatment equipment

A technology for processing equipment and kitchen waste, applied in chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve the problems of occupying large land resources, complex waste composition, high content of toxic and harmful substances, and achieving maintenance difficulties Small, reduced cost and energy consumption, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

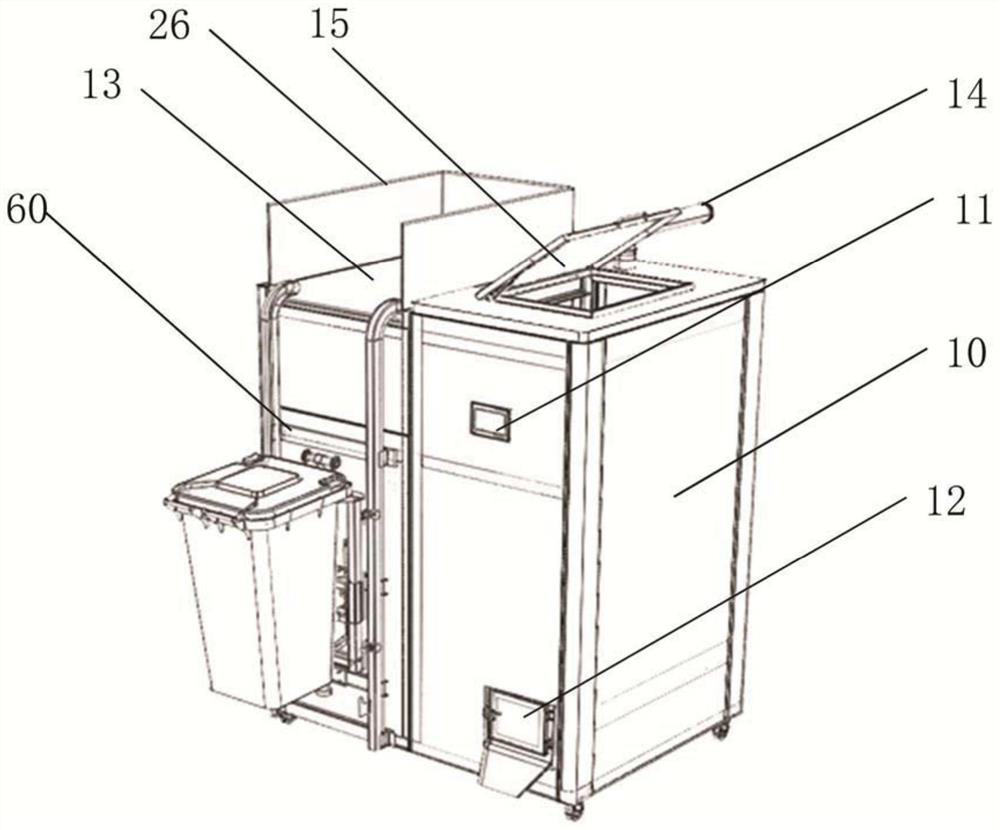

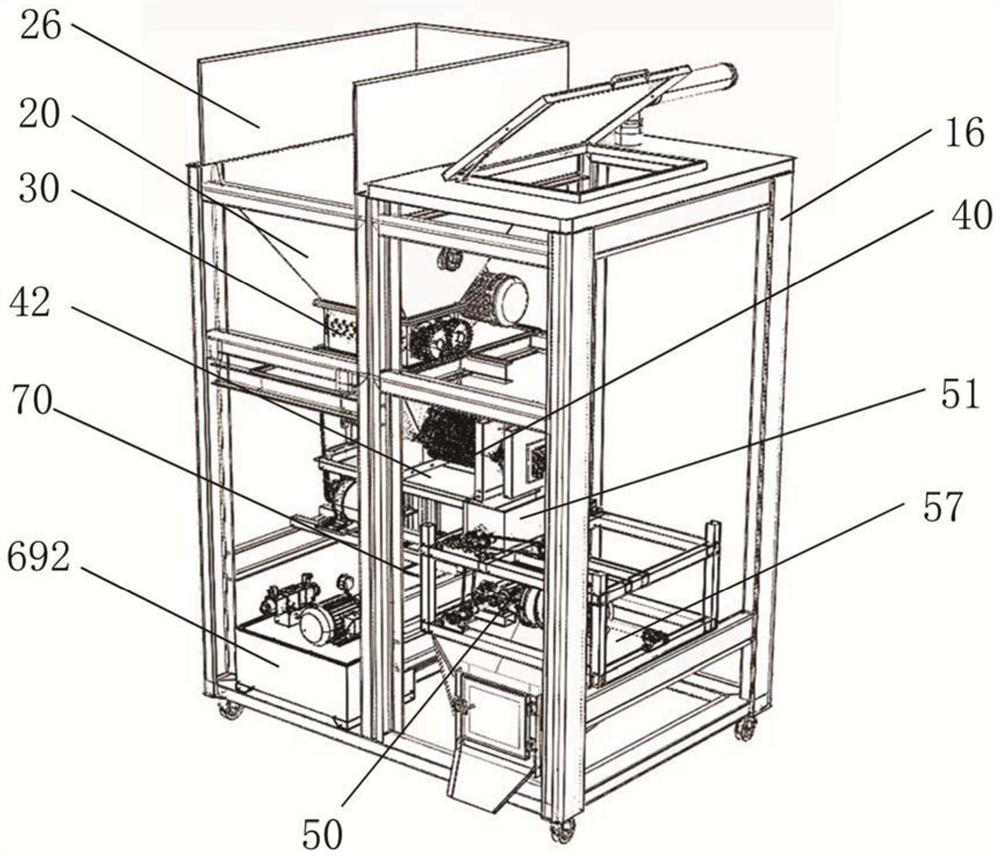

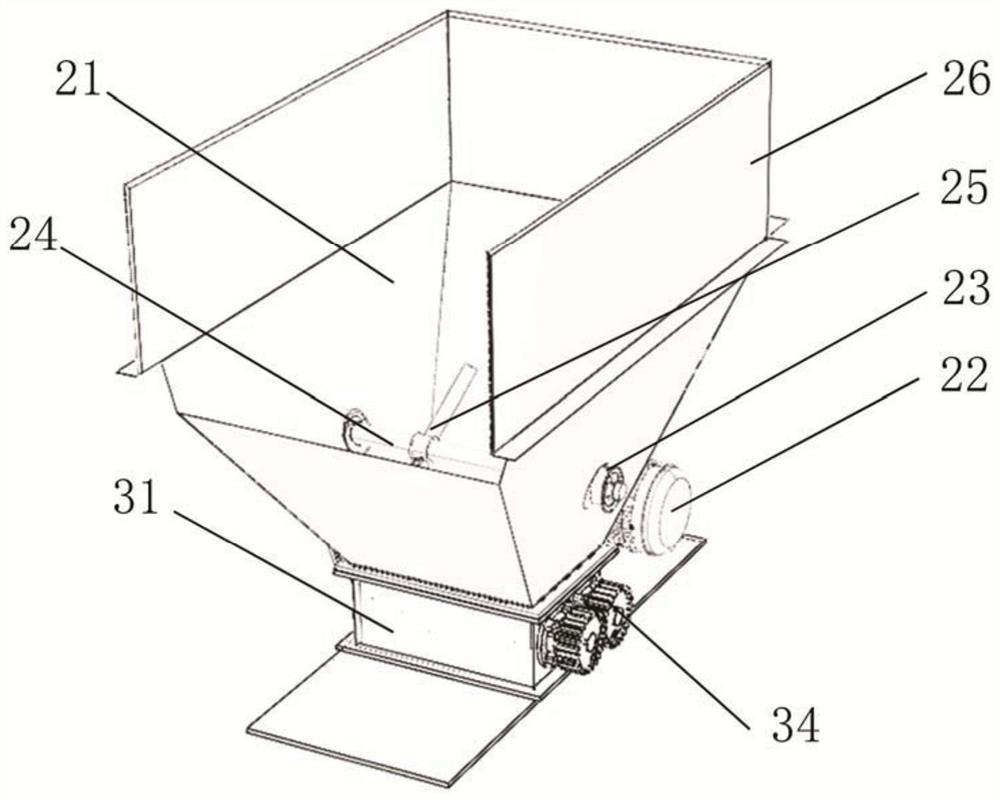

[0047] See figure 1 with figure 2 The present invention provides a technical solution: kitchen waste treatment equipment, including the box 10, the feed device 20, the wet mill pulverizing apparatus 30, the dry wet separation device 40, the drying device 50, the lifting of the flip device 60 and the oil separation Device 70.

[0048] See Figure 1-2 The casing 10 includes an inner frame 16 and an outer panel, and the front side of the casing 10 is provided with a touch panel 11, and the upper end of the casing 10 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com