Method for manually adjusting clamping distance tested by tension tester

A tensile testing machine and manual adjustment technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of low accuracy of test results, large error of test clamp distance, and low tensile strength, so as to improve residual value, Effects of preventing damage and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

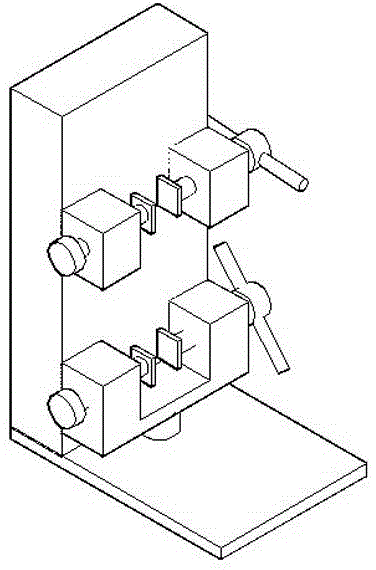

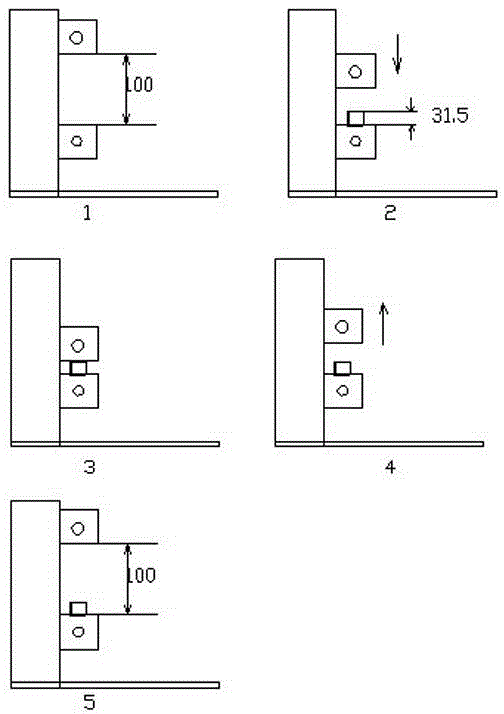

[0023] The method of the present invention will be further described below in conjunction with the accompanying drawings.

[0024] a. The required test clamp distance is 100mm, turn on the machine and start the system;

[0025] b. Take a brand new square or rectangular eraser, use a ruler or a vernier caliper to accurately measure the length of the longest side when it is placed upright (refer to the length of the eraser manual), such as 31.5mm, and then place the eraser upright in the middle of the lower fixture;

[0026] c. Use the "standard manual speed" in the "console setting" of the computer software, and cooperate with the "jog control panel" on the instrument to jog downward to move the beam in the direction of compression. When it is about to approach the rubber, use the software "control "Use slowed hand control speed" in "Table Settings", move the beam down slowly, and stop when the upper clamp is slowly close to the rubber. Due to the elasticity of the rubber, it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com