a manhole cover

A manhole cover and manhole cover seat technology, which is applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the problems of unreported manhole cover application, poor road surface fit, noise pollution, etc., to eliminate urban black holes and improve production efficiency High, less welding process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

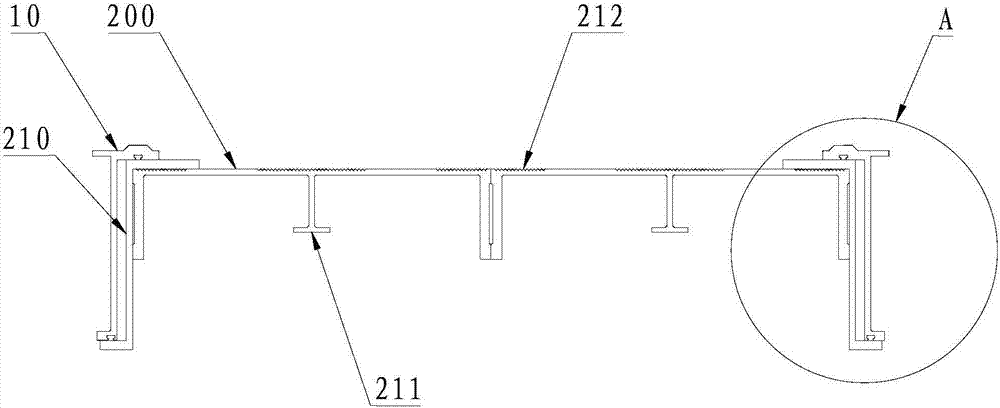

[0037] Please refer to Figure 1 to Figure 4 Shown, embodiment one of the present invention is:

[0038] A well cover, comprising a well cover base frame 1 and a well cover panel 2 sleeved in the well cover base frame 1;

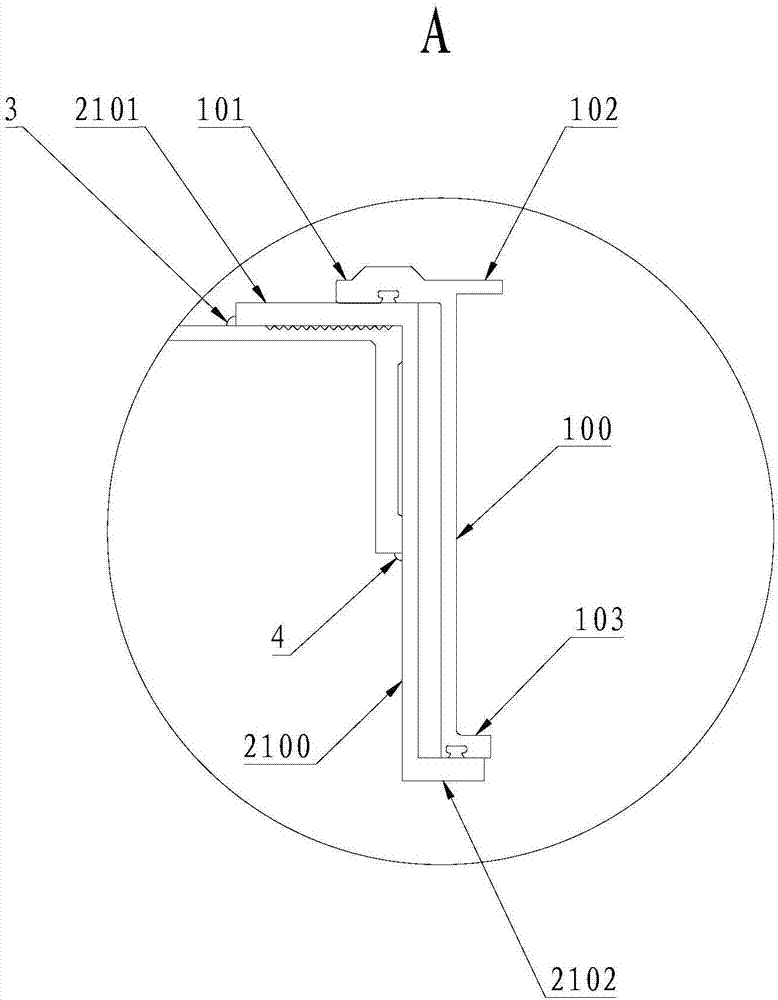

[0039] The manhole cover seat frame 1 is a rectangular frame composed of four first aluminum profiles 10 welded end to end in sequence. 100 at the top and extend horizontally to the first stopper 101 of the manhole cover seat frame 1, the first support part 102 arranged at the top of the first main body part 100 and horizontally extended to the outside of the manhole cover seat 1 and the first support part 102 arranged at the first main body part 100 The bottom end and the first wedging part 103 extending horizontally to the outside of the manhole cover frame 1;

[0040] The well cover panel 2 is composed of a panel assembly 20 and a frame assembly 21. The panel assembly 20 is composed of two or more U-shaped aluminum profiles 200 welded side by side. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com