Improved shell charcoal activation furnace

A technology of fruit shell activated carbon and activation furnace, which is applied in the direction of inorganic chemistry, carbon compounds, chemical instruments and methods, etc. It can solve the problems of poor smoke exhaust, lack of strength, and influence on the whereabouts of carbon materials, so as to achieve improved activation effect and stable quality , the effect of not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

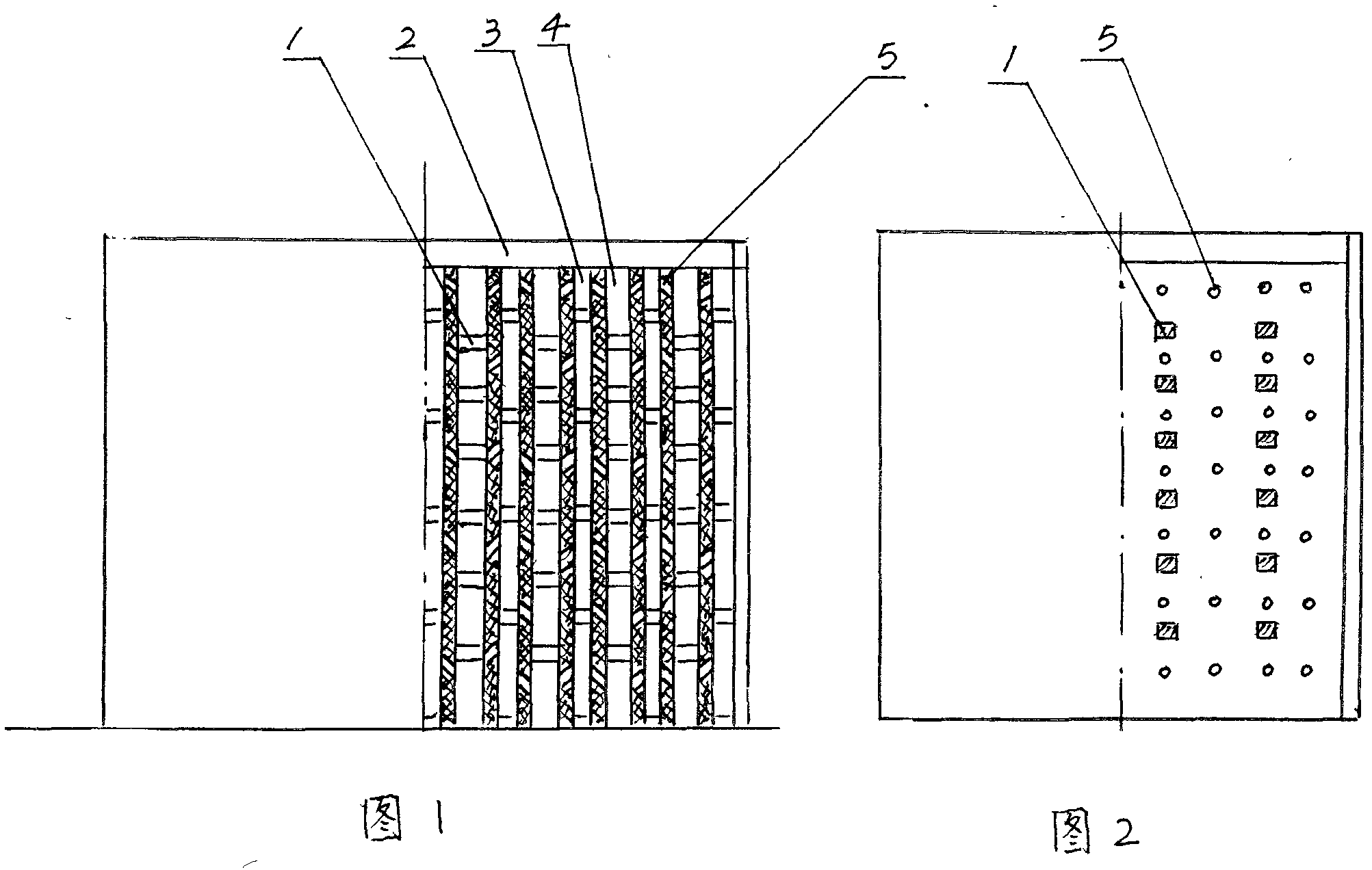

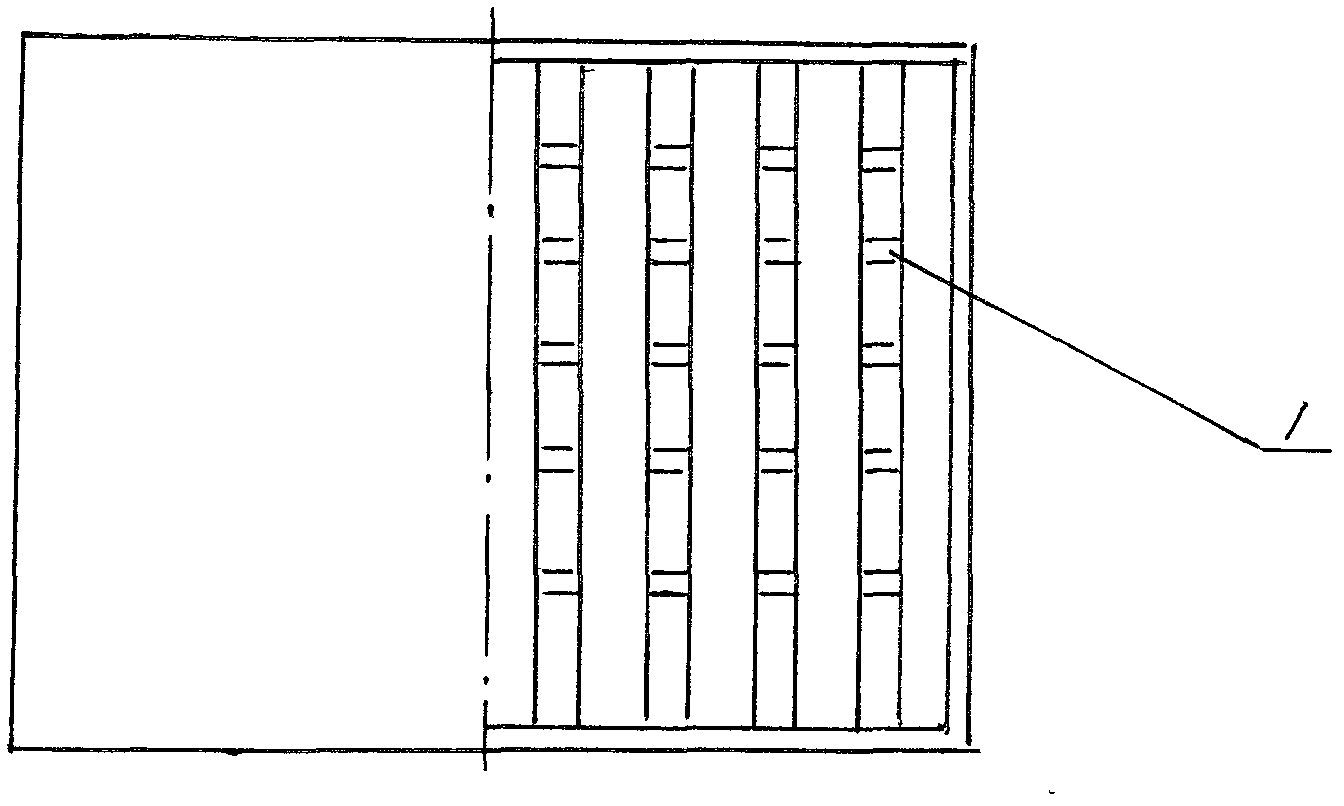

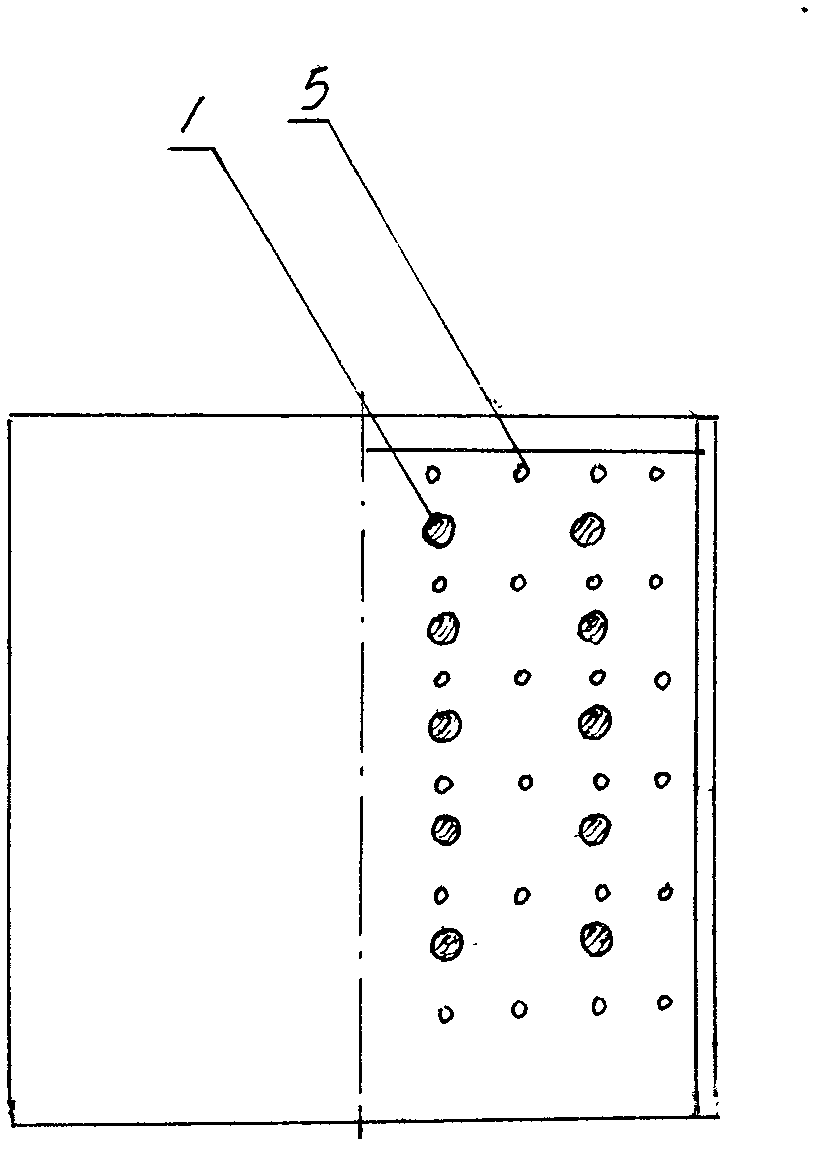

[0016] The present invention is composed of a feeder 4, a flue 3 and a steam supply system. The feeder and the flue are arranged alternately. The feeder includes a feeding slot 2, a carbonization section, an activation section, and a discharge port from top to bottom. The flue is divided into several Each layer is connected end to end to form a circulating flue. There are smoke exhaust holes 5 between the feeder and the flue. Reinforcing ribs 1 are evenly arranged horizontally and vertically in the feeder to form a grid-shaped feeder. The feeder and the smoke The smoke exhaust hole between the channels is an oblique hole, and the smoke inlet connected with the material channel is at a low position.

[0017] The reinforcing ribs are equidistantly arranged horizontally and vertically, and aligned up and down.

[0018] The reinforcing ribs are arranged equidistantly in the horizontal and vertical directions, and two adjacent rows up and down are arranged in a staggered manner.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com