Antistatic butyronitrile gloves and preparation method thereof

A nitrile glove and the technology of the production method are applied in the direction of gloves, protective clothing, clothing, etc., which can solve the problems of poor anti-static effect and unsustainable anti-static performance, and achieve accelerated vulcanization and cross-linking rate, long-lasting anti-static effect, The effect of improving antistatic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

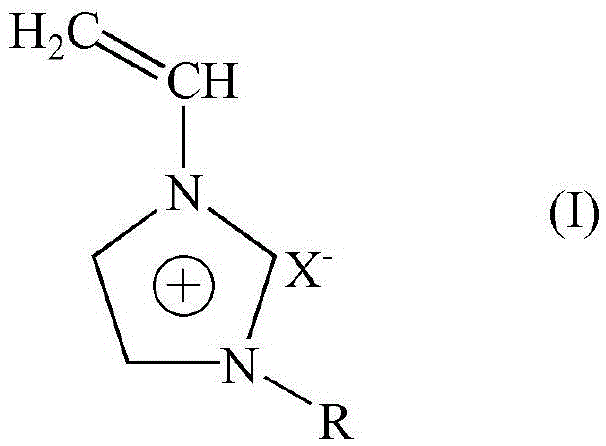

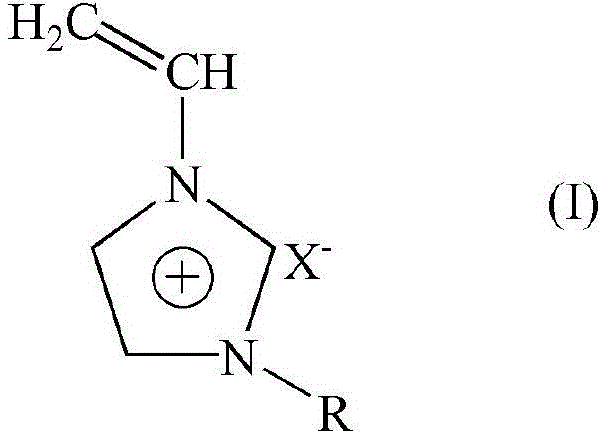

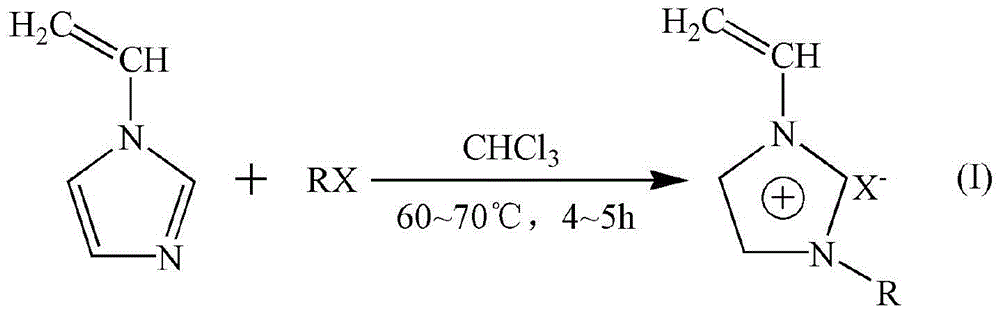

[0036] Example 1: 20 parts of nitrile latex, 77.7 parts of deionized water, 0.5 parts of potassium hydroxide, 0.3 parts of 2-mercaptobenzothiazole, 0.2 parts of sulfur, 0.3 parts of magnesium oxide, 1-vinyl-3-methyl 0.5 part of imidazolium chloride salt, 0.5 part of titanium dioxide.

[0037] The manufacture method of present embodiment antistatic nitrile gloves comprises the following steps:

[0038] (1) Prepare materials, prepare 1-vinyl-3-methylimidazolium chloride antistatic agent; add 83.9 parts of deionized water, 15 parts of calcium nitrate, 0.1 part of propylene glycol alginate, and 1 part of anti-sticking agent into the batching bucket Prepare coagulant solution and stir evenly; prepare 0.01mol / L chlorine water for later use;

[0039] (2) Cleaning the hand model, first cleaning the hand model in an acidic solution with a pH value of 2, then cleaning in an alkaline solution with a pH value of 14, then rinsing, and drying in an oven at 45°C;

[0040] (3) Glue adjustme...

Embodiment 2

[0044] Example 2: 20 parts of nitrile latex, 78.2 parts of deionized water, 0.5 parts of potassium hydroxide, 0.3 parts of hexamethylenetetramine, 0.2 parts of sulfur, 0.3 parts of magnesium oxide, 1-vinyl-3-butyl 0.5 part of imidazolium chloride salt.

[0045] The manufacture method of this embodiment antistatic nitrile gloves is the same as embodiment 1, and the formula is changed into the above formula, and titanium dioxide is not added in this embodiment.

Embodiment 3

[0048] Example 3: 30 parts of nitrile latex, 67.4 parts of deionized water, 0.4 parts of potassium hydroxide, 0.2 parts of hexamethylenetetramine, 0.3 parts of sulfur, 0.4 parts of zinc oxide, 1-vinyl-3-hexylimidazole 0.8 parts of chlorine salt, 0.5 parts of titanium dioxide.

[0049] The manufacture method of present embodiment antistatic nitrile gloves comprises the following steps:

[0050] (1) Prepare materials, prepare 1-vinyl-3-hexylimidazolium chloride antistatic agent; add 86.35 parts of deionized water, 12 parts of calcium nitrate, 0.15 parts of propylene glycol alginate, and 1.5 parts of anti-sticking agent into the batching tank for preparation Coagulant solution, just stir evenly; prepare 0.01mol / L chlorine water, set aside;

[0051] (2) Cleaning the hand model, first cleaning the hand model in an acidic solution with a pH value of 3, then cleaning in an alkaline solution with a pH value of 12, then rinsing, and drying in an oven at 45°C;

[0052] (3) Adjust glue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com