A kind of polyoxymethylene fiber for dredging static electricity and preparation method thereof

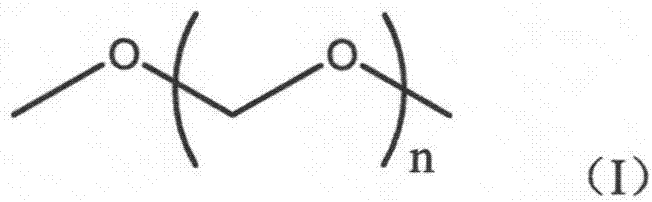

A technology of polyoxymethylene fiber and polyoxymethylene, applied in the manufacture of conductive/antistatic filaments, fiber chemical characteristics, rayon manufacture, etc., can solve the problem of difficulty in absorbing antistatic agents, the influence of antistatic effects, Limit the antistatic effect and other problems, achieve the effect of excellent antistatic effect, stable size, and prevent friction sparks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

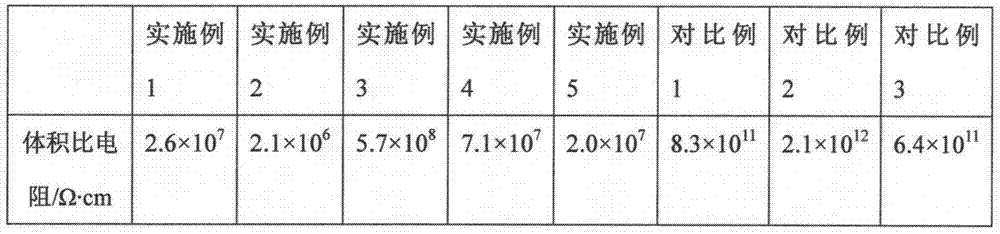

[0033] A polyoxymethylene fiber for dredging static electricity, consisting of 100 parts by mass of polyoxymethylene, 4 parts by mass of conductive carbon black grafted with formal on the surface, 1 part by mass of antioxidant 1010 and 0.5 parts by mass of calcium stearate Composition, its preparation method is:

[0034] Step a: According to the volume ratio of 1:1, respectively take a nitric acid solution with a concentration of 30% and a hydrogen peroxide solution with a concentration of 10%, mix them to obtain an oxidant solution and add it to the reaction vessel, and add 5 grams per 100 ml of the oxidant solution The feed ratio of conductive carbon black, add conductive carbon black (CB), the reaction is carried out under the conditions of mechanical stirring and oil bath heating, the oil bath temperature is 40 degrees Celsius, after 30 minutes of reaction, cool to room temperature, filter and repeat with deionized water Wash until the filtrate is neutral, filter to obtain...

Embodiment 2

[0038] A polyoxymethylene fiber for dredging static electricity, consisting of 100 parts by mass of polyoxymethylene, 5 parts by mass of conductive carbon black grafted with formal on the surface, 1 part by mass of antioxidant 1010 and 1.5 parts by mass of calcium stearate Composition, its preparation method is:

[0039] Step a: according to the volume ratio of 1:2, respectively take a nitric acid solution with a concentration of 35% and a hydrogen peroxide solution with a concentration of 15%, mix them to obtain an oxidant solution and add it to the reaction vessel, and add 7 grams per 100 milliliters of the oxidant solution The feed ratio of conductive carbon black, add conductive carbon black (CB), the reaction is carried out under the conditions of mechanical stirring and oil bath heating, the oil bath temperature is 50 degrees Celsius, after 60 minutes of reaction, cool to room temperature, filter and repeat with deionized water Wash until the filtrate is neutral, filter to...

Embodiment 3

[0043] A polyoxymethylene fiber for dredging static electricity, consisting of 100 parts by mass of polyoxymethylene, 6 parts by mass of conductive carbon black grafted with formal on the surface, 10102 parts by mass of antioxidant and 1.5 parts by mass of calcium stearate , its preparation method is:

[0044] Step a: According to the volume ratio of 1:3, respectively take a nitric acid solution with a concentration of 40% and a hydrogen peroxide solution with a concentration of 20%, mix them to obtain an oxidant solution and add it to the reaction vessel, and add 8 grams per 100 milliliters of the oxidant solution The feed ratio of conductive carbon black, adding conductive carbon black (CB), the reaction is carried out under the conditions of mechanical stirring and oil bath heating, the oil bath temperature is 60 degrees Celsius, after 45 minutes of reaction, cool to room temperature, filter and repeat with deionized water Wash until the filtrate is neutral, filter to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com