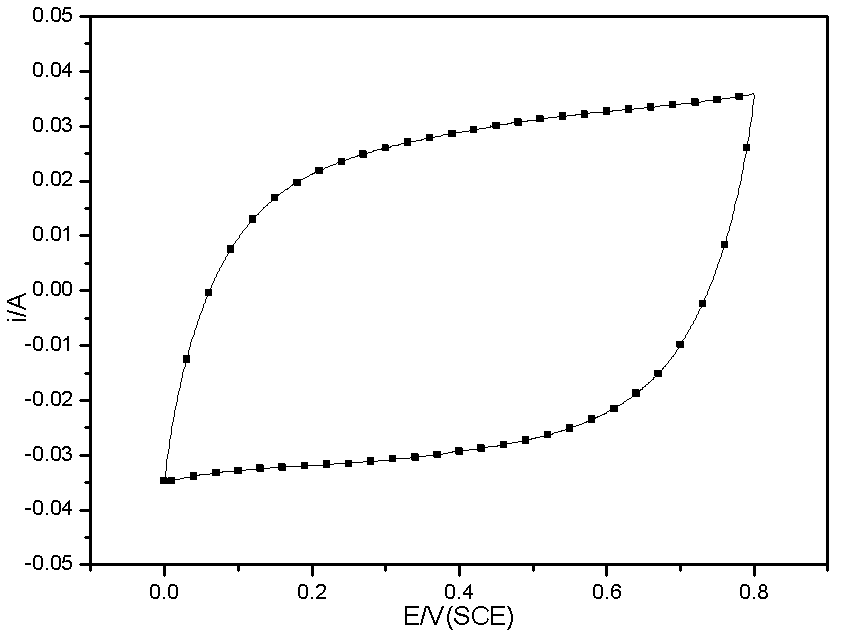

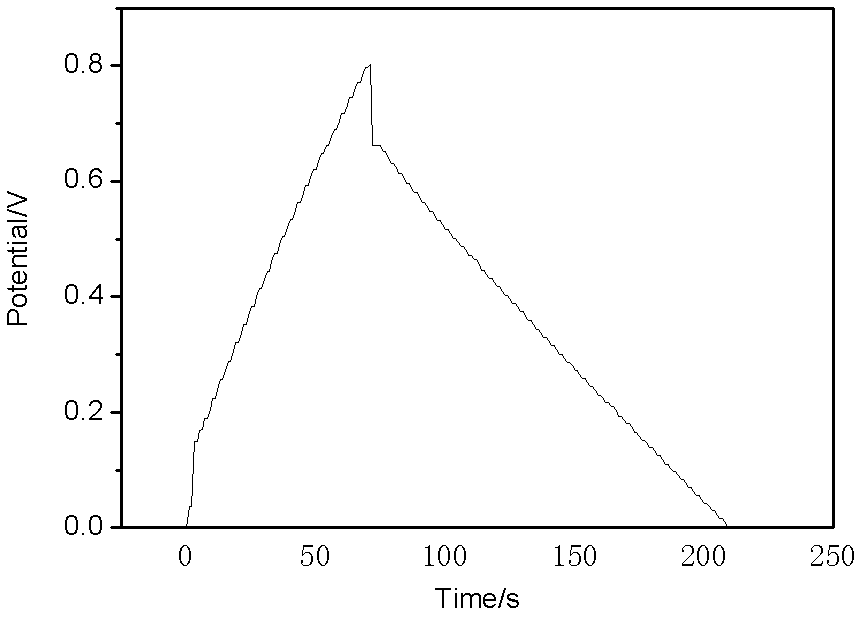

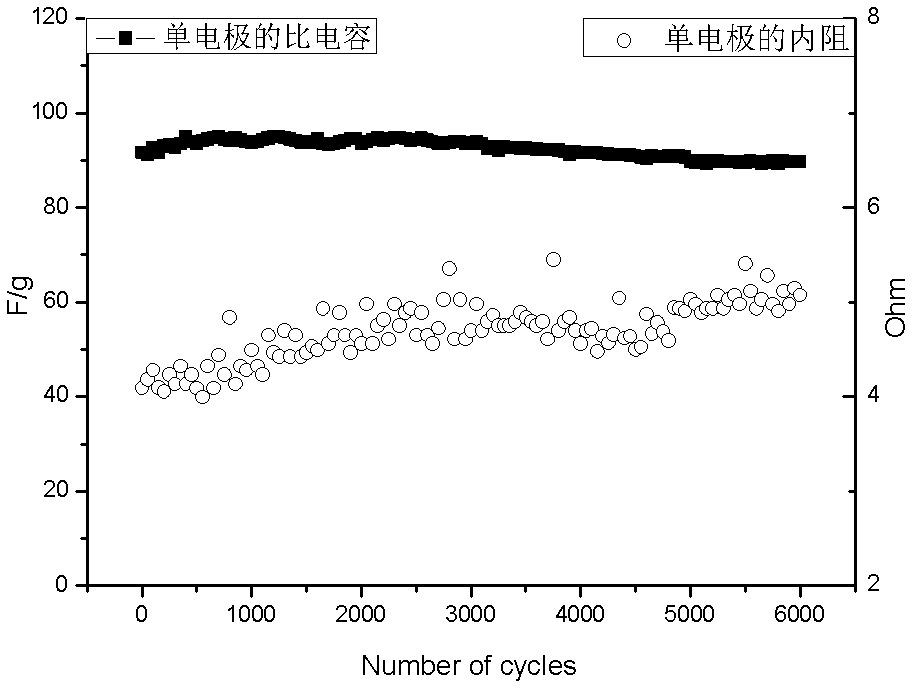

Low inner resistance manganese dioxide electrode for water system supercapacitor and preparation method thereof

A manganese dioxide electrode and supercapacitor technology, applied in the field of electronics, can solve problems such as production scale limitation, and achieve the effects of improving bonding strength, low equipment cost, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] The composition of the low internal resistance manganese dioxide electrode for water system supercapacitor of the present invention is calculated by weight fraction: A 二氧化锰 +B 乙炔黑 +C 碳纳米管 +D 聚四氟乙烯 = 100%, A 二氧化锰 +B 乙炔黑 +C 碳纳米管 = 95%, D 聚四氟乙烯 =5%, 2%≤B 乙炔黑 ≤15%, 2%≤C 碳纳米 管 ≤15%, 4%≤B 乙炔黑 +C 碳纳米管 ≤30%, the preparation method comprises the following steps: (1) preparing manganese dioxide powder; (2) mixing; (3) stirring; (4) coating; (5) rolling; (6) drying; (7) ) clipping.

[0061] Manganese dioxide powder is prepared: firstly, bulk manganese dioxide is prepared by electrochemical deposition, and then ultrafine manganese dioxide powder is obtained by ball milling.

[0062] The mixing process is as follows: put a certain proportion of manganese dioxide powder, acetylene black, and carbon nanotubes in a ball mill tank for mixing, wherein the ball milling speed is 50-200 rpm, and the ball milling time is 1-5 hours .

[0063] The mixing process is as follows: di...

Embodiment 1

[0070] 1. Preparation of manganese dioxide powder: first prepare massive manganese dioxide by electrochemical deposition, and then obtain ultrafine manganese dioxide powder by ball milling;

[0071] 2. Mixing: put manganese dioxide powder: acetylene black: carbon nanotubes in a ball milling tank at a ratio of 85:5:5 for ball milling and mixing. Ball milling parameters are: ball milling speed: 50 rpm, ball milling time: 5 hours;

[0072] 3. Stirring: Disperse polytetrafluoroethylene in deionized water, weigh an appropriate amount of mixed powder and disperse in it, mechanically stir while ultrasonically vibrating until the powder is evenly dispersed. Powder: polytetrafluoroethylene is stirred in a ratio of 95:5;

[0073] 4. Coating: The slurry is coated on the collector using an automatic continuous coating machine, with a coating width of 50mm and a thickness of 200um. The coating process can be dried by circulating hot air, and the temperature of the hot air is controlled at...

Embodiment 2

[0078] 1. Preparation of manganese dioxide powder: first prepare massive manganese dioxide by electrochemical deposition, and then obtain ultrafine manganese dioxide powder by ball milling;

[0079] 2. Mixing materials: put manganese dioxide powder: acetylene black: carbon nanotubes in a ball milling tank at a ratio of 75:10:10 for ball milling and mixing. The ball milling parameters are: ball milling speed 100 rpm, ball milling time 3 hours;

[0080] 3. Stirring: Disperse polytetrafluoroethylene in deionized water, weigh an appropriate amount of mixed powder and disperse in it, mechanically stir while ultrasonically vibrating until the powder is evenly dispersed. Powder: polytetrafluoroethylene is stirred in a ratio of 95:5;

[0081] 4. Coating: The slurry is coated on the current collector using an automatic continuous coating machine, with a coating width of 50mm and a thickness of 100um. The coating process can be dried by circulating hot air, and the temperature of the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com