Micro-nano double-stage porous copper and preparation method thereof

A micro-nano, porous copper technology, applied in the field of porous metal preparation, can solve the problems of complex preparation process, high requirements for precursor alloy phase composition, and no continuous ligaments formed by metal materials, etc., and achieve short preparation process and simple method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The present invention also provides a method for preparing micro-nano dual-stage porous copper, comprising the following steps:

[0023] Step 1, mix Cu powder and Zn powder with a molar ratio of 3:7-5:5 evenly and press it into a billet, place it in a tube furnace and raise the temperature to 400-500°C under an argon atmosphere, keep it warm for 4-8 hours and then follow the furnace Cool to room temperature to obtain the precursor CuZn alloy;

[0024] In step 2, the precursor is placed in a 0.5 mol / L hydrochloric acid solution for dealloying until no obvious bubbles escape, and the micro-nano dual-stage porous copper can be prepared.

Embodiment 1

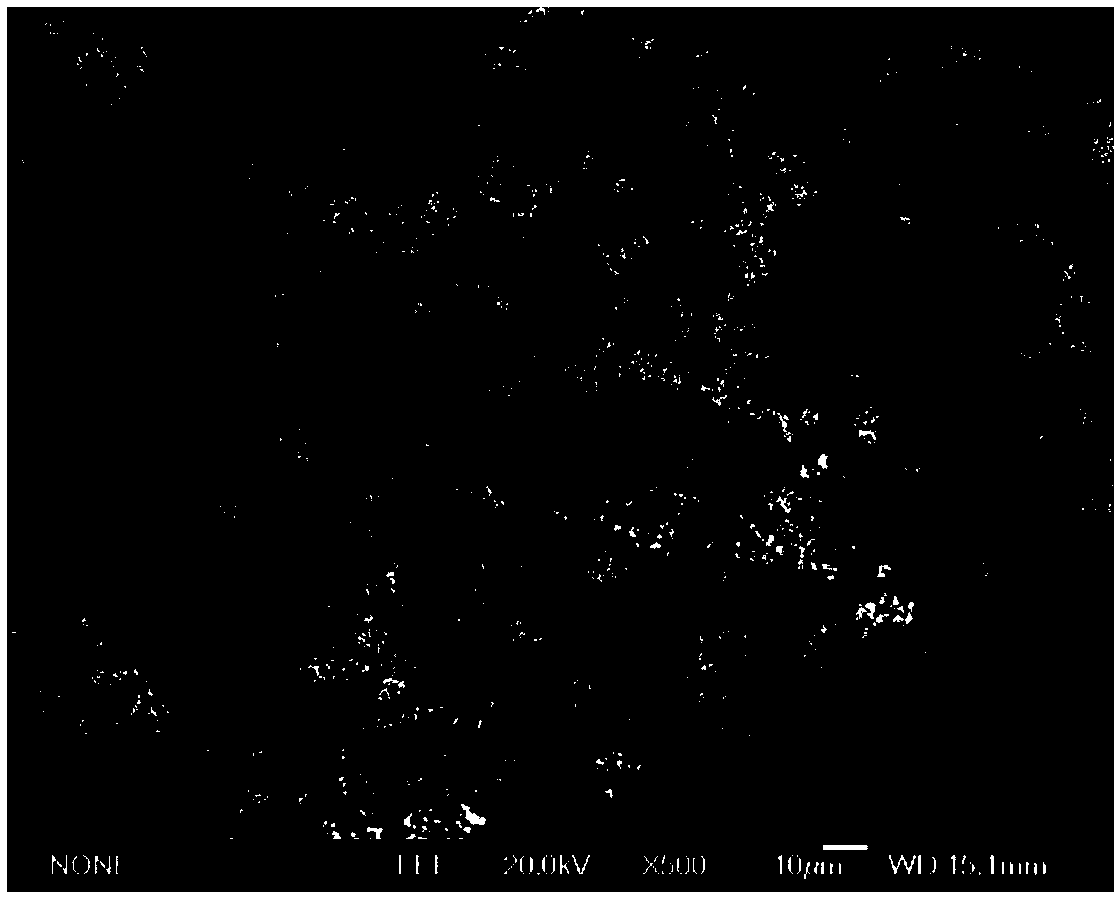

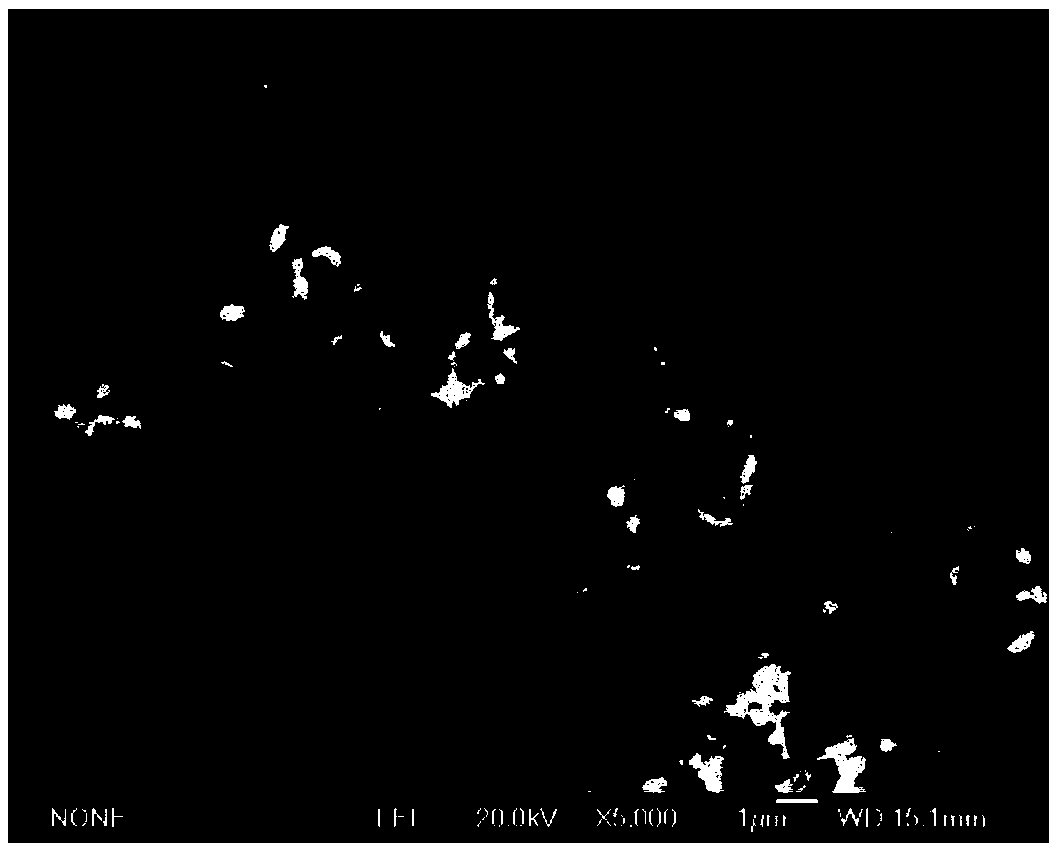

[0026] Mix Cu powder and Zn powder with a molar ratio of 3:7 evenly and press it into a billet, place it in a tube furnace under an argon atmosphere and raise the temperature to 400 °C, keep it warm for 4 hours, and then cool to room temperature with the furnace to obtain the precursor Cu 30 Zn 70 Alloy; then place the precursor in a 0.5mol / L hydrochloric acid solution for dealloying until no obvious bubbles escape, and prepare micro-nano dual-stage porous copper with an average pore diameter of 3.34 μm for micropores and 162 nm for nanopores.

Embodiment 2

[0028] Mix Cu powder and Zn powder with a molar ratio of 3:7 evenly and press it into a billet, place it in a tube furnace under an argon atmosphere and raise the temperature to 400 °C, keep it warm for 8 hours, and then cool to room temperature with the furnace to obtain the precursor Cu 30 Zn 70 Alloy; then place the precursor in 0.5mol / L hydrochloric acid solution for dealloying until no obvious bubbles escape, and prepare micro-nano dual-stage porous copper, with an average micropore diameter of 2.18 μm and an average nanopore diameter of 184 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com