Antistatic master batch for plastic and plastic film containing antistatic master batch

A technology for antistatic masterbatch and plastic film, applied in the field of antistatic masterbatch for plastics and plastic film containing the antistatic masterbatch, can solve the problems of extravasation, affecting the appearance of products, etc., and achieve the effect of enhancing electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

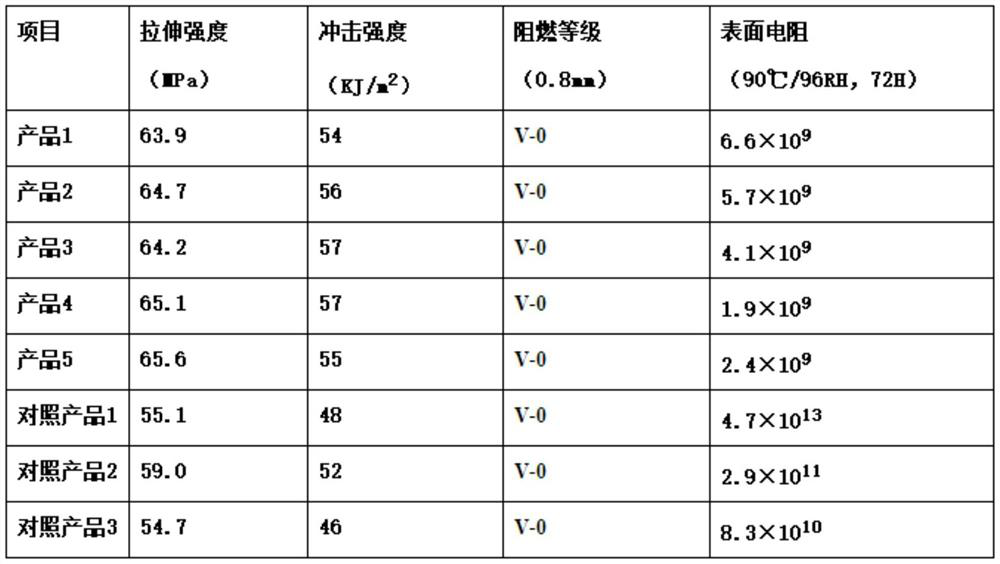

Examples

preparation example Construction

[0048] The preparation method of the modified graphene adopted in the following examples is as follows:

[0049] Step i: Use the Hummers method to prepare graphene oxide. Specifically, mix 2g of graphite, 1gNaNO3, and 46ml of concentrated sulfuric acid with a mass concentration of 98% in an ice-water bath, stir for 30 minutes, make it fully mixed, and weigh 6g of KMnO4 After adding the above mixed solution for 2 hours and continuing to stir for 2 hours, move it into a warm water bath at 35°C and continue stirring for 30 minutes; then slowly add 92ml of distilled water, and control the reaction solution at about 98°C for 15 minutes, then add an appropriate amount of 30% H2O2 to remove excess Then add 140ml of distilled water to dilute, filter while hot, and wash with 0.01mol / L HCl, absolute ethanol and deionized water successively until there is no SO in the filtrate 4 2- Until it exists, graphite oxide is obtained; then graphite oxide is ultrasonically dispersed in water to o...

Embodiment 1

[0054] The antistatic masterbatch I provided in this embodiment comprises the following raw materials in mass percentage: 10% of conductive active components, 0.1% of peroxide, and the rest are resin carriers; wherein, the resin carrier is ethylene-vinyl acetate copolymer, and its VA The content is 32wt%, and the melt index is 43g / 10min (190°C, 2.16kg), and the peroxide is dibenzoyl peroxide.

[0055] The conductive active components used in this embodiment include poly(N-methylpyrrole gel) loaded with modified graphene and polyethylene glycol with a mass ratio of 1:1 (note, the modified graphene used is modified Graphene ), the poly-N-methylpyrrole gel loaded with modified graphene is prepared by the following steps:

[0056] Step 1: Add modified graphene to deionized water, ultrasonically disperse for 30 minutes, then add lignin powder, stir well, then add glacial acetic acid dropwise, adjust the pH of the solution to 5.5, then add potassium persulfate, heat to 85 ℃ const...

Embodiment 2

[0066] The antistatic masterbatch II provided by this embodiment includes the following raw materials in mass percentage: 24% of conductive active components, 0.2% of peroxide, and the rest are resin carriers; wherein, the resin carrier is ethylene-vinyl acetate copolymer, and its VA The content is 32wt%, and the melt index is 43g / 10min (190°C, 2.16kg), and the peroxide is tert-amyl peroxyacetate.

[0067] The conductive active component adopted in the present embodiment comprises poly(N-methylpyrrole gel) loaded with modified graphene and polyethylene glycol with a mass ratio of 1:1 (note, the modified graphene used is modified graphene ), the poly-N-methylpyrrole gel loaded with modified graphene is prepared by the following steps:

[0068] Step 1: Add modified graphene to deionized water, ultrasonically disperse for 40 minutes, then add lignin powder, stir well, then add glacial acetic acid dropwise, adjust the pH of the solution to 5, then add potassium persulfate, heat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com